Abstract

This chapter summarizes the preparation and assembly of inorganic nanosheets prepared from synthetic ion-exchangeable layered solids. A wide variety of compounds, which are classified into cation-exchangeable layered oxometallates and metal phosphates and anion-exchangeable layered hydroxides, are exfoliated into the nanosheets. The cation-exchangeable solids are exfoliated through intercalation of suitable cations called an exfoliating reagent exemplified by quaternary organoammonium ions and subsequent infinite interlayer swelling with water. In contrast, the anion-exchangeable solids are exfoliated in polar organic solvents like formamide. The interlayer swelling is basically explained by an osmotic mechanism, and affected by several parameters such as the type of exfoliating reagent. Layered compounds with a broad range of composition and physicochemical properties have been successfully exfoliated and used in diverse applications. Because the exfoliated nanosheets are assembled into organize higher order structures for their applications, typical assembly techniques are also described. The nanosheets are easily assembled to bulk materials such as porous solids and cast films, or fabricated into nanostructured thin films with layer-by-layer stacking. Characteristic applications can be explored based on suitable choices of the nanosheet species and assembled structures. Moreover, colloidal states of the nanosheets can also provide specific nanosheet-based structures.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Layered crystal

- Ion-exchange

- Exfoliation

- Exfoliating reagent

- Nanosheet

- Osmotic swelling

- Titanate

- Niobate

- Perovskite

- Metal phosphate

- Layered double hydroxide (LDH)

- Aggregation

- Film

- Layer-by-layer (LbL) assembly

- Colloid

1 Introduction

Exfoliated inorganic nanosheets of ion-exchangeable layered solids were obtained for the first time from the smectite group of clay minerals, which are natural cation-exchangeable layered crystals consisting of negatively charged aluminosilicate layers with interlayer exchangeable cations [1, 2]. These clay minerals spontaneously undergo infinite swelling in water by taking the solvent into their interlayer spaces when the interlayer cations are Na+ or Li+, which can be hydrated to a large extent. The infinite swelling leads to exfoliation of individual layers to yield clay nanosheets. Such interlayer swelling is possible for various other ion-exchangeable layered solids if efficient interactions exist between the interlayer cations and solvent molecules. To date, exfoliation by the interlayer swelling has been realized for numerous synthetic ion-exchangeable layered solids.

Because the ion-exchangeable layered solids include both of cation- and anion-exchangeable materials, we now have a rich library of negatively and positively charged inorganic nanosheets [3–5]. Negatively charged nanosheets are usually obtained by exfoliation of layered oxometallates and metal phosphates, while positively charged ones are prepared from layered hydroxides. The nanosheets possess a wide variety of physicochemical properties. Nanosheets of the oxides, metal phosphates, and hydroxides composed of main-group elements are rather electronically inert and optically transparent. Oxometallates and hydroxides of transition metal and rare-earth elements are often photochemically and electronically active, showing various electric, optic, and magnetic functions.

This chapter describes fundamental aspects of the inorganic nanosheets obtained from ion-exchangeable layered solids other than the smectite group of clay minerals that are reviewed in the preceding chapter. It includes details of exfoliation such as the role of exfoliating reagents and delamination mechanisms, the state of the exfoliated nanosheets in the solvents, preparation and structures of nanosheet assemblies, and brief comments on the structure and functions of some typical nanosheet species.

2 Cation-Exchangeable Layered Solids and Their Exfoliation

2.1 Cation-Exchangeable Layered Solids

Most of the cation-exchangeable layered solids that can be exfoliated into the nanosheets are layered oxometallates and metal phosphates. Table 3.1 lists such materials except for the clay minerals. Structures of these layered solids consist of negatively charged metal oxide or phosphonate layers and interlayer exchangeable cations. For many transition metal-based oxometallates such as titanates, niobates, manganates, and ruthenates, the oxide layers are usually constructed of metal-oxygen (MO6) octahedral connected by corner- and edge-sharing, while layered silicates are built up from corner-sharing SiO4 tetrahedra. The metal phosphates layers consist of MO6 octahedra and PO4 tetrahedra. These layers have negative charges stoichiometrically determined by their composition. In most cases, the layer charge density is too high to allow spontaneous exfoliation through the interlayer solvation. This situation is overcome by the use of exfoliating reagents as described below.

2.2 Exfoliation

Cation-exchangeable layered solids are usually exfoliated into nanosheets through exchange of the interlayer cations for appropriate cations that are often called exfoliating reagents. The exfoliating reagents are usually organic cations with appropriate bulkiness and high affinity for the solvent. The exfoliating reagents are first intercalated to the layered crystals through ion exchange, and then drag the solvent molecules into the interlayer spaces (Fig. 3.1). Typically, organic cations represented by tetrabutylammonium ions (TBA+) are used for the exfoliation in water while long-chain organic species are employed for exfoliation in organic solvents. The organoammonium exfoliating reagents are often intercalated to the layered solids with the aid of acid-base reactions when they cannot be directly incorporated [32]. This method involves acid treatment of the starting layered solids, by the treatment of which the interlayer cations are exchanged for H+ ions, and subsequent reaction with organic amine molecules that react with the H+ ions by the acid–base mechanism to form interlayer organoammonium ions that induce exfoliation.

The exfoliation through the ion-exchange route facilitates formation of the single nanosheets. This is guaranteed by the presence of interlayer exchangeable cations located in all the interlayer spaces with the same crystallographic microenvironment because of the stoichiometric distribution of the layer charges; a known exception is hexaniobate (\({\text{Nb}_{6}\text{O}_{17}}^{4-}\)) nanosheets as described in Sect. 3.4.2 [33]. The incorporated exfoliating reagents attract solvent molecules equally into all of the interlayer spaces to infinitely swell the interlayer spaces. The driving force for the swelling is solvation of the exfoliating reagents by dipole interactions with water and other polar solvent molecules. As a result of infinite swelling, individual layers of the mother crystals are exfoliated into the nanosheets. Because the obtained nanosheets bear negative charges, exfoliating reagents such as TBA+ ions are attached to the nanosheets to compensate the layer charge.

In contrast to exfoliation in aqueous systems, that in nonpolar organic solvents has rarely been examined. Such exfoliation can be realized by the use of organophilic exfoliating reagents such as long-chain organic molecules through hydrophobic interactions with the nonpolar solvents. However, this process is more difficult than exfoliation in water because the inorganic layers themselves are highly polar, and tend to expel the nonpolar solvents because of their electric charges. Although this problem can be overcome by covalent bonding of organic molecules, this technique has only been applied to selected materials as described later.

3 Exfoliation Mechanism in Aqueous Systems

According to the systematic studies conducted by Sasaki and coworkers on lepidocrocite-type layered titanate [6, 34–39], H x Ti2−x/4□ x/4O4 (x ~ 0.7, □: vacancy) [40–42], osmotic swelling plays a key role in the exfoliation mechanism of cation-exchangeable layered solids in water (Fig. 3.2). This section describes the exfoliation mechanism and important factors affecting the nanosheet generation of the titanate in water as an example of the exfoliation of cation-exchangeable layered solids.

Schematic illustration of the swelling and exfoliation process of lepidocrocite-type titanate. Reprinted with permission from [38]. Copyright 2014 American Chemical Society

3.1 Osmotic Swelling

The exfoliation of cation-exchangeable layered solids begins by gigantic or infinite swelling of the interlayer spaces. Such swelling is generally called osmotic swelling. This concept was proposed in the 1930s and discussed until the 1970s to explain very high degree of swelling observed for the smectite group of clay minerals in water [1, 2, 43]. For the case of the layered titanate H x Ti2−x/4□ x/4O4, each crystallite effectively draws a huge amount of water molecules into its interlayer spaces through dipole interactions with the interlayer cations when they are TBA+ ions [6, 35]. As a result, the basal spacing of the titanate layers reaches more than several tens of nanometers, which is more than ten times that of the starting titanate crystal (~1 nm). However, the amount of incorporated water molecules in the swollen state is too large to be explained by molecular interactions between the interlayer TBA+ ions and water. In fact, the process is rationalized by the osmotic pressure between the interlayer spaces and outside solvents. Because the hydrated interlayer space is recognized as a TBA+ solution with a high concentration, a large amount of water molecules outside the interlayer spaces can penetrate into the interlayer spaces driven by the difference in osmotic pressure between inside and outside the interlayer spaces.

In addition to such a qualitative explanation, recent studies on layered titanate H0.8Ti1.2Fe0.8O4 have enabled quantitative understanding of its osmotic swelling. In these studies, swelling by several primary, tertiary, and quaternary organoammonium ions are compared [36–38]. Most of the organoammonium ions show the same amount of incorporation, and the same degree of interlayer expansion induced by the gigantic swelling (Fig. 3.3). In the fully swollen stage, the concentration of organoammonium ions in the interlayer regions, i.e., in the swollen phase gives an osmotic pressure equal to the atmospheric pressure; the outside solvents contain few organoammonium ions under such conditions. These facts indicate that the swelling of the layered titanate proceeds until the interlayer osmotic pressure is balanced by the atmospheric pressure. This is the evidence for the osmotic, i.e., colligative nature of the gigantic swelling caused by the organoammonium ions.

