Abstract

Bacteria, fungi, and graminaceous plants synthesize siderophore for scavenging iron from environment to inhibit the growth of pathogens by depriving of iron. At this study, 19 siderophore producing bacterial strains were isolated from heat treated samples by O-CAS agar screening and liquid CAS assay. Among them, strain MB8 produced a relatively high level of siderophore (70.38 % SU, ++++). Comparative sequence analysis of 16S rRNA gene identified MB8 as a Bacillus subtilis strain. With Arnow analysis, the siderophore of MB8 was confirmed to be one type of catecholate. Furthermore, fermentation parameters affecting the siderophore production by MB8, including carbon sources and amino acids, were investigated at individual levels. Antimicrobial activity assay showed that the siderophore exhibited significant antimicrobial activity against Proteus vulgaris, Staphylococcus aureus, Micrococcus luteus, Escherichia coli, Vibrio parahaemolyticus, and Mucor. Our results indicated that B. subtilis MB8 had the potential to be used as a probiotic organism.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Iron is essential for almost all organism by virtue of its unique chemical properties, the ability to coordinate and activate oxygen, and the possession of an ideal redox chemistry (FeII → FeIII → FeIV) for involvement in electron transport and metabolic processes. Higher organisms acquire iron nutrient from diet, while microorganisms obtain iron element only from environment. Despite the abundance of iron in the earth’s crust, iron is not readily bio-available in aerobic environments due to the low solubility of iron (III). These environmental restrictions and biological imperatives have prompted microorganisms to synthesize siderophores can sequester and solubilize the nonsoluble surrounding iron in order to make it biologically available. Siderophores are relatively low molecular weight (500−1,500 dalton) iron-chelating ligands, and are synthesized under conditions of iron starvation by non-ribosomal peptide synthetases (NRPS) or NRPS independent pathways [1].

Until now, there are about 500 different siderophores discovered and of which 270 siderophores have been structurally characterized [2]. Based on their structural features, siderophores comprise three basic groups, the hydroxamate, the catecholate, and hydroxycarboxylate. The probiotics strain Escherichia coli Nissle 1917 produces the catecholate enterobactin and salmochelin, the hydroxamate aerobactin, and the mixed-type siderophore yersiniabactin [3]. And Pseudomonas aeruginosa synthesizes pyochelin and pyoverdine. Pyoverdine, which contained hydroxamates and catecholates group, is a yellow-green, fluorescent, water-soluble pigment [4].

Siderophore-mediated iron acquisition is essential for the survival of some pathogenic bacteria. The siderophores secreted by nonpathogenic strains was compete iron with pathogenic bacteria to inhibit their growth. The siderophore provide iron not only for itself, but also for others organism. The organic Fe chelators can not only enhance plant yield, but also protect the environment and water by avoiding the use of pesticides [5].

In this study, a bacillus strain secreting siderophores was isolated and identified. The siderophore secreted was catecholate and its antimicrobial activity was characterized. Moreover, the fermentation parameters for siderophore production were investigated.

2 Materials and Methods

2.1 Samples Collection

The chicken fecal samples were collected from five henneries located at Beijing Huairou district and Henan province. The samples were stored in sterile sealed bags at 4 °C refrigerator ready for use.

2.2 Media and Culture Condition

The medium used in this work included MKB medium [6]; Arginine medium [7] (AM); Luria-Bertani (LB) medium [8]; Czapek Dox medium [8]; CAS [9] solution; AM was modified by replacing glucose of arginine medium with 20 g/L glycerol along with the reduction of arginine to 1 g/L.

2.3 O-CAS Assay and CAS Liquid Assay

2 g samples were dissolved with 10 mL PBS buffer and heated at 80 °C for 20 min. When cooled to room temperature, 0.2 mL suspension was spreaded on AM agar plate and incubated at 37 °C for 24 h. Then 15 mL CAS agar medium were applied over the colonies [10].

The strains which showed positive responses in the O-CAS assay were recovered and purified by streaking. Single colonies were inoculated into AM, and incubated at 37 °C with a shaking speed 200 rpm for 24 h. Supernatant was harvested by centrifugation at 10,000 rpm for 5 min, and mixed with equal volume CAS solution. Siderophores, if present, will remove iron from the dye complex, resulting in a reduction in blue color of the solution. Measure the absorbance (OD680 [11]) to test the loss of blue color after 1 h. For OD680 measured, the AM medium were used as blanks, and the mixture of AM plus CAS assay solution was used as a reference (Ar). The samples (As) should have a lower reading than the reference. Siderophore units are defined as SU = [(Ar–As)/Ar] × 100 % [12]. And As/Ar stands for the siderophore activity level, ranging from 0 to 1. In general the more siderophore is produced, the lower of As/Ar value was [13]. All these experiments were conducted at least three times with three replicates for each one.

