Abstract

Measuring process based on laser tracker, iGPS and other digital measurement instruments becomes more and more important in digital manufacturing. Traditionally, a measuring process is planned based on human knowledge in planning strategies, measuring regulations, instruments, measuring operations and historical data. Relatively, computer aided measuring planning (CAMP) makes the process formatted, and enables manufacturers to improve measurement accuracy and efficiency and reduce the cost. To implement CAMP for digital measuring process, the concept of general measurement space (GMS) is proposed, and a multi-dimensional model (MDM) is built to support the structural storing and handling of the key information for measuring process. The model has multi attributes in three dimensions, which describe and classify multi-source and heterogeneous data related to a measuring process. Finally, the GMS’s characteristics matrix is constructed, providing a feasible way to evaluate measurement plans based on measuring process knowledge.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Multi-dimension model

- Computer-aided measuring planning

- General measurement space

- Digital measurement instrument

- Digital manufacturing

1 Introduction

Digital measurement technologies have been increasingly and widely employed, which provide more efficient and highly precise approaches for inspection and quality assurance in digital manufacturing process, and thus have drawn significant attention from manufacturers [1–5]. Digital metrologies are based on laser tracker, photogrammetry, iGPS and other digital measurement instruments; while improving the forms of measuring and inspecting, their applications also bring a new principle: measurement is not just an operation for geometrical dimensions inspection, but becomes the eyes of entire production process for digital data transferring, collecting and quality assurance.

In comparison to the traditional measurement approaches, digital metrologies have the attributes in both progressiveness and complexity [6]; in order to meet the requirements of measurement accuracy, measuring time and total cost for a given task, it is necessary to plan the measuring process based on the human knowledge in planning strategies, measurement instruments, historical data and measuring operations, followed by making out a measurement plan for guiding the measuring process. The most important factor during measurement planning is accuracy, which is consisting of trueness and precision. The trueness reflects the systematic errors and the precision reflects the random errors [7]. For applications of digital metrologies, measurement plan is significantly important for ensuring the accuracy, validity and creditability of measuring results that is output by the measuring process.

Measurement planning based on the historical knowledge is aimed at ensuring the measurability of measuring process, which is determined by a number of manifold factors involved in the process. The relations between measurability and process factors are the foundation of measurement plan decision, and they are embedded in historical data of measuring process. Therefore, data collection from measuring process and structural storage and analysis are critical for measurement planning in digital manufacturing. However, there is a lack of research on how to integrate the complex historical information from measuring process, and to build up the relationship between measurability and process factors; and thus measurement planning without the support of historical information is still non-formatted and uncertain.

In order to integrate, express and take full reuse of historical information for measurement planning, a multi-dimensional measuring process model based on general measurement space (GMS) is proposed; a methodology, which is based on the GMS model, for formally integrating and expressing different measuring process information is presented and discussed; finally, the GMS’s characteristics matrix is constructed, providing a feasible way of evaluating and optimizing measurement plans in digital manufacturing.

2 Related Works

Digital measurement has become one of the critical parts in product manufacturing. As a typical application form, instruments such as laser trackers, iGPS are largely used to measure the position and orientation of complex components during fixtures calibration and components alignment by Boeing, Airbus, Rolls-Royce and other manufacturers [8–10]. Widely employments accumulate a large amount of process information for knowledge integration.

In order to optimize the measurement plan of measuring process, the majority of the research focuses on precision analysis of digital instruments. Jamshidi analyzed the relation between precision and physical structure of iGPS, and compared it with laser tracker [11–13]; Muelaner proposed a mathematical model for evaluating the measurement capability of different instruments, which is able to support instruments selection for measurement planning [14]; on the basis of principle analysis, Du conducted research on how the precision of iGPS measurement field is affected by its deployment types [15]; Wang investigated the error sources of large scale measurement system and proposed a method for uncertainty evaluation [16]. Their research usually established the link between precision and parameters of special instrument, but was only a part of the measuring process and not enough for measurement planning.

For knowledge management of measuring process, Maropoulos firstly proposed the concept of metrology process model [17, 18]; then, Chen used a measurement field model with input and output to express digital measuring process, analyzed its attributes and discussed the evaluation method [19]; subsequently, a measurement data model based on key measurement characteristics was given for unifying, storing and managing the measuring process data in product assembly [20].