Quantity of intercalated ammonium for tertiary amines and quaternary ammonium hydroxides as a percentage ratio of the cation-exchange capacity (CEC) of the lepidocrocite-type titanate crystals. The open symbols represent tertiary amines, while the filled symbols represent quaternary ammonium hydroxides. The numbers in the panel are the ratios of the starting amine or ammonium hydroxide to the CEC of the crystals. All lines except the one for TBAOH overlap, suggesting that these tertiary amines and quaternary ammonium hydroxides have similar affinities for the crystals. The lower intercalation of TBAOH is likely due to steric effects. Reprinted with permission from [38]. Copyright 2014 American Chemical Society

3.2 From Swelling to Exfoliation

Exfoliation of the cation-exchangeable layered solids is understood as shear-induced liberation of the stacked nanosheets in the gigantically swollen state. The attractive electrostatic interactions between the negatively charged layers through the interlayer cations are weakened under the swollen conditions, and overcome with mechanical shear applied by stirring the solvents. The shear stress causes the exfoliation to form the nanosheets dispersed in the solvent.

Formation of the monolayer (single) nanosheets has been clarified in the exfoliation of lepidocrocite-type titanate H x Ti2−x/4□ x/4O4 [6, 34, 35]. X-ray diffraction (XRD) showed that the basal spacing of the titanate increased while maintaining high stacking regularity upon the intercalation of TBA+ ions and their hydration as indicated by the shift of the basal reflection accompanied by higher order peaks to lower diffraction angles with maintaining their sharpness. However, when the sample reached the osmotic swelling, the basal reflection disappeared and broad peaks appeared at higher angles. The broad peaks were assigned to the exfoliated monolayer nanosheets according to the X-ray scattering because they were fitted by the square of the structural factor estimated by assuming the single nanosheets. Similar patterns have been obtained following exfoliation of other ion-exchangeable layered solids such as a perovskite-type niobate [44], manganate [45], and layered double hydroxide (LDH) [29]. Their scattering profiles depended on the exfoliated compounds and were fitted by the square of the structural factors of the corresponding nanosheet species (Fig. 3.4).

Typical experimental profile of the diffraction envelope (solid line) and square of calculated structure factor (broken line) for nanosheets. a Repidocrocite-type titanate \({\text{Ti}}_{{0.{91}}} {{\text{O}}_{ 2}}^{{0.{36} - }}\); b Perovskite-type niobate \({\text{Ca}}_{ 2} {\text{Nb}}_{3} {{\text{O}}_{10}}^{ - }\); and c Tungstate \({{\text{Cs}}_{4} {\text{W}}_{11} {\text{O}}_{36}}^{2 - }\). The square of calculated structure factor fits well with the experimental profile. Reprinted with permission from [4]. Copyright 2010 John Wiley and Sons

3.3 Effects of the Exfoliating Reagent and Temperature

Regarding the relationship between the interlayer swelling and exfoliation, the osmotic swelling is essentially independent of the exfoliation although the former is a prerequisite for the latter. This relationship has been clarified by studying the swelling of lepidocrocite-type titanate H0.8Ti1.2Fe0.8O4 with different primary, tertiary, and quaternary organoammonium ions [36, 38]. The organoammonium ions that can exfoliate the titanate are limited to several species such as TBA+, ethylammonium, and propylammonium (PA+). In contrast, although 2-(dimethylamino)ethanol (DMAE+) gigantically swelled this titanate, it hardly induced the exfoliation even when the swollen titanate powders were mechanically shaken in water (Fig. 3.5). In addition, quaternary TBA+ and tetramethylammonium (TMA+) ions both exfoliated this titanate, but the former species induced swelling to give unilamellar nanosheets faster than the latter.

a Optical photographs of the crystals swollen with ethylamine, DMA, and N,N-dimethylbutylamine before and after overnight mechanical shaking. b Optical microscopy images of solutions after overnight shaking. Left ethylamine, middle DMA, and right N,N-dimethylbutylamine. c AFM images of delaminated nanosheets in ethylamine and N,N-dimethylbutylamine. Reprinted with permission from [38]. Copyright 2014 American Chemical Society

These observations indicate that appropriately bulky and moderately polar organoammonium ions work as efficient exfoliating reagents. Cations that are small such as methylammonium and alkali metal cations strongly attaches to the anionic inorganic layers in close proximity in the interlayer spaces, which prohibits hydration of the cations. Highly polar cations such as DMAE+, with positive charges that are localized at the end or edge of the molecules, are thought to strongly interact with water to form hydrogen-bonding networks between the layers to withstand the shear force inducing the exfoliation. A recent study has indicated that organic cations other than the organoammonium species act as the exfoliating reagents of lepidocrocite-type titanate H0.8Ti1.2Fe0.8O4 if the organic species fulfils the above requirement. In fact, tetrabutylphosphonium ions can exfoliate the titanate; they work better than TBA+ ions because of their bulkiness [39].

Temperature can be another critical parameter affecting the exfoliation. Titanate nanosheets directly synthesized by hydrolysis–polycondensation of a titanium alkoxide in the presence of tetraalkylammonium ions [46] showed reversible exfoliation–stacking behavior under thermal stimuli [47]. The titanate nanosheets prepared by this method were similar to those obtained by exfoliation of tetratitanate H2Ti4O9, and dispersed stably in water at room temperature to give a transparent colloid. However, these nanosheets were stacked at high temperatures to make the colloid turbid, and were then re-exfoliated by lowering the temperature again. This temperature-induced stacking–exfoliation was reversible for many times, and the transition temperature depended on the tetraalkylammonium species coexisting in the system (Fig. 3.6). This behavior has been ascribed to the temperature dependence of the thickness of the electrical double layers at the titanate nanosheets.

a Transient transmittance at 550 nm of TBA+–TiO x during temperature switching between 25 and 70 °C. b Photographs of TBA+–TiO x colloidal solution at room (RT) and high temperature (HT around 60 °C). Reprinted with permission from [47]. Copyright 2014 Royal Society of Chemistry

3.4 Nanosheet Size

The lateral size of the exfoliated nanosheets reflects the size of the mother crystals of the layered solids. Nanosheets with a lateral dimension of micrometers have been obtained from the exfoliation of single crystalline layered titanate H x Ti2–x/4□ x/4O4 [48] and niobate K4Nb6O17 [33] with a millimeter to centimeter-scale of crystallite size (Fig. 3.7). The size decrease in the lateral direction compared with that of the starting crystallites is caused by breakage of the nanosheets by the mechanical shear applied during the swelling and exfoliation processes. Since this is unavoidable and uncontrollable in the current experimental techniques for exfoliation, the nanosheets produced have large size distributions in the lateral direction although their thickness is monodisperse because the swelling of the ion-exchangeable layered solids occurs equally in all of the interlayer spaces as described above. The size distribution of nanosheets can be narrowed by gradient centrifugation [49]. The average lateral size of the nanosheets can be reduced by ultrasonic irradiation of the colloidal nanosheets after the exfoliation [50].

TEM image of a large niobate nanosheet prepared by exfoliation of single crystalline K4Nb6O17. Reprinted with permission from [33]. Copyright 2002 Royal Society of Chemistry

4 Exfoliation of Typical Cation-Exchangeable Layered Solids

This section briefly describes the structure, exfoliating behavior, and use of the exfoliated nanosheets obtained from typical cation-exchangeable layered solids.

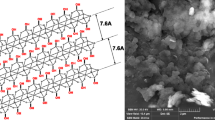

4.1 Titanates

Layered titanates are the materials whose exfoliation has been studied the most of various ion-exchangeable layered solids [51], as described Sect. 3.3. These materials consist of negatively charged titanium oxide layers constructed of corner- and edge-shared TiO6 octahedra and interlayer exchangeable cations [52, 53]. While lepidocrocite-type titanate H x Ti2–x/4□ x/4O4 characterized by the edge-shared connection of TiO6 octahedra in a flat manner is the most well-known compound [41], other titanates such as trititanate H2Ti3O7 and tetratitanate H2Ti4O9, both of which have zigzag-shape titanate layers with the corner- and edge-shared TiO6 octahedra, are also available (Fig. 3.8) [54–58]. For the lepidocrocite-type titanate, Ti atoms in the layers can be partly substituted with other metallic species such as Mg, Mn, Fe, and Co, as exemplified by H0.8Ti1.2Fe0.8O4 [7, 36, 59–63].

Layered titanates are usually obtained with alkali cations as the interlayer exchangeable cations; e.g., Cs x Ti2–x/4□ x/4O4, Na2Ti3O7, and K2Ti4O9 [40, 64, 65]. The alkali cations are readily exchanged for H+ ions by acid treatments, and then the obtained titanic acids react with organoammonium ions as the exfoliating reagent by the acid-base mechanism. While TBA+ is employed in most cases [6, 9, 34, 35, 66, 67], short-chain organoammonium monocations have been used for trititanate H2Ti3O7 and tetratitanate H2Ti4O9 [8, 68].

The exfoliation of the layered titanates in organic solvents has been investigated. Tetratitanate H2Ti4O9 has been exfoliated in nonpolar solvents such as benzene, chloroform, octanol, and ethylacetate after grafting long-chain organosilyl moieties onto the titanate layers [69, 70]. A recent study has reported that lepidocrocite-type titanate H x Ti2−x/4□ x/4O4 can be exfoliated in toluene after intercalation of tetradecylammonium and octadecylammonium ions (Fig. 3.9) [71].

Schematic illustration of the approach for preparing the lepidocrocite-type titanate nanosheets in an organic solvent. a The pristine titanate with the interlayer space of d 0; b The precursor composite with the intercalation of the long-chain alkylammonium ions in the interlayer space; and c The delamination into toluene through the hydrophobic interaction and the formation of the composite nanosheets on a silicon substrate. The d (001) and t indicate the interlayer distance of the precursor composite and the thickness of the composite nanosheets, respectively. Reprinted with permission from [71]. Copyright 2009 American Chemical Society

Applications of the titanate nanosheets by utilizing their wide band-gap semiconducting [72–76] and dielectric properties [4, 77, 78] have been examined. Titanate nanosheets have been investigated as photocatalysts for a long time as described in Chaps. 15–17 [79–84]. Nitrogen- and iodine-doping of lepidocrocite-type titanate nanosheets can narrow their band-gap to result in visible-light photocatalytic activity [85, 86]. In other researches, the titanate nanosheets are employed as dielectric building blocks in electronic devices prepared by layer-by-layer (LbL) assembly of various nanosheets [77, 87]. Lepidocrocite-type titanate nanosheets partially substituted by Mn, Fe, and Co exhibit redox, magnetooptic, and ferromagnetic properties that reflect the nature of dopants [59–62, 88].