2.4 Siderophore Typing by Chemical Methods

The Arnow assay was used to detect catecholate type siderophore [14]; the FeCl3 assay was used to detect hydroxamate type siderophore [15], and the Shenker assay was used to detect carboxylate type siderophore [16]. All the assays were conducted at least three times with three replicates for each one.

2.5 Identification by 16S rRNA Sequencing

Genomic DNA of MB8 was extracted as described previously [17]. Then MB8 strain was identified by 16S rRNA gene sequence analysis. Universal primers 27F (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-GGTTACCTTGTTACGACTT-3′) were used to amplify 16S rRNA gene fragment PCR products were sequenced directly. Sequence homology search was carried out with BLAST provided by NCBI [18].

2.6 Growth and Siderophore Production

The isolate was inoculated in 100 mL AM by transferring 1 % seed cultures and incubated for 48 h at 37 °C with a shaking 200 rpm. Cell density was tested at an interval of 2 h up to 48 h. 1 mL culture supernatant was mixed with 1 mL of CAS solution to measure the siderophore production. A reference was prepared by mixing AM medium and CAS solution. Both the test and reference were read at 680 nm.

2.7 The Effect of Fermentation Parameters

In order to verify whether carbon source [7] and amino acid [7] had an influence on siderophore unit and growth of MB8, xylose, maltose, lactose, soluble starch, sucrose, fructose, and glycerol were used as an alternative carbon source to glucose in AM. Moreover, arginine was replaced with alanine, cysteine, aspartic acid, histidine, glutamate, glutamine, and glycine, respectively, to investigate the amino acid effect on siderophore production. All above experiments were performed for 36 h at 37 °C with a shaking speed 200 rpm.

2.8 Antimicrobial Activity Analysis

Overnight cultures of E. coli, Staphylococcus aureus, Proteus vulgaris, Micrococcus luteus, and Vibrio parahaemolyticus were inoculated to 30 mL MKB medium at 1 % inoculum, respectively. In the same time, the siderophore extract was added to the cultures with different ratios. 1 g/L 2, 3-DHBA and PBS buffer was used as negative control. All cultures were incubated at 37 °C for 16 h. Cell density were tested by measurement of OD600, and the inhibition ratio was calculated as the following:

Added 10 mL of PBS buffer to PDA slant of mucor, the suspension was transfer to 30 mL Czapek Dox medium with 3 % inoculums. In the same time, the siderophore extract was added to the cultures with different ratios. 1 g/L 2, 3-DHBA and PBS buffer was used as negative control. All cultures were incubated at 37 °C for 48 h. The cultures were filtered and the biomass was dried completely before measurement of mycelium weight. The inhibition ratio = (dry weight of mycelium of without siderophore extract − dry weight of mycelium with siderophore extract)/dry weight of mycelium without siderophore extract [5].

3 Results and Discussion

3.1 Isolation and Identification of Siderophore Producing Bacillus Strains

According to the method described, a total of 19 strains showed a positive response to O-CAS assay. Among them, MB8 strain changed the color of CAS rapidly within 15 min, then turned into nacarat in 30 min. Therefore, strain MB8 is tentatively considered as a potentially strong siderophore producer.

The 19 isolated strains were subjected to CAS liquid assay, and they have different siderophore yields. The siderophore units of strain MB8 in liquid AM was 64.53 % (As/Ar = 0.35) and siderophore activity level was ++++. The obtained result was similar to Bacillus spp. ST13 isolated from human stool, and siderophore units of this strain was approximately 70 % [19]. The results suggested that strain MB8 was a highly siderophore producing strain.

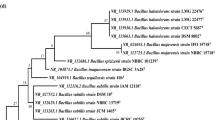

The genomic DNA of MB8 was extracted and used as templates to amplify 16S rRNA gene fragments by PCR method. Homology alignments were performed via BLAST provided by NCBI. The taxonomy classification was carried out by Classifier of RDPII [18]. Both analyses gave similar results that strain MB8 was homologous to Bacillus subtilis with 100 % similarity [22].

3.2 Siderophore Typing and Siderophore Production

The culture of strain MB8 was spin and the supernatant was collected. With Arnow method, the supernatant was analyzed. The colorless supernatant turned into dark red rapidly (OD510 = 0.762), equivalent to 44 mg/mL 2, 3-DHBA. Therefore, the siderophore synthesized by strain MB8 was catecholate type siderophore. The result was consistent with previous findings [20, 21].

