Abstract

This chapter will introduce the APS used in the case studies from AspenTech, JDA, OM Partners, Oracle and SAP: aspenONE, JDA Manufacturing Planning Suite, OM Plus, Value Chain Planning and SAP Advanced Planner and Optimizer (APO). As these tools regularly consist of a multitude of software modules and special add-ons, only a brief survey without claiming completeness can be given. Furthermore, different lines of business can use different modules of an APS. It is also possible to use an APS only partially, e.g. without modules for scheduling or only using modules for demand planning and demand fulfillment. For each individual case the composition of modules has to be evaluated and selected (see Chap. 16).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

This chapter will introduce the APS used in the case studies from AspenTech, JDA, OM Partners, Oracle and SAP: aspenONE, JDA Manufacturing Planning Suite, OM Plus, Value Chain Planning and SAP Advanced Planner and Optimizer (APO). As these tools regularly consist of a multitude of software modules and special add-ons, only a brief survey without claiming completeness can be given. Furthermore, different lines of business can use different modules of an APS. It is also possible to use an APS only partially, e.g. without modules for scheduling or only using modules for demand planning and demand fulfillment. For each individual case the composition of modules has to be evaluated and selected (see Chap. 16).

1 AspenTech: AspenONE

AspenTech was founded in 1981 with the objective of commercializing technology that was developed as part of the Advanced System for Process Engineering (ASPEN) Project at the Massachusetts Institute of Technology. Headquartered in Burlington, Massachusetts, AspenTech is one of the leading providers of software for process industries. Its focus has been on applying process engineering know-how to modeling the manufacturing and supply chain processes that characterize the process industries. In 1994, the company went public and in the years afterwards it grew mainly through acquisitions of small companies like Chesapeake Decision Sciences Inc. Due to this acquisition strategy AspenTech incorporated technologies in the four areas engineering, process simulation, plant operations and supply chain management. Today AspenTech offers integrated solutions for chemical, pharmaceutical, petroleum, oil and gas, and engineering and construction companies which are all sold under the name aspenONE. AspenONE provides a single platform that integrates AspenTech’s core products, one of them being Aspen PIMS for planning and scheduling in the process industries, especially in petroleum (and oil and gas) industries.

1.1 AspenTech’s Software Modules

AspenTech offers distinct supply chain software suites for several industries, distributed as aspenONE packages. Each of these packages consists of various modules especially suited to its industry. With respect to the case study of Chap. 24 in the following we will mainly focus on the aspenONE solution for the petroleum industry (see also Fig. 18.1).

- Strategic Planning :

-

provides the tools necessary to assess the economic and operational impacts of long-term strategic plans for multiple scenarios. It is used to evaluate the impacts of new markets and new government regulations, as well as the effects of modifying physical assets and downstream networks. This assessment can include adding or removing terminals, tanks and transportation modes, developing financial budgets and operations models, and performing capital investment analysis.

- Collaborative Demand Manager :

-

is a solution, applicable across all of the vertical industries served by Aspen Tech, offering the functions demand planning and collaborative forecasting. The resulting consensus demand plan is a primary input into downstream functions such as master planning. It supports history conditioning, forecast generation, reconciling forecasts with firm orders, reviewing forecast accuracy, reporting forecast error on different levels, creating an annual budget, and comparing versus year-to-date projections. The collaboration capability allows for marketing and sales data, customer data, and point-of-sale (POS) data to be incorporated into the demand plan via a web-based interface. Forecasts, sales history, budgets, and constrained forecasts can be aggregated to any brand, family, region, market or custom grouping required by the business. This module bases on statistical methods augmented with real-time collaborative data collected from the different stakeholders aiming at the increase of forecast accuracy. With the help of the coefficient of variation analysis it can be decided which customers require close cooperation and which customers’ demand can be forecast with statistical methods based on historical data to arrive at an accurate forecast. The statistical method to be used can be selected automatically by the tool relying on a best-fit analysis or manually by the user.

- Supply Chain Planner :

-

offers mid-term planning functionality for use of labor and equipment, raw materials or feed stocks, inbound/outbound transportation, storage capacity, and other constraints that may affect the decision of what to make, when, and in what quantity. Aspen Supply Chain Planner also provides web-based S&OP Analytics for company-wide reporting and access to data during the planning process. It is further enhanced by a scenario tool to make “what-if” analysis in case of, for instance, capacity or demand changes. Petroleum Supply Chain Planner includes a set of capabilities that are targeted specifically at the petroleum industry. It offers multi-plant operational planning, multi-plant blend optimization, inventory balancing of crude and intermediates, and capital investment analysis. It is built on Aspen PIMS (Process Industry Modeling System). Optimization techniques include non-linear and successive linear programming, non-linear recursion, mixed integer modeling and further heuristics. AspenTech integrates the CPLEX and XPRESS algorithms as solvers. Furthermore it offers simulator interfaces that link to process simulator models. Aspen PIMS is a scalable planning system that includes a set of capabilities that are targeted specifically for the petroleum industry. PIMS helps companies optimize feedstock selection, product slate, plant design, and operational execution. Originally, the single-plant, single-period base formulation of Aspen PIMS provides the foundation for other functionality. Aspen PPIMS allows the user to solve multi-period problems, with the help of periodic-specific data that is added to the base model. Aspen MPIMS is the global model that allows the user to link together a number of single-plant Aspen PIMS models to form a complex multi-source, multi-plant, multi-market supply/demand/distribution network. Aspen XPIMS solves multi-plant and multi-location models with interplant transfer, distribution to market demands, and distribution of feeds to plants. MPIMS and PPIMS are prerequisites to XPIMS.

