Abstract

In this chapter, recent developments of so called non-metallocene early transition metal (group 3–5) complexes as the catalyst precursors for olefin polymerization have been described. These catalysts display unique characterisitics especially for ethylene (co)polymerization, and high isospecificity ([mmmm] > 99.6 %) in propylene polymerization has been achieved in some catalyses. The ligand modification plays an essential key role not only for the catalytic activity, but also for control of tacticity and/or living nature in these catalyses.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Molecular Weight Distribution

- Ultra High Molecular Weight Polyethylene

- Ethylene Polymerization

- High Molecular Weight Polymer

- Titanium Complex

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

3.1 Introduction

After a discovery of so called metallocene catalysts [Cp2ZrCl2—methylaluminoxane (MAO) catalyst] by Kaminsky et al. [1, 2], many researchers focused on design and synthesis of bridged (ansa) metallocene (see Reviews for metallocenes [3–6]; Frontiers in Metal-Catalysed Polymerization (special issue) [7–10]) and half-titanocene complex (exemplified as constrained geometry catalyst, CGC) (see Reviews for linked half-titanocenes [11–13]) for efficient ethylene/α-olefin copolymerization and isospecific polymerization of α-olefins. Nonbridged (unbridged) half-titanocene catalysts (see Reviews for nonbridged half-titanocenes [14–17]), described in Chap. 2, may also be considered as the related stream, although the basic concept in the catalyst design is somewhat different. In olefin polymerization using metallocene catalysts, it has been postulated that the cationic alkyl species, Cp2Zr+R, play an essential key role as the active species [3–6]. Therefore, researchers only focused on generating 14e species from the catalyst precursor. Later it has been well known exemplified as [Me2Si(C5Me4)(NtBu)]TiCl2 (CGC) that 12e species also plays a role, suggesting many promising possibilities for designing efficient catalysts with various ligand. After a report concerning 1-hexene polymerization using a titanium complex containing bis(amide) ligand as the catalyst precursor by Dr. McConville [18, 19], described below, many researchers from both academic and industry invloved in the project for exploring a possibility with various early transition metals. Nowadays, tremendous number of reports have been known for this project, and some of them are very important from both academic and industrial point of view (see Reviews for post-metallocenes [20–24]; Metal-catalysed Polymerisation (special issue) [25]; Selected reviews for living polymerization [26–28]). In this chapter, efforts for designing molecular catalysts with early transition metals have been briefly reviewed.

3.2 Design, Synthesis of Molecular Catalyst with Early Transition Metals

3.2.1 Titanium, Zirconium, and Hafnium Complexes

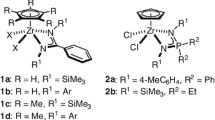

As described above, titanium complex (1) containing bis(amide) ligand [18, 19] and zirconium complex with tridentate diamido ligand, [NON]ZrMe2 (2) [29], for 1-hexene living polymerization introduced promising possibility for designing efficient catalyst, which does not contain cyclopentadienyl ligand (called non-metallocene catalyst), for olefin polymerization (Scheme 3.1). The catalytic activities by 1 in 1-hexene polymerization were suppressed upon addition of toluene, suggesting a possibility of coordination of toluene to the cationic catalytically-active species. Reaction of 1 with B(C6F5)3 in n-pentane gave insoluble yellow-orange solids that was considered as a true catalyst for the living polymerization. The pentane suspensions slowly evolved CH4 over several hours to give the pentane-soluble [ArN(CH2)3NAr]Ti[CH2B(C6F5)2](C6F5), which was structurally characterized and was inactive for the polymerization of α-olefins [30]. The resultant poly(1-hexene)s prepared by 1, 2 possessed atactic stereo-regularity.

Although the resultant polymer in the above reports afforded atactic poly(1-hexene), Eisen et al. presented synthesis of isotactic polypropylene by zirconium complexes containing tris(amidinate) ligand with chiral N-substituents, [N(R*)-C–N]3ZrCl (3) [31]. In the propylene polymerization by 3—MAO catalyst in toluene, isotacticities for the resultant polymers were dependent upon the propylene pressure; the attempt under the atmospheric pressure of propylene was not successful. They speculated that one ancillary ligand was not acting as a spectator ligand, and MAO extracted one benzamidinate ligand from 3. This displacement reaction would afford the proposed catalytically active species 3′. Isospecific propylene polymerization took place if zirconium complexes containing bis(amidinate) complexes (4), bearing achiral substituents R, at higher propylene pressures [32]. As shown in Table 3.1, the stereo-regularity in the resultant polypropylene was modulated by the pressure (from atactic to isotactic through elastomers). The different effects in the polymerization process such as the nature of solvent or cocatalyst, temperature, pressure, Al/M molar ratio (M = Ti, Zr), and the relationship between the symmetry of the complex and the polymer microstructure had been investigated [34]. The stereoregular errors were formed by the intramolecular epimerization of the growing chain at the last inserted unit. It was thus proposed that epimerization becomes faster than the stereoregular insertion of propylene at lower propylene pressure, leading to the formation of atactic polymer [34] (Scheme 3.2).

Isospecific living polymerization had been achieved by using C 2 symmetrical zirconium complex containing chelate bis(phenolate) ligand (4b, Scheme 3.3) [35]. Upon activation of 4b with B(C6F5)3, 1-hexene polymerization took place (rather efficiently), affording poly(1-hexene) with narrow molecular weight distribution (18 kg-polymer/mol-Zr·h, M w = 12000, M w/M n = 1.15, >95 % isotacticity). It was thus assumed that the high isotacticity would be due to a steric bulk of the tBu group in 4b, because the polymerization by 4a under the same conditions afforded atactic poly(1-hexene) with higher activity (35 kg-polymer/mol-Zr·h, M w = 23000, M w/M n = 1.57) [35]. The chloride analogue (4c) showed remarkable activity (5400 kg-polymer/mol-Zr·h), but the polymerization did not take place in a living manner, suggesting that the electronic factor on the phenyl group plays a role for exhibiting the high activity. In contrast, the titanium analogue of 4c showed relatively high activity (200 kg-polymer/mol-Ti·h), affording ultra high molecular weight poly(1-hexene) with low PDI value as well as with relatively high isotacticity (M w = 5.50–19.0 × 105, M w/M n = >1.2, mm = 60 %) [36].

Titanium and zirconium complexes containing amine bis(phenolate) ligand (5) showed remarkable catalytic activity for α-olefin polymerization (Scheme 3.3) [36], and the reaction by the titanium analogue (R = tBu, X = OMe) proceeded in a living manner, affording block copolymer consisting of poly(1-hexene) and poly(1-octene). An extra arm donor ligand plays an essential role to exhibit high catalytic activity, because the activity with the zirconium analogue (6) was extremely low [37]. This may be due to the fact that 6 folds pseudo-trigonal bipyramidal geometry whereas the complexes 5 fold distorted octahedral geometry around the metal center, which lead to the different bond angles between two benzyl (Bn) group (117.4º in 6 and 93.7º in 5) [37]. More recently, Kol demonstrated that octahedral C 1-symmetric titanium catalysts containing salalen ligand (7) are highly effective for isospecific propylene polymerization to afford polymers with extraordinary high isotacticity with high melting transition temperature ([mmmm] > 99.6 %, T m = 169.9 ºC) [43].