As shown in Fig. 10.1, MB8 grew at a relatively slow speed. The culture entered the stationary phase at 30 h. The production of siderophore was consistent with the growth curve of the MB8, and the siderophore unit of MB8 achieved the maximum (SU = 70.38 %) at 36 h. It took about 12 h for MB8 to enter log phase. The long log phase phenomenon was probably due to the nutrient deficiency of synthetic medium [23].

3.3 Investigation of the Fermentation Parameters Affecting Siderophore Production

The siderophore production by MB8 was affected by the carbon source used. As shown in Fig. 10.2, the growth on glycerol stimulated the very high siderophore production (SU = 72.13 %, OD600 = 1.888), while the strain produced a relatively less amount of siderophore (SU = 70.49 %, OD600 = 1.86) with glucose as the sole carbon source. The siderophore unit of MB8 using maltose, lactose, fructose, starch, or sucrose as carbon source were 40.54, 38, 28.76, 60.51, and 61.85 %, respectively. Glycerol was chosen as the optimal carbon source.

MB8 couldn’t grow in the medium with alanine or cysteine. As shown in Fig. 10.3, in the medium with aspartic acid, glutamine, arginine, glutamic acid, glycine or histidine, the siderophore units of strain MB8 was 12.44, 4.31, 72.06, 6.94, 63.06, or 65.79 %, respectively. The results demonstrated that arginine was chosen as the optimal growth amino acid, consistent with results obtained in Bacillus megabacterium [7].

3.4 Effect of Arginine Concentrations

No data were available about the relationship between the arginine concentration and the siderophore production. In order to evaluate the positive effect of arginine on the siderophore production by strain MB8, the medium was supplemented with arginine in various concentrations ranging from 0 to 4 g/L. As shown in Fig. 10.4, the increase of arginine concentration did not always irritate the siderophore production of MB8, both the siderophore production and the cell density of strain MB8 were restrained by high concentrations of arginine. In the absence of arginine, MB8 didn’t grow at all, indicating MB8 couldnot synthesize arginine. In the presence of 1 g/L arginine, the siderophore unit of strain MB8 reached at the maximum level (SU = 74.89 %). The SU and cell density gradually decreased along with the incease of arginine concentration. In the presence of 4 g/L argine in the medium, SU of strain MB8 was almost zero. The results showed that the optimal concentration of arginine was 1 g/L along with 20 mL/L glycerol.

3.5 Antimicrobial Activity Analysis

To determine whether the antagonistic substance of MB8 was catecholate siderophore, the siderophore of strain MB8 was preliminarily purified as described [23]. The effects of the siderophore extract on microbial growth were measured. In the presence of low concentrations of siderophore, an obvious antagonism effect on the growth of P. vulgaris, S. aureus, and M. luteus was observed, while the relatively low inhibition effect was observed in the growth of V. parahaemolyticus and E. coli (Table 10.1). In the presence of high concentrations of siderophore, all tested microorganisms grew poorly (Table 10.1).

The siderophore extract also showed inhibition effect on the growth of Mucor. In the presence of 20 % siderophore, the inhibition rate was 88.7 %. Until now, all fungal siderophores were hydroxamate-type with the exception of the polycarboxylaterhizoferrin [24]. Fungi acquired iron element by transporting siderophores into fungal cells through an energy-dependent process. In the transporting process, the fungal siderophores bound with the specific receptors on the membrane. The siderophore synthesized by strain MB8 was catecholate type and could be recognized by fungal receptors. This explained why the siderophore of MB8 had an obvious inhibition effect on the growth of mucor. Usually, Bacillus species didn’t have such extensive antagonism spectrum as reported in our study [7, 19]. Our results suggested that for the first time, the siderophore extract from a Bacillus strain exhibited the antagonism activity against microorganisms.

4 Conclusions

In this study, a high siderophore producing Bacillus strain MB8 was isolated. With 16S rRNA sequence analysis, MB8 was identified as B. subtilis. After optimization of the fermentation parameters, MB8 produced the siderophore unit up to 74.89 %. The siderophore extract had an obvious antagonistic effect on the growth of P. vulgaris, S. aureus, M. luteus, V. parahaemolyticus, E. coli, and Mucor. It was suggested that B. subtilis MB8 had the potential to be used as a probiotic due to its ability synthesizing the catecholate type siderophore with the broad antagonism activity against bacteria and fungus.