PIMS Platinum leverages the data from traditional PIMS and enhances it with a new layered application to visualize the output. It facilitates profitable refining decisions through customizable layouts and 2D and 3D charts. Customized reports can be saved to reveal only the data pertinent to the planner so that more time can be spent running scenarios and analyzing results. These reporting views can also be saved and easily shared among key stakeholders. Aspen PIMS-AO (Advanced Optimization) adds capabilities for performing extended non-linear programming, solution ranging, and global optimization. It lets users optimize a combination of several objectives by setting primary, secondary, and tertiary goals for a solution. For example, Aspen PIMS-AO can be set up to provide a balance between the economic objective while maximizing total crude unit throughput and minimizing the purchase of a particularly risky imported crude. It identifies the optimum solution while providing sufficient detail on secondary and tertiary objectives. Aspen PIMS-AO reveals local optima and the highest value global solution. It also provides a convenient way to automatically vary selected feedstock purchase costs or product sales prices and monitor the development of the solution as these variables change.

- Plant Scheduler :

-

is the basic module of the Aspen Plant Scheduler family which is a three-tiered scheduling solution to address the varying degrees of scheduling complexity. Plant Scheduler provides basic finite capacity production scheduling. The schedule is readily viewed and manipulated via an interactive Gantt chart called the Planning Board. Based on a simulation engine, drag-and-drop manual schedule modifications are accompanied by inventory projections and exception reporting to assist the scheduler in visualizing the impact of changes. Plant Scheduler-EA (Extended Automation) generates detailed plant production plans using advanced heuristics and further solvers, creating an optimal short-term schedule of operations. While minimizing changeover, production and inventory costs, Aspen Plant Scheduler-EA determines the precise timing and sequence of production activities throughout the plant. It works in finite capacity in order to generate production plans that are feasible from both a capacity and material flow perspective. Plant Scheduler-EO (Extended Optimization) layers on top of Plant Scheduler-EA, optimizes specific aspects of a schedule such as blend recipes or tank selection and considers routing and batch sizes. Aspen Petroleum Scheduler formerly known as Aspen Orion is a petroleum-specific scheduling module which provides event-based coordinated scheduling and enables generation of optimal recipes for individual blends on an event-driven time period basis. For optimized blending, it integrates with Aspen Refinery Multi-Blend Optimizer.

- Primary Distribution Planning for Petroleum :

-

generates distribution plans, optimizes multi-commodity and multi-period transport of several modes of distribution, and analyzes economics of the buy versus make trade off and export/import alternatives.

- Distribution Scheduler :

-

plans replenishments while minimizing transport and handling cost. It creates distribution schedules for bulk shipping (focusing on mode selection and sourcing as e.g. necessary in chemical companies) and for packaged goods shipping (focusing on load consolidation as e.g. necessary in CPG companies).

- Inventory Manager :

-

allows process manufacturers to calculate inventory levels and targets of safety and cycle stocks in complex distribution networks. It calculates target minimum and maximum inventory levels.

- ATP/CTP/PTP :

-

Available-To-Promise, Capable-To-Promise, and Profitable-To-Promise refer to the ability to commit and fulfill customer requests for product delivery quickly and reliably. ATP evaluates whether there is inventory available for the customer order or when inventory will be available, given the current production schedules. CTP is an extension to this capability, where the model attempts to reschedule production in order to fulfill the order. PTP takes this to another level where the profitability of taking the order is determined. Aspen Capable-To-Promise links Order Fulfillment systems directly to scheduling and/or planning applications. Orders can be promised to customers interactively based on existing inventory, already-planned production, available but not yet scheduled capacity, or any combination of these sources.

1.2 Coordination of Modules

AspenTech’s APS modules are built on a relational database model which allows the relevant data to be shared across several modules without unnecessary duplication. This database also transforms and manages the master and transactional data from ERP systems or other legacy plant systems required to maintain a timely and accurate representation of business and manufacturing functions.

2 JDA: Manufacturing Planning Suite

JDA, based in Scottsdale, Arizona, with European branch offices offers a broad range of supply chain, retail merchandising, store operations and all-channel commerce solutions through the cloud to synchronize and optimize the management of the flow of goods from raw materials to finished products and into the hands of consumers.

JDA was established in 1978, when it offered its first software solutions for the Retail-Industry. Over time JDA developed and acquired solutions in the area of merchandize planning, allocation planning, planograms and replenishment planning. Starting with the acquisition of Manugistics in 2006 and continuing with the acquisition of i2 Technologies in 2010, JDA complemented its portfolio with solutions for Strategic Network Planning, Demand Planning, Supply Chain Planning (Master Planning), Factory Planning and Scheduling, Inventory Optimization, Order Promising, and Transportation Planning. Through the merger with Redprairie in late 2012 JDA created an integrated Supply Chain offering connecting retail with manufacturing and supply chain planning with supply chain execution. JDA now offers five major solution suites: Distribution Centric Supply Chain, Retail Planning, Collaborative Category Management, Manufacturing Planning, and Store Operations.