Zirconium complexes bearing two salicylaldiminato-type ligands (8 in Scheme 3.4) exhibited remarkable catalytic activities for ethylene polymerization [44]. As shown in Table 3.2, the activity and the molecular weight of the polymer were dependent upon the substituent on the ligand. The activity was also affected by the centered metal [45], and increasing the steric bulk especially on both the phenoxy group in ortho position and the imino group strongly affected the catalytic activity. Molecular weights in the resultant PE were varied by the ligand modification [44]. The zirconium complex containing N-(3-cumyl-5-methyl-salicylidene)cyclohexylaminato ligand showed the highest activity for ethylene polymerization (4315000 kg-PE/mol-Zr·h) at 25 °C.

Importantly, ethylene polymerization by the fluorinated phenoxy-imine analogue (8′) proceeded in a living manner [46], and the living polymerization of propylene afforded polypropylene with highly syndiotactic steroregularity [47, 48]. These living polymerizations took place even at room temperature, and synthesis of various block copolymers has been achieved in this catalysis [46–48]. The catalytic activity in the ethylene polymerization was high [46], whereas the activity for propylene polymerization was moderate but the polymerization proceeds in a highly syndiospecific manner although these Ti complexes possess C 2 symmetry [47, 48]. In ethylene polymerizations using titanium complexes with various fluorine containing phenoxy-imine chelate ligands, the complexes having a fluorine atom adjacent to the imine nitrogen showed the living nature at 50 °C, whereas the complexes possessing no fluorine adjacent to the imine nitrogen afforded polyethylenes having M w/M n values of ca. 2 with β-hydrogen transfer as the main termination pathway. In addition to the DFT calculation results, they assumed that the presence of a fluorine atom adjacent to the imine nitrogen is the requirement for the high-temperature living polymerization, because the fluorine of the active species for ethylene polymerization interacts with a β-hydrogen in the polymer chain, resulting in the prevention of β-hydrogen transfer [46].

Based on 13C NMR studies, they proposed that syndiotacticity in the propylene polymerization was governed by a chain-end control mechanism and that the polymerization is initiated exclusively via 1,2-insertion followed by 2,1-insertion as the principal mode of polymerization, and that the polypropylenes produced with the Ti complexes possess regio-block structures. Substitutions on the phenoxy-imine ligands affected both the catalytic activity and the stereo specificity, and the steric bulk of the substituent in ortho position of the phenoxy oxygen plays a decisive role in achieving high syndioselectivity for the chain-end controlled polymerization (Table 3.3) [47, 48]. The Ti complex having SiMe3 group in ortho position of the phenoxy ligand afforded highly syndiotactic, nearly monodisperse polypropylenes (94–90 % rr) with extremely high melting temperatures (T m = 156–149 °C). The polymerization behavior of the Ti complexes was explained by the proposed chain-end controlled, site-inversion mechanism for the formation of syndiotactic polypropylene by 8′. Copolymerization of ethylene with α–olefin by 8′ also proceeded in a living manner in the presence of MAO, and various block copolymers were also thus prepared [49].

Synthesis of the related complexes such as titanium complexes containing two indole-imine ligands (9) [50], pyrrolide-imine ligand (10) were known [51], and living copolymerization of ethylene with norbornene took place if 10 was used as the catalyst precursor [52, 53].

Chain Shuttling Polymerization

Precise synthesis of microblock ethylene/1-octene copolymers which possesses two compositions (copolymers with low/high 1-octene contents) in a polymer chain was also achieved by adopting the polymerization process called “Chain Shuttling Polymerization” in the presence of two catalysts (with efficient/inefficient comonomer incorporations, different monomer reactivity, Scheme 3.5) and chain transfer reagent (Et2Zn etc.) [54]. The resultant polymers (prepared by adding Et2Zn during polymerization results in a block copolymer microstructure with intimately mixed interchain hard and soft segments) possess higher transparency than the polymers with two physical blend of high- and low-density polymers, and possessed higher melting temperature and low glass transition temperature (due to a block segment with low 1-octene content). These are recognized as a new technology for evolution of new polymers on the basis of precise olefin polymerization technique [54].

Precise synthesis of microblock copolymers by “chain shuttling polymerization” [54]

The isospecific α-olefin polymerization catalyst (11) was developed by DOW on the basis of 1600 catalyst screenings (required only for 3 weeks) by using “high throughput screening” (Symyx Technologies) technique: this demonstrated a new methodology for the catalyst development [55, 56]. Another key issue on this process is adopting rapid chain transfer reactions enabled by presence of Et2Zn (rapid chain transfer by Et2Zn [57–60]): rapid polymer exchange between 8′′ and 11 through Zn afforded the polymers with multiblock (microblock) microstructure.

Ligand Modification from Ethylene Polymerization Catalyst to Trimerization Catalyst

It has been known in that ethylene polymerization catalyst was tuned to the ethylene trimerization by the ligand modification. [(η 5-C5H5)CMe2Ph]TiCl3—MAO catalyst exhibited moderate catalytic activity with high selectivity for ethylene trimerization, whereas ethylene polymerization took place by [(η 5-C5H5)CMe3]TiCl3 [61]. Titanium trichloride complexes containing monoanionic tridentate ligands (12,13) exhibited moderate to high catalytic activities for ethylene polymerization (Scheme 3.6) [62, 64]: 12 showed better catalyst performance for ethylene copolymerization with 1-hexene and norbornene [62]. In contrast, complex 14 showed remarkable selectivity in ethylene trimerization in the presence of MAO, and second order dependence of activity on ethylene pressure (suggesting the metallacycle mechanism) was observed [65]. These would suggest that the effective catalyst for the polymerization can be tuned to the effective catalyst for the trimerization by the ligand modification.

Ti–Al Hetero Bimetallic Complexes Containing Chelate Trianionic Donor Ligand

Titanium complexes with tris(aryloxo)amine or bis(aryloxo)(alkoxo)amine ligand, Ti(OR′)[(O-2,4-R2C6H2-6-CH2)3N] or Ti(OR′)[(O-2,4-R2C6H2-6-CH2)2(OCH2CH2)N] (R = Me, tBu; R′ = iPr, tBu), exhibited from moderate to high catalytic activity for ethylene polymerization especially at high temperature (100–120 ºC), and the activities increased upon addition of small amount of AlMe3 [66, 68]. The resultant polymers possessed unimodal molecular weight distributions, suggesting that the polymerization proceeded with a uniform catalytically-active species. The resultant heterobimetallic Ti–Al complexes (15, 16) exhibited moderate catalytic activities upon heating under ethylene pressure even in the absence of any additional cocatalyst, strongly suggesting that cleavages of Ti–O bonds would generate the catalytically active cationic species in this catalysis (Scheme 3.7) [67, 68].

Isospecific/Syndiospecific Styrene Polymerization

Titanium complexes containing 1,4-dithiabutane-bridged derivatives (17) showed notable catalytic activities affording isotactic polystyrene with unimodal molecular weight distributions, whereas the 1,5-dithiapentane-bridged derivatives (18) showed low catalytic activities affording syndiotactic polystyrene (Scheme 3.8) [69]. The analogous zirconium, hafnium complexes of 17 also showed the low catalytic activity to afford isotactic polystyrene, suggesting that C 2-symmetric ligand sphere should play a crucial role for this isospecific polymerization [69, 71].

As shown in Table 3.4, the substituents on the ligand affected the activity and stereoselectivity, and these facts were evidently related to the effect of these substituents on the stereorigidity of the catalyst precursors. Complexes bearing less bulky ortho-substituents R1 in the aromatic ring (H, Me, iPr) allowed rapid interconversion on the NMR time scale, while the complexes with bulky groups (tBu, CMe2Ph) were stereorigid at temperatures up to 100 °C. Small ortho-substituents thus led to configurational lability at room temperature and resulted in the loss of both activity and stereospecificity. Syndiospecific styrene polymerization with relatively low activity was observed by titanium complexes with 1,5-dithiapentanediyl-linked bis(phenolato) ligands. Only the configurationally stable 1,4-dithiabutanediyl-linked phenolates with bulky ortho-substituents appeared to be capable of stabilizing a C 2-symmetric, helical ligand sphere at the titanium center and thereby provided an active site for the isospecific styrene polymerization [71].