4.2 Niobates and Tantalates

Layered niobates and tantalates, exemplified by HNb3O8, K4Nb6O17, and HTaO3, possess structures and properties similar to those of the layered titanates [15, 32, 89–93]. Figure 3.10 shows schematic structures of some layered niobates. These materials are constructed from connected NbO6 or TaO6 octahedra that form electrically negative layers with interlayer cations. Binary oxometallates including a transition metal in addition to Nb or Ta are also known: e.g., HTiNbO5, HNbWO6, and HTaWO6 [94–98]. Lepidocrocite-type titanoniobate H0.7Ti1.825−x Nb x O4 (x = 0–0.33) has also been prepared [99]. Most of these layered materials can be exfoliated by the reaction of H+-exchanged layered crystals with TBA+ ions [11, 14, 15, 100, 101]. Other reported exfoliating reagents in water are triethanolammonium cations and NH2(CH2)10COOH molecules [102, 103]. Fluoroniobate K2NbO3F [104] has been reported to be exfoliated in water by an ultrasonic treatment without exfoliating reagents. However, this could be different from ordinary exfoliation because the exfoliated crystals are recovered as KNbO3 with a 3D cubic structure [105, 106].

Schematic representation of the crystal structures of a HTiNbO5, b HNb3O8, c K4Nb6O17, and d LiMWO6 (M=Nb, Ta). d Reprinted with permission from [107]. Copyright 2009 American Chemical Society

Among the layered niobates and titanates, hexaniobate K4Nb6O17 shows special exfoliating behavior. This material is characterized by two types of alternating interlayer spaces called interlayers I and II. The interlayer K+ ions can be directly exchanged for various cations without acid treatment and those in interlayer I show higher reactivity than those in interlayer II [91, 108, 109]. Exfoliation induced by treating K4Nb6O17 with PA+ ions yielded bilayer nanosheets through swelling of interlayer I, because PA+ ions displace the K+ ions only in interlayer I [33, 110, 111]. Exfoliation was also achieved by the two-stage process of acid treatment and subsequent TBA+ or butylammonium exchange, which also generates the bilayer nanosheets [10, 100, 112, 113].

Exfoliation of the layered niobates in organic solvents has been achieved for K4Nb6O17 by making the interlayer spaces hydrophobic by grafting long-chain organic moieties onto the niobate layers. Grafting is attained after expanding the interlayer spaces with dodecylammonium ions (DA+). Because the exchange of K+ for DA+ occurred in both interlayers I and II [109], grafting took place in both interlayer spaces to give monolayer nanosheets. Grafting of octadecyltrimethylsilyl groups enabled exfoliation in tetrachloromethane [114]. To graft phenylphosphonate moieties in K4Nb6O17, interlayer expansion was carried out with dioctadecyldimethylammounium ions in addition to DA+; the former only expanded interlayer I, while the latter expanded both interlayer spaces. This enabled two types of grafting of phenylphosphonate groups, and provided both of the bilayer and monolayer nanosheets upon exfoliation in acetonitrile (Fig. 3.11) [115].

Preparation of monolayer- and bilayer-nanosheets by exfoliation of layered hexaniobate K4Nb6O17 modified with phenylphosphonic acid. Reprinted with permission from [115]. Copyright 2014 American Chemical Society

Niobate and tantalate nanosheets have been used as semiconducting photocatalysts and dielectric materials similar to the titanate nanosheets [10, 78, 87, 102, 116–125]. Photoelectrochemical cells have also been constructed containing these nanosheets [126–128]. In addition, because the acid strength of H+ ions on the niobate and tantalate nanosheets is greater than those on the titanate nanosheets [32], they have been applied as strong solid acid catalysts [13, 107, 129, 130].

4.3 Perovskite-Type Titanates, Niobates, and Tantalates

Perovskite-type titanates, niobates, and tantalates are members of cation-exchangeable layered oxometallates characterized by perovskite-type oxide layers [131, 132]. Each perovskite-type layer is a slice of a cubic crystal of ABO3 perovskite cut in parallel to its (100) direction with containing n B-site sheets (sheets of connected BO6 octahedra), which sandwiches to interlayer cations such as alkali metal ions to build up the layered structure (Fig. 3.12). The Dion–Jacobson (DJ) phase M[A n−1B n O3n+1] [133, 134] and Ruddlesden–Popper (RP) phase M2[A n−1B n O3n+1] (M=Na, K, etc.; A=Ca, Sr, lanthanide, etc.; B=Ti, Nb, Ta) [135–137] are known. The number of B-site sheets, n, reflects the thickness of a perovskite-type layer; the layer thickness with n ≥ 3 is much larger than that of the conventional layered titanates, niobates, and tantalates described in the above sections. The interlayer cations are usually exchanged for H+ ions by acid treatment prior to the exfoliation because the interlayer alkali ions M+ are strongly held by the perovskite-type layers [138]. Considering the DJ and RP phases, the former incorporates organoammonium ions more easily than the latter because the latter has a higher layer charge density and interlayer cations in more confined environments [139].

Exfoliation of perovskite-type niobate HCa2Nb3O10 (DJ phase, n = 3) has been investigated ahead of other layered titanates, niobates, and tantalates using a commercial monoamine surfactant as the exfoliating reagent [16]. To date, exfoliation of HCa2Nb3O10 has been frequently carried out mainly with TBA+ ions [140–143]. Formation of the monolayer nanosheets has been established by the XRD study [44]. Niobates and tantalates with thicker layers, HCa2Na n−3Nb n O3n+1 (DJ phase, n = 4–6), those partially substituted by lantanide elements such as HLn1−x La x Nb2O7 (Ln = Sm3+, Eu3+, Gd3+, etc.; DJ phase; n = 2), and those doped with fluorine and nitrogen such as HRbSrNb2O6F (DJ phase, n = 2) can also be exfoliated [144–151]. For the RP phase, H2[A n−1B n O3n+1] (A = Na, Ca, Sr, La; B = La, Ti; n = 2 or 3), H2SrTa2O7 (n = 2), H1.67Bi0.21Sr0.85Ta2O7 (n = 2), and H2Sr1.5Ta3O10 (n = 3) form nanosheets with the aid of organoammonium cations [18, 152–154]. Li2Bi4Ti3O12 (RP phase, n = 3) has been exfoliated in water without an exfoliating reagent to yield [Bi4Ti3O12]− nanosheets accompanied by reduction of water [155]. Exfoliation in organic solvents has been achieved for HLaNb2O7 by grafting a siloxane-terminated polymers and alkoxysilane through controlled hydrolysis–condensation reactions [17].

Applications of the perovskite-type oxometallates are similar to those of the other layered titanates, niobates, and tantalates described above. Photocatalysts, photoelectrodes, and photoconductive films of the perovskite-type nanosheets have been prepared [44, 128, 156–166]. The dielectric properties of such nanosheets have also been utilized [167–169]. Rare-earth substituted nanosheets have been examined as photoluminescent materials [144–147, 150, 153].

4.4 Other Transition-Element Oxometallates

4.4.1 Manganates

Layered manganate with the birnessite-type structure A x MnO2·nH2O (A=Na, K), also known as δ-MnO2, has been exfoliated to yield manganese oxide nanosheets. The layered structure consists of anionic manganese oxide layers of edge-shared MnO6 octahedra and interlayer cations (Fig. 3.13) [170–172]. Sodium manganate synthesized by oxidation of Mn2+ species in an alkaline solution [19, 173] and potassium manganate prepared by oxidation of Mn2O3 through calcination [45, 174] or by reduction of permanganate ions with KOH are used as the starting materials of the nanosheets [175]. After exchange of the interlayer alkali ions for H+ ions, the layered manganate is exfoliated with the aid of TBA+ or TMA+ ions. Complete exfoliation to monolayers was established by the XRD analysis. In addition, the manganate nanosheets have been directly synthesized by oxidation of Mn2+ ions in the presence of TBA+ ions [176]. Because of the mixed-valent and redox-active nature of the manganese oxides, the manganate nanosheets are applicable to electrochemical devices such as supercapacitors and lithium-ion batteries [175, 177, 178].

Schematic representation of the crystal structure of layered manganate K0.45MnO2. Reprinted with permission from [174]. Copyright 2006 American Chemical Society

4.4.2 Cobaltates

Since layered lithium cobaltate LiCoO2 is known as an electrode material of lithium-ion batteries [179–181], exfoliation of layered cobaltates has been investigated. LiCoO2 has an α-NaFeO2-type structure, which is related to the rock salt structure and consists of [CoO2]− layers and interlayer Li+ ions [182] (Fig. 3.14). LiCoO2 has been exfoliated by the acid treatment and successive reaction with TMA+ ions [20]. Multicomponent cobaltate Li[Mn1/3Co1/3Ni1/3]O2 and nonstoichiometric cobaltate Na x CoO2 have also been exfoliated in a similar manner [183]. The exfoliated cobaltate nanosheets are promising for use in lithium-ion batteries, although detailed results have not appeared yet. In addition, the p-type wide band-gap semiconducting nature of the cobaltate [184] is attractive because many other semiconducting oxometallates, such as titanates and niobates, are n-type. Nanosheets prepared from Na x CoO2 exhibited thermoelectric properties after reconstruction of the layered structure with Ca2+ ions [185].