In the following we concentrate on the Manufacturing Planning Suite which mainly, but not exclusively, consists of the former APS modules from Manugistics and i2 Technologies. These modules were united in one platform. Planning functions that were covered by Manugistics and by i2 modules were added just once to JDA Manufacturing Planning Suite, by selecting the better suited of the corresponding Manugistics and i2 modules. All modules of the planning suite are now accessible via one user interface. The planning suite also provides cloud-based services.

2.1 Modules of the JDA Manufacturing Planning Suite

In the following, we describe the core Manufacturing Planning Suite modules in more detail and link them to the according business processes of the SCM Matrix (see Fig. 18.2). Further, we give an overview of additional JDA supply chain solutions. The JDA Manufacturing Planning Suite components are complemented by a set of services ranging from strategic consulting, implementation consulting and education services. The solution is delivered through the cloud with services for rapid project launches, high performance application management services as well as value added services to constantly adapt the customers’ solutions to changing business environments.

- Supply Chain Strategist (SCS) :

-

supports strategic what-if-analysis across the entire supply chain. The optimal combination and location of production sites, distribution centers and other entities is determined. Material flows with all related costs as well as constraints can be modeled in different scenarios.

- Sales & Operations Planning (S&OP) :

-

supports the S&OP process by profitable synchronization of demand and supply, identification and quantification of opportunities and risks, through conduction of what-if scenario analysis and by tying tactical plans to strategic objectives. Effectively sitting “on top” of the mid-term planning solutions of the Manufacturing Planning Suite it is integrated to the “below” optimization solutions in order to enable fast data reconciliation. This enables executive reviews and informed decision making supported by comprehensive S&OP process orchestration. Key enablers are extensive rapid impact analysis tools as well as interactive rough cut capacity planning combined with qualitative data analysis and issue tracking. There exists an Oliver Wight Class A Management best practice template for S&OP. The S&OP module relies on in-memory cube technology.

- Demand :

-

supports the forecasting process through statistical methods, inclusion of causal factors and management of multiple inputs from different organizational units. For the selection of the best suited statistical method for the forecasting object (e.g. a product, SKU, product group, etc.) JDA offers a method called Demand Classification which suggests the appropriate algorithm based on an analysis of the object’s history and auto-configures it on object level to improve forecast accuracy. POS (point of sales) data can be integrated and different views on demand data can be offered. Furthermore, in-memory cube tools enable efficient access to relevant data. Forecast data can be aggregated and allocated across sales hierarchies, product hierarchies and time, or can be segmented into further definable hierarchies, e.g. manufacturing locations, packaging types or financial measures. Attach-rate forecasting supports the creation of dependent forecasts. Dependent forecasts are used for example in the consumer packaged goods industry or consumer electronics industry to derive a forecast for individual finished goods (e.g. digital camera and memory card) from a forecast for a bundle of finished goods (e.g. camera plus memory card that is bundled for marketing purposes). This functionality is also used in industries like the high-tech industry where a forecast on component level is derived from the forecast on finished goods level to drive purchasing decisions (see Chap. 23).

- Inventory Optimization (IO) :

-

provides micro-segmentation capabilities to drive differentiated inventory strategies combined with a multi-echelon inventory optimization engine based on the mathematical convolution of the functions describing the demand and supply variability. Three main workflows are supported: strategic inventory target setting, e.g. on an annual or quarterly basis, tactical review of the targets including auto-approve, auto-reject and manual approval of target changes based on definable thresholds and thirdly short term root-cause analysis to prevent impeding stock-outs or to do an analysis in the retrospective.

- Enterprise Supply Planner (ESP) :

-

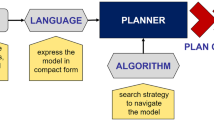

enables modeling and optimizing supply chains with respect to material, capacity, transportation and customer-service constraints. The ESP Supply Planning module generates optimized, feasible plans across several factories and independent ERP systems. The Strategy Driven Planning allows planners to define types of problems and strategies to solve them. Furthermore, it is possible to apply appropriate solvers like Linear Programming, heuristics and genetic algorithms. The module provides overall visibility over the supply chain model and the generated plan including a variety of predefined reports in order to analyze the plan and compare multiple planning scenarios to each other. The main plan generation engines are complemented with an ad-hoc scenario-engine called Pro-Agile in order to support user-driven short term plan adaptation and decision support through rapid scenario creation. The ESP Deployment module enables optimized decisions to assign supply to demand on a short-term level.

- Factory Planner (FP) :

-

provides detailed visibility over the production plan and helps to reduce manufacturing cycle times. It generates optimized production plans by scheduling backward from the requested date, as well as scheduling forward from current date while considering material and capacity constraints simultaneously. After a first infinite planning step where demand and supply is matched, a finite capacity plan can be determined by JDA’s proprietary Constraint Anchored Optimization. However, the planner can manually interact by analyzing capacity shortages and performing what-if-analysis. In the last planning step a detailed schedule can be generated for the factory.

