Abstract

In the chemical industry final products of one producer act as input material to the production process of the following producer (i.e. the customer of the first producer). The following producer may be also a chemical company, further refining and processing the input chemicals, or it may be a producer of some other products, such as textiles, food, pharmaceuticals, etc., using the input chemicals as ingredients for their final products. As production lead times in the chemical industry are usually longer than the order lead times, chemicals are—in most cases—produced in make-to-stock mode. Thus, after production, the final products are pushed into a distribution network and stored in distribution centers. The structure and operational parameters (e.g. safety stock levels) of the distribution network are directly influencing the performance of the chemicals supply chain.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

In the chemical industry final products of one producer act as input material to the production process of the following producer (i.e. the customer of the first producer). The following producer may be also a chemical company, further refining and processing the input chemicals, or it may be a producer of some other products, such as textiles, food, pharmaceuticals, etc., using the input chemicals as ingredients for their final products. As production lead times in the chemical industry are usually longer than the order lead times, chemicals are—in most cases—produced in make-to-stock mode. Thus, after production, the final products are pushed into a distribution network and stored in distribution centers. The structure and operational parameters (e.g. safety stock levels) of the distribution network are directly influencing the performance of the chemicals supply chain.

In this case study we describe the reorganization of the European distribution network of a global chemicals manufacturer. The analysis and the optimization of the distribution network has been supported by PRODISI SCO, an APS-module specialized in Strategic Network Design. The structure of the case study is as follows:

-

Section 19.1 describes the structure and the typology of the supply chain and the situation prior to the reorganization of the distribution network.

-

The objectives of the project are summarized in Sect. 19.2.

-

Section 19.3 introduces a framework used to structure and guide the project.

-

The initial model of the distribution network, called baseline model, is described in Sect. 19.4.

-

Section 19.5 summarizes the creation and analysis of scenario models.

-

Results and lessons learned are the topic of Sect. 19.6.

1 Case Description

1.1 Structure of the Chemicals Supply Chain

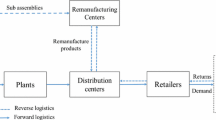

A typical chemicals supply chain consists of suppliers (being not considered in this case study), manufacturing plants (own and sub-contracted plants), distribution centers (typically multi-staged, central and regional DCs), and the customers’ sites.

The chemical company described in this case study is a worldwide leader in specialty and basic chemicals, with approx. 10,000 employees and subsidiaries worldwide. There are five business units, each being specialized in a particular product portfolio (e.g. oleochemicals, care chemicals, nutrition & health, functional products, and process chemicals). Important clients are in the detergents and cleaners industry, the health and nutrition sector, the cosmetics industry, and a number of other industrial markets such as coatings and inks, textiles and plastics, as well as synthetic lubricants, agriculture, mining, and oil extraction. The company has several production plants and warehouses across Europe. Due to the current production and distribution network there are about 30 % of compound deliveries. These are transports between the plants and/or warehouses, as well as supplies to the European sales organizations and end customers. The following figures describe the supply chain structure in Europe:

-

10,000 articles

-

14 production sites

-

24 toll manufacturers

-

A two-staged distribution network with 40 locations, consisting of larger distribution centers and smaller shipping points

-

16,000 customers (goods recipients)

-

2.6 million tons of transport volume per annum

-

280,000 delivery notes with 400,000 positions per annum.

Table 19.1 summarizes the typology of the chemicals supply chain.

1.2 As-Is Situation

Because of a constant growth and expansions of business, it was necessary to consolidate and adjust the corporate structure in Europe. To support these measures, a cross-European supply chain organization was formed. The tasks of this organizational unit are to consolidate the regional markets and country-specific customers and to formulate suggestions for restructuring the existing distribution network structure. The design of a European network structure should be assisted and possible financial benefits realized.

In detail, the supply chain organization was facing the following issues:

-

There was no overview over the complete network structure.

-

The material flows of the product groups were not known in detail.

-

The independent sales and logistics organizations in the European countries had no consolidated processes; there was only very little exchange of information between the European organizations.

-

The master data (ZIP codes, country codes, etc.) were neither harmonized nor well maintained (e.g. transport cost data).

2 Objectives of the Project

In general, the benefits of a network redesign will lead to competitive advantage by providing faster and more accurate supply of products to customers at reduced costs. The main goal of strategic network design is to redesign the supply chain and find the best possible network configuration between suppliers, production sites, distribution centers and customers, so that the material flow, in this network, guarantees the maximum profit.