Schematic representation of the crystal structure of layered manganate LiCoO2. Reprinted with permission from [181]. Copyright 2004 American Chemical Society

4.4.3 Ruthenates

Inspired by the excellent properties of RuO2 as an electrochemical capacitor [186], exfoliation of layered ruthenates has been investigated. The first ruthenate exfoliated was K0.2RuO2.1 whose structure has not been determined [21]. Exfoliation was realized by acid and subsequent TBA+ treatment. NaRuO2 with an α-NaFeO2-related structure was also exfoliated by the same method after oxidative deintercalation of Na+ ions to Na0.22RuO2 [22]. The ruthenate nanosheets exhibited superior performance as an electrochemical capacitor compared with that of bulk RuO2 crystals. A metal–insulator–metal structure applicable to an ultrathin capacitor has been obtained by combining the \({\text{Ru}}_{{0.{95}}} {{\text{O}}_{2}}^{0.2 -}\) and dielectric \({\text{Ca}}_{2} {\text{Nb}}_{3} {\text{O}}_{10}^{-}\) nanosheets [168].

4.4.4 Tungstates

Exfoliation of layered tungstates has been reported for H2W2O7, which is obtained from Bi2W2O7 possessing an Aurivillius-type perovskite structure with vacant A-sites by abstraction of the \({\text{Bi}}_{2} {{\text{O}}_{3}}^{ + }\) unit through an acid treatment [23]. The protonated tungstate was exfoliated through reaction with TBA+ ions. Exfoliation of layered tungstate Cs6+x W11O36 was also achieved by acid and subsequent TBA+ treatment. In this case, mesh-like tungstate nanosheets with interconnected pyrochlore-type channels were obtained (Fig. 3.15), and the nanosheets show photochromic behavior like that of WO3 [24].

Crystal structure of Cs6+x W11O36 viewed along the [110] direction, a Pyrochlore-type channels appeared in b the section view and in c the plane view (a 35° tilt from the horizontal alignment); Cs ions are omitted to highlight the channel structure. Reprinted with permission from [24]. Copyright 2008 American Chemical Society

4.5 Silicates

Layered silicates are oxides consisting of anionic silicate layers constructed of corner-shared SiO4 tetrahedra and interlayer exchangeable cations [187–189]. The structure of layered silicates can be recognized by the numbers of the sheets of connected SiO4 tetraheda stacked in each oxide layer. While kanemite NaHSi2O5·3H2O and apophyllite KCa4[Si4O10]2(F, OH)·38H2O are single-sheet silicates [190, 191], octosilicate Na8H8Si32O72·32H2O is a double-sheet silicate [192] (Fig. 3.16). Magadiite has thick silicate layers (more than three sheets), although its crystal structure has not been determined [193]. From a physicochemical point of view, the layered silicates are chemically stable and optically transparent similar to the clay minerals but they do not show specific electronic and photochemical properties. Such properties are different from those of the transition-metal oxometallates described above.

Although the cation-exchangeable layered silicates intercalate many guest molecules through various mechanisms including cation exchange, acid-base reaction, polar adsorption, and grafting, they do not show high exfoliating reactivity. There is no reliable report of the TBA+-induced exfoliation of a silicate in water. Exfoliation of octosilicate in water has been realized by multistep modification of the silicate layers; the Si–OH groups on the layer surfaces were grafted with organosilyl moieties possessing mercapto terminal groups, and then the terminals were oxidized to hydrophilic –SO3H groups [25]. Grafting of a silane coupling reagent with imidazolium functional groups has also enabled exfoliation of octosilicate in water (Fig. 3.17) [194]. As for exfoliation in an organic solvent, silylation of apophyllite has been reported to give transparent gels of the silicate nanosheets in CCl4 [195].

Surface modification of octosilicate with the sulfonic acid group for exfoliation in water. Reprinted with permission from [25]. Copyright 2009 American Chemical Society

4.6 Metal Phosphates

Metal phosphates are water-insoluble acidic salts obtained form multivalent metal ions with amphoteric nature, such as Zr4+, Ti4+, Al3+, and Sb5+, and phosphoric acid. Among various cation-exchangeable amorphous metal phosphates, α-zirconium phosphate (α-Zr(HPO4)2, α-ZrP) was first found to exist as a layered solid [196]. Various cation-exchangeable layered metal phosphates have since been synthesized. Their structures are characterized by the connection of the MO6 octahedra and PO4 tetrahedra to form negatively charged layers (Fig. 3.18). Interlayer exchangeable cations, e.g., H+ ions for α-ZrP, are held by the P–O− moieties on the layer surfaces. Layered metal phosphates exhibit high intercalating reactivity through various mechanisms similar to that of layered silicates [197, 198].

Schematic representation of the crystal structure of α-ZrP. Reprinted from [199]. Copyright 1982 Elsevier Inc

In 1985, α-ZrP was found to form a stable colloid in water after reaction with PA+, which is recognized as the first example of the exfoliation of a layered metal phosphate [26]. Later, formation of α-ZrP nanosheets was confirmed by exfoliation using TBA+ or a commercial surfactant [100, 200]. γ-ZrP, a polymorph of α-ZrP, can also be exfoliated in water using dimethylamine as the exfoliating reagent [201]. Meanwhile, α-ZrP nanosheets in an aqueous colloidal state after exfoliation with PA+ underwent sol–gel transition of the colloid upon displacing the solvent (water) for an organic one such as N,N-dimethylformamide, N-methylformamide, tetrahydrofuran, alcohols, or chloroform [202].

Exfoliation of metal phosphates has been extended to materials other than ZrP. Among these materials, layered antimony phosphate H3Sb3P2O14 [203] is important because it is exfoliated in water without the aid of an exfoliating reagent. Exfoliation is induced by dialyzing H3Sb3P2O14 obtained by acid treatment of K3Sb3P2O14 in water [27]. Complete exfoliation to monolayer nanosheets is supported by the liquid crystallinity of the resulting nanosheet colloid (see Chap. 8). Layered aluminophosphate (C2H5NH3)3Al3P4O16 was also directly delaminated in a water–ethanol mixture [204]. Ultrasound irradiation assisted exfoliation of iron phenylphosphate Fe(OH)(C6H5PO4H)1.6(HPO4)0.4 in water and olivine-type iron phosphate NH4FePO4 in formamide [205]. In contrast, exfoliation of α-titanium phosphate and α-tin phosphate was realized using TBA+ in acetonitrile [206].

4.7 Other Cation-Exchangeable and Related Materials

There are a few layered oxides that can be exfoliated through appropriate interlayer modifications. Although layered oxovanadium phosphate VOPO4·2H2O is not ion-exchangeable, it can intercalate various polar organic molecules including alcohols and amines [207]. Exfoliation occurs in polar organic solvents after intercalation of aromatic 4-butylaniline or acrylamide [208, 209]. Layered cuprate Bi2Sr2Ca m−1Cu m O y , known as a high-temperature superconducting oxide having a perovskite-related structure, can also be exfoliated [210, 211]. After the starting cuprate was intercalated with HgX2 (X=Br, I), and then with alkylpyridinium iodide, the material was exfoliated in acetone. Exfoliation of layered molybdate Na0.9Mo2O4 in water was realized by conventional acid and TBA+ treatment [212].

Layered solids that do not intrinsically have exchangeable cations can be converted to cation-exchangeable materials through reductive intercalation of interlayer cations. The reduced materials have nonstoichiometric interlayer charges with a low density compared with that of the stoichiometric compounds, and the interlayer spaces can often be infinitely swollen spontaneously like clay minerals. For example, FeIIIOCl can be reduced by Fe0 to Fe II x/2 [Fe II x Fe III1−x ]OCl. The intercalated Fe2+ ions are exchangeable, and the interlayer space is swelled infinitely in water [213]. Many transition-metal dichalcogenides can be intercalated with alkali cations such Li+ and Na+ through partial reduction of the chalcogenide layers [214]. Solvation of the cations in polar solvents yields colloidal dispersions of the chalcogenide nanosheets [215].

5 Exfoliation of Anion-Exchangeable Layered Solids

The library of anion-exchangeable layered solids is still not as rich as that of cation-exchangeable ones. Anion-exchangeable layered solids are classified into LDHs and layered hydroxide salts, and the former is more common than the latter. Exfoliation of these anion-exchangeable layered solids yields positively charged nanosheets, which are important as the counterparts of the negatively charged nanosheets obtained from the cation-exchangeable materials.

5.1 Layered Double Hydroxides (LDHs)

LDHs are binary metal hydroxides with a general formula of [M 2+1− x M 3+ x (OH)2][Xm−] x/m ·nH2O, where M2+ and M3+ are metal ions and Xm− is an interlayer exchangeable anions. Usually, M2+ is Ca2+, Mg2+, Fe2+, Ni2+, or Zn2+, M3+ is Al3+, Cr3+, Mn2+, Fe3+, or Gd3+, and Xm− is CO3 2−, SO4 2−, Cl−, or \({{\text{NO}}_{3}}^{-}\). Combination of Li+ and Al3+ is also possible. Organic anions such as carboxylate and sulfonate can also be the Xm− species. LDHs are easily synthesized by liquid phase reactions under ambient conditions: typically, controlled precipitation of M2+ and M3+ species in an alkaline solution. Investigations of LDHs began before the 1940s and their structure and anion exchange behavior were clarified until the 1980s [216–220]. Today, chemical science of LDHs has been grown into a large research field in materials chemistry, and many review articles and books on LDHs have been published [4, 221–225]. Exfoliation of LDHs has also been summarized in detail in a recent review [226], which complements the present section.