- Sequencing :

-

supports manufacturing environments requiring detailed scheduling and sequencing. It builds detailed sequences and schedules based on different algorithms suited for different industry sectors recognizing the differences between process and discrete manufacturing. The flexible definition of constraints and the selection and parameterization of an appropriate optimization algorithm allows the handling of a large number of complex constraints and generation of optimized schedules. For application in process industry scenarios, complex change-over matrices might be setup and used for computation of a schedule. Constraints include shop floor capacities, workload balancing, material availability, etc. Additionally, an interactive schedule editor allows for manual changes.

- Order Promiser (OP) :

-

provides functionality to assign short supply to customers and to quote feasible delivery dates for customer orders. Allocation of supply (ATP, Available-to-Promise, and A-ATP, Allocated ATP) can be based on current and projected inventory positions or available capacities (CTP, Capable-to-Promise, and A-CTP, Allocated CTP). It respects customer priorities modeled in a sales hierarchy (e.g. global pool of available supply versus restricted supply for important customers only), fair share and profitability based strategies with the assignment of supply to particular customers. Orders are promised in real-time based on the current and projected status of inventories and capacities in the supply chain network. It typically is integrated to existing order management systems and respects all supply and its allocations. For SAP ERP environments JDA provides a standard integration package to connect SAP SD with JDA Order Promiser in real-time.

2.2 Coordination of JDA Planning Modules

The planning workflows using the modules of the JDA Manufacturing Planning Suite described above are coordinated by the JDA Platform . JDA Platform provides a common user interface for all modules embedded in a Web-User Interface and a pre-packaged application integration.

JDA Platform is an open and service based architecture that incorporates several modules for data integration (see below), managing data, for establishing workflows across systems and for measuring and comparing performance indicators through reporting capabilities spanning the entire supply chain. JDA Platform includes the SCPO data warehouse (Supply Chain Planning and Optimization) which incorporates all data relevant for planning in an integrated data model. Data integration is based on the SCPO data model between the JDA planning modules (e.g. Enterprise Supply Planning, Factory Planning, Demand, etc.), and towards external systems. The functionality can be exposed both as an API and a service. A new forecast, for example, that is created using JDA Demand, can be automatically transferred via the Platform to JDA ESP as input to the master planning process. Supported by a design environment, the JDA Platform Studio, logic across applications and detailed workflows can be adapted to changes in business processes.

JDA Platform Reporting provides reports and dashboards to create individual reports of key performance indicators of the supply chain, to compare multiple plans and simulations and to alert users to potential problems so they can be resolved proactively.

2.3 System Integration

The data integration between the JDA planning modules internally and to external systems like an ERP-system is achieved by JDA Platform Services, which support existing Enterprise Application Integration (EAI) software such as

-

Webmethods for message-based integration and Extract-Transfer-Load (ETL) concepts

-

Informatica for mass data transfer.

JDA Platform uses services of multiple JDA modules and integrated external systems to define workflows and logic across these applications. Based on a common data model for the workflows it connects business relevant services and enables a synchronization of the underlying systems.

JDA Platform also supports Supply Chain Master Data Management (MDM) through a process-oriented data management tool that enables enterprises to create a common business vocabulary for all their data but also manages business rules, like the relationship of an order to its shipping details. It also manages data synchronization processes between applications—if data changes in one application, it will synchronize the impact of that change with all affected applications.

2.4 Collaboration Modules

Collaborative planning with suppliers is supported by the Collaborative Supply Execution (CSE) module. CSE is a system that helps companies bring together all their supplier interactions related to direct material procurement irrespective of the size, process or technological sophistication of the suppliers. It enables the company and its supply partners to collaborate on supply plans, purchase orders/schedules, inventory, shipments, receipts and invoices, which allows for the company to manage the entire order lifecycle for orders with different business processes including managing lean processes like VMI, JIT, Kanban, etc., by connecting order execution with shipment visibility. The Demand module of JDA supports collaborative planning with customers.

2.5 Overview of Further JDA Supply Chain Suites

- Distribution Centric Supply Chain Suite (DCS) :

-

provides single enterprise-wide demand shaping and forecasting to optimize both planning and execution decisions. It enables proactive constraint-aware planning to minimize rework and deliver profitable decisions while streamlining execution. DCS features intelligent Order Lifecycle Management to orchestrate flexible and profitable order fulfillment decisions and maximize pallet and load building results through dynamic wave planning, robust containerization and iterative task optimization that considers warehouse inventory availability, assets, and labor and transportation constraints. The DCS solution suite combines JDA Demand’s demand planning and JDA’s Fulfillment’s distribution planning capability with the execution capabilities of JDA Warehouse Management (WMS), Transportation Management (TMS) and Workforce Management (WFM).

- Retail Planning Suite (RP) :

-

is a merchandise planning and assortment management solution enabling retailers and wholesalers to establish financial, merchandise and localization strategies driving consumer centric, inventory and item lifecycle plans. It has embedded retail optimization and analytics to provide consumer demand insights driving strategies and assortment recommendations. Based on visual planning it provides plan evaluation, performance insights and consumer offer validation and enables end-to-end financial merchandise planning, space-aware assortment and micro and macro space management.

- Collaborative Category Management Suite (CCM) :

-

provides an end-to-end solution allowing manufacturers to collaborate with retailers to automate localized assortment and space plans, and monitor plans at the shelf. The suite combines many of the JDA Retail capabilities around space planning, floor planning and space automation to make them available for manufacturers. Complemented with the demand classification, forecasting and collaboration capabilities this suite is intended for joint category management between manufacturers and retailers. It includes cloud collaboration capabilities and space-based insights to monitor execution results, leading to deeper analytics and driving proactive recommendations.

