Abstract

Delivery of drugs through the skin is challenging because of the excellent barrier properties of the stratum corneum (SC). Several enhancement methods including chemical and physical means have been used to overcome the barrier but these methods disrupt the stratum corneum. More recently, using supersaturated systems that contain drug concentrations higher than its solubility has been evaluated as an enhancement technique. Supersaturated states are thermodynamically unstable and tend to crystallize either during preparation or during storage. However, a number of polymers act as anti-nucleants and keep the drug in solution by inhibiting the crystallization process. There are numerous studies that show that significant permeation enhancement can be achieved by using such polymers to stabilize supersaturation. However, efforts in commercializing this technology have been minimal mainly due to several challenges that need to be overcome prior to successful commercialization. If these challenges are overcome, supersaturation as a permeation enhancement technique can become an innovative commercial strategy for transdermal drug delivery systems.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Transdermal drug delivery

- Transdermal delivery systems

- Permeation enhancement

- Supersaturated systems

- Anti-nucleant polymers

- Degree of supersaturation

1 Introduction

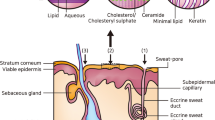

The stratum corneum (SC) is the outermost layer of the skin and acts as a primary barrier to the permeation of chemicals across the skin. In order to achieve transdermal penetration enhancement across SC, physical and chemical methods are applied for effective drug delivery. The physical enhancement techniques include iontophoresis, sonophoresis, electroporation, microneedle-based devices, liquid jet injectors, powder injectors, ultrasound, laser radiation, radiofrequency, magnetophoresis, and temperature. The chemical penetration enhancement methods involve either disrupting the stratum corneum by fluidizing or disrupting the intercellular lipids and are achieved through the use of different chemical classes including sulfoxides, azone, pyrrolidones, fatty acids, alcohols, glycols, and terpenes (Rai 2010). The physical and chemical enhancement techniques mentioned above can be expensive and can potentially give rise to toxicity and irritation (due to disruption in the SC integrity). Supersaturation provides a potentially safe, inexpensive mechanism for penetration enhancement of drugs. Also the use of supersaturated systems does not interfere with the SC integrity.

A supersaturated system, by definition, is a system where the concentration of a chemical compound in solution exceeds that of a saturated solution. This system is thermodynamically unstable and, in many cases, results in the formation of crystals spontaneously (labile state). If the compound remains in solution under supersaturated conditions, the state is called metastable state. Because of the nature of metastable state, addition of foreign particles or external forces such as ultrasound, nucleation results in crystallization. The boundary between the metastable and labile states is called the critical degree of supersaturation (Fig. 11.1). The degree of supersaturation (DS) is then dependent on the concentration of the drug on the solution and the temperature of the system.

The advantages of supersaturated systems for percutaneous penetration were first recognized by Higuchi (Higuchi 1960) (Fig. 11.2). The role of supersaturation in transdermal delivery has been tested and found effective consistently in the past (Coldman et al. 1969; Guy 2007; Morrow 2007); however, in order to achieve supersaturation, the choice of optimal solvents or co-solvents is critical (Poulsen et al. 1968). The concept and the understanding of supersaturated systems were borne out of the crystallization theory, where a solution must be first of all supersaturated in order for crystals to form. The precise mechanism of nucleation and subsequent crystal growth is not fully understood. There are multiple theories proposed in the literature for predicting crystal growth (Frank 1949; Mehta et al. 1970; Rodríguez-Hornedo and Wu 1991). It has been observed that the choice of solvent is critical for the type of crystals (e.g., hydrate, alcoholate) and polymorphs formed in the solution (Corrigan and Timoney 1974; Khoshkoo 1991). It has also been observed that different polymorphs of a compound can have different saturated solubilities in a solvent and, therefore, one can be supersaturated with respect to the other. Solvate forms of drugs, sometimes called pseudopolymorphs, can also have different solubilities and dissolution rates to their corresponding non-solvate forms. Similar to polymorphs, an anhydrous form of a drug can be supersaturated with respect to its hydrate form (de Smidt et al. 1986; Davis 1993).

Higuchi’s model of percutaneous absorption (Higuchi 1960)

2 Method of Preparation for Supersaturated Solutions

There are four primary methods of preparing the supersaturated solutions, viz., biphasic or binary mixing (addition of a substance to a solution which reduces the solubility of the solute); evaporation; heating and then cooling; and via chemical reactions (of two or more solutes to produce a new compound which is less soluble in solution than the original starting solutes), e.g., melt extrusion technology, granulation. The supersaturated solutions prepared using all the above techniques have shown increased percutaneous permeation of drugs in the past (Adrian et al. 2002).