In summary, the research and applications of digital metrologies are still in their infancy; the lack of investigations on measuring process model and information integration causes that, a large amount of historical information and knowledge of measuring process haven’t been fully discovered, managed and reused. Data collecting and information modeling and analyzing of measuring process have significances for measurement planning and the development of digital metrologies and in manufacturing.

3 Multi-dimensional Model of Measuring Process

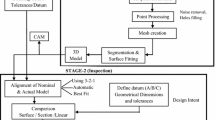

Measuring process consists of four stages: demands analysis, process planning, data collection and result output; in order to describe the useful information in measuring process, firstly, on the foundation of object-oriented modeling methodologies, measurement space is considered as an object with functions of receiving demands, executing commands and outputting result; therefore, measuring process can be described by behaviors of measurement space, and information in the process can be described by attributes of measurement space.

Traditional measurement space is considered to be a three-dimensional geometrical space; in order to embed the manifold elements, general measurement space (GMS) model with three dimensions and ten attributes is proposed as the model of measuring process, as shown in Fig. 1; it integrates five key elements in measuring process: people, machine, material, method and environment.

Attributes of GMS are classified into three dimensions: (1) Physical dimension includes basic elements of measuring process such as instrument, target and environment; (2) Process dimension includes additional elements for implementing the behaviours and functions of measuring process, such as plan, operator and algorithm; (3) Characteristics dimension includes key characteristics of measuring process, such as accuracy, cost, time and range, these characteristics are determined by attributes of physical and process dimensions. Based on the GMS model, measuring process can be described as: demands inputting, GMS constructing, characteristics evaluating and result outputting.

3.1 Attributes in Physical Dimension

In physical dimension, instrument attribute is used to describe information and knowledge of digital measurements, such as laser tracker, photogrammetry, iGPS, and laser radar and so on. Measurement targets of GMS are usually comprised of optical target points (OTPs) on the surfaces of different features and structures. Environment attribute is used to describe temperature, humidity, air pressure and other factors that influence on the measuring process. Contents of attributes in physical dimension are shown in Fig. 2.

3.2 Attributes in Process Dimension

Attributes of plan, operator and algorithm in process dimension determine the operation mechanism of GMS. Process plan file is used to describe processes, steps of measuring process; a measuring step is mainly comprised of geometrical features and OTPs. Additionally, referred standards and specifications and product model are also included in the plan file. Operator attribute distinguishes different workers by their work number, skills, technical levels and other features, technical level of operator will affect the measurement results to a certain extent. Algorithms, such as auto measuring algorithm, abnormal point judgment algorithm, data fusion algorithm and so on, are called from the algorithm database; different algorithms which implement the same function will lead to different result. Contents of attributes in process dimension are shown in Fig. 3.

3.3 Attributes in Characteristics Dimension

In characteristics dimension, accuracy describes the measured systematic error and random error of any point in GMS, systematic error of measuring process can be removed from the final result, while random error will be given out with the final result in the form of uncertainty or precision. Measurement cost mainly consists of utilization cost, deployment cost and operating cost: (1) utilization cost can be calculated in terms of the selected measurement system’s value and activity depreciation; (2) deployment cost is arisen from by the setting-up and deployment of the system in real manufacturing and assembly environments; (3) operating cost is introduced by real measurement operations. Measurement time is the total time consumed in the measuring process for completing a single measurement task. At the present stage, measurement accuracy is the most important characteristic that has received extensive attention during the digital measuring process.

4 Structural Data Model Based on MDM

The GMS model has classified and described the multi-source information in measuring process. On the foundation of this, it is necessary to build structural data models to integrate and express the information with a formatted form, which is easy to be used by program for knowledge-based reasoning, and then realizing the CAMP of measuring process for measurement planning.

4.1 Data Structure of Physical Dimension

Information in physical dimension includes instrument knowledge, target knowledge and environment knowledge, which can be transformed to structured information. Through analyzing their properties and relations among those properties, an Entity-Relation diagram is built to give the information model of knowledge in physical dimension, as shown in Fig. 4.