The supply chain management department, responsible for Germany and Europe, had to build a European distribution network with optimized costs for the whole supply chain. Furthermore, a distribution network should be created that is able to react faster to changes in the production network and to maximize the economic performance of the supply chain. The detailed objectives of the project, European Distribution Network Concept, were the following:

-

The European material flows and the complete European network, consisting of production plants, distribution centers, shipping points, and customers, should be made transparent.

-

A concept for simulating changes in the European supply chain should be developed.

-

An IT-based tool for simulating changes to the existing supply chain structure should be implemented, to find an optimal supply chain structure and supply chain configuration. The supply chain structure is defined as all production plants, distribution centers, warehouses and shipping points, and customers. The supply chain configuration is the network combining these elements. The tool should support the modeling of the supply chain structure and its configuration. Optimization of the supply chain should be supported as well as simulation of so-called “what-if” scenarios. Product flows, associated costs, capacities, and service constraints from raw materials through production and distribution should be included in the model. In addition, “on” or “off” decisions about physical locations and transport links should be supported as well as particular attributes within the network components, e. g. adjusted shipment lot sizes, target stock levels, capacities and costs. The impact of changes to the network structure should be simulated not only locally, but also across the entire supply chain.

-

A continuous improvement process should be implemented, that is driven by the supply chain management department using the distribution network simulation tool, in order to optimize transportation and warehousing costs. The project had to take into consideration all critical cost elements, including real estate, warehouse labor, inbound transportation, outbound transportation and key inventory cost factors.

3 Framework for Strategic Network Design

The framework for strategic network design consists out of the following four building blocks:

-

1.

As-is analysis

-

2.

Software selection

-

3.

Baseline model

-

4.

Alternative scenarios

3.1 As-Is Analysis

In the As-Is Analyze phase all relevant information regarding the supply chain is gathered. This information forms the foundation for the requirements analysis, the selection of the appropriate Strategic Network Design module supporting the requirements, and the creation of a baseline model. During the As-Is Analyze phase the following information were collected and analyzed:

-

Structure of the supply chain (production sites-, stocking locations, distribution centers, shipping points, suppliers)

-

Configuration of the supply chain (transportation links and modes)

-

Customer groups and product groups

-

Changeable and unchangeable parts of the supply chain

-

Structure of transactional systems (e.g. ERP-systems).

Based on the information collected for the analysis, the scope of the project had to be defined precisely. In this project, it was decided to include the shipment areas of production plants (only finished products), the DCs, the shipping points and the customers into the scope. From the analysis, requirements for the software selection have to be derived. For instance, in this project, the existence of non-linear cost functions for transportation costs was confirmed. Further it was detected that in some distribution centers, materials were re-packaged (for instance bulk material was re-packaged into bags). Thus, the software module used for strategic network design must be able to represent the transformation of one material number (e.g. bulk material) into another material number (e.g. bags); for this purpose, bills of materials data structures must be supported by the software module.

3.2 Software Selection

Out of the results of the As-Is Analysis and the scope and requirements of the project, the best suitable APS software can be chosen. There is a broad variety of tools on the market, most of them designed to solve specific problems and therefore having specific data requirements. For an overview of Strategic Network Design modules see Chap. 16.

When selecting the appropriate simulation tool—besides the results of the As-Is situation—the following criteria’s should be considered:

-

One-time planning vs. regular planning

-

Single period vs. multi period models

-

Optimization vs. manual calculation of scenarios.

In this case study it was decided to regularly use the software tool, to update the models and assess the current configuration of the distribution network (regular planning). The planning horizon is 1 year, consisting of a single period. And, due to the complexity of the distribution network and the huge amount of data (see Sect. 19.1), it was obvious that an automatic optimization was required. Out of a short list of three Strategic Network Design modules, PRODISI SCO by PROLOGOS was selected. The two main reasons for the selection of PRODISI were (1) the features and the good optimization results of the network optimization algorithms of PRODISI and (2) the ability of PRODISI to represent complex and detailed transportation cost structures.

3.3 Baseline Model

The baseline model is the representation of the As-Is network in the simulation software. To develop the baseline model three steps are required as shown in Fig. 19.1.