3.2.2 Vanadium Complexes

Classical Ziegler type vanadium catalysts (ex. VOCl3, VCl4, VCl3–AlBr3, AlCl3–AlPh3, AliBu3, SnPh4) are known to display unique characteristics in olefin polymerization. In general, these catalyst systems afforded (i) high molecular weight linear polyethylene with uniform molecular weight distribution [72–74], and (ii) high molecular weight amorphous polymers applied to syntheses of ethylene/propylene/diene copolymers (called EPDM, synthetic rubbers) [75–77], ethylene/cyclic olefin copolymers (COC). Moreover, (iii) the catalyst system [V(acac)3 (acac = acetylacetonato)—Et2AlCl] polymerizes propylene to give not only a syndiotactic “living” polymer with narrow molecular weight distribution (M w/M n = 1.05–1.20) [78–80], but also diblock copolymers of propylene and methyl methacrylate (MMA) [78–80]. On the basis of ESR and titration results, vanadium(III) species were postulated to play an important role as the catalytically active species [81–84], although it was estimated that fewer than 1 % of vanadium species were catalytically active in the mixture [83].

One of the main disadvantages of using this type of vanadium catalysts is the deactivation associated with the reduction to inactive vanadium(II) species. Although very high initial activities were observed by adopting these catalysts, the reduction causes very poor overall productivities. This problem could be overcome by reactivation of inactive vanadium(II) center to active vanadium(III) species by addition of re-oxidants such as hexachlorocyclopentadiene [85], ethyl trichloroacetate [86], and the polymerization proceeded without significant decrease in the activity by continuous addition of an aluminum alkyl and the re-oxidants even at high temperature (>105 ºC) [86].

As described above, the classical Ziegler type vanadium catalysts displayed unique characteristics as the olefin polymerization catalysts. Therefore, design and synthesis of new vanadium complex catalysts directed toward the controlled polymerization has been recognized as an attractive target [11–13, 29, 87–90]. Although examples for synthesis of vanadium complexes used as the catalyst precursors for olefin polymerization were known, however, known examples which exhibit the above described unique characteristics of using these transition metal complexes had been limited until recently [20–24, 86, 87–90].

3.2.2.1 Vanadium(III), (IV) Complexes

Vanadium(III), (IV) complexes have been focused on design of the efficient polymerization catalysts, because these were assumed to play an important role as the active species in olefin polymerization. Since only a trace of actual active species were present due to that these species would be unstable and be readily reduced by Al cocatalyst to afford the catalytically inactive vanadium(II) species, many researchers thus concentrate on stabilization of the oxidation state of the catalytically active species by an appropriate ligand modification [23, 86].

Dinuclear vanadium(III) chloride complex (19) containing bis(amido)amine ligand of type, (Me3SiNCH2CH2)2NSiMe3, exhibited remarkable catalytic activity for ethylene polymerization in the presence of MAO, Me2AlCl at 50 ºC [activity: 237 kg-PE/mol-V·h (MAO), 660 kg-PE/mol-V·h (Me2AlCl); ethylene 300 psig (20.4 atm), Al/V = 60 (molar ratio)] [91]. Resultant polyethylene prepared by 19—Me2AlCl catalyst possessed high molecular weight with uniform molecular weight distribution (M w = 7.21 × 105, M w/M n = 2.3). The catalyst system was short-lived, does not remain to be active for no more than 20–30 min, and this may be attributed to the reduction of the vanadium(III) center to an inactive divalent species. The reaction of 19 with AlMe3, Me2AlCl and MAO in n-hexane initially gave a red solution, which after a few days afforded another vanadium(II) complex identified as 19b (Scheme 3.9). This result thus suggested that no ligand dissociation occurred in the present catalyst system but aggregation with the cocatalyst. The question of how the reduction of 19 afforded the inactive divalent species (19b) was thus considered. The reaction of 19 with AlCl3 afforded disproportionated compounds, (tetravalent) 19c and (one divalent and two trivalent) 19d, clearly indicating that disproportionation was the basis of a reduction of the vanadium center. These results suggested a possibility of the reduction of 19 affording 19b and that the addition intermediate 19a, which is likely to be the catalytically-active species, has the intrinsic instability of a vanadium-carbon bond [91].

Reaction of dinuclear vanadium(III) chloride complex containing bis(amido)amine ligand [91]

A mixed-valent vanadium complex containing dithiolate ligand (20c, Scheme 3.10) showed moderate catalytic activity for ethylene polymerization in the presence of both Et2AlCl and MgCl2 [activity 254 kg-PE/mol-V·h, ethylene 6 atm, 50 ºC, 15 min.] [92], but the activity was lower than those by the aryloxo analogues (20a, 1990 kg-PE/mol-V·h; 20b, 1020 kg-PE/mol-V·h), under the same conditions (in n-hexane) [92]. The ligand in 20c transferred to Al alkyls upon treatment with AlMe3 affording vanadium(II) chloride and [AlMe{μ2-O(CH2CH2S)}]2 [93]. Use of thiobis(phenoxy) ligand improved the activity, and the complex 21 showed remarkable activities in the presence of cocatalyst [activity = 11708 kg-PE/mol-V·h (AliBu3), 8184 (Et2AlCl), 4736 (MAO); ethylene 5 atm, Al/MgCl2/V = 100/10/1 (AliBu3, Et2AlCl) or 3000/10/1 (MAO)] [94]. The resultant polymers possessed unimodal molecular weight distributions (M w/M n = 2.28–3.12), suggesting that these polymerizations proceeded with uniform catalytically active species.

Vanadium(III) complexes containing two or three O,N-chelating aminophenolate ligand (22,23) exhibited activities for ethylene/propylene copolymerization in the presence of Et2AlCl·EtAlCl2 [95]. The bis(phenoxy) complex (23) showed higher activity [159 kg-polymer/mol-V·h·bar, 8 bar of ethylene/propylene (ratio 1/2) in pentamethylheptane at 30 ºC for 10 min.] than the tris(phenoxy) complex (22, 27 kg-polymer/mol-V·h·bar). Olefin polymerization using a series of vanadium complexes containing an amine bis(phenolate) ligand, [(O-2,4-Me2C6H2-6-CH2)2(Me2NCH2CH2)N]2− (exemplified as complex 24), with various oxidation states (II-V) were explored [96, 97]. Complex 24 showed notable activity in ethylene polymerization in the presence of EtAlCl2, but showed negligible activity in the presence of MAO [96]. Copolymerizations of ethylene with 1-hexene, norbornene were attempted, but the activities decreased and the resultant polymers possessed a mixture of coplymers with different compositions estimated by their DSC thermograms [96]. Vanadium(III) complex containing bis(phenoxy)pyridine ligand (25) showed remarkable catalytic activity for propylene polymerization in the presence of MAO (activity 803 kg-PP/mol-V·h, propylene 5 atm in toluene at 0 ºC for 30 min, Al/V = 3000), affording high molecular weight polymer with uniform molecular weight distribution (M w = 1.17 × 106, M w/M n = 2.03) [98]. The resultant polymer possessed large extent of regio irregular as generally seen in those prepared by vanadium catalysts.