Entity of instrument has properties of manufacturer, model, type, number, name, precision, calibration cycle, calibration date, cost, purchase date and others; it is contained in both instrument database and knowledge in physical dimension. Entity of target has properties of number, nominal value of its coordinate, actual value of its coordinate, uncertainty, is abnormal, is valid and others, it is also contained in knowledge in physical dimension. Entity of environment has properties of temperature, humidity, air pressure, time and others, it is contained in knowledge in physical dimension; the time properties is used to record the measuring time of other properties of environment.

4.2 Information Model of Process Dimension

Knowledge about process plan, operator and algorithm are the main contents in process dimension. Manufacturers are usually skilled to build valid databases for storing, managing and calling resources of their employee and algorithm, because of that those information is easy to be transformed to structured data. By contrast, a process plan file is usually complex and mixed document, which contains lots of structured and non-structured information. In order to unify those information in process dimension for knowledge discovering and reusing, a unified information model based on standards of XML, I++ and DMIS is proposed, the model uses a tree structure and embeds the information of operator and algorithm into itself, as shown in Fig. 5.

4.3 Data Structuring for Characteristics Dimension

-

Accuracy, cost, time and range are four main characteristics of GMS, and their value determine that if the GMS meet the requirements of measurement task. Data of these attributes is usually continuous, and has some uncertainty and error. Therefore, a method is discussed as follows, for transforming those continuous data to discrete and structured data.

-

Step 1: Determine the full range of characteristics’ value based on historical information and knowledge in physical and process dimensions.

-

Step 2: Set the threshold value of different levels based on experience and expert scoring method, and then give out the levels with its range of characteristics’ value.

-

Step 3: According to the levels, mapping the actual value of characteristics from original data to level data, and form structured data in characteristics dimension. The flow is depicted in Fig. 6.

5 Characteristics Matrix for Measurement Planning

To make out a reasonable measurement plan based on multi-dimensional model with historical information includes three steps:

-

(1)

Construct process model and integrate process information for knowledge discovering and storing;

-

(2)

Reveal and present the mapping relationship between characteristics and the basic attributes in physical and process dimensions;

-

(3)

Determine the values of transfer factors from basic attributes to characteristics based on historical knowledge;

-

(4)

Calculate and evaluate the measurement capability of the GMS according to the given deployments, and provide guides and optimization decisions for measurement planning.

The third and fourth sections have given out a measuring process model and structured forms of process knowledge. Thus, in this section, a characteristics relation matrix (CRM) of GMS will be discussed for expressing the relations between characteristics and basic attributes.

The CRM includes two matrixes: characteristics value matrix and characteristics weights matrix, as shown in Fig. 7. In the value matrix, element aij reflects the influence of the jth basic attribute on the ith characteristic, while in the weights matrix, element vij is the weights of aij in all six ai, and

The final capability of the GMS is the sum of four characteristics, and is defined as Measurement Capability Index (MCI), which is derived as:

where, the factor Ci is the value of the ith characteristic, and the factor wi is the weights of the ith characteristic in MCI. For different measurement tasks, the importance rank of four characteristics may be not the same, as a result, the value of wi will be decided in the actual process based on the specific demands.

On the basis of the CRM, the relationship between MCI and all basic attributes can be presented as followed:

Equation (3) provides a way for calculating the MCI based on the historical knowledge and actual measurement plan prior to executing the measuring process; for calculating one of those characteristics, it is only required to focus on the referred line of the CRM; taking the accuracy prediction as an typical example, the relationship between accuracy and basic attributes can be expressed as:

The relationship expressed by Eq. (4) is the foundation of accuracy prediction. Then, it is necessary to determine the weights v1j and value a1j for each pair of accuracy-attribute.

6 Conclusions

Research and applications of digital measurement technologies have stimulated the development of digital manufacturing technologies; in the meantime, the methods of measuring planning become critical problems to be resolved in measuring process. Computer-aided measurement planning makes not only the process formatted, and also for manufacturers to improve product quality and reduce manufacturing cost.

A measuring process model was proposed with a definition of general measurement space. The model has three dimensions to classify and integrate measuring process knowledge. Through analyzing the contents and forms of different information collected for measuring process, the approaches of data structuring and management have been discussed. Finally, a feasible way for evaluating and optimizing measurement plan based on characteristics matrix was explored.

Future work will focus on historical data collecting, database constructing and evaluation of characteristics relation matrix, in order to improve the methodology of computer-aided digital measurement planning.