The preparation of biphasic mixtures can be explained by constructing a curve for the saturated solubility of the drug in a binary co-solvent system where the drug is more soluble in one of the solvents than the other (Fig. 11.3). By preparing a saturated solution of the drug in solvent B and diluting with solvent A, a point, E, is obtained along the line CD, where C represents 100 % of solvent A and D represents 100 % solvent B. This is a supersaturated solution and its degree of saturation is calculated by dividing the amount of drug in solution by its saturated solubility in the same co-solvent mixture. In this example, the solution E has two degrees of saturation. Crystallization in a biphasic system is inhibited (or retarded) by addition of an anti-nucleant polymer to solvent A (Adrian 2002).

The diffusion studies of the biphasic mixture of water to the solutions of hydrocortisone acetate in propylene glycol (PG) and the anti-nucleant polymers polyacrylate, PVP, and HPMC indicated that the supersaturated solutions gave an increase in flux when compared with the saturated solutions and that the flux was proportional to the degree of saturation. It was also found that a 0.02 % supersaturated gel of hydrocortisone acetate was bioequivalent to a 1 % cream in reducing a surfactant-induced erythema (Davis and Hadgraft 1991; Davis 1993). Similar observation with increase in flux from increasing DS has also been observed in fentanyl delivery when supersaturated solutions with different DS were prepared using PG/water and PG/ethanol systems (Santos et al. 2011). An 18-fold increase in the concentration of estradiol in the stratum corneum was observed within ten minutes of exposure to a supersaturated solution when compared with a saturated solution in the same co-solvent mixture (Megrab et al. 1995). A testosterone-supersaturated solution with 2.5° of supersaturation in 1/1 ethanol/PG was found to show flux (across hairless rat skin) similar to that of metered dose transdermal spray system under commercial development (MDTS®, Acrux Ltd., Australia, www.acrux.com.au) (Leichtnam 2006). The delivery of piroxicam from a fourfold supersaturated solution across silicone and human skin in vitro was increased four times compared to the drug delivery of a saturated solution in the same vehicle. The solutions up to 4° of saturation were found to be stable for 16 h and then crystallization was observed (Pellett et al. 1997). It was also demonstrated via tape stripping technique that the intercellular regions of the stratum corneum were capable of maintaining supersaturated systems as the drug is transported across the stratum corneum (Pellett et al. 1997). In another study with delivery of fluocinonide across silicone membranes using in vitro diffusion cells, supersaturated solutions up to 3.8° of saturation were prepared using PVP and a vehicle composition of ethanol, water, glycerol, and propylene glycol, and it was found that fluocinonide permeation across silicone membranes was linearly related to degree of saturation (Schwarb et al. 1999). Permeation studies of ketotifen from silicon-based pressure-sensitive adhesive (PSA) with n-hexane and another solvent dichloromethane, tetrahydrofuran, acetone, ethyl acetate, or toluene demonstrated that the formulation was in a supersaturated state (Inoue et al. 2005).

Supersaturation can also be achieved by evaporation of the volatile components in the formulation resulting in decreased solubility in the residual component of the skin surface leading to increased thermodynamic activity. However, the only drawback of supersaturation achieved via evaporation is the lack of control on concentration of the supersaturated solution thereby having less control on flux via that solution. The evaporation theory can be tested by occluding/un-occluding the formulation when volatile solvents are present in the vehicle (Tanaka et al. 1985). Just like binary systems, control of crystallization is important to maintain the supersaturated state of drug in solution. In a study where nifedipine was dissolved in combination of vehicles like isopropyl myristate, PG, and acetone and studies for permeation across an ethylene-vinyl acetate copolymer membrane, the initial flux values in the system were found to be greater than the final steady-state fluxes attributing to the crystallization of the drug component. The incorporation of anti-nucleant polymers into the IPM:PG:acetone vehicle led to a three to five times enhancement in flux (Kondo and Sugimoto 1987). These findings of increased permeation across the lipoidal membrane were confirmed in an in vivo/in vitro correlation study where similar observations were reported across excised male Wistar rat skin in vivo using the nifedipine solution in 75:25 ethanol and diethyl sebacate combinations (Kondo et al. 1987). In another study, hydrocortisone was dissolved in a mixture of acetone and water, and up to 3.9° of saturation was achieved giving a proportional increase in flux, which was monitored across an ethylene-vinyl acetate copolymer membrane after the evaporation of volatile component (Theeuwes et al. 1976). The increase in delivery of sodium nonivamide acetate has also been tested across rat skin from supersaturated solutions prepared by evaporation of the volatile components of an aqueous ethanolic vehicle, and two components, methyl cellulose and hydroxypropyl cellulose, were found to have a stabilizing effect as an anti-nucleant preventing crystallization within the skin membrane (Fang et al. 1999).