Taking into account the above reports (vanadium complexes using chelate anionic and neutral donor ligands) [91–98], as described above, control, stabilization of the oxidation state, catalytically active species) by an appropriate ligand modification seems to be a key for the efficient catalyst with vanadium(III), although the actual active species including the activation/polymerization mechanism are still not clear at the present stage.

A series of vanadium(III) complexes containing β-enaminoketonato [99, 100], phenoxy-imine [101–104], imino-pyrrolide [105] ligands (exemplified in Scheme 3.11) were tested as olefin polymerization catalyst in the presence of Et2AlCl and Cl3CCO2Et. The selected results are summarized in Table 3.5 [99, 100, 103, 105]. The observed activities by certain complexes were slightly/apparently higher than those by VCl3(THF)3, and the activities decreased at 70 ºC probably due to the rapid deactivation even for short period (5 min) and in the presence of excess amount of re-oxidant (300 equivalent to V). On the basis of these data, it seems that 26b (R1;R2 = tBu;CF3) [99, 100], 26d (R1;R2 = Ph;CH3) [99, 100], 27 h [103] showed higher activities. The related phenoxy-imine analogues showed low activities under the same conditions [101–104]. Placement of neutral donor ligands (amine, pyridine) into the phenoxy-imine ligands in 27 was not effective; the observed activity by 27 h was relatively close to 26e. Although both the activities and the polymerization behavior were affected by the ligand substituents, the detailed explanation by electronic/steric factors seems difficult (factors such as ligand transfer to Al, reductions etc.). In contrast, the imino-pyrrolide analogues (28) showed remarkable activities [105], and the activities by 28 increased in the order (ethylene 1 atm, 50 ºC for 5 min): 28c (R = 2,6-iPr2C6H3) > 28b, e (Ph, C6F5) > 28d (4-CF3C6H4) > 28a (cyclohexyl). The results thus suggest that both electronic and steric factors play an important role (probably for strong coordination).

Complex 27c showed high activity in the ethylene/norbornene copolymerization and the activity was close to that by 27h under the same conditions, although the activity by 27c was lower than that by 27h in the ethylene polymerization [103]. Complexes 28 showed moderate comonomer incorporation with higher activities in ethylene/10-undecen-1-ol copolymerizations, affording the copolymers with relatively low molecular weights (M n = 3.1–52.5 × 103) [105]: the M n values decreased upon increasing the comonomer content [105].

Vanadium(III) complex containing neutral bis(imino)pyridine ligand (29a) exhibited remarkable catalytic activities for ethylene polymerization in the presence of MAO, affording the polymers with broad molecular weight distributions [activities 1420, 2240 kg-PE/mol-Vh, with Al/V = 600, 60 (molar ratio), respectively; ethylene 100 psig (6.8 atm), 50 ºC, 15 or 30 min] (Scheme 3.12) [106]. The activities decreased at 140 ºC, and the molecular weight distributions in the resultant polymers were dependent upon the Al/V molar ratios. The reaction with ethylene using the complexes (29d, e) containing mono substituted aromatic group on the imino ligand (in place of 2,6-diisopropylphenyl) afforded oligomeric mixtures and polyethylene (products by Schultz-Flory distribution) [107], (Dimerization of propylene (selectivity 80–95 %) [108]), and the reaction with propylene by 29f, g afforded oligomers with relatively high C6 selectivity (80–95 %, major products: methylpentenes) [107], (Dimerization of propylene (selectivity 80–95 %) [108]). These results suggested that the observed trend concerning the ligand effect was very similar to that observed in the ethylene polymerization/oligomerization using iron(II) complexes containing similar ligands [109–115]. The bis(carbene)pyridine complex (30) showed remarkable activities for ethylene polymerization, and the activity was affected by the Al cocatalyst employed [116]. The activity decreased in the order (ethylene 1 atm in toluene at r.t. for 30 min, Al/V = 500, molar ratio): 1446 kg-PE/mol-V·h (MMAO, methyl-isobutyl-aluminoxane) > 1280 (MAO) > 586 (dried MAO and AliBu3) > 278 (Et2AlCl).59

(Arylimido)vanadium(IV) dichloride complexes (31, Scheme 3.13) showed high activities for ethylene polymerization in the presence of Al cocatalyst [activity by 31b: 59 kg-PE-mol-V·h (MAO, Al/V = 500), 120 kg-PE-mol-V·h (Et2AlCl, Al/V = 10); ethylene 1 atm, 20 ºC in toluene, 2 or 10 min], affording the polymers with uniform molecular weight distributions [117, 118]. The activities in ethylene/propylene copolymerization using vanadium(IV) complexes containing two amide ligands (32) were affected by the Al cocatalyst employed, and the activity by 32a decreased in the order: Et2AlCl·EtAlCl2 (860 kg-polymer/mol-V·h) > EtAlCl2 (330) > Et2AlCl (80) > AlEt3 (24) [conditions: ethylene + propylene total 2 bar in hexane at 22 ºC for 15 min, Al/V = 40 (molar ratio)] [119]. The isopropyl amide complex (32a) showed higher activity than the cyclohexyl analogue (32b) [119], and the resultant polymer possessed high molecular weight with uniform molecular weight distribution (32a—Et2AlCl·EtAlCl2 catalyst, M w = 2.29 × 106, M w/M n = 3.0, ethylene 73 wt%). Vanadium(IV) complex with chelate bis(amide) ligand (34) showed higher activity than the bis(amide) analogue (33) in ethylene polymerization [activities in the presence of Et2AlCl·EtAlCl2: 213 kg-PE/mol-V·h, 54 kg-PE/mol-V·h for 34, 33, respectively: ethylene 1 atm in toluene at 30 ºC, Al/V = 50]. Although the activity in the ethylene polymerization by 36 is close to that by 32a (178 kg-PE/mol-V·h), 34 showed higher activity in ethylene/propylene copolymerization [120].

Vanadium(IV) complex with N,O-bidentate ligand (35b) showed higher activity than 35a, probably owing to increasing the steric bulk, and the activity was highly affected by the Al cocatalyst employed [EtAlCl2 >> Et2AlCl > MAO]. The resultant polymers possessed rather high molecular weights with moderate distributions [121]. The salen-type tetradentate complexes (36, 37) also showed from moderate to high activities for ethylene polymerization [122, 123], and the activities of 37 were higher than 36: the activities were affected by the ortho- substituent in the phenoxo moiety, and by Al cocatalyst employed. However, the resultant polymer possessed broad molecular weight distributions (M w/M n = 7.3–10.4), suggesting generation of multiple catalytically active species [122, 123].

3.2.2.2 Vanadium(V) Complexes

As described above, VOCl3 showed moderate activities for ethylene/propylene (co)polymerization in the presence of Al alkyls, however, one of the major concerns associated with use of vanadium(V) complexes as catalysts for Ziegler-Natta polymerizations is a facile reduction to yield lower-valent complexes. Use of arylimido analogues seemed to be promising, because a series of trichloride analogues, V(NAr)Cl3, can be prepared in high yields by treating VOCl3 with various isocyanates (ArNCO) [124–126], and these complexes showed moderate thermal stability, as demonstrated by synthesis of V(N-2,6-iPr2C6H3)(CH2Ph)3 from the trichloride analogues by treating with PhCH2MgCl in n-hexane [127]. The reported fact is noteworthy, because the most common problem encountered in attempts to synthesize vanadium(V) alkyls was the reduction of the metal center upon alkylation. Placement of appropriate alkyl substituent in the arylimido ligand is important for stabilization of the oxidation state upon the alkylation, and the approach is useful for synthesis various vanadium(V)-alkyls [128–131].