- Store Operations Suite (SO) :

-

is designed to maximize the retail supply chain organization’s operation and workforce utilization through optimization, integration and mobility that delivers higher profitability, better customer service, improved compliance, enhanced goal adherence or lowered operating cost. The SO suite uses JDA’s workforce management capabilities. It supports a single view on the global retail supply chain. SO integrates planning across different stages and enables the simultaneous planning of work and tasks, e.g. in store pricing.

3 OM Partners: OMP Plus Suite

OM Partners, headquartered in Wommelgem Belgium, was founded in 1985. Initially developing mathematical programming software, the company gradually extended to provide a complete suite of supply chain planning software called OMP Plus. Unlike competition, the company grew organically in the past 28 years, with a strong foothold in the Mill Products (paper, metals, plastics and floor coverings) and Semi Process industries (chemicals, food and beverages, consumer products). OM Partners followed the internationalization of its customers and has now offices in the USA, China, United Arab Emirates and several key European countries.

3.1 OMP Plus Modules

Initially developed as stand-alone applications, OM Partners has now integrated all modules into the OMP Plus suite. An overview of all modules is provided in Fig. 18.3.

- Supply Chain Network Design :

-

manages different strategic supply chain questions and provides optimization functionalities to solve these. It uses a standard discounted cash flow optimization model that can be customized. OMP Plus enables scenario management and has extended reporting and visualization capabilities, leveraging the functionality of the whole OMP Plus suite.

- Inventory and Portfolio Optimization :

-

builds on the Strategic Supply Chain Network Design functionality to determine target safety stock levels. Based on the optimization results, the module runs a multi-echelon simulation model that will calculate safety stocks for every product at every level of the supply chain. Forecast accuracy metrics can be sourced from the Forecasting module directly and the results can be populated directly to the Master Planning module.

- Forecasting :

-

in OMP Plus provides a flexible modeling of demand information and advanced statistical methods to derive forecasts and measure forecast accuracy. Built in artificial intelligence functionality identifies exceptional sales patterns and helps choose the most adequate forecast aggregation/disaggregation strategy. The forecasts are populated automatically to all other modules.

- Sales and Operations Planning (S&OP) :

-

balances demand with supply within a tactical horizon. OMP Plus’ S&OP functionality uses data from the operational plan as input (firmed production plan, current inventories). The Sales and Operations Plan can be run at an aggregated level as well as at a detailed level. In case of a run at an aggregated level, the S&OP target volumes will be automatically populated to the Supply, Manufacturing and DRP planning module as guidelines. OMP Plus allows planners to use optimization techniques to run a value-based S&OP (contribution maximization or cost minimization).

- Supply, Manufacturing, DRP and Transport Planning/Scheduling :

-

encompasses decisions on supply planning, master production scheduling and distribution planning. It mostly operates using daily planning buckets, receiving planning data from the S&OP module, the forecasting module as well as the inventory optimization module. Planning results are fed back to the ERP system using standard interfaces (see next section and Chap. 26 for a practical application). In the past 25 years, OMP has developed a various range of optimization models and custom heuristics (solvers) for discrete and process industry applications. One of OMP Plus’ strengths is the ability to run solvers interactively, provide a good visualization of the results and let the planner the freedom to take over only a part of the solver’s results.

- Order Management, Allocation and Promising :

-

is also covered in OMP Plus. Two main functionalities are available. On the one hand, it allocates orders to forecasts automatically based on user-defined logic. On the other hand, OMP Plus provides advanced functionality to allocate orders to supply using business rules, allowing accurate promise dates based on Available-to-Promise (ATP), Capable-to-Promise (CTP) or mixed ATP/CTP logics. The benefits of business rules are that it allows the planner to automate part of the allocation work while taking into account very specific constraints without “hard-coding” them. The allocation plan is visible within the whole OMP Plus suite, providing real-time visibility on product availability.

3.2 Coordination and Integration Modules

Due to the consolidation of all modules in the OMP Plus suite, all modules now use the same data model and are accessed using the same application. A user can be modifying forecasts next to scheduling production and adjusting S&OP forecast within the same session. Consistency of planning can be ensured using a hierarchical planning products structure. Thanks to the in-memory functionality of OMP Plus, changes by a planner can be immediately seen by another planner.

- OMP Integrator :

-

makes it possible to link OMP Plus with ERP systems such as SAP or Oracle. This link can be file- or message-based (e.g. iDocs for SAP ERP). OMP Integrator also provides standard integration with SAP using the POIM/POIT interface and OMP’s own SAI modules.

- OMP Data Manager :

-

provides a standard interface to maintain OMP Plus data without going into the SQL database itself.

- OMP Feedback Manager :

-

provides functionality to link non-ERP systems such as quality or shop-floor systems with the OMP Plus Suite.

- OMP Reporter :

-

includes embedded versions of SAP Crystal Reports®; and MapInfo®;. This allows users to create their own visualization of planning data and results.

3.3 Collaboration Modules

OMP provides a web-based functionality to enter and share forecasts via a portal (intra- or extranet). The same applies for all planning results within the OMP Plus suite using Crystal Reports.