When a solution is prepared from cooling it to a temperature below that of the saturated solubility, the solution may crystallize or a stable supersaturated system may result. A tenfold increase in the permeation was observed when an indomethacin gel was prepared by heating a mixture of the drug with hydrogenated soybean phospholipid and liquid paraffin to 95 °C, cooling to room temperature, placing it in an air incubator at 40 °C for 3 days, and then storing at room temperature, compared to that prepared at room temperature in the same vehicle components. Supersaturated solutions of flurbiprofen and ketoprofen also showed an increase in the permeation rates from the heated and cooled formulations, but no difference in the rates for ibuprofen formulations was observed (Henmi et al. 1994).

3 Role of Anti-nucleant Polymers

Supersaturated systems, by definitions, are unstable in their native state. In order to stabilize a supersaturated system and to achieve effective transdermal enhancement, it is absolutely crucial to keep the process of crystal formation to its minimum. For this purpose, anti-nucleant polymers are used in the supersaturated system. Some of the common polymers used as effective anti-nucleants are hydroxypropyl methyl cellulose (HPMC), polyvinyl pyrrolidone (PVP), polyvinyl alcohol (PVA), polyethylene glycol (PEG), and Eudragits (acrylic polymers). These polymers have been shown to inhibit the crystal growth of compounds like paracetamol, nifedipine, spironolactone, sulfamethiazole, hydroflumethiazide, n-paraffin, estradiol, and griseofulvin from supersaturated solutions in a particular solvent and delivery systems (Simonelli et al. 1970; Corrigan and Timoney 1975; Sekikawa et al. 1978; Holden 1979; Hasegawa et al. 1985; Femi-Oyewo and Spring 1994; Kotiyan and Vavia 2001; Valenta and Auner 2004). Use of copolymers of methacrylic acid (Eudragit® E, EuE, and Eudragit® RL, EuRL) as ibuprofen crystal inhibitors in the matrices was found to prevent the drug crystallization for more than 12 months (Cilurzo et al. 2005). In another study, supersaturated solutions of ibuprofen were prepared using 25 % PG, 5 % vitamin ETPGS (d-alpha tocopheryl polyethylene glycol 1,000 succinate), and 5 % ethylene oxide/propylene oxide block copolymer (pluronic F127) solvents and their combinations to achieve different DS (0.5, 1, 2.5, 5.0, 10.0, 25.0, and 50), and it was found in that study that vitamin ETPGS improved the flux better compared to PG and pluronic F127. The optimization of the vitamin ETPGS/ibuprofen formulation with polymeric stabilizers like HPMC and PVP K-30 resulted in inhibiting crystal growth (HPMC showed better crystal growth inhibition compared to that of PVP K-30). However, the use of PVP K-30 increased the permeation rate of drug through the skin relative to the HPMC (Ghosh and Michniak-Kohn 2012).

How to select an appropriate polymer for a particular drug-solvent system is of a concern. The concept of nucleation and crystallization is not completely understood but efforts have been made to study the process using techniques like differential scanning calorimetry (DSC). In a study involving isothermal crystallization of lidocaine (LC) in supersaturated polyacrylate pressure-sensitive adhesive (LC/Duro-Tak® 87-2287 (DT2287)) system, some of the common reasons for crystallization are given (Cui and Frank 2005). Multiple theories have been proposed for the inhibition of crystal formation by the use of polymer additives and therefore stabilization of supersaturated solution of a compound in a solvent. In a study involving the preparation of supersaturated sulfamethiazole solution in presence of PVP, it was suggested that PVP formed a netlike structure over a growing crystal face with fingerlike crystal growths occurring between the pores of the PVP network, and due to the curvature of these protrusions, a higher degree of supersaturation was required to continue crystal growth (Simonelli et al. 1970). In another study involving the investigation of crystallization and morphology of hydrocortisone acetate crystal formation, it was proposed and observed via IR spectroscopy that crystal growth was inhibited by absorption of polymer, PVP into the growing crystal surface through hydrogen bonding (Raghavan et al. 2001). Similar observation of presence of hydrogen bond was also observed in an ibuprofen – HPMC system (Iervolino et al. 2001). In yet another study, the preparation and stabilization of colloidal dispersions of triclosan, an antimicrobial agent used up to 2 % in cosmetic and detergent formulations for disinfection of the skin, were performed from supersaturated solutions of triclosan either in the absence or presence of the polymer, HPMC, and it was observed that the particle sizes of triclosan were stabilized in the range of 90–250 nm after addition of HPMC in a water-propylene glycol co-solvent system, whereas large-shaped crystal morphology was observed in the absence of polymer (Raghavan et al. 2003). Stabilization of fentanyl in the supersaturated PG/water formulation with 3DS was achieved by addition of 1 % hydroxypropyl cellulose (HPC) leading to improved permeation flux across the skin. Fentanyl crystal growth was retarded minimally using HPMC or PVP K90 at 1 % (w/v) for the 5 DS formulation compared with HPC (Santos et al. 2011).