The most ubiquitous LDH is [Mg1−x Al x (OH)2](CO3) x/2 (Mg–Al–CO3 LDH), known as hydrotalcite. The layered structure of Mg–Al LDHs is derived from that of brucite Mg(OH)2, which has hexagonal layers consisting of connecting MgO(OH) octahedra. Although the hydroxide layers of brucite are attracted by van der Waals interactions, partial isomorphous substitution of Mg2+ for Al3+ in Mg–Al LDHs generates positive charges in the layers to allow electrostatic stacking with the interlayer anions for charge compensation. Such electrostatic layering is also observed for other LDHs; nevertheless, they are classified into hexagonal and rhombohedral polymorphs (Fig. 3.19) [216, 222]. The interlayer anions of LDHs are exchanged for many other inorganic and organic anions. However, \({{\text{CO}}_{3}}^{{{2}{-}}}\) is highly selective compared with other anions, particularly inorganic ones. Thus, selection of the initial interlayer anion is important to accomplish the desired anion exchange.

Schematic representation of the crystal structure of an LDH showing the polymorphic stacking patterns: a hexagonal, b rhomohedral. Reprinted with permission from [222]. Copyright 2002 Royal Society of Chemistry

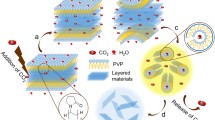

Although exfoliation of LDHs has been achieved by various methods since its discovery in 2000 [227], treating LDHs with interlayer NO3 – anions in formamide is the most common method today [228]. In the first study of this method, Mg–Al–\({{\text{NO}}_{3}}^{-}\) LDH prepared by a hydrothermal reaction of Mg(NO3)2 and Al(NO3)2 in the presence of hexamethyleneteramine was mechanically shaken in formamide [28]. Exfoliation into unilamellar LDH nanosheets through osmotic swelling has been confirmed by the XRD measurements, as mentioned in Sect. 3.3.2. Figure 3.20 schematically illustrates the exfoliation process in formamide. The use of hexamethylenetetramine as the alkaline reagent and the high reaction temperature under hydrothermal or refluxing conditions yielded large LDH crystallites and thus large exfoliated nanosheets with a lateral dimension of micrometers. The formamide method has been rapidly expanded to a wide range of LDHs such as Co–Al–\({{\text{NO}}_{3}}^{-}\) LDH prepared from other routes like conventional coprecipitation [29, 229, 230]. Other interlayer anions such as \({{\text{CO}}_{3}}^{{{2}{-}}} ,{{\text{ClO}}_{4}}^{-}\), and amino acids also tolerate exfoliation in formamide; in fact, amino acids were identified as appropriate anions for formamide prior to \({{\text{NO}}_{3}}^{-}\).

Schematic model of the possible exfoliation mechanism for LDHs in formamide. Reprinted with permission from [29]. Copyright 2006 American Chemical Society

LDHs incorporating long-chain organic species, e.g., dodecylsulfate anions, as an exfoliating reagent are exfoliated in organic solvents. The interlayer organic anions are introduced by anion exchange from inorganic anions or direct synthesis before exfoliation. Various organic solvents, from polar butanol and acrylate to nonpolar toluene and tetrachloromethane, are available for exfoliation [227, 231–233]. Exfoliation of dodecylsulfate-intercalated LDHs in toluene causes gelation of the solvents (Fig. 3.21) [234, 235]. Borate anions can also be utilized as the exfoliating reagent of LDHs for exfoliation in nonpolar hydrocarbons [236].

Schematic representation of the exfoliation of organically modified LDHs in toluene and photographs of the gelled nanosheet colloids. Reprinted with permission from [234]. Copyright 2006 American Chemical Society

Exfoliation of LDHs in water can be achieved by introducing carboxylate anions such as lactate, acetate, and formate into their interlayer spaces [237–240]. Hydrogels were obtained upon exfoliation of Mg–Al–acetate LDH in water. For the case of Mg–Al–methoxide LDH, addition of water causes hydrolysis of the methoxide species in the interlayer spaces, and the hydrolysis induces exfoliation in water [241]. LDHs with interlayer perchlorate anions have been exfoliated in an aqueous solution of amino acids [242].

Like the nanosheets of cation-exchangeable layered solids such as clay minerals and oxometallates, exfoliated LDH nanosheets have been examined for various applications. Specific functions have been designed by the combination of divalent and trivalent metal cations in the LDHs and the positively charged nature of the nanosheets. Although Mg–Al LDHs are chemically inert, those containing transition metals show a variety of physicochemical properties. Redox-active LDHs are obtained with Ni2+, Co2+, and Mn2+, and they have been prepared and examined in supercapacitors and lithium-ion batteries [243, 244]. LDHs with Cr3+ and Fe3+ have optical absorption in the visible region, and thus exhibit photocatalytic activities [245, 246]. In addition, the positively charged nature of LDH nanosheets allows them to be used as supports of anionic functional molecules that are luminescent, thermochromic, piezochromic, or photosensitizing molecules [247–250]. The positively charged nanosheets can also be used as macro-countercations of the negatively charged oxometallate nanosheets to yield heterocoagulated and superstructured nanosheet assemblies [251, 252]. Used as supports or carriers of bioactive molecules such as proteins, genes, and drugs [253–255] based on the biocompatibility of Mg–Al and Zn–Al LDHs [256, 257] is another growing field.

5.2 Layered Hydroxide Salts

There are metal hydroxide salts (or metal basic salts) that possess anion-exchangeable layered structures. A typical example is copper hydroxyacetate (basic copper acetate) Cu2(OH)3(CH3COO)·H2O, also known as botallackite [258, 259]. In this compound, acetate groups coordinated to Cu2+ in the hydroxide layers are projected into the interlayer spaces, and are partly exchanged for other anions. This layered hydroxide salt can be exfoliated in formamide under solvothermal conditions to yield CuO nanosheets [30]. Analogs of this compound with long-chain carboxylates MII(OH)3(C n H2n+1COO) (MII = Cu, Ni, Co; n = 17, 19, 21) are swollen and stably dispersed in toluene, suggesting exfoliation occurs [260]. This system is characterized by colloidal liquid crystallinity. Layered zinc hydroxybenzoate Zn(OH)1.66(C6H5COO)0.34, which is structurally different from the botallackite analogs, has been exfoliated in C3–C5 alcohols [261].

Another class of layered hydroxide salts subjected to exfoliation is lanthanide hydroxides Ln2(OH)3[Am−]1/m (Ln = lanthanide; Am− = interlayer anion such as Cl− and NO3−). Although basic salts of lanthanides have been known for a long time [262, 263], they have recently been rediscovered as anion-exchangeable layered solids [264–266]. Their luminescent and magnetic properties originating from the lanthanide ions have activated this research [264, 266]. Nanosheets of these compounds are also attracting interests in this trend. Exfoliation of layered lanthanide hydroxides has been accomplished by intercalating dodecylsulfate ions through anion exchange and subsequent agitation in formamide (Fig. 3.22) [31, 267].

a AFM image, b TEM image, and c model of the preparation process for Eu(OH)3−x nanosheets. Reprinted with permission from [31]. Copyright 2002 Royal Society of Chemistry

6 Assembly of the Nanosheets

The exfoliated nanosheets obtained from ion-exchangeable layered solids can be used in practical applications by assembling them appropriately. Employing each nanosheet as a building block, we can construct various nanostructured materials. Nanosheets with different physicochemical properties can be integrated with themselves or other species, including molecules, polymers, and nanoparticles to yield desired materials by fusion of their structures and functions. In such nanosheet assemblies, the electric charges and 2D morphology of the nanosheets play vital roles. Various nanostructures have been organized through electrostatic interactions between the nanosheets, and their 2D shape readily leads to anisotropic nanostructures. The colloidal and interfacial properties of the nanosheets are also important because the nanosheets are usually manipulated in solvents. This section briefly summarizes research on nanosheet assemblies, which are classified into three types based on their preparation techniques.

6.1 Aggregation to Bulk Solids

6.1.1 Porous Solids

Evaporation of the solvent from colloidal nanosheets usually causes reformation of the layered structure through restacking of the nanosheets. However, porous structures with high surface areas can be obtained if the restacking is appropriately interrupted. To ensure pore generation, templates or pillaring reagents are often used in the aggregation processes. As a direct method without templates, disordered porous aggregates of clay nanosheets with “house-of-cards” structure have been produced [1]. This structure has been obtained by aggregation of small clay nanosheets through face-to-edge electrostatic interactions between them.

For oxometallate and metal phosphate nanosheets, aggregates with high surface areas have been prepared from the nanosheets of, for example, lepidocrocite-type titanate H x Ti2–x/4□ x/4O4, perovskite-type niobate HCa2Nb3O10, and α-ZrP without the aid of templates [268–270]. Flocculation of titanate nanosheets with Keggin-type [Al13O4(OH)24(H2O)12]7+ (\({{\text{Al}}_{13}}^{7 + }\)) cations yielded pillared porous structures with a high surface area (>200 m2 g−1) [271, 272]. Aggregation with metal or oxide nanoparticles is also an effective approach to generate porous structures (Fig. 3.23) [10, 273]. However, hybridization with inorganic nanoparticles has attracted more attention from a functional viewpoint. Based on their cocatalyst or visible-light antenna functions, hybridization with titanate and niobate nanosheets has led to advanced photocatalysts [157, 274, 275].