In step 1 the model assumptions are developed. First, the elements of the network have to be determined and included into the data set. Second, the constraints that shall be represented in the model have to be determined, e.g. capacity constraints, source-destination combinations, handling of products in specific sites. Third, aggregation rules are determined. An example is the aggregation of shipping conditions into groups, such that all shipping conditions in the same group, can be represented with the same cost function. Fourth, filter rules are defined to filter wrong or inaccurate data, and to limit the data set to the elements of the network that are in scope.

The second step is the implementation of the baseline model. In this step, the data set is extracted from the transactional systems, and all aggregation and filtering rules determined in step 1 are applied. Then, the data set is imported into the APS tool. Furthermore, the APS tool is customized according to the functional requirements and the constraints determined in step 1.

After the baseline model was implemented, it is evaluated against reality. This takes place in step 3. An important indicator for the validity of the baseline model is the correspondence between the calculated transportation costs based on the baseline model and the actual transportation costs from the considered period.

3.4 Alternative Scenarios

One of the reasons for the implementation of a Strategic Network Design module of an APS is the ability to quickly evaluate alternative scenarios. The creation and evaluation of alternative scenarios is divided into three steps. Figure 19.2 summarizes the approach for the development of alternative scenarios.

The first step is to envision a new scenario. Ideas for new scenarios can be drawn from the analysis of the baseline model in order to find areas for improvement. Other sources for new ideas can be observations of issues in the real world network, e.g. high transportation costs per unit in specific regions of the distribution network, or the business development strategy. For instance, the expansion of business in a specific area can be supported by the evaluation of an appropriate scenario.

In the second step, the envisioned scenarios are designed and detailed. It is important to assign a specific and well-defined objective function to each scenario in order to use the network optimization functionality of the APS. Examples for objective functions are: “Minimizing the fixed costs of the locations by keeping a given service level” or “Minimizing the transport costs with the actual given network structure and locations”.

After the design of the scenarios these have to be implemented in the APS tool. Since some scenarios are not included in the baseline model, additional data has to be collected (e.g. new locations in new markets, where there was no business so far). After implementing the scenarios, the optimization will take place automated by an optimizer or manually by the planner.

An evaluation of the alternative scenario models is necessary in most cases because not all constraints and evaluation criteria’s can be incorporated into the model. These are mainly soft factors like regulations with the workers union if locations are shut down or availability of new employees if new locations in new markets will be opened. For these reasons the different alternative scenarios will be evaluated outside the APS tool. The decision which scenarios will be implemented in reality will be taken based on the evaluation.

4 Setting Up the Baseline Model

In this section we describe specific issues and challenges we had to face when setting up the baseline model. As already mentioned, the scope was the European distribution network, including plants, distribution centers and customers’ sites. The production plants were fixed objects for the purpose of this project. Thus, the re-allocation of products to different production plants was not in scope. Suppliers were not in cope and thus not included in the model. The APS PRODISI SCO from PROLOGOS was used to model the network.

4.1 Data Collection

The first big challenge when building the European model for the customer was the collection of all required basic data, mainly the delivery notes with some additional attributes from all the European logistics organizations. For this purpose, a specification of the data model was given to the logistics departments of all European country organizations. The heads of logistics in the country organizations were made responsible to collect all data according to the basic model data for their country.

When checking and filtering the returned data from the different countries a loop back was often necessary, in order to deal with country-specific issues (e.g. specific shipping conditions, free of charge deliveries) and data errors. Although all European countries use the same type of ERP system (SAP), single attributes from the data sets have still to be harmonized, in order to integrate them into one data model (e.g. ZIP codes).Footnote 1

Besides the basic data for the model, all transportation and warehouse related cost data for the model had to be manually collected, in order to have a cost basis for the evaluation of alternative scenarios (see next section). The cost data was not stored in the ERP systems and had to be compiled from multiple local data sources. As a consequence, the collection and transformation of cost data was very time consuming and required a lot of data checking. Sometimes it was even not possible to get a fixed cost function, e.g. for the transportation relation from one warehouse to all locations in a country. Based on the cost of the past transports a cost function was then extrapolated.

4.2 Modeling of Distribution Network

The modeling of the locations (production sites, toll manufacturers, distribution centers, etc.) turned out to be the next challenge. In PRODISI the distribution network is modeled by a directed, acyclic graph. The nodes represent the locations of the network, and the arcs represent the material flows between the locations. In most cases, material flows from the manufacturing plants to the distribution centers, and from there to the customers’ sites (three-staged network). However, in reality, there are further flows

-

From a manufacturing plant to a toll manufacturer or to some other plant

-

From a regional warehouse to some other warehouse or shipping point.