However, presence of a polymer in the drug solution does not necessarily affect drug permeation in all cases. In a study of the effect of hydroxypropyl-β-cyclodextrin (HPβCD) on in vitro transdermal permeation of corticosterone through hairless mouse skin, contradictory evidences have been observed between the groups. Shaker et al. have been observed that use of HPβCD, PVP, or the HPβCD/PVP combination does not affect the permeation of corticosterone across synthetic cellulose membrane or the hairless mouse skin, whereas Loftson et al. have reported an increase in permeation of corticosterone in presence of HPβCD (Loftsson and Sigurðardóttir 1994; Shaker et al. 2003; Torres-Labandeira et al. 1991). Similarly, use of 2-hydroxypropyl-ß-cyclodextrin has also been found not to alter crystal growth in ibuprofen solution (Iervolino et al. 2001). A very similar observation was observed in a study of testosterone, added in excess to 4:1:1 (v/v) ethanol/PG/water along with multiple anti-nucleant polymers (PVP Kollidon®30, vinylpyrrolidone-vinyl acetate copolymer Kollidon®VA64, a randomly methylated cyclodextrin RAMEB, methacrylic acid and ethyl acrylate copolymer Eudragit®L100-55, nonionic poly (ethylene oxide) polymer Polyox®WSR N-10, hydroxypropyl methyl cellulose Methocel®E5, hydroxypropyl methyl cellulose phthalate HPMCP®50, and hydroxypropyl cellulose Klucel®EF) to prevent crystallization. It was found that only Kollidon®VA64 and a cyclodextrin derivative, RAMEB, at 5 % conc., showed promise in the preparation of supersaturated solution with a degree of supersaturation between 1.4 and 2.6, but the supersaturated state existed only for 6 h (Leichtnam et al. 2006).

4 Determination of Supersaturation and Crystal Growth

The easiest way to determine crystal formation is via spreading the solution into a thin film on a slide and visually observing the crystals under the microscope. Other methods to determine the solubility of the drug and crystal formation are via methods like isothermal heat conduction, microcalorimetry, X-ray diffraction, and DSC (Theeuwes et al. 1974; Latsch et al. 2004a, b). Along from experimental techniques, computational techniques like kinetic Monte Carlo method has been used for predicting of Oswald ripening and evolution in crystal formation/growth of a supersaturated solution (Zeng et al. 2004, 2006).

5 Synergistic Use of Supersaturation Along with Other Enhancement Technologies/Methods

Synergistic effect of supersaturation along with the use of the chemical enhancer, oleic acid, was observed on the flurbiprofen permeation across human skin. The stratum corneum of human skin was pretreated for 1 h with a 2.8 % ethanolic (EtOH) solution of oleic acid (OA), and a supersaturated solution of flurbiprofen with six degrees of saturation was applied on the skin. Compared to ER=1.0 with saturated solution of flurbiprofen in EtOH, the 2.8 % OA in EtOH showed an ER of 2.1, whereas the sixfold supersaturated solution showed an ER of 4.5, whereas in presence of both supersaturation and oleic acid, the enhancement ratio (ER) of 9.9 was observed (Pellett 2012).

Transdermal films of caffeine and sumatriptan have been shown to result in generation of supersaturated state of drug on the skin surface leading to increased permeation (Nicoli 2005; Femenía-Font et al. 2006).

Non-entrapped hydrocortisone (HC) liposomal supersaturated system has been shown to increase the transdermal flux due to increase in thermodynamic activity of the drug caused by accumulation of HC in the skin creating a supersaturated state (Barichello et al. 2006). Another similar approach is applied in delivery of paclitaxel using paclitaxel-loaded methoxy poly(ethylene glycol)-block-poly(d, l lactic acid (PEDELLA) diblock copolymer nanoparticles (PNPs), synthesized from polycondensation of d,l-lactic acid and mPEG. In this study, PNPs showed better permeation compared to that of the supersaturated solution of paclitaxel in water. However, such approach can be combined along with the supersaturation to obtain an effective transdermal penetration (Li et al. 2008).

Similar observation was observed with estradiol permeation across human skin and silastic membrane when the effect of propylene glycol-induced enhancement was observed along with the effect of supersaturated solution. Both the methods increased the percutaneous permeation of estradiol separately and showed synergism in enhancement when used together. Propylene glycol was believed to increase the partitioning of estradiol into the membrane whereas supersaturation was believed to increase the concentration of compound in the vehicle beyond that of the normally limited saturated solubility leading to enhanced drug permeation (Megrab et al. 1995). Similarly, maintenance of supersaturated state of estradiol in a drug-adhesive patch system is important to be controlled and monitored for proper drug release from patch system. This can be achieved by use of an appropriate polymer, casting solvent, drug loading, and thickness (μm) of the adhesive layer (Imani et al. 2010; Jain and Banga 2010: Pattnaik et al. 2011).