It turned out that the arylimido-aryloxo analogue (38) showed remarkable activities not only for ethylene polymerization [132–135], but also for ethylene/norbornene copolymerization [136] especially in the presence of halogenated Al alkyls (Et2AlCl, Me2AlCl, EtAlCl2 etc.) [134–136], affording high molecular weight polymers with uniform distributions. Selected results in the ethylene polymerization catalyzed by V(N-2,6-Me2C6H3)Cl2(O-2,6-Me2C6H3) (38) are summarized in Table 3.6 [135]. The activity was highly dependent upon the Al cocatalyst employed, and the activities in toluene decreased in the order: iBu2AlCl (52000 kg-PE/mol-V·h) > EtAlCl2 (37400) > Me2AlCl (27500) > Et2AlCl (11700) > MAO (2930) >> Et2Al(OEt), Me3Al, Et3Al (trace or less). The activity did not decrease after 30 min, and was highly affected by the solvent employed; the activity of 584000 kg-PE/mol-V·h (TOF 20800000 h−1, 5780 s−1) was attained in CH2Cl2 in the presence of EtAlCl2. The resultant polymers prepared in toluene possessed ultra high molecular weights with unimodal molecular weight distributions (the M ν values in the resultant polymers prepared in the presence of iBu2AlCl, Me2AlCl were 9.87–12.5 × 106, 8.98 × 106, respectively). The activity decreased upon addition of CCl3CO2Et, which is commonly used as the effective additives in the polymerization using vanadium(III) and/or vanadium(IV) complexes. The results clearly suggest that the active species were thus different from those prepared from vanadium(III), (IV) complexes. It was assumed that the observed difference in the catalytic activities in the presence of MAO and Et2AlCl cocatalyst would be due to the different catalytically active species, catalyst/cocatalyst nuclearity effect [137, 138] generated in the two catalyst systems, as shown in Scheme 3.14 [23].

The (imido)vanadium(V) complexes containing (2-anilidomethyl)pyridine ligand, V(NR)Cl2[2-ArNCH2(C5H4N)] [R = 1-adamantyl (Ad), cyclohexyl (Cy), phenyl (Ph)], exhibited remarkably high catalytic activities for ethylene dimerization in the presence of MAO, affording 1-butene exclusively (selectivity from 90.4 to > 99 %, Scheme 3.17) [139]. The phenylimido analogue (40) also afforded 1-butene under the same conditions, whereas the 2,6-dimethylphenylimido analogue (39) afforded polyethylene. The cyclohexylimido analogues also showed high activities to afford 1-butene exclusively. The adamantylimido analogues (41) showed the highest activities (TOF: 2730000 h−1) for ethylene dimerization. These results thus clearly indicate that (i) the electronic nature of the imido ligand directly affects the activity, and (ii) the steric bulk of the imido substituents plays an essential key role toward the selectivity in this catalysis [139]. Moreover, 41—Et2AlCl, Me2AlCl afforded ultra high molecular weight polyethylene, suggesting a presence of proposed reaction scheme shown in Scheme 3.15 [140]. On the basis of reactions under various conditions, and ESR and NMR experiments, it was thus proposed that cationic vanadium(V)-alkyls play an important role in these catalysis [140].

3.2.3 Miscellaneous Early Transition Metal Complex Catalysts

3.2.3.1 Scandium Complexes

Examples for olefin polymerization using non-metallocene type scandium complex catalysts still have been limited but demonstrate promising possibilities: examples as catalyst precursors for conjugated diene polymerization (butadiene, isoprene) have also been reported. The complex containing β-diketiminato “nacnac” (42, Scheme 3.16) exhibited moderate to high catalytic activities for ethylene polymerization [1200 kg-PE/mol-Sc·h (MAO, Al/Sc = 20), 300 kg-PE/mol-Sc·h {B(C6F5)3, ca. 1 equiv.}: ethylene 300 psi, 50 ºC, cyclohexane/toluene], affording high molecular weight polymers with uniform distributions (M w = 8.51–18.7 × 105, M w/M n = 1.7–2.48) [141]. The reaction of 42 with 1.0 equiv. of B(C6F5)3 afforded monocationic [(nacnac)ScMe]+[μ-Me-B(C6F5)3]−, and the dicationic species [(nacnac)Sc]2+[μ-Me-B−(C6F5)3]2 by treating 42 with 2.0 equiv. of B(C6F5)3 exhibited moderate catalytic activity for ethylene polymerization (1 atm at r.t.) [141]. In contrast, ethylene polymerization using the admidinate analogue, [ArNC(Ph)NAr]Sc(CH2SiMe3)2(THF) (43) was low [activity 120 kg-PE/mol-Sc·h, ethylene 5 bar, {PhN(H)Me2}(C6F5)4, 30 ºC 20 min], and the acitivity by the Y, Gd, Nd complexes showed higher catalytic activities (1.0–1.5 × 104 kg-PE/mol-M·h) under the same conditions [142]. A dicationic scandium complexes containing a C 3-chiral ligand, prepared from [iPr-trisox]Sc(CH2SiMe3)3 (44) with 2.0 equiv. of [Ph3C][B(C6F5)4], exhibited remarkable catalytic activities for 1-hexene polymerization [2.03–36.2 × 103 kg-polymer/mol-Sc·h at −30–21 ºC], and the activity increased at higher temperature. The resultant polymer prepared at −30 ºC possessed highly isotactic structure (mmmm = 90 %) with narrow molecular weight distribution (M w/M n = 1.18, M w = 7.50 × 105), suggesting a possibility of living polymerization [143]. In addition to promising results by half-metallocene type scandium complex in ethylene copolymerization (with styrene, cyclic olefins etc.) [144–147], these results suggest that the non-metallocene type scandium complexes would exhibit unique characteristics as the catalyst precursors for olefin polymerization.

Scandium complexes containing [6-amino-6-methyl-1,4-diazepine] ligand (45, Scheme 3.17) exhibited high activities for ethylene polymerization in the presence of [PhN(H)Me2][B(C6F5)4], affording polymer with unimodal molecular weight distribution [2660 kg-PE/mol-Sc·h, ethylene 5 bar, in toluene at 50 ºC]: the activity increased at 70 ºC (5800 kg-PE/mol-Sc·h) [148]. Although the dialkyl analogues containing monoanionic tridentate ligand, Sc(L)(CH2SiMe3)2(THF) [L = 6-RN-1,4,6-trimethyl-1,4-diazepine] (R = Me, PhMe2Si), exhibited negligible catalytic activities for ethylene polymerization in the presence of [PhN(H)Me2][B(C6F5)4], the THF-free complex exhibited high activity under the same conditions [2920 kg-PE/mol-Sc·h, ethylene 5 bar, toluene, 50 ºC, 10 min], affording high molecular weight polymer with uniform distribution (M w = 1.2 × 106, M w/M n = 1.9) [149]. Removal of THF is thus found to be prerequisite for exhibiting remarkable activity. Ethylene polymerization using Sc complexes containing linked triazacyclononane(TACN)-amide ligands, [Me2Si(Me2TACN)(NR)]Sc(CH2SiMe3)2 (46, R = tBu, sBu), were explored in the presence of borate cocatalysts [150]. These complexes exhibited high catalytic activities at 70 ºC in the presence of [Ph3C][B(C6F5)4] [activity = 2705 kg-PE/mol-Sc·h (R = tBu), 1810 kg-PE/mol-Sc·h (R = sBu): ethylene 5 bar, toluene, 10 min], affording relatively high molecular weight polymers with uniform distributions. The activity in the presence of [Ph3C][B(C6F5)4] was higher than that in the presence of [PhN(H)Me2][B(C6F5)4], and the activity at 70 ºC was higher than that conducted at 50 ºC. The yttrium analogues exhibited further higher catalytic activities under the same conditions [150].