These flows within the same level of the network even form loops. For instance, one material might be transported from one warehouse to a second and from there back to the first one.

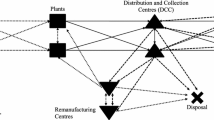

In order to represent these material flows in PRODISI we decided to double all plants, warehouses and shipping points and represented them on two separate levels. Thus, the original, three-staged network became a network with five levels: Level 0 representing the customers, levels 1 and 2 the warehouses and shipping points, and levels 3 and 4 the plants and toll manufacturers. Figure 19.3 shows the structure of the model.

The “simple” material flows—plant X → warehouse Y → customer Z—are represented in this model by a chain of five locations, i.e. plant X → plant X → warehouse Y → warehouse Y → customer Z. The transportation costs from one location to the second representation of this location in the model were set to zero (see Fig. 19.3).

4.3 Transportation Links

Transportation links connecting sites that lay within the scope of one ERP-system, can easily be included into PRODISI. However, there are many transportation links spanning the “borders” between the European ERP-systems. For example, consider a situation where some Plant 4711 in Country 1 (in ERP-system 1) delivers a product to some Distribution Center 0815 in Country 2 (in ERP-system 2). Note, that both countries are represented in different ERP-systems. As a consequence, Plant 4711 is only represented in ERP-system 1, and DC 0815 is only represented in ERP-system 2. Figure 19.4 illustrates this example.

Transportation links from Plant 4711 to DC 0815, i.e. deliveries of products from Plant 4711 to DC 0815, are represented by delivery notes in ERP-system 1 (and by purchase orders and goods receipts in ERP-system 2). Thus, there is a formal supplier-to-customer relationship in both ERP-systems established. In order to establish the required transportation links in PRODISI, we setup a table with all locations of the network and used the country codes and ZIP codes as identifiers for the locations. As all delivery notes contain the country code and ZIP code, it was possible to check for each delivery note whether it represented

-

An internal delivery, i.e. a transportation link to an internal node in the distribution network

-

Or an external delivery, i.e. a transportation link to an actual customer.

In all delivery notes representing internal deliveries the destination address was then replaced by the location code of the receiving site (see Fig. 19.4).

4.4 Bills of Materials

The focus of the project was on the European distribution network. Usually when modeling distribution networks there is no need to represent bills of materials as only finished goods have to be considered. However, in this project there were some materials that were shipped as bulk products (tank car, full truck) from a plant to a distribution center, and were then packaged into smaller packaging sizes, e.g. bags. Unfortunately, PRODISI is not able to represent bills of materials directly.

Our solution was to identify all locations where the in-flow and out-flow material quantities, including changes of stock levels, were not balanced. We implemented a simple heuristic, matching in-flow quantities with out-flow quantities based on bills of materials that were manually maintained by the project team in an Access database. The heuristics detected in-balances of the material flow and changed the upstream delivery notes such that the delivery notes are adjusted to match the downstream delivery notes (after change of material codes, e.g. due to re-packaging). Figure 19.5 illustrates the transformation of delivery notes, in order to represent bills of materials.

Note, that due to the fact that we used a heuristic, we just estimated the actual material flows and related costs. However, by comparing the results from the baseline model with reality we learned that the deviation of computed costs to actual costs was very low and did not impact conclusions drawn from the model.

4.5 Product Groups

In order to facilitate the modeling of the later scenarios and because of a restriction in the software, it was necessary to build up to 60 logistical product groups. Logistical product groups are defined as products which have the same material flows in the network. In later scenarios you can then easily reallocate complete groups of material to other locations or fix them to specific locations.

For the implementation of the APS tool we have chosen a two-step approach. First, we built a model for each individual country (or data set), in order to control the consistency and robustness of the model with less data and under less complexity. This made it easier for the responsible logistic department to compare the model with reality. After the correction and fine-tuning of each individual model, all of them were integrated into a complete European model, which then was the basis for the alternate scenarios.