It has been observed that it is difficult to maintain the stability of the testosterone-supersaturated solution in a mechanical aerosol delivery system. In a study involving preparation/delivery of stable testosterone solution in 3:1 ethanol/PG mixture containing a high percentage of propellant (~50 %), crystallization was observed on the skin surface from the aerosol and spray system, whereas the solution did not exhibit this problem after application (Leichtnam et al. 2006). In another metered dose aerosol (MDA) system, consisting of hydrofluoroalkane 134a, ethanol, poly(vinyl pyrrolidone) K90, and beclomethasone dipropionate (BDP), with different concentration (0, 5 or 10 % w/w) of polyethylene glycol (PEG) 400, different degree of saturation of 6 for 0 and 5 % PG and DS = 10 for 10 % PG formulation was achieved. It was found that the rate of drug release was controlled by the DS and the increased mobility of the PEG films and slower supersaturation kinetics allowed a more sustained drug release (Reid et al. 2008). It was observed that the formulations with higher DS show rapid recrystallization on the skin. However, in a highly volatile spray system, BDP supersaturation for extended periods of time has been considered less important than generating instantaneous, high levels of supersaturation to enhance drug release (Reid et al. 2009).

6 Use of Supersaturation in Other Dosage Forms

Some of the other polymers used for prevention of crystallization in non-transdermal systems are 2-hydroxypropyl-ß-cyclodextrin (to prevent crystallization of amorphous nifedipine in spray-dried powders) (Uekama et al. 1992), and ß-cyclodextrins (for the inhibition of crystal growth of isosorbide 5-mononitrate in tablets or powders) (Uekama et al. 1985). Hydroxypropyl cyclodextrins have also been used to supersaturate pancratistatin, an anticancer drug, for parenteral use (Torres-Labandeira et al. 1991). In a study involving permeation of supersaturated diazepam (DZP) across polydimethylsiloxane (PDMS) membranes, chosen as an in vitro model for nasal mucosa, it was observed that there was a proportional increase in DZP flux across PDMS membrane up to 3× supersaturation, and beyond this point only minor increment in flux was observed. Such supersaturated solutions of DZP in [glycofurol (GF)/water] co-solvent systems can result in rapid response to epileptic seizure emergencies (Hou and Siegel 2006). The role of excipient selection in the solid dosage form formulations is also very important. Some of the important properties taken into consideration for excipient selection are molecular weight, topological polar surface area (TPSA), log P, pKa, and molecular volume for screening the excipient materials. Some of the known excipients used in the solid dosage systems to achieve supersaturation – PEG400 in solution, HPMC E5 in coated bead, hydrophilic cyclodextrin, HPβBD in tablets, polyoxyl 40 hydrogenated castor oil CremophorRH40, and tocopheryl polyethylene glycol 1,000 succinate TPGS in capsule – have been tested and found efficient in increasing the oral bioavailability of the formulation (Vandecruys et al. 2007).

7 Commercialization of Supersaturated Transdermal Drug Delivery Systems

Increasing thermodynamic activity beyond saturation is an attractive methodology to enhance penetration of actives across skin since other technologies that utilize chemical and physical enhancement technique might not be feasible due to bulkiness of devices, higher cost, lack of patient compliance, chances of irritation, etc. Review of the literature suggests that supersaturation as an enhancement technique has been evaluated intensely in the last 20+ years. Most of the work on supersaturated systems to date has come from academic groups and minimal efforts have gone into developing supersaturated systems into a commercially viable product. The main bottleneck for a product that contains the drug in a supersaturated state is the stability of the product during (1) manufacture, (2) storage, (3) supply chain management, and (4) end use by the patients.

7.1 Manufacture

The process for manufacturing the product might involve heating and cooling at different temperatures, which is conducive to nucleation. Extreme care must be taken to control the process in order to avoid any nucleation. Further, mixing usually involves high shear mixing that can cause crystallization to occur. Other processes that can induce nucleation are packaging and analytical testing.

7.2 Storage

The stability of a product under the storage conditions specified in the label claim of a product determines its shelf life. It is known that supersaturated systems can become unstable upon storage for long periods of time. In addition, there are some formulations that require storage at refrigerated temperatures, which can cause thermodynamic instability. Based on the stability studies, a shorter shelf life might be required.

7.3 Supply Chain Management

Following manufacture, the products have to be transported from the manufacturer to the sales and distribution warehouses and to retail stores upon sales. Extreme care would be required to monitor and conduct thorough stability studies under different conditions of transport and storage in order to make sure the product is thermodynamically stable under these conditions.