Schematic illustration of the formation of porous structures by aggregation of niobate nanosheets in the presence of oxide nanoparticles. Reprinted with permission from [10]. Copyright 1997 American Chemical Society

Deposition of the nanosheets onto polystyrene (PSt) particles yielded core-shell and macroporous aggregates [276]. Removal of the PSt particles by calcination produced macroporous structures. However, the final structure depended the relative size of the nanosheets and PSt particles. While using nanosheets larger than the PSt particles yielded disordered pores with crumpled nanosheets, employing smaller nanosheets than the PSt particles formed ordered pores reflecting the colloidal crystallinity of the PSt particles. A recent study revealed that surfactant micelles can also act as macropore templates in nanosheet aggregates (Fig. 3.24) [277].

Synthesis of crystalline mesoporous materials from coassembly of niobate nanosheets and polymeric micelles based on colloidal chemistry. Reprinted with permission from [277]. Copyright 2015 John Wiley & Sons, Inc

Heterocoagulation of negatively charged nanosheets such as titanate with cationic species is also a useful method to aggregate nanosheets into specific structures. Although disordered aggregates are generally obtained upon mixing negatively and positively charged colloidal nanosheets [278], aggregates with layered structures have been obtained for mixtures of lepidocrocite-type titanate or perovskite-type niobate with LDH nanosheets (Fig. 3.25) [251]. The titanate or niobate nanosheets and LDH nanosheets are stacked by sandwiching with each other. The basal spacing determined by XRD analyses corresponded to the sum of the monolayer thicknesses of titanate or niobate and LDH nanosheets, confirming the alternating stacking of nanosheets. Meanwhile, heterocoagulation of lepidocrocite-type titanate nanosheets with biomolecules can improve the functions of the biomolecules. One example is the stabilization of enzyme molecules by the titanate nanosheets against UV light exposure [279]. Another example is that antibody molecules immobilized on the nanosheets underwent antigen recognition [280].

XRD and TEM characterizations of the LDH/titanate or niobate nanosheet aggregates with alternately stacked layered structures. a [Mg2/3Al1/3(OH)2]1/3+/Ti0.91 \({{\text{O}}_{2}}^{{0.{36} - }}\) and B) [Mg2/3Al1/3(OH)2]1/3+/Ca2Nb3 \({{\text{O}}_{10}}^{ - }\). Reprinted with permission from [4]. Copyright 2010 John Wiley & Sons, Inc

6.1.2 Cast Films

Deposition of nanosheets onto flat substrates generally produces films because of their 2D morphology. Such nanosheet films are usually prepared by drop- or spin-casting on a substrate [281–284]. Electrophoretic deposition of titanate, cobaltate, and LDH nanosheets has also been reported [9, 20, 285]. Nanosheet films have been used as electrodes and ion-exchangeable films. In these cast films, the deposited nanosheets are usually restacked to form layered structures that are disordered compared with the structures before exfoliation and often possess pores among the restacked nanosheets. Interstices and overlaps between the nanosheets are also usually unavoidable. These features facilitate molecular diffusion in the films, which is desirable for the electrochemical and ion-exchange processes. However, an almost “perfect” cast film with neat sheet tiling has been fabricated with lepidocrocite-type titanate nanosheets [286]. In this process, large nanosheets prepared from single crystals were deposited onto a substrate, which was modified in advance with cationic polymers in order to ensure the attachment of the negative nanosheets in a flat manner without interstices. Overlapping patches were then removed by ultrasonication (Fig. 3.26).

Schematic illustration of the preparation of “perfect” cast film of lepidocrocite-type titanate nanosheets. Reprinted with permission from [286] (illustration of graphical abstract). Copyright 2004 John Wiley & Sons, Inc

Nanosheet cast films are often prepared with ionic functional molecules, which can be incorporated in and/or adsorbed on the restacked nanosheets. The ionic molecules are immobilized through electrostatic interactions with the electrically charged nanosheets. Titanate nanosheets of H2Ti3O7 exfoliated by PA+ can regulate the orientation of cyanine dye molecules in their cast films [8]. When cast films of niobate nanosheets of K4Nb6O17 exfoliated by triethanolammonium ions were soaked in an aqueous methylviologen (MV2+) solution, photoinduced electron transfer occurred from the niobate nanosheets to the adsorbed MV2+ ions. The photochemical behavior was somewhat different from that observed for a conventional intercalation compound of the niobate and MV2+, reflecting the difference in microenvironment of the MV2+ ions [102]. MV2+ has also been incorporated into an electrophoretically deposited titanate nanosheet film, and the film exhibited photoinduced electron transfer [287, 288]. Confinement of rare-earth cations in titanate and hydroxide nanosheet films through electrostatic self-assembly can provide specific microenvironments to realize photoluminescence of the rare-earth ions [289].

Hierarchically organized heterostructures consisting of titanate nanosheet cast films with immobilized MV2+ and mesoporous silica powders including porphyrin have been produced (Fig. 3.27) [290–292]. Upon visible-light excitation of the porphyrin molecules, photoinduced electron transfer occurred from the porphyrin to MV2+ across the interface of the titanate nanosheets and mesoporous silica. A long-lived photoproduct was obtained by appropriate modification of the higher order structure.

Schematic structure of the [porphyrin–mesoporous silica (MPS)]/[MV2+–titanate nanosheet (TNS)] hybrid films. Reprinted from [290]. Copyright 2006 The Chemical Society of Japan

6.1.3 Transformation to Nanoscrolls

Morphological transformation of nanosheets to nanoscrolls has been reported for nanosheets exfoliated from several cation-exchangeable layered solids. This transformation occurs by scrolling of the nanosheets into tubules. This phenomenon was discovered for niobate nanosheets obtained from K4Nb6O17 (Fig. 3.28), and ascribed to their asymmetric surface structure given by the bilayer structure as mentioned in Sect. 3.4.2 [112]. However, the scrolling has also been found for nanosheets exfoliated from other precursors such as lepidocrocite-type titanate, perovskite-type titanate and niobate, and manganate, which all form monolayer nanosheets [152, 293, 294].

TEM image of the niobate nanoscrolls of obtained from hexaniobate nanosheets. Reprinted with permission from [112]. Copyright 2000 American Chemical Society

The niobate nanoscrolls prepared from K4Nb6O17 have been used as a 1D analog of the nanosheets. Their photo- and thermocatalytic properties have been examined in detail [10, 295–297]. In addition, incorporation of an azobenzene derivative (Azo) into niobate nanoscrolls has been investigated [298, 299]. In this system, cationic Azo molecules were intercalated into the scrolled nanosheets by cation exchange. The incorporated Azo molecules underwent photoisomerization, and their trans–cis transformation at the molecular level was magnified as sliding of the scrolled nanosheets, resulting in shape change at the micrometer-level.

It should be noted that all of the nanoscrolls mentioned above were identified only after the removal of solvents; clear evidence for scrolling of the nanosheets in the colloidal state has not been reported yet. This suggests that the nanosheets are scrolled as they dry, which is supported by the liquid crystallinity of the colloidal nanosheets. The liquid crystalline behavior of the niobate and titanate nanosheets is explained by individual nanosheets being well dispersed and retaining their 2D shape in the colloids [50, 300, 301]. Therefore, scrolling would occur during drying of the nanosheets. Removal of the solvent from the colloids concentrates coexisting electrolytes to facilitate aggregation of the nanosheets. This leads to wrinkling of the nanosheets and then the formation of nanoscrolls; thus, scrolling can be recognized as self-aggregation of nanosheets.

6.2 Layer-by-Layer Assemblies

LbL assembly is a technique used for fabricating multilayer thin films by repeated deposition of a monolayer onto a substrate. Although this method requires more elaborate operations than conventional film preparation techniques such as simple casting and spin-coating, LbL assembly is advantageous to precisely assemble thin films with defined nanostructures. Because the nanosheets exfoliated from ion-exchangeable layered solids bear electric charges, electrostatic sequential deposition, which is only called LbL assembly in a narrow sense, has been used more frequently for preparing thin films than the Langmuir–Blodgett (LB) method.

6.2.1 Electrostatic LbL Assemblies

This type of assemblies is obtained by alternating deposition of cationic and anionic monolayers onto a substrate [302, 303]. The first example of an electrostatic LbL assembly using exfoliated nanosheets was reported in 1984 for clay, α-ZrP, and niobate (from K4Nb6O17) nanosheets [100, 304]. Film fabrication was initiated by grafting cationic groups onto a glass substrate. The substrate was soaked in an aqueous colloidal suspension of nanosheets to deposit them on the substrate. Then, the substrate was withdrawn from the colloid, rinsed adequately, and transferred to an aqueous solution of polycations, such as poly(allylammonium), poly(diallyldimethylammonium), and polyethyeneimine, which caused the polymer countercations to adsorb on the nanosheets [305]. Multilayer films were fabricated by repeating the alternate deposition of nanosheets and polycations. Figure 3.29 illustrates the deposition process. Electrostatic LbL assembly has been rapidly extended to other electrically charged nanosheets such as titanates, manganates, and LDHs [28, 305, 306]. For the LbL assembly of LDH nanosheets, poly(styrene 4-sulfonate) has been used as a typical polymer counteranion. Inorganic clusters (e.g., \({{\text{Al}}_{13}}^{7 + }\)), biomacromolecules (e.g., cytochrome c), and nanoparticles can also be employed as the countercations [100, 307]. Alternating deposition of more than two kinds of the nanosheets such as cationic and anionic ones has yielded superstructured nanosheet multilayer films [251, 308, 309].