4 Oracle: Value Chain Planning

Oracle, founded in 1977 and headquartered in Redwood Shores, California, started as a specialist for relational database software, but has in the meantime extended its portfolio to a broad range of software packages on business intelligence, business applications, collaboration, and middleware. In 2005, Oracle took over Peoplesoft, a software company traditionally offering ERP software for non-productive and manufacturing industries, which again had acquired J.D.Edwards, a Denver-based provider of ERP and Advanced Planning software for medium-sized companies, in 2003. Due to these acquisitions and the later acquisition of Demantra—a specialist for demand management, sales & operations planning and trade promotion management—in 2006, Oracle had a broad choice to streamline its advanced planning solution Oracle Value Chain Planning (VCP) as part of its more comprehensive Supply Chain Management suite (see e.g. Oracle 2014).

4.1 Oracle’s APS Modules

In the following, selected APS software modules of Oracle’s Value Chain Planning are briefly introduced. An overview of the most important ones is given in Fig. 18.4.

- Strategic Network Optimization (SNO) :

-

is intended to be applied on the strategic planning level. Optimization methods of Linear and Mixed Integer Programming (CPLEX; see IBM ILOG CPLEX Optimizer 2014) and special purpose heuristics (e.g. for capital asset management and single sourcing) support the choice of appropriate supply chain structures. The most striking feature of SNO is its visualization. Even complex supply chains can be “designed” graphically without any knowledge of mathematical modeling being necessary. The case study of Chap. 21 will show that SNO is not restricted to strategic planning, but can also be used for Master Planning.

- Advanced Supply Chain Planning (ASCP) :

-

is Oracle’s actual tool for mid-term Master Planning and Production Planning in multi-site supply chains. It offers three different types of algorithms, namely unconstrained, constrained and optimization-based planning. The unconstrained one bases on principles of Distribution Requirements Planning (DRP) and Materials Requirements Planning (MRP). The constrained one also applies priority rules in a successive manner, but at least tries to respect limited capacities and given delivery dates. If this is not successful due to the algorithm’s heuristic nature, violations of constraints are explicitly revealed to the user. Optimization-based planning uses LP and MIP methods to minimize costs or maximize profits while simultaneously taking into account all relevant supply chain constraints. ASCP also comprises a simple scheduling tool in order to quickly build rough schedules for a short-term horizon or to simulate the effects of mid-term planning on short-term scheduling.

As a fast and interactive, alternative tool for mid- and short-term planning, also Rapid Planning can be used.

- Demand Management(DM) :

-

is a module that originates from Oracle’s acquisition of Demantra in 2006. It uses a mixed-model Bayesian approach to forecast multi-dimensional data hierarchies. Mixed-model means that causal forecasting is applied (see Chap. 7) and that several possibly fitting causal models are weighted with probabilities in order to get an overall forecast. Even though causal factors like seasonality, prices and promotions can already be respected by DM, in consumer goods industries DM can be supplemented by Trade Promotion Management (TPM) , which is further specialized on analyzing and predicting the effects of trade promotions. In order to hedge against forecast errors, the software module Inventory Optimization can be applied. It proposes safety stock levels for multi-echelon supply chains.

- Production Scheduling (PS) :

-

is concerned with short-term production planning and detailed scheduling. Its original version was mainly dedicated to multi-stage production processes with floating bottlenecks and complex BOMs, which can frequently be found in discrete parts’ production.

However, during the last versions a number of further functionalities have been added to PS in order to extend its footprint also to process industries (thus being able to handle planning tasks that in former times had been in charge of a module called Production Scheduling Process). For example, Campaign Run Optimization heuristically tackles lotsizing and scheduling problems by letting the user define preferences for building lot sequences (e.g., with respect to changeover costs or changeover times) and by solving continuous Linear Programs as sub-problems to determine appropriate lot sizes and inventories.

- Global Order Promising (GOP) :

-

Based on a capacitated ASCP run, GOP allows to define ATP and CTP for multi-stage supply chains and BOMs. Allocation and consumption rules—including “stealing” or “nesting”, as they are successful in yield management systems of service industries like the airline industry—can be defined to prioritize customer groups of higher importance. Besides ATP and CTP checks, GOP provides also “Profitable To Promise”(PTP) functionality, i.e. different fulfillment options can be assessed by their profit margin. As a new feature, GOP now also allows to extend ATP and CTP checks to a company’s immediate suppliers.

Advanced Procurement and Transportation Management (OTM) are not part of Oracle VCP in a strong sense. They originally stem from Oracle’s Enterprise Resource Planning and Value Chain Execution solutions. They are mentioned here to emphasize that there are further software modules of Oracle’s Supply Chain Management suite, which do offer some planning functionality and thus supplement Oracle VCP.

4.2 Coordination of Modules

The VCP software modules do not directly communicate with each other. Instead, the horizontal and vertical information exchange between the different software modules of Oracle VCP is established via a common data base, the so-called Planning Data Store . All VCP modules read their planning data from and write their planning results to this data base. Data are always stored in the highest level of detail necessary. Thus, aggregation and disaggregation rules have to be defined if modules like DM, SNO, ASCP or PS need to work on different levels of aggregation. For example, if DM and ASCP work with products groups and months, but PS with final items and days, the latter one would define the storage detail. Then, a transfer of forecasts from DM to ASCP would necessitate a disaggregation followed by an aggregation, even though both of them actually work on the same level of aggregation. Nevertheless, the user is not bothered because data transformation happens in the background.