Trialkyl complexes containing four different neutral tridentate ligands (47, 48a–c) were used as the catalyst precursors for polymerization of ethylene, 1-hexene in the presence of [Ph3C][B(C6F5)4] in toluene (ethylene 6 bar, 33–36 ºC, 10 min). Ring size of the tridentate ligand affected the activity for ethylene polymerization [activity = 60 kg-PE/mol-Sc·h (48b), 4380 kg-PE/mol-Sc·h (48c)], and replacement of NMe group with S (48a) was also effective (activity = 5160 kg-PE/mol-Sc·h): the HC(Me2pz)3 analogue (47) also exhibited high catalytic activity (4980 kg-PE/mol-Sc·h). However, the resultant polymers possessed broad molecular weight distributions, although the 1-hexene polymerizations resulted in the polymers with uniform molecular weight distributions in most cases [151]. Taking into account these results, design of cationic Sc(III) alkyl complexes play an essential key role as the active species for olefin polymerization, and the ligand modifications which stabilize the oxidation state should be important for the efficient catalyst. Later, monoanionic bidentate or tridentate anilido-pyridine ligands (49, 50) were prepared and their catalyst performances for ethylene polymerizations were explored [152, 153].

3.2.3.2 Niobium and Tantalum Complexes

The Nb complexes 51 can be considered to contain either a neutral butadiene (C4) ligand and a Nb(III) metal center or a dianionic butadienide (C4 2−) ligand and a Nb(V) center (Scheme 3.18) [154]. The activity in ethylene polymerization by Cp*NbMe2(butadiene) was 39 kg-PE/mol-Nb·h, affording high molecular weight polymer with narrow molecular weight distribution. PDI (M w/M n) values are very small (1.05) when these polymerizations were performed at low temperature (−20 ºC), suggesting the polymerization proceeds in a living manner. Half-metallocene analogue, Cp*Ta(= NtBu)Cl2, exhibited high catalytic activity for ethylene/1-octene copolymerization [40200 kg-polymer/mol-Ta·h: ethylene 500 psig (ca. 34 atm), 140 ºC, 15 min] in the presence of Al imidazolide ([HNMe(C18H37)2][(C6F5)3AlNC3H3NAl(C6F5)3]), affording the copolymer with uniform molecular weight distributions [155]. The activity was higher than that by the bis(amide) analogue (52, 6000 kg-polymer/mol-Ta·h) [155]. Niobium complexes containing tris(pyrazolyl)borate ligand (53) exhibited moderate catalytic activity for ethylene polymerization in the presence of B(C6F5)3, and the activity was affected by the R substituent: the methyl analogue (R = Me) exhibited higher activity (130 kg-polymer/mol-Nb·h) than the H analogue. Treatment of the precatalyst with MAO does not result in any polymerization [156]. Bis(pyridyl-amido)niobium(V) (54) showed activity for ethylene polymerization upon addition of B(C6F5)3, but the activity was low (4.4 kg-polymer/mol-Nb·h) and rapid decomposition of the catalytically active species was observed [157]. Analogous bis(pyridylamide) complexes (55, 56) showed very high activity, up to 23900 kg-PE/mol-Ta·h (ethylene 5 bar, 80 ºC), and rapid decrease in the activity was observed at low temperature [158].

More recently, four Ta complexes bearing tris(pyrazolyl)borate ligands (57a–d) were found to exhibit catalytic activities for ethylene polymerization. Activity in the presence of AliBu3/[Ph3C][B(C6F5)4] is higher than that in the presence of dried MAO; the sterically encumbered 57c, d showed higher activities [activity: 77100 kg-PE/mol-Ta·h (57c) and 51300 kg-PE/mmol-Ta·h (57d)], and some of the highest values reported to date for Ta-based catalysts [159].

3.3 Summary and Outlook

As described above, tremendous number of reports have been known for this project, and some of them are very important from both academic and industrial point of view [20–28]. It is clear that fine-tuning of the ligand plays a crucial role in this catalysis. Unfortunately, recent examples for chromium complex catalysts are not listed and these are also important on relevance of their ethylene trimerization catalysts [160]. Very successful examples such as highly isospecific polymerization of α-olefins, and living polymerization, so called chain shuttling polymerization have been demonstrated among recent advances in this research subject. These several promising findings that should be very important from both academic and industrial viewpoints have been demonstrated. These efforts will pave new promising possibilities for evolution of new fine polyolefins with unique properties by incorporation of new comonomers and/or by adopting new synthetic strategies. We highly expect more progress in this field in the near future.

References

Sinn H, Kaminsky W (1980) Adv Organomet Chem 18:99

Sinn H, Kaminsky W, Vollmer HJ, Woldt R (1980) Angew Chem Int Ed 19:390

Brintzinger HH, Fischer D, Mülhaupt R, Rieger B, Waymouth RM (1995) Angew Chem Int Ed Engl 34:1143

Kaminsky W (1996) Macromol Chem Phys 197:3907

Kaminsky W, Arndt M (1997) Adv Polym Sci 127:143

Suhm J, Heinemann J, Wörner C, Müller P, Stricker F, Kressler J, Okuda J, Mülhaupt R (1998) Macromol Symp 129:1

Gladysz JA (2000) Chem Rev 100:1167

Ittel SD, Johnson LK, Brookhart M (2000) Chem Rev 100:1169

Alt HG, Köppl A (2000) Chem Rev 100:1205

Chen EY-X, Marks TJ (2000) Chem Rev 100:1391

McKnight AL, Waymouth RM (1998) Chem Rev 98:2587

Braunschweig H, Breitling FM (2006) Coord Chem Rev 250:2691

Cano J, Kunz K (2007) J Organomet Chem 692:4411

Stephan DW (2005) Organometallics 24:2548

Nomura K, Liu J, Padmanabhan S, Kitiyanan B (2007) J Mol Catal A 267:1

Nomura K (2009) Dalton Trans 8811

Nomura K, Liu J (2011) Dalton Trans 40:7666

Scollard JD, McConville DH (1996) J Am Chem Soc 118:10008

Scollard JD, McConville DH, Payne NC, Vittal JJ (1996) Macromolecules 29:5241

Britovsek GJP, Gibson VC, Wass DF (1999) Angew Chem Int Ed Engl 38:428

Gibson VC, Spitzmesser SK (2003) Chem Rev 103:283

Bolton PD, Mountford P (2005) Adv Synth Catal 347:355

Nomura K, Zhang S (2011) Chem Rev 111:2342

Makio H, Terao H, Iwashita A, Fujita T (2011) Chem Rev 111:2363

Milani B, Claver C (eds) (2009) Dalton Trans 8769

Coates GW, Hustad PD, Reinartz S (2002) Angew Chem Int Ed 41:2236

Domski GJ, Rose JM, Coates GW, Bolig AD, Brookhart M (2007) Prog Polym Sci 32:30

Sita LR (2009) Angew Chem Int Ed 48:2464

Baumann R, Davis WM, Schrock RR (1997) J Am Chem Soc 119:3830

Scollard JD, McConville DH, Rettig SJ (1997) Organometallics 1810:16

Averbuj C, Tish E, Eisen MS (1998) J Am Chem Soc 121:8755

Volkis V, Shmulinson M, Averbuj C, Lisovkii A, Edelmann FT, Eisen MS (1998) Organometallics 17:3155