7.4 Patient Compliance

Upon receiving a prescription, the patient can potentially carry the product during travel or can store under different conditions of temperature and humidity. Extensive stability studies would be required to provide sufficient guidance and warnings to patients on how to store and use the product. In addition, some drug molecules, when used excessively, can cause skin irritation and hence might not be practical for the use of supersaturated concentrations.

Most of these challenges can be overcome through proper design of product including packaging. For example, the drug solution can be stored in the stable form in a container separated from the co-solvent and can be mixed at the time of use. Such a methodology has been used in products such as benzoyl peroxide – clindamycin gel (Benzaclin) and benzoyl peroxide-erythromycin gel (Benzamycin), where the benzyl peroxide gel is stored in a separate jar and clindamycin or erythromycin is compounded with the gel by the pharmacist. Extensive research needs to be undertaken by the industry in order to overcome these challenges in order to successfully bring this technology to the product. There is a huge potential for this technology to be exploited with proper choice of drug, optimization of the development and manufacturing processes, and innovative design.

8 Conclusions

Presently, it is well known that supersaturated solutions of different chemical compounds and drugs molecules have been shown to improve transdermal flux (Davis and Hadgraft 1991; Moser et al. 2001). The real challenge in maintaining a supersaturated state of a chemical compound in solution is to tailoring the solvent system and use of anti-nucleant polymers to achieve the maximum thermodynamic activity while still maintaining the compound’s stability in solution. Use of anti-nucleant polymers has been tested and found effective; however, the concepts behind selection of an appropriate polymer for a particular supersaturated system in order to achieve maximum drug delivery are still not well understood. In spite of the huge challenges in developing a stable supersaturated product that can be commercialized, extensive research and development efforts as well as innovative designs can exploit the potential advantages of the technology.

References

Adrian D et al (2002) The application of supersaturated systems to percutaneous drug delivery. In: Transdermal drug delivery systems. Edited by Richard H.Guy and Jonathan Hadgraft, CRC Press, Informa Healthcare, New York

Barichello JM et al (2006) Inducing effect of liposomalization on the transdermal delivery of hydrocortisone: creation of a drug supersaturated state. J Control Release 115(1):94–102

Cilurzo F et al (2005) Polymethacrylates as crystallization inhibitors in monolayer transdermal patches containing ibuprofen. Eur J Pharm Biopharm 60(1):61–66

Coldman MF et al (1969) Enhancement of percutaneous absorption by the use of volatile: nonvolatile systems as vehicles. J Pharm Sci 58(9):1098–1102

Corrigan OI, Timoney RF (1974) Anomalous behaviour of some hydroflumethiazide crystal samples. J Pharm Pharmacol 26(10):838–840

Corrigan OI, Timoney RF (1975) The influence of polyvinylpyrrolidone on the dissolution properties of hydroflumethiazide. J Pharm Pharmacol 27(10):759–764

Cui Y, Frank SG (2005) Isothermal crystallization kinetics of lidocaine in supersaturated lidocaine/polyacrylate pressure sensitive adhesive systems. J Pharm Sci 94(9):2039–2048

Davis AF, H.J. (1993) Supersaturated solutions as topical drug delivery systems. Pharm Skin Penetration Enhancement 59:243–267, J. H. KA Walters. New York, Marcel Dekker

Davis AF, Hadgraft J (1991) Effect of supersaturation on membrane transport: 1. Hydrocortisone acetate. Int J Pharm 76(1–2):1–8

de Smidt JH et al (1986) Dissolution of theophylline monohydrate and anhydrous theophylline in buffer solutions. J Pharm Sci 75(5):497–501

Fang J-Y et al (1999) Transdermal delivery of sodium nonivamide acetate from volatile vehicles: effects of polymers. Int J Pharm 176(2):157–167

Femenía-Font A et al (2006) Bioadhesive monolayer film for the in vitro transdermal delivery of sumatriptan. J Pharm Sci 95(7):1561–1569

Femi-Oyewo MN, Spring MS (1994) Studies on paracetamol crystals produced by growth in aqueous solutions. Int J Pharm 112(1):17–28

Frank FC (1949) The influence of dislocations on crystal growth. Discuss Faraday Soc 5:48–54

Ghosh I, Michniak-Kohn B (2012) A comparative study of Vitamin E TPGS/HPMC supersaturated system and other solubilizer/polymer combinations to enhance the permeability of a poorly soluble drug through the skin. Drug Dev Ind Pharm 38(11):1408–1416

Guy RH (2007) Transdermal science and technology – an update. Dryg Deliv Syst 22(4):442–449

Hasegawa A et al (1985) Physical properties of solid dispersions of poorly water-soluble drugs with enteric coating agents. Chem Pharm Bull (Tokyo) 33(8):3429–3435