References

Jody, M., Amir, K., et al.: Measurement assisted assembly and the roadmap to part-to-part assembly. In: Proceedings of DET 2011 7th International Conference on Digital Enterprise Technology (2011)

Muelaner, J.E., Maropoulos, P.G.: Design for measurement assisted determinate assembly (MADA) of large composite structures. J. CMSC 5(2), 18–25 (2010)

Du, F.Z., Chen, Z.H.: Research on the implementation technologies of measurement driven aircraft sub-assembly digital joining system. Aeronaut. Manufact. Technol. 17, 52–55 (2011)

Wang, Z., Liang, M., et al.: High accuracy mobile robot positioning using external large volume metrology instruments. Int. J. Comput. Integr. Manuf. 24(5), 484–492 (2011)

Liu, S.L., Luo, Z.G., et al.: 3D measurement and quality evaluation for complex aircraft assemblies. Acta Aeronaut. et Astronaut. Sin. 34(2), 409–418 (2013)

Peggs, G.N., Maropoulos, P.G., et al.: Recent developments in large-scale dimensional metrology. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 223, 571–595 (2009)

DE-DIN. Accuracy (trueness and precision) of measurement methods and results - Part 4: Basic methods for the determination of the trueness of a standard measurement method (ISO 5725–4:1994) (2003)

Yu, Y., Tao, J., et al.: Assembly technology and process of Boeing 787 jet. Aeronaut. Manufact. Technol. 14, 44–47 (2009)

Jamshidi, J., Kayani, A., et al.: Manufacturing and assembly automation by integrated metrology systems for aircraft wing fabrication. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 224(25), 25–36 (2010)

Jayaweera, N., Webb, P., et al.: Measurement assisted robotic assembly of fabricated aero-engine components. Assembly Autom. 30(1), 56–65 (2010)

Muelaner, J.E., Wang, Z., et al.: Study of the uncertainty of angle measurement for a rotary-laser automatic theodolite (R-LAT). Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 223, 217–229 (2009)

Maisano, D.A., Jamshidi, J., et al.: Indoor GPS: system functionality and initial performance evaluation. Int. J. Manuf. Res. 3(3), 335–349 (2008)

Maisano, D.A., Jamshidi, J., et al.: A comparison of two distributed large-volume measurement systems: the mobile spatial coordinate measuring system and the indoor global positioning system. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 223(B3), 511–521 (2009)

Muelaner, J.E., Cai, B., et al.: Large volume metrology instrument selection and measurability analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 224(6), 853–868 (2010)

Du, F.Z., Chen, Z.H., et al.: Precision analysis of iGPS measurement field and its application. Acta Aeronaut. et Astronaut. Sin. 33(9), 1737–1745 (2012)

Wang, Q., Zissler, N., et al.: Evaluate error sources and uncertainty in large scale measurement systems. Robot. Comput. Integr. Manuf. 29(1), 1–11 (2013)

Maropoulos, P.G., Zhang, D., et al.: Key digital enterprise technology methods for large volume metrology and assembly integration. Int. J. Prod. Res. 45(7), 1539–1559 (2007)

Maropoulos, P.G., Guo, Y., et al.: Large volume metrology process models: a framework for integrating measurement with assembly planning. CIRP Ann. – Manufact. Technol. 57, 477–480 (2008)

Chen, Z.H., Du, F.Z.: Research on key measurement field building technologies for aircraft digital assembly. Aeronaut. Manufact. Technol. 22, 44–47 (2012)

Chen, Z.H., Du, F.Z., et al.: Key measurement characteristics based inspection data modeling for aircraft assembly. Acta Aeronaut. et Astronaut. Sin. 33(11), 2143–2152 (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Tang, X., Chen, Z. (2015). A Multi-dimensional Model for Computer-Aided Measuring Planning (CAMP) in Digital Manufacturing. In: Fred, A., Dietz, J., Liu, K., Filipe, J. (eds) Knowledge Discovery, Knowledge Engineering and Knowledge Management. IC3K 2013. Communications in Computer and Information Science, vol 454. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-46549-3_4

Download citation

DOI: https://doi.org/10.1007/978-3-662-46549-3_4

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-46548-6

Online ISBN: 978-3-662-46549-3

eBook Packages: Computer ScienceComputer Science (R0)