5 Alternative Scenarios

With the complete baseline model the project target to improve the overall transparency over all locations and the complete European material flow, was fulfilled. In this phase the focus lays on the simulation of new network scenarios, in order to streamline the material flow and to consolidate the network structure, to gain cost savings. The creation and design of the alternative scenarios was done in a workshop with all regional supply chain managers. A few scenarios were already proposed by the central supply chain organization through the detailed analysis of exceptions in the baseline model (e.g. customers in Italy delivered from Spain, but with materials which can also be produced in Italy). For most scenarios no additional data collection was necessary because the focus was more on streamlining the existing supply chain than on expanding it.

One easy to implement scenario was to simulate the material flow of one particular material group. For this simulation the logistical material grouping functionality was used to limit the input data to the simulation. The goal was to see if the closing of a production facility for this material group will have a big effect on the network because of more transportation activities from other locations. The cost benefits (because of necessary renovation) of removing the products from the production facility and the higher transportation costs were calculated and a decision was made.

In the next scenario a more political issue was investigated. In one area several storage locations belonging to different divisions of the business were located only a few kilometers apart from each other. Technically there were no restrictions for joint storing of material used by different divisions. Together with the leaders from the affected divisions a new local warehouse structure was designed for this area. The special requirements of the divisions were collected and different possible locations for a central warehouse used by all divisions were chosen by an evaluation done outside the APS tool. In a simulation run, these different locations were brought into the model and the optimizer was let to choose the best solution according to transportation costs. With the outside evaluation and the cost calculation from the APS tool, a robust business case could be presented to the business managers. For a special location, mainly delivering to end-customers not to the network, the transportation structure and customer structure was extracted from the baseline model to perform a tender for transportation services. With the tender data given from the APS tool the transportation companies returned a new cost function for the deliveries to the end-customers. The tool was used to compare the related transportation costs by taking the received cost function into account.

Even if some scenario to be implemented needs no additional data compared to the baseline model, a few optimization runs have to be executed in order to detect possible data errors that might falsify the result of the simulation (e.g. a cost function with zero cost on a specific transport relation). Before presenting the results from a scenario run, a rough-cut plausibility check should be done. Otherwise, small errors in the input data may lead to wrong conclusions, which then might foil the credibility of the whole baseline model and APS-based simulation.

6 Results and Lessons Learned

Due to the existence of five SAP ERP-systems in the European country organizations, the implementation of PRODISI provided for the first time a transparent, consolidated view on the demand fulfilment structures, the transportation links and operations, and the stock situation. This improved transparency enabled the newly formed cross-European supply chain organization to improve the network structure, to reduce inventories, while keeping a good service level. In particular, the following benefits were created:

-

Reduced transportation costs for the fulfilment of customer orders by switching to a distribution center that is more closely located to the delivery site

-

Avoidance of costs for the required renovation of a distribution center by moving products to another distribution center at the same operating and transportation cost structure

-

Reduced fixed costs of four distribution centers in a region and reduce the transportation and delivery costs by calculating the optimal location for a new distribution center and closing the four old distribution centers.

To optimize a complex baseline model by pressing the overall “optimization button” makes no sense, because the results depend heavily on accurate data and cannot be interpreted by the planners in a big model. Even if it is the best solution, no acceptance of this result can be achieved, because there is still a resistance to use advanced optimization algorithms and somehow believe in the results of the sometimes called “black box”. Because of these reasons it is recommended to design small alternative scenarios where it is possible to control the correct data input and avoid data errors. In small scenarios it is partially possible—even in big models—to understand the results of an optimizer. The acceptance of the user is higher and the benefits are still very high and near to an overall optimal solution.

The most important topic is the collection of the correct basic input data and the cost information. The greatest effort for this project was spent to cross-check the collected data, filter it and harmonize the different country-specific data sets, in order to build one common European model. Therefore not only in the implementation of more tactical and operational APS systems, the quality of data input is determining the quality of the results.

Notes

- 1.

Note that there were five individual ERP-systems for the European country organizations, as mentioned already in Sect. 19.1.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Häberle, J., Kilger, C. (2015). Strategic Network Design in the Chemical Industry. In: Stadtler, H., Kilger, C., Meyr, H. (eds) Supply Chain Management and Advanced Planning. Springer Texts in Business and Economics. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-55309-7_19

Download citation

DOI: https://doi.org/10.1007/978-3-642-55309-7_19

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-55308-0

Online ISBN: 978-3-642-55309-7

eBook Packages: Business and EconomicsBusiness and Management (R0)