Data exchange and information flows can be automated using the Advanced Planning Command Center (APCC) and the Business Process Execution Language (BPEL) . The APCC is a central planning cockpit that allows access to the above software modules of VCP, manages planning scenarios (e.g., S&OP; see below), and consolidates the manifold KPIs, which result from the planning modules, to compact business reports. Because of this latter functionality it serves as a business intelligence layer for the planning software. While BPEL builds the technical basis do develop user-defined workflows, APCC helps to administrate and concert these different workflows.

4.3 System Integration

BPEL is part of the Oracle Fusion Middleware (FMW) , which is not only responsible for the “internal” information exchange between the different software modules of Oracle VCP, but also connects Oracle VCP with “external” software suites like, for example, Enterprise Resource Planning or Customer Relationship Management software. FMW consists of several software suites addressing, for example, service-oriented architectures, business process management and data integration. These again contain many software modules like the Oracle BPEL Process Manager (providing BPEL) or the Oracle Data Integrator (allowing to extract, transform and load data concerning the Planning Data Store). These can be used to build flexible adapters, e.g., connecting to Oracle’s inhouse ERP software Oracle Peoplesoft Enterprise One , but also to third party applications or applications in the cloud.

4.4 Collaboration Modules

DM already offers a basic functionality for web-based collaboration between a company’s internal (e.g., its various purchasing, production, and sales departments) and external (e.g., suppliers and customers) supply chain partners.

This can further be enhanced by Demantra Real-Time Sales and Operations Planning (S&OP) , which is specialized on consolidating information of several functional departments like finance, sales, marketing, logistics and production in real-time. For example, it can be used to obtain a consensus forecast of the various internal members of a company’s sales hierarchy. But external supply chain members can be integrated in this process, too, e.g., when point-of-sales data of retailers are collected to improve the forecasts of a consumer goods manufacturer in a CPFR-like collaboration process (see Chap. 14).

However, S&OP can also help to agree on a mid-term master plan by offering a common interface and pre-defined workflows for a comfortable interplay between sales-related VCP modules like DM or TPM and operations-related modules like SNO or ASCP, supporting several planning rounds. For instance, a scenario could look like this: TPM forecasts the effects of a price discount on demand. Both price and demand forecasts are sent to ASCP in order to check whether supply chain capacity is sufficient or capacity enhancements like overtime would still be profitable to fulfill the increased demand. If not, TPM would again forecast the effects of a decreased discount, etc. Typically, S&OP is executed in fixed frequencies, for example, once per month. “Real-time” means in this context that S&OP permanently compares the mid-term S&OP master plan with actual data in order to generate alerts if serious deviations occur.

The Collaborative Planning module of VCP supports external collaboration by posting demand forecasts and replenishment information across the whole supply chain and by supporting Vendor Managed Inventory processes from both the vendors’ and the customers’ points of view. Note that further collaboration functionalities can be found in other modules of the Oracle system. For example, APCC can allow access also to external supply chain partners.

5 SAP: SCM and SAP APO

SAP AG (Walldorf/Germany) has been active in the APS market since 1998. The Advanced Planner and Optimizer (APO) was originally intended and sold as an independent software suite. Until 2007 it was part of the mySAP suite and it is now sold as SAP Supply Chain Management supplemented with different solutions/systems like Extended Warehouse Management (EWM), Transportation Management or Supply Network Collaboration (SNC).

The technology for this applications is based on SAP Netweaver, which provides an application and integration platform for all SAP applications. Netweaver hosts several components and the Business Intelligence including the Business Information Warehouse (SAP’s Data Warehouse ).

In 2010 SAP introduced SAP HANA , an in-memory database technology to reduce the access times and enable near real-time access to business data. The first applications were in the area of business intelligence and analytics. Starting from 2013 all SAP SCM solutions are enabled to access and store their data in HANA.

This section will provide an overview of selected APO components. For more information, see the current SCM documentations (e.g. SAP 2014 and Dickersbach 2009).

5.1 SAP’s Software Components

APO is a fully integrated APS. All APO components can be accessed through the Supply Chain Cockpit and have an identical look-and-feel. The paragraphs below give a brief description of the individual APO components illustrated in Fig. 18.5 based on SCM 7.0.

- Demand Planning :

-

offers—in addition to conventional statistical methods—promotion planning tools, life cycle concepts, what-if-analysis, phase-in planning for new product initiation and collaborative forecasting methods. Reports on forecast accuracy can be generated and alerts can be raised. Furthermore, this component provides OLAP tools for Data Warehouse integration. It provides a functionality called characteristics-based-forecasting having special aggregation and disaggregation procedures for components of configurable products and material availability constraints.

- Supply Network Planning :

-

serves planning and optimization functionality that take into consideration capacity and material availability constraints and costs. Optimization is based on automatically generated Linear and Mixed Integer Programming models (see Chap. 30) which use IBM ILOG CPLEX (see IBM ILOG CPLEX Optimizer 2014) as a solver. Decomposition rules regarding time, resources and products can be applied to speed up the solution process. Additionally, proprietary heuristic approaches are used, such as Capable-to-Match (CTM), a rule based approach. Simulations of different supply chain configurations as well as matching of supply and demand with respect to alternative production sites, substitution of products, prioritizing customers, shelf-life etc. are supported. Alerts can be raised in case of late deliveries and violation of bottleneck capacities. Supply Network Planning contains the components Deployment, Safety Stock Planning and Transport Load Builder (see below). Supply Network Planning provides functionality to manage different planning scenarios, and thus, can be used for evaluation in strategic planning. An explanation tool for the optimizer communicates the reasons for a solution to the user (e.g. capacity constraints led to a stock out).