Henmi T et al (1994) Application of an oily gel formed by hydrogenated soybean phospholipids as a percutaneous absorption-type ointment base. Chem Pharm Bull (Tokyo) 42(3):651–655

Higuchi T (1960) Physical chemical analysis of percutaneous absorption process from creams and ointments. J Soc Cosmet Chem 11:85–87

Holden GAT, J. (1979) Inhibition of crystallization by polymers. Polym Prepr Am Chem Soc Div Poly Chem 20:766–769

Hou H, Siegel RA (2006) Enhanced permeation of diazepam through artificial membranes from supersaturated solutions. J Pharm Sci 95(4):896–905

Iervolino M et al (2001) Penetration enhancement of ibuprofen from supersaturated solutions through human skin. Int J Pharm 212(1):131–141

Imani M et al (2010) Effect of adhesive layer thickness and drug loading on estradiol crystallization in a transdermal drug delivery system. AAPS PharmSciTech 11(3):1268–1275

Inoue K et al (2005) Enhancement of skin permeation of ketotifen by supersaturation generated by amorphous form of the drug. J Control Release 108(2–3):306–318

Jain P, Banga AK (2010) Inhibition of crystallization in drug-in-adhesive-type transdermal patches. Int J Pharm 394(1–2):68–74

Khoshkoo SA, J (1991) Crystallization of polymorphs: effects of supersaturation and solvent. J Pharm Pharmacol 43:36

Kondo S, Sugimoto I (1987) Enhancement of transdermal delivery by superfluous thermodynamic potential. I. Thermodynamic analysis of nifedipine transport across the lipoidal barrier. J Pharmacobiodyn 10(10):587–594

Kondo S et al (1987) Enhancement of transdermal delivery by superfluous thermodynamic potential. II. In vitro-in vivo correlation of percutaneous nifedipine transport. J Pharmacobiodyn 10(11):662–668

Kotiyan PN, Vavia PR (2001) Eudragits: role as crystallization inhibitors in drug-in-adhesive transdermal systems of estradiol. Eur J Pharm Biopharm 52(2):173–180

Latsch S et al (2004a) Use of isothermal heat conduction microcalorimetry, X-ray diffraction, and optical microscopy for characterisation of crystals grown in steroid combination-containing transdermal drug delivery systems. Eur J Pharm Biopharm 57(2):397–410

Latsch S et al (2004b) Determination of the physical state of norethindrone acetate containing transdermal drug delivery systems by isothermal microcalorimetry, X-ray diffraction, and optical microscopy. Eur J Pharm Biopharm 57(2):383–395

Leichtnam M-L et al (2006a) Enhancement of transdermal testosterone delivery by supersaturation. J Pharm Sci 95(11):2373–2379

Leichtnam M-L et al (2006b) Formulation and evaluation of a testosterone transdermal spray. J Pharm Sci 95(8):1693–1702

Li J et al (2008) Methoxy poly(ethylene glycol)-block-poly(D, L-lactic acid) copolymer nanoparticles as carriers for transdermal drug delivery. Polym Int 57(2):268–274

Loftsson T, Sigurðardóttir AM (1994) The effect of polyvinylpyrrolidone and hydroxypropyl methylcellulose on HPβCD complexation of hydrocortisone and its permeability through hairless mouse skin. Eur J Pharm Sci 2(4):297–301

Megrab NA et al (1995) Oestradiol permeation through human skin and silastic membrane: effects of propylene glycol and supersaturation. J Control Release 36(3):277–294

Mehta SC et al (1970) Rate of crystal growth of sulfathiazole and methylprednisolone. J Pharm Sci 59(5):638–644

Morrow DIJ, McCarron PA, Woolfson AD, Donnelly RF (2007) Innovative strategies for enhancing topical and transdermal drug delivery. Open Drug Deliv J 1:36–59

Moser K et al (2001) Enhanced skin permeation of a lipophilic drug using supersaturated formulations. J Control Release 73(2–3):245–253

Nicoli S, Colombo P, Santi P (2005) Release and permeation kinetics of caffeine from bioadhesive transdermal films. AAPS J 7(1):E218–E223

Pattnaik S et al (2011) Effect of casting solvent on crystallinity of ondansetron in transdermal films. Int J Pharm 406(1–2):106–110

Pellett MAW, AC, Brain KR, Hadgraft J (2012) Synergism between supersaturation and chemical enhancement in the permeation of Flurbiprofen through human skin. Perspectives in Percutaneous Penetration Thirteenth International Conference. La Grande Motte, France: 1–4

Pellett MA et al (1997a) The penetration of supersaturated solutions of piroxicam across silicone membranes and human skin in vitro. J Control Release 46(3):205–214