References

Oves-Costales D et al (2009) The long-overlooked enzymology of a nonribosomal peptide synthetase-independent pathway for virulence-conferring siderophore biosynthesis. Chem Commun 43:6530−41

Hider RC, Kong X (2010) Chemistry and biology of siderophores. | Nat Prod Rep 27:637–657

Valdebenitoa M et al (2006) Environmental factors influence the production of enterobactin, salmochelin, aerobactin, and yersiniabactin in Escherichia coli strain Nissle 1917. Int J Med Microbiol 296(8):513–520

Vandenende C (2004) Functional characterization of an aminotransferase required for pyoverdine siderophore biosynthesis in Pseudomonas aeruginosa PAO1. J Bacteriol 186(17):5596–5602

Radzki W et al (2013) Bacterial siderophores efficiently provide iron to iron-starved tomato plants in hydroponics culture. Antonie Van Leeuwenhoek 104(3):321–330

Pi H et al (2012) Role of catecholate siderophores in gram-negative bacterial colonization of the mouse gut. PLoS ONE 7(11):1–8

Santos S et al (2014) Siderophore production by Bacillus megaterium: effect of growth phase and cultural conditions. Appl Biochem Biotechnol 172(1):549–560

Du L, Lu F (2006) The experiment technology of microbiology. China Light industry Press, Beijing

Schwyn B, Neilands JB (1987) Universal chemical assay for the detection and determination of siderophores. Anal Biochem 160(1):47–56

Pérez-Miranda S et al (2007) O-CAS, a fast and universal method for siderophore detection. J Microbiol Methods 70(1):127–131

Zhao X et al (2006) Improvement and analysis in over-siderophores production bacteria filtrating and detecting. J Microbiol Biotechnol 33:95–98

Persmark M et al (1989) Isolation, characterization, and synthesis of chrysobactin, a compound with siderophore activity from Erwinia chrysanthemi. J Biol Chem 264:3187–3193

Manjanatha MG et al (1992) Tn5 mutagenesis of Chinese Rhizobium fredii for siderophore overproduction. Soil Biol Biochem 24(2):151–155

Arnow LE (1937) Colorimetric determination of the components of 3, 4 - dihydroxyphenylalaninetyrosine mixtures. J Biol Chem 118:531–537

Lee J et al (2012) Siderophore production by actinomycetes isolates from two soil sites in Western Australia. Biometals 25(2):285–296

Shenker M et al (1992) Utilization by tomatoes of iron mediated by a siderophore produced by Rhizopus arrhizus. J Plant Nutr 15(10):2173–2182

Sambrook JF, Russell DW (2001) Molecular cloning: a laboratory manual, 3rd edn. Cold Spring Harbor Press, New York

Zhang J, Madden T (1997) PowerBLAST: a new network BLAST application for interactive or automated sequence analysis and annotation. Genome Res 7(6):649–656

Ahire J et al (2011) Bacillus sp. of human origin: a potential siderophoregenic probiotic bacteria. Appl Biochem Biotechnol 164:386–400

Hu X, Boyer GL (1995) Isolation and characterization of the siderophore N-deoxyschizokinen from Bacillus megaterium ATCC 19213. Biometals 8(4):357–364

Kh L et al (2001) Partial characterization of polyfermenticin SCD, a newly identified bacteriocin of Bacillus polyfermenticus. Appl Microbiol 32(3):146–151

Lin Y et al (2014) Potential biocontrol Bacillus sp. strains isolated by an improved method from vinegar waste compost exhibit antibiosis against fungal pathogens and promote growth of cucumbers. Biol Control 71:7–15

Ak P et al (2009) Production, purification and chemical characterization of the catecholate siderophore from potent probiotic strains of Bacillus sp. Bioresour Technol 100:368–373

Renshaw JC et al (2002) Fungal siderophores: structures, functions and applications. Mycol Res 106(10):1123–1142

Acknowledgments

This work was partly supported by the national natural science foundation of China (grant no. 31370205) and the science and technology program from Beichen District of Tianjin, China (grant no. BCNYKJ-18).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Zhu, H., Yang, H. (2015). Isolation and Characterization of a Highly Siderophore Producing Bacillus subtilis Strain. In: Zhang, TC., Nakajima, M. (eds) Advances in Applied Biotechnology. Lecture Notes in Electrical Engineering, vol 332. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-45657-6_10

Download citation

DOI: https://doi.org/10.1007/978-3-662-45657-6_10

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-45656-9

Online ISBN: 978-3-662-45657-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)