- Global ATP :

-

performs a rule based multi-level component and capacity check based on current data. It provides product substitution methods, alternative site selection for production and purchasing, and methods for allocating scarce products and components to customers, markets, orders etc.

- Production Planning and Detailed Scheduling (PP/DS) :

-

offers methods for optimizing detailed capacity and material planning simultaneously. It can perform multi-level forward and backward scheduling. Different constraints can be considered in simulations and interactive scheduling using gantt-charts is provided. Current, short-term data can be integrated into optimization runs. Production Planning and Detailed Scheduling uses proprietary evolutionary algorithms (see Chap. 31). These approaches can be combined with decomposition approaches regarding time and resources. An explanation protocol can be used to understand and analyze the solution.

- Deployment and Transport Load Builder (TLB) :

-

allocates actual supply (produced quantities and inventory) to planned supply. This allocation is controlled by push and pull strategies, predefined quotas and priority rules. For example, results from the Supply Network Planning optimization run can be used for defining such quotas. Inventory and allocation plans are displayed graphically. Transport Load Builder ensures that vehicles are loaded within a specified minimum and maximum range. Iterations are used to derive a feasible deployment plan respecting vehicle loads (see SAP 2014).

- Transportation Planning and Vehicle Scheduling (TP/VS) :

-

is a planning component for transportation processes. On the basis of shipment requirements optimal vehicle loadings and routings can be derived. A proprietary evolutionary algorithm (see Chap. 31) and additional heuristics supplement TP/VS’s solution process. TP/VS allows to model e.g. multi-pick, multi-drop scenarios, the inclusion of hubs, compatibilities and time windows.

5.2 Coordination and Integration of Software Components

APO offers a graphical user interface, the Supply Chain Cockpit , that gives an overview of the supply chain being modeled and from which all APO software components can be accessed. The Supply Chain Cockpit also provides the Supply Chain Engineer to graphically build a macro-model of the supply chain. This model can be shown in detailed views, and special information can be extracted for each entity. The Alert Monitor is also part of this component. APO planning components use a common database. To enable fast access for all software components this database is kept memory resident (the so-called liveCache ).

With the introduction of SAP HANA the Supply Chain InfoCenter was built to provide a unified user interface (UI) for analytics and operational reporting. The InfoCenter is placed as an alternative to reporting via BW and is integrated through HANA into the data from the ERP and APO. This enables the planner to process near real-time data and to gain an overview of supply chain metrics like demand, supply and stock information.

SAP Supply Chain Event Management provides automated collection and tracking of information such as order status, shipments and inventory using Internet and mobile technologies. In response to exception-based events activities in planning and execution system can automatically be triggered.

5.3 System Integration

APO provides two different options for integrating OLTP systems. The Core Interface (CIF) allows direct access to SAP ERP data objects and vice versa. Integration to non SAP systems is achieved through so-called Business Application Programming Interfaces (BAPIs). By using BAPIs the objects of APO can be accessed by a kind of programming language. Thus, it is possible to map, for example, ASCII-files to APO data objects. SAP also provides the Business Information Warehouse for storing historical data. APO is able to receive these data, which are particularly relevant for Demand Planning, using predefined queries and OLAP tools.

5.4 Software Components for Collaboration

SAP uses Internet and associated technologies, such as XML, to enable the collaboration between business partners. Using conventional Internet browsers APO can be accessed online. The SAP APO Collaborative Planning modules enable this collaboration. They support consensus based planning processes for collaboration on shared plans within demand planning, procurement planning etc. (e.g. Inventory Collaboration Hub, web-interfaces of Demand Planning). They further provide read-write data access as well as access to planning activities for authorized users using Internet browsers, user specific negotiation processes, user defined screens and workplaces, visualization of alerts, the connection to multiple systems, and links to partner systems.

References

Dickersbach, J. (2009). Supply chain management with SAP APO (3rd ed.). Berlin/New York: Springer.

IBM ILOG CPLEX Optimizer (2014). Homepage, http://www-03.ibm.com/software/products/de/ibmilogcpleoptistud/. Visited on Feb. 28, 2014.

Oracle (2014). Homepage, http://www.oracle.com. Visited on Feb. 28, 2014.

SAP (2014). SAP help portal, http://help.sap.com/. Visited on Feb. 28, 2014.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Lebreton, B., Meyr, H., Rosič, H., Seipl, C., Wetterauer, U. (2015). Architecture of Selected APS. In: Stadtler, H., Kilger, C., Meyr, H. (eds) Supply Chain Management and Advanced Planning. Springer Texts in Business and Economics. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-55309-7_18

Download citation

DOI: https://doi.org/10.1007/978-3-642-55309-7_18

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-55308-0

Online ISBN: 978-3-642-55309-7

eBook Packages: Business and EconomicsBusiness and Management (R0)