Pellett MA et al (1997b) Supersaturated solutions evaluated with an in vitro stratum corneum tape stripping technique. Int J Pharm 151(1):91–98

Poulsen BJ et al (1968) Effect of topical vehicle composition on the in vitro release of fluocinolone acetonide and its acetate ester. J Pharm Sci 57(6):928–933

Raghavan SL et al (2001) Crystallization of hydrocortisone acetate: influence of polymers. Int J Pharm 212(2):213–221

Raghavan SL et al (2003) Formation and stabilisation of triclosan colloidal suspensions using supersaturated systems. Int J Pharm 261(1–2):153–158

Rai V, Ghosh I, Bose S, Silva SMC, Chandra P, Michniak-Kohn B (2010) A transdermal review on permeation of drug formulations, modifier compounds and delivery methods. J Drug Deliv Sci Tech 20(2):75–87

Reid M et al (2008) Manipulation of corticosteroid release from a transiently supersaturated topical metered dose aerosol using a residual miscible Co-solvent. Pharm Res 25(11):2573–2580

Reid ML et al (2009) Transient drug supersaturation kinetics of beclomethasone dipropionate in rapidly drying films. Int J Pharm 371(1–2):114–119

Rodríguez-Hornedo N, Wu H-J (1991) Crystal growth kinetics of theophylline monohydrate. Pharm Res 8(5):643–648

Santos P et al (2011a) Enhanced permeation of fentanyl from supersaturated solutions in a model membrane. Int J Pharm 407(1–2):72–77

Santos P et al (2011b) Formulation issues associated with transdermal fentanyl delivery. Int J Pharm 416(1): 155–159

Schwarb FP et al (1999) Effect of concentration and degree of saturation of topical fluocinonide formulations on in vitro membrane transport and in vivo availability on human skin. Pharm Res 16(6):909–915

Sekikawa H et al (1978) Inhibitory effect of polyvinylpyrrolidone on the crystallization of drugs. Chem Pharm Bull (Tokyo) 26(1):118–126

Shaker DS et al (2003) Mechanistic studies of the effect of hydroxypropyl-β-cyclodextrin on in vitro transdermal permeation of corticosterone through hairless mouse skin. Int J Pharm 253(1–2):1–11

Shefter E, Higuchi T (1963) Dissolution behavior of crystalline solvated and nonsolvated forms of some pharmaceuticals. J Pharm Sci 52(8):781–791

Simonelli AP et al (1970) Inhibition of sulfathiazole crystal growth by polyvinylpyrrolidone. J Pharm Sci 59(5):633–638

Tanaka S et al (1985) Studies on drug release from ointments. V. Release of hydrocortisone butyrate propionate from topical dosage forms to silicone rubber. Int J Pharm 27(1):29–38

Theeuwes F et al (1974) Quantitative analytical method for determination of drugs dispersed in polymers using differential scanning calorimetry. J Pharm Sci 63(3):427–429

Theeuwes F et al (1976) Transference: a comprehensive parameter governing permeation of solutes through membranes. J Membr Sci 1:3–16

Torres-Labandeira JJ et al (1991) Oversaturated solutions of drug in hydroxypropylcyclodextrins: parenteral preparation of pancratistatin. J Pharm Sci 80(4):384–386

Uekama K et al (1985) Stabilization of isosorbide 5-mononitrate in solid state by β-cyclodextrin complexation. Int J Pharm 25(3):339–346

Uekama K et al (1992) Inhibitory effect of 2-hydroxypropyl-beta-cyclodextrin on crystal-growth of nifedipine during storage: superior dissolution and oral bioavailability compared with polyvinylpyrrolidone K-30. J Pharm Pharmacol 44(2):73–78

Valenta C, Auner BG (2004) The use of polymers for dermal and transdermal delivery. Eur J Pharm Biopharm 58(2):279–289

Vandecruys R et al (2007) Use of a screening method to determine excipients which optimize the extent and stability of supersaturated drug solutions and application of this system to solid formulation design. Int J Pharm 342(1–2):168–175

Zeng J et al (2004) Numerical simulations of crystal growth in a transdermal drug delivery system. J Cryst Growth 262(1–4):602–611

Zeng J et al (2006) Numerical study of a drug release profile in the transdermal drug delivery system. Langmuir 22(3):1333–1340

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Rai, V., Raghavan, L. (2015). Transdermal Drug Delivery Systems Using Supersaturation. In: Dragicevic, N., Maibach, H. (eds) Percutaneous Penetration Enhancers Chemical Methods in Penetration Enhancement. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-45013-0_11

Download citation

DOI: https://doi.org/10.1007/978-3-662-45013-0_11

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-45012-3

Online ISBN: 978-3-662-45013-0

eBook Packages: MedicineMedicine (R0)