Shmulinson M, Galan-Fererea M, Lisovskii A, Nelkenbaum E, Semiat R, Eisen MS (2000) Organometallics 19:1208

Volkis V, Nelkenbaum E, Lisovskii A, Hasson G, Semiat R, Kapon M, Botoshansky M, Eishen Y, Eisen MS (2003) J Am Chem Soc 125:2179

Tshuva EY, Goldberg I, Kol M (2000) J Am Chem Soc 122:10706

Segal S, Goldberg I, Kol M (2005) Organometallics 24:200

Tshuva EY, Goldberg I, Kol M, Weitman H, Goldchmidt Z (2000) Chem Commun 379

Tshuva EY, Goldberg I, Kol M, Weitman H, Goldchmidt Z (2001) Chem Commun 2120

Tshuva EY, Goldberg I, Kol M, Goldchmidt Z (2001) Organometallics 20:3017

Tshuva EY, Groysman S, Goldberg I, Kol M, Goldchmidt Z (2002) Organometallics 21:662

Groysman S, Goldberg I, Kol M, Genizi E, Gildschmidt Z (2003) Organometallics 22:3013

Gryosman S, Tshuva EY, Goldberg I, Kol M, Goldschmidt Z, Shuster M (2004) Organometallics 23:5291

Press K, Cohen A, Goldberg I, Venditto V, Mazzeo M, Kol M (2011) Angew Chem Int Ed 50:3529

Matsui S, Mitani M, Saito J, Tohi Y, Makio H, Matsukawa N, Takagi Y, Tsuru K, Nitabaru M, Nakano T, Tanaka H, Kashiwa N, Fujita T (2001) J Am Chem Soc 123:6847

Matsui S, Fujita T (2001) Catal Today 66:63

Mitani M, Mohri J, Yoshida Y, Saito J, Ishii S, Tsuru K, Matsui S, Furuyama R, Nakano T, Tanaka H, Kojoh S, Matsugi T, Kashiwa N, Fujita T (2002) J Am Chem Soc 124:3327

Mitani M, Furuyama R, Mohri J, Saito J, Ishii S, Terao H, Kashiwa N, Fujita T (2002) J Am Chem Soc 124:7888

Mitani M, Furuyama R, Mohri J, Saito J, Ishii S, Terao H, Nakano T, Tanaka H, Fujita T (2003) J Am Chem Soc 125:4293

Furuyama R, Mitani M, Mohri J, Mori R, Tanaka H, Fujita T (2005) Macromolecules 38:1546

Matsugi T, Matsui S, Kojoh S, Takagi Y, Inoue Y, Nakano T, Fujita T, Kashiwa N (2002) Macromolecules 35:4880

Yoshida Y, Matsui S, Takagi Y, Mitani M, Nakano T, Tanaka H, Kashiwa N, Fujita T (2001) Organometallics 20:4793

Yoshida Y, Saito J, Mitani M, Takagi Y, Matsui S, Ishii S, Nakano T, Kashiwa N, Fujita T (2002) Chem Commun 1298

Yoshida Y, Mohri J, Ishii S, Mitani M, Saito J, Matsui S, Makio H, Nakano T, Tanaka H, Onda M, Yamamoto Y, Mizuno A, Fujita T (2004) J Am Chem Soc 126:12023

Arriola DJ, Carnahan EM, Hustad PD, Kuhlman RL, Wenzel TT (2006) Science 312:714

Boussie TR, Diamond GM, Goh C, Hall KA, LaPointe AM, Leclerc M, Lund C, Murphy V, Shoemaker JAW, Tracht U, Turner H, Zhang J, Uno T, Rosen RK, Stevens JC (2003) J Am Chem Soc 125:4306

Boussie TR, Diamond GM, Goh C, Hall KA, LaPointe AM, Leclerc M, Murphy V, Shoemaker JAW, Turner H, Rosen RK, Stevens JC, Alfano F, Busico V, Cipullo R, Talarico G (2006) Angew Chem Int Ed 45:3278

Britovsek GJP, Cohen SA, Gibson VC, Maddox PJ, van Meurs M (2002) Angew Chem Int Ed 41:489

Britovsek GJP, Cohen SA, Gibson VC, Maddox PJ, van Meurs M (2004) J Am Chem Soc 126:10701

van Meurs M, Britovsek GJP, Gibson VC, Cohen SA (2005) J Am Chem Soc 127:9913

Mitani M, Nakano T, Fujita T (2003) Chem Eur J 9:2396

Deckers PJW, Hessen B, Teuben JH (2001) Angew Chem Int Ed 40:2516

Hu W, Sun X, Wang C, Gao Y, Tang Y, Shi L, Xia W, Sun J, Dai H, Li X, Yao X, Wang X (2004) Organometallics 23:1684

Wang C, Sun X, Guo Y, Gao Y, Liu B, Ma Z, Xia W, Shi L, Tang Y (2005) Macromol Rapid Commun 26:1609

Wang C, Ma Z, Sun X, Gao Y, Guo Y, Tang Y, Shi L (2006) Organometallics 25:3259

Suzuki Y, Kinoshita S, Shibahara A, Ishii S, Kawamura K, Inoue Y, Fujita T (2010) Organometallics 29:2394

Wang W, Fujiki M, Nomura K (2004) Macromol Rapid Commun 25:504

Gurubasavaraj PM, Nomura K (2010) Organometallics 29:3500

Padmanabhan S, Katao S, Nomura K (2007) Organometallics 26:1616

Capacchione C, Proto A, Ebeling H, Mülhaupt R, Möller K, Spaniol TP, Okuda J (2003) J Am Chem Soc 125:4964

Beckerle K, Capacchione C, Ebeling H, Manivannan R, Mülhaupt R, Proto A, Spaniol TP, Okuda J (2004) J Organomet Chem 689:4636

Capacchione C, Manivannan R, Barone M, Beckerle K, Centore R, Oliva L, Proto A, Tuzi A, Spaniol TP, Okuda J (2005) Organometallics 24:2971

Carrick WL (1958) J Am Chem Soc 80:6455

Carrick WL, Kluiber RW, Bonner EF, Wartman LH, Rugg FM, Smyth JJ (1960) J Am Chem Soc 82:3883

Phillips GW, Carrick WL (1962) J Polym Sci 59:401

Junghanns E, Gumboldt O, Bier G (1962) Makromol Chem 58:18

Natta G, Mazzanti G, Valvassori A, Sartori G, Fiumani D (1961) J Polym Sci 51:411

Christman DL, Keim GI (1968) Macromolecules 1:358

Doi Y, Ueki S, Keii T (1978) Macromolecules 12:814

Doi Y, Hizal G, Soga K (1987) Makromol Chem 188:1273

Doi Y, Koyama T, Soga K (1985) Makromol Chem 186:11

Natta G, Zambelli A, Lanzi G, Pasquon I, Mognaschi ER, Segre AL, Centola P (1965) Makromol Chem 81:161

Zambelli A, Pasquon I, Signorini R, Natta G (1968) Makromol Chem 112:160

Lehr MH (1968) Macromolecules 1:178

Lehr MH (1969) Macromolecules 2:217

Gumboldt A, Helberg J, Schleitzer G (1967) Makromol Chem 101:229

Christman DL (1972) J Polym Sci Part A-1 10:471

For recent reviews (vanadium catalysts), see: Hagen H, Boersma J, van Koten G (2002) Chem Soc Rev 31:357

Gambarotta S (2003) Coord Chem Rev 237:229

Nomura K (2005) In: Bevy LP (ed) New developments in catalysis research, NOVA Science Publishers, New York, USA, p 199