By appropriately combining nanosheets and counterions, the resulting nanosheet assemblies can show various functions. As an example, photoenergy conversion systems have been organized by assembling nanosheets and photofunctional molecules such as a sensitizers, electron/energy donors, and acceptors (Fig. 3.30) [12, 310]. Interlayer electron/energy transfer separated by the nanosheets has been identified. Use of the photocatalytically active semiconductor nanosheets, exemplified by titanates, enables their contribution to the photoprocesses [12, 311]. Photoinduced electron transfer between the electron-donating and -accepting nanosheets has been observed in a superstructured nanosheet film [308]. Meanwhile, LbL assembly of dielectric titanate and niobate nanosheets produces multilayer films with unusual electronic and magnetic properties, such as high-κ dielectric property [59–61, 87].

Possible architectures for photoinduced intra- (left) and interlayer (right) energy transfer followed by interlayer electron transfer. Reprinted with permission from [12]. Copyright 119 American Chemical Society

The LbL method is not limited to deposition on flat substrates. LbL fabrication of α-ZrP multilayer films on SiO2 particles with polymer countercations was reported in 1995 [310]. In this system, by attaching photofunctional moieties such as photoseisitizing ruthenium-bipyridine and electron accepting viologen units to the polymer side chains, and by stacking the polymer layers to sandwich the α-ZrP nanosheets, photoinduced electron transfer occured in the multilayer films reflecting the stacking sequence of the polymer layers and nanosheets. The formation of nanosheet multilayers on PSt particles by LbL assembly gave materials with a core-shell structure [312–314]. These core-shell particles were converted to hollow capsules after removal of the PSt cores by calcination.

6.2.2 Langmuir–Blodgett Films

The LB technique has also been used for fabricating inorganic nanosheet films although it is more complicated and time-consuming than electrostatic LbL deposition [315]. The LB method is advantageous to obtain high quality films with neat tiling. In fact, high-quality nanosheet multilayer films with few interstices and overlaps have been obtained with this technique [77]. LB films have been fabricated from the nanosheets of exfoliated layered titanates and niobates as well as clay minerals [77, 316–318]. Since these nanosheets are hydrophilic because of their layer charges, they are electrostatically attached by long-chain organic cations prior to LB casting (Fig. 3.31). By this treatment, they become located at the air–water interface and can be transferred onto a substrate at an appropriate surface pressure. Film deposition without the amphiphilic additives has also been achieved [77, 318].

Schematic illustration of the preparation process of the dioctadecyldimethylammonium bromide (DODAB)/titanate nanosheet alternating film using the LB technique. Reprinted with permission from [316]. Copyright 2001 American Chemical Society

Nanosheet LB films prepared from perovskite-type niobate HSr2Nb3O10 displayed photoconductivity [80]. When a LB film deposited with long-chain alkylammonium ions was irradiated with UV light, the alkylammonium ions were decomposed by the photocatalytic activity of the niobate nanosheets, and then the film showed conductivity under the irradiation [156, 319]. Although LB films of nanosheets exfoliated from perovskite-type niobate (HCa2Nb3O10) were paraelectric, they became ferroelectric when the perovskite nanosheets were appropriately superstructured with other niobate and titanate nanosheets [320].

6.2.3 Nanosheet Monolayer Films as Substrates for Crystal Growth

Nanosheet monolayer films deposited by the LB technique have been used as seed layers on which 3D crystals are grown with specific orientations. Thin films of cubic perovskites SrTiO3 and BaTiO3 have been epitaxially grown in the [100] direction on the LB monolayer perovskite-type niobate nanosheets exfoliated from HCa2Nb3O10. Epitaxial growth was realized because of the crystallographic compatibility of the nanosheet surface and the (100) plane of the cubic perovskites (Fig. 3.32) [321–323]. LB monolayers of manganate and tungstate (Cs4W11O36) nanosheets have been used for the growth of ZnO thin films in the [001] direction [321, 324].

6.3 Assemblies of the Nanosheets in the Colloidal State

Organization of nanosheets in the colloidal state yields characteristic assembled structures that are different from the bulk and LbL assemblies. A typical example is the liquid crystalline phase transition of the colloids (Fig. 3.33) [27, 325–328]. The liquid crystalline phases provide orientationally ordered structures of nanosheets in solvents, as described in Chap. 8. The fluid nature of the liquid crystalline phases enables macroscopic alignment of the colloidal nanosheets under external fields [325, 329, 330]. Another example is the sol–gel transition of colloidal nanosheets. While the exfoliated nanosheets are obtained as colloidal gels in some cases, a reversible sol–gel transition upon external pH stimuli has been reported for a colloid of niobate (K4Nb6O17) nanosheets [331].

Naked-eye observation of liquid crystalline nanosheet colloids of H3Sb3P2O14. Test-tubes filled with aqueous suspensions of the nanosheets, observed between crossed polarizers (a–e) (the isotropic phase in c and d appears dark). Reprinted with permission from [27]. Copyright 2001 Nature Publishing Group

Controlled aggregation of the colloidal nanosheets can provide specifically organized nanosheets in the powder form. Alternate stacking of niobate/titanate (exfoliated from K4Nb6O17 or H x Ti2–x/4□ x/4O4, respectively) and tungstate (prepared from H2W2O7) nanosheets has been attained through a thiol–ene click reaction (Fig. 3.34) [332, 333]. When niobate or titanate nanosheets with attached alkene moieties were mixed with tungstate nanosheets anchored by thiol groups, the click reaction proceeded between the niobate/titanate and tungstate nanosheets to bind them, resulting in the selective formation of a heterostructured product that was settled out from the colloid. Because the product consisted of two semiconducting oxides with different band positions, it realized efficient photoinduced electron transfer.

Alternating layers of metal oxide obtained by a click reaction. Reprinted with permission from [332]. Copyright 2004 John Wiley & Sons, Inc

Emulsification of oil–water systems is also a promising way to assemble the colloidal nanosheets. Moderately hydrophobized solid particles are known to stabilize emulsions like organic surfactants. Such emulsions, called Pickering emulsions, have recently attracted attention because of their high stability and unusual properties induced by the particle emulsifiers [334, 335]. The emulsification induces particle aggregation at the oil–water interface. Ion-exchangeable layered crystals have also been examined as solid emulsifiers because their hydrophobicity can be modified by intercalation of organic molecules into the interlayer spaces or grafting them to the nanosheet surfaces. Although non-exfoliated layered crystals have been used in most cases [336–339], emulsification by α-ZrP and graphene oxide nanosheets has recently been reported (Fig. 3.35) [340, 341]. This suggests the applicability of other exfoliated nanosheets as solid emulsifiers.

Toluene-in-water emulsions stabilized by α-ZrP-ODI and nonmodified α-ZrP nano-sheets. a Micrograph of uniform toluene-in-water droplets stabilized by α-ZrP-ODI nano-sheets. b Micrograph of polydispersed toluene-in-water emulsion droplets stabilized by non-modified α-ZrP nano-sheets. c Toluene-in-water emulsions stabilized by non-modified α-ZrP (right) and stabilized by α-ZrP-ODI nano-sheets (left). Reprinted with permission from [341]. Copyright 2012 Royal Society of Chemistry

7 Summary and Outlook

Ion-exchangeable layered solids can be exfoliated by osmotic swelling with solvents; in most cases after displacing the interlayer ions for suitable ones called exfoliating reagents, which have an affinity for the employed solvent. There are a number of ion-exchangeable layered solids such as oxometallates, metal phosphates, and hydroxides, with a broad range of compositions. Thus, the inorganic nanosheets obtained through exfoliation possess diverse physicochemical functions based on their electric, magnetic, optic, photochemical, catalytic, and redox properties. The nanosheets can be assembled to form a variety of hierarchical structures; they are not limited to stacked films but can form porous solids, transformed structures such as nanoscrolls, and structured colloids. Many inorganic ion-exchangeable layered solids are still waiting for the development of exfoliation technology, and a much richer library of advanced materials based on exfoliated nanosheets should be established in the near future. In addition, combination of nanosheets with other building blocks with different structural motifs, such as porous powders, 0D and 1D particles, and biological macromolecules, will expand both the structural and functional variety of nanosheet-based materials.

References

van Olphen H (1991) Clay colloid chemistry (reprinted edition). Krieger, Malabar

Smalley M (2006) Clay swelling and colloid stability. Taylor & Francis, Boca Raton

Sasaki T (2007) J Ceram Soc Jpn 115:9

Ma R, Sasaki T (2010) Adv Mater 22:5082

Gunjakar JL, Kim IY, Lee JM, Jo YK, Hwang S-J (2014) J Phys Chem C 118:3847

Sasaki T, Watanabe M, Hashizume H, Yamada H, Nakazawa H (1996) Chem Commun 229

Harada M, Sasaki T, Ebina Y, Watanabe M (2002) J Photochem Photobiol, A 148:273

Miyamoto N, Kuroda K, Ogawa M (2004) J Mater Chem 14:165

Sugimoto W, Terabayashi O, Murakami Y, Takasu Y (2002) J Mater Chem 12:3814

Abe R, Shinohara K, Tanaka A, Hara M, Kondo JN, Domen K (1997) Chem Mater 9:2179

Nakato T, Miyamoto N, Harada A (2004) Chem Commun 78

Kaschak DM, Lean JT, Waraksa CC, Saupe GB, Usami H, Mallouk TE (1999) J Am Chem Soc 121:3435

Takagaki A, Yoshida T, Lu D, Kondo JN, Hara M, Domen K, Hayashi S (2004) J Phys Chem B 108:11549

Prasad G, Takei T, Arimoto K, Yonesaki Y, Kumada N, Kinomura N (2006) Solid State Ionics 177:197

Fukuda K, Nakai I, Ebina Y, Ma RZ, Sasaki T (2007) Inorg Chem 46:4787

Treacy MMJ, Rice SB, Jacobson AJ, Lewandowski JT (1990) Chem Mater 2:279

Tahara S, Takeda Y, Sugahara Y (2005) Chem Mater 17:6198

Schottenfeld JA, Kobayashi Y, Wang J, Macdonald DD, Mallouk TE (2008) Chem Mater 20:213