Redshaw C (2010) Dalton Trans 39:5595

Feghali K, Harding DJ, Reardon D, Gambarotta S, Yap G, Wang Q (2002) Organometallics 21:968

Janas Z, Jerzykiewicz LB, Sobota P, Richards RL (1999) Chem Commun 1015

Janas Z, Jerzykiewicz LB, Przybylak S, Richards RL, Sobota P (2000) Organometallics 19:4252

Janas Z, Wiśniewska D, Jerzykiewicz LB, Sobota P, Drabenta K, Szczegot K (2007) Dalton Trans 2065

Hagen H, Boersma J, Lutz M, Spek AL, van Koten, G (2001) Eur J Inorg Chem 117

Lorber C, Wolff F, Choukroun R, Vendier L (2005) Eur J Inorg Chem 2850

Lorber C (2009) Pure Appl Chem 81:1205

Golisz SR, Bercaw JE (2009) Macromolecules 42:8751

Tang L-M, Wu J-Q, Duan Y-Q, Pan L, Li Y-G, Li Y-SJ (2008) Polym Sci Part A Polym Chem 46:2038

Wu J-Q, Li B-X, Zhang S-W, Li Y-SJ (2010) Polym Sci Part A Polym Chem 48:3062

Wu J-Q, Pan L, Hu N-H, Li Y-S (2008) Organometallics 27:3840

Wu J-Q, Pan L, Liu S-R, He L-P, Li Y-S (2009) J Polym Sci Part A Polym Chem 47:3573

Wu J-Q, Pan L, Li Y-G, Liu S-R, Li Y-S (2009) Organometallics 1817:28

Houghton J, Simonovic S, Whitwood AC, Douthwaite RE, Carabineiro SA, Yuan J-C, Marques MM, Gomes PT (2008) J Organomet Chem 693:717

Xu B-C, Hu T, Wu J-Q, Hu N-H, Li Y-S (2009) Dalton Trans 8854

Reardon D, Conan F, Gambarotta S, Yap G, Wang Q (1999) J Am Chem Soc 121:9318

Schmidt R, Welch MB, Knudsen RD, Gottfried S, Alt HG (2004) J Mol Catal A 222:17

Lang JRV, Denner CE, Alt HG (2010) J Mol Catal A 322:45

Britovsek GJP, Gibson VC, Kimberley BS, Maddox PJ, McTavish SJ, Solan GA, White AJP, Williams DJ (1998) Chem Commun 849

Britovsek GJP, Bruce M, Gibson VC, Kimberely BS, Maddox PJ, Mastroianni S, McTavish SJ, Redshaw C, Solan GA, Stromberg S, White AJD, Williams DJ (1999) J Am Chem Soc 121:8728

Britovsek GJP, Dorer BA, Gibson VC, Kimberely BS, Solan GA (1999) WO 99/12981

Small BL, Brookhart M, Bennett AMA (1998) J Am Chem Soc 120:4049

Small BL, Brookhart M (1998) J Am Chem Soc 120:7143

Small BL, Brookhart M (1999) Macromolecules 32:2120

Bennett AMA (1998) WO 98/27174

McGuinness DS, Gibson VC, Steed JW (2004) Organometallics 23:6288

Lorber C, Donnadieu B, Choukroun R (2000) Dalton Trans 4497

Lorber C, Choukroun R, Donnadieu B (2002) Inorg Chem 41:4217 (synthesis)

Desmangles N, Gambarotta S, Bensimon C, Davis S, Zahalka H (1998) J Organomet Chem 562:53

Cuomo C, Milione A, Grassi A (2006) J Polym Sci Part A Polym Chem 44:3279

Białek M, Czaja K, Szydło E (2009) J Polym Sci Part A Polym Chem 47:565

Białek M, Czaja K (2008) J Polym Sci Part A Polym Chem 46:6940

Białek M, Czaja K (2008) Polimery 53:364

Devore DD, Lichtenhan JD, Takusagawa F, Maatta E (1987) J Am Chem Soc 109:7408

Buijink J-KF, Teubin JH, Kooijman H, Spek AL (1994) Organometallics 13:2922

Nomura K, Davis WM, Schrock RR (1996) Inorg Chem 35:3695

Murphy VJ, Turner H (1997) Organometallics 16:2495

Yamada J, Nomura K (2005) Organometallics 24:2248

Nomura K, Onishi Y, Fujiki M, Yamada J (2008) Organometallics 27:3818

Zhang W, Nomura K (2008) Organometallics 27:6400

Nomura K, Zhang W (2010) Chem Sci 1:161

Nomura K, Sagara A, Imanishi Y (2001) Chem Lett 36

Wang W, Yamada J, Fujiki M, Nomura K (2003) Catal Commun 4:159

Nomura K, Sagara A, Imanishi Y (2002) Macromolecules 35:1583

Wang W, Nomura K (2006) Adv Synth Catal 348:743

Wang W, Nomura K (2005) Macromolecules 38:5905

Macchioni A (2005) Chem Rev 105:2039

Li H, Marks TJ (2006) Nuclearity and cooperatively effects in binuclear catalysts and cocatalysts. Proc Natl Acad Sci USA 103:15295

Zhang S, Nomura K (2010) J Am Chem Soc 132:4960

Igarashi A, Zhang S, Nomura K (2012) Organometallics 31:3573

Hayes PG, Piers WE, McDonald R (2002) J Am Chem Soc 124:2133

Bambirra S, Bouwkamp MW, Meetsma A, Hessen B (2004) J Am Chem Soc 126:9182

Ward BD, Bellemin-Laponnaz S, Gade LH (2005) Angew Chem Int Ed 44:1668

Luo Y, Baldamus J, Hou Z (2004) J Am Chem Soc 126:13910

Li X, Baldamus J, Hou Z (2005) Angew Chem Int Ed 44:962

Cui D, Nishiura M, Hou Z (2005) Macromolecules 38:4089

Li X, Hou Z (2005) Macromolecules 38:6767

Ge S, Bambirra S, Meetsma A, Hessen B (2006) Chem Commun 3320

Ge S, Meetsma A, Hessen B (2007) Organometallics 26:5278

Bambirra S, van Leusen D, Tazelaar CGJ, Meetsma A, Hessen B (2007) Organometallics 1014:26

Tredget CS, Clot E, Mountford P (2008) Organometallics 27:3458

Zimmermann M, Törnroos KW, Waymouth RM, Anwander R (2008) Organometallics 27:4310

Jian Z, Cui D (2012) Dalton Trans 41:2367

Mashima K, Fujikawa S, Tanaka Y, Urata H, Oshiki T, Tanaka E, Nakamura A (1995) Organometallics 14:2633

Feng S, Roof GR, Chen EYX (2002) Organometallics 21:832

Jaffart J, Nayral C, Choukroun R, Mathieu R, Etienne M (1998) Eur J Inorg Chem 425

Spannenberg A, Fuhrmann H, Arndt P, Baumann W, Kempe R (1998) Angew Chem Int Ed 37:3363

Hakala K, Lofgren B (1997) Macromol Chem Rapid Commun 18:635

Michiue K, Oshiki T, Takai K, Mitani M, Fujita T (2009) Organometallics 28:6450

McGuinness DS (2011) Chem Rev 111:2321

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Nomura, K., Zhang, W. (2014). Olefin Polymerization with Non-metallocene Catalysts (Early Transition Metals). In: Osakada, K. (eds) Organometallic Reactions and Polymerization. Lecture Notes in Chemistry, vol 85. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-43539-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-662-43539-7_3

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-43538-0

Online ISBN: 978-3-662-43539-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)