Liu Z-h, Ooi K, Kanoh H, Tang W-p, Tomida T (2000) Langmuir 16:4154

Kim TW, Oh E-J, Jee A-Y, Lim ST, Park DH, Lee M, Hyun S-H, Choy J-H, Hwang S-J (2009) Chem Eur J 15:10752

Sugimoto W, Iwata H, Yasunaga Y, Murakami Y, Takasu Y (2003) Angew Chem Int Ed 42:4092

Fukuda K, Saida T, Sato J, Yonezawa M, Takasu Y, Sugimoto W (2010) Inorg Chem 49:4391

Schaak RE, Mallouk TE (2002) Chem Commun 706

Fukuda K, Akatsuka K, Ebina Y, Ma R, Takada K, Nakai I, Sasaki T (2008) ACS Nano 2:1689

Ide Y, Ozaki G, Ogawa M (2009) Langmuir 25:5276

Alberti G, Casciola M, Costantino U (1985) J Colloid Interface Sci 107:256

Gabriel J-CP, Camerel F, Lemaire BJ, Desvaux H, Davidson P, Batail P (2001) Nature 413:504

Li L, Ma R, Ebina Y, Iyi N, Sasaki T (2005) Chem Mater 17:4386

Liu Z, Ma R, Osada M, Iyi N, Ebina Y, Takada K, Sasaki T (2006) J Am Chem Soc 128:4872

Demel J, Zhigunov A, Jirka I, Klementova M, Lang K (2015) J Colloid Interface Sci 452:174

Ida S, Sonoda Y, Ikeue K, Matsumoto Y (2010) Chem Commun 46:877

Raveau B (1984) Rev Chim Miner 21:391

Miyamoto N, Yamamoto H, Kaito R, Kuroda K (2002) Chem Commun 2378

Sasaki T, Watanabe M, Hashizume H, Yamada H, Nakazawa H (1996) J Am Chem Soc 118:8329

Sasaki T, Watanabe M (1998) J Am Chem Soc 120:4682

Geng F, Ma R, Nakamura A, Akatsuka K, Ebina Y, Yamauchi Y, Miyamoto N, Tateyama Y, Sasaki T (2013) Nat Commun 4:1632

Maluangnont T, Matsuba K, Geng F, Ma R, Yamauchi Y, Sasaki T (2013) Chem Mater 25:3137

Geng F, Ma R, Ebina Y, Yamauchi Y, Miyamoto N, Sasaki T (2014) J Am Chem Soc 136:5491

Geng F, Ma R, Yamauchi Y, Sasaki T (2014) Chem Commun 50:9977

Hervieu M, Raveau B (1981) Rev Chim Miner 18:642

Sasaki T, Watanabe M, Michiue Y, Komatsu Y, Izumi F, Takenouchi S (1995) Chem Mater 7:1001

Sasaki T, Izumi F, Watanabe M (1996) Chem Mater 8:777

Barbier G (1934) Compt Rend 199:226

Ebina Y, Sasaki T, Watanabe M (2002) Solid State Ionics 151:177

Omomo Y, Sasaki T, Wang L, Watanabe M (2003) J Am Chem Soc 125:3568

Ohya T, Nakayama A, Takahasbi B, Ohya Y, Takahashi Y (2002) Chem Mater 14:3082

Kamada K, Soh N (2014) RSC Adv 4:8682

Tanaka T, Ebina Y, Takada K, Kurashima K, Sasaki T (2003) Chem Mater 15:3564

O’Neill A, Khan U, Coleman JN (2012) Chem Mater 24:2414

Miyamoto N, Nakato T (2004) J Phys Chem B 108:6152

Wang L, Sasaki T (2014) Chem Rev 114:9455

Le Granvalet-Mancini M, Brohan L, Marie A-M, Tournoux M (1994) Eur J Solid State Inorg Chem 31:767

Ide Y, Sadakane M, Sano T, Ogawa M (2014) J Nanosci Nanotechnol 14:2135

Fujiki Y, Komatsu Y, Ohta N (1980) Chem Lett 1023

Izawa H, Kikkawa S, Koizumi M (1982) J Phys Chem 86:5023

Clément P, Marchand R (1983) C R Acad Sci Paris II(296):1161

Izawa H, Kikkawa S, Koizumi M (1983) Polyhedron 2:741

Sasaki T, Watanabe M, Komatsu Y, Fujiki Y (1985) Inorg Chem 24:2265

Osada M, Ebina Y, Takada K, Sasaki T (2006) Adv Mater 18:295

Osada M, Ebina Y, Fukuda K, Ono K, Takada K, Yamaura K, Takayama-Muromachi E, Sasaki T (2006) Phys Rev B 73:153301

Osada M, Itose M, Ebina Y, Ono K, Ueda S, Kobayashi K, Sasaki T (2008) Appl Phys Lett 92:253110

Dong XP, Osada M, Ueda H, Ebina Y, Kotani Y, Ono K, Ueda S, Kobayashi K, Takada K, Sasaki T (2009) Chem Mater 21:4366

Gao T, Fjellvåg H, Norby P (2009) J Mater Chem 19:787

Berry KL, Aftandilian VD, Gilbert WW, Meibohm EPH, Young HS (1960) J Inorg Nucl Chem 14:231

Andersson S (1961) Acta Crystallogr 14:1245

Besselink R, Stawski TM, Castricum HL, Blank DHA, ten Elshof JE (2010) J Phys Chem C 114:21281

Wang Y, Sun C, Yan X, Xiu F, Wang L, Smith SC, Wang KL, Lu GQ, Zou J (2011) J Am Chem Soc 133:695

Sugimoto W, Ohuchi K, Murakami Y, Takasu Y (2005) Bull Chem Soc Jpn 78:633

Ide Y, Ogawa M (2005) Chem Lett 34:360

Ide Y, Ogawa M (2006) J Colloid Interface Sci 296:141

Honda M, Oaki Y, Imai H (2014) Chem Mater 26:3579

Shibata M, Kudo A, Tanaka A, Domen K, Maruya K, Onishi T (1987) Chem Lett 1017

Miyata H, Sugahara Y, Kuroda K, Kato C (1988) J Chem Soc, Faraday Trans 1(84):2677

Nakato T, Kuroda K (1995) Eur J Solid State Inorg Chem 32:809

Domen K, Kondo JN, Hara M, Takata T (2000) Bull Chem Soc Jpn 73:1307

Osterloh FE (2008) Chem Mater 20:35

Akatsuka K, Haga M, Ebina Y, Osada M, Fukuda K, Sasaki T (2009) ACS Nano 3:1097

Osada M, Sasaki T (2012) Adv Mater 24:210

Choy J-H, Lee H-C, Jung H, Kim H, Boo H (2002) Chem Mater 14:2486

Umemura Y, Shinohara E, Koura A, Nishioka T, Sasaki T (2006) Langmuir 22:3870

Shibata T, Sakai N, Fukuda K, Ebina Y, Sasaki T (2007) Phys Chem Chem Phys 9:2413

Matsumoto Y, Ida S, Inoue T (2008) J Phys Chem C 112:11614

Allen MR, Thibert A, Sabio EM, Browning ND, Larsen DS, Osterloh FE (2010) Chem Mater 22:1220

Jo YK, Kim IY, Gunjakar JL, Lee JM, Lee NS, Lee SH, Hwang SJ (2014) Chem Eur J 20:10011

Liu G, Wang LZ, Sun CH, Chen ZG, Yan XX, Cheng L, Cheng HM, Lu GQ (2009) Chem Commun 1383

Liu G, Sun C, Wang L, Smith SC, Lu GQ, Cheng H-M (2011) J Mater Chem 21:14672

Osada M, Takanashi G, Li B-W, Akatsuka K, Ebina Y, Ono K, Funakubo H, Takada K, Sasaki T (2011) Adv Funct Mater 21:3482

Osada M, Sasaki T, Ono K, Kotani Y, Ueda S, Kobayashi K (2011) ACS Nano 5:6871

Bizeto MA, Shiguihara AL, Constantino VRL (2009) J Mater Chem 19:2512

Lagaly G, Beneke K (1976) J Inorg Nucl Chem 38:1513

Gasperin M, Le Bihan MT (1982) J Solid State Chem 43:346

Gasperin M (1982) Acta Cryst. B 38:2024

Nedjar R, Borel MM, Raveau B (1985) Mater Res Bull 20:1291

Wadsley AD (1964) Acta Cryst 17:623

Blasse G, de Pauw ADM (1970) J Inorg Nucl Chem 32:3960

Rebbah H, Borel MM, Raveau B (1980) Mater Res Bull 15:317

Rebbah H, Hervieu M, Raveau B (1981) Mater Res Bull 16:149

Bhat V, Gopalakrishnan J (1988) Solid State Ionics 26:25

Song H, Sjåstad AO, Fjellvåg H, Okamoto H, Vistad ØB, Arstad B, Norby P (2011) J Solid State Chem 184:3135

Keller SW, Kim H-N, Mallouk TE (1994) J Am Chem Soc 116:8817

Du GH, Yu Y, Chen Q, Wang RH, Zhou W, Peng LM (2003) Chem Phys Lett 377:445

Nakato T, Edakubo H, Shimomura T (2009) Micropor Mesopor Mater 123:280

Park I, Han YS, Choy JH (2009) J Nanosci Nanotechnol 9:7190

Galasso F, Darby W (1962) J Phys Chem 66:1318

Toda K, Tokuoka S, Uematsu K, Sato M (2002) Key Eng Mater 214–215:67