Abstract

Today the most important concern of the managers is to make their firms viable in the competitive trade world. Managers are looking effective tools for decision making in the complex business world. This paper addresses a hierarchical multi objective production-distribution planing problem under fuzzy random environment. A mathematical model is presented to describe the purpose problem. To deal the uncertain environment, the fuzzy random variables are first transformed into trapezoidal fuzzy numbers, and by using the expected value operation, the trapezoidal fuzzy numbers are subsequently defuzzified. For solving the multi-objective problem a weighted sum base genetic algorithm is applied. Finally, the result of a numerical example are presented to demonstrate the practical and efficiency of the optimized model.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Multi-objective optimization

- Fuzzy lead-time

- Fuzzy inventory cost parameters

- Inventory planing

- Interactive fuzzy decision making method

1 Introduction

A supply chain contains all activities that transform raw materials to final products and deliver them to the customers. Production-distribution (PD) planing is most important operational function in a supply chain. In today competitive environment, it is required to plan the products, manufactured and distribution, also need for higher efficiency, lower production cost and maximize the customer satisfaction. In general PD problems in supply chains, the decision maker attempts to achieve the following (a) set overall production levels for each product category for each source (manufacturers) to meet fluctuating or uncertain demand for various destinations (distributors) over the intermediate planning horizon, and (b) make right strategies regarding production, subcontracting, back-ordering, inventory and distribution levels, and thus determining appropriate resources to be used [1, 24]. Several methods and algorithms have been developed to solve various PD problems in certain environments [4, 5, 23].

In real-world PD problems, however, related environmental coefficients and parameters, including market demand, available labor levels and machine capacities, and cost/time coefficients, are often imprecise/fuzzy because of some information being incomplete or unobtainable. It is critical that the satisfying goal values should normally be uncertain as the cost coefficients and parameters are imprecise/fuzzy in practical PD problems [20, 24]. The practical PD problems generally have conflicting goals in term of the use of organizational resources, and these conflicting goals must be simultaneously optimized by the decision makers in the framework of imprecise aspiration levels [17, 18]. The conventional deterministic techniques cannot solve all integrating PD programming problems in uncertain environments. PD planning is a core issue influencing the producer, distributor and customer. The importance of PD planning has already been recognized [10, 23] and structure and different views of PD planning have been proposed in a great deal of research [2, 4, 15, 16, 21, 22].

The uncertainty in PD system is widely recognized because uncertainties exist in a variety of system components. As a result, the inherent complexity and stochastic uncertainty existing in real-world PD decision making have essentially placed them beyond conventional deterministic optimization methods. While, modeling a production distribution problem, production costs, purchasing, selling prices, transportation cost, delivery time and demand of products in the objectives and constraints are defined to be confirmed. However, it is seldom so in the real-life. For example, holding cost for an item is supposed to be dependent on the amount put in the storage. Similarly, set-up cost also depends upon the total quantity to be produced in a scheduling period, transportation cost depend upon the number of items delivered and scheduling the good network,delivery time also depend upon the production capacity and communication network. So, due to the specific requirements and local conditions, uncertainties may be associated with these variables and the above goals and parameters are normally vague and imprecise, i.e. fuzzy random variable in nature. However, from the previous study review, there appear to be few literature that deal with the uncertainty environment using both fuzziness and randomness in supply chain PD planning problem. Kwakernaak [13, 14] introduced a mathematical model by using fuzzy random variables, which was later developed more clearly by Kruse and Meyer [12]. In the Kwakernaak/Kruse and Meyer approaches, fuzzy random variables is viewed as a fuzzy perception/observation/report of a classical real-valued random variable. Xu and Pei [25] proposed a construction supply chain management PD planning, a bi-level model with demand and variable production costs with both fuzzy and random varieties is developed. From a probability space fuzzy random variable is a measurable function to a collection of fuzzy variables, so, roughly speaking, an fuzzy random variable is a random variable that takes fuzzy values. In this paper, for production-distribution planning, a bi-level multi objective model with demand, production costs, selling price and transportation costs all are considered as a fuzzy random.

This paper contributes to current research as follows: first, a multi-objectives model is proposed which considers two objective functions in large-scale industry which solve PD planing problem. In addition, fuzzy random variables are used to describe the demand,variable production costs, transportation cost and delivery time, which assists decision makers to make more effective and precise decisions. In the following sections of this paper is designed as follow. In Sect. 52.2 multi objective problem description and motivation of using fuzzy random variables are described. A mathematical model is used to optimized the production-distribution planing is explained in Sect. 52.3. In Sect. 52.4 fuzzy random simulation based genetic algorithm is explained. A numerical example is parented in Sect. 52.5 to show the significance of proposed model. At the end conclusions are given in Sect. 52.6.

2 Multi Objective Problem Description

This paper consider multi-objective PD problems examined here can be described as follows. Assume that the decision maker attempts to determine the integrating PD plan for \(K\) types of homogeneous commodities from \(L\) sources (factories) to \(M\) destinations (distribution centers) to satisfy the market demand. Every source has a supply of the commodity available to distribute to various destinations, and each destination has its forecast demand for the commodity to be received from the sources. The estimate demand, unit cost coefficients, and machine capacity are normally imprecise/fuzzy random owing to incomplete and unobtainable information over the intermediate planning horizon. This work focuses on developing a expected programming method for optimizing the PD plan in fuzzy random environments.

The need to describe uncertainty in PD planning is widely acknowledged because uncertainties exist in a variety of system components and a linkage to the regulated policies. In PD the source of the uncertainty mainly has four aspects in the PD planning: production cost; transportation cost, market demand and delivery time. Uncertainty in production mainly exist on the reliability of the production system. Such as; machine fault, change in input prices, executive deviation of the plan etc. Similarly, uncertainty exist in the market demand of the product. Randomness exist in the market demand because of change in product price and season, disaster, market competitors influence etc. Uncertainty also exist in transportation cost of product, transfer to the sale markets. Such as change in flue price, market distance from distribution center, quantity of order etc. Uncertainty may exist in the delivery time because of labor strike, machine working and shortage of components that help in manufacturing the products etc. Generally we define out the uncertainty first with the help of sampling analysis on the base of statistical data when considering the production cost, market demand, transportation cost and delivery time. Then we can value them and make fuzzy random variables with the help of expert experiences. In such a case of study, because it is very difficult to estimate the accurate value of all these fuzzy random variables. It is mostly defined by giving a range in which the most possible value is considered as a random variable, i.e, viz \((a,\rho ,b)\). On the basis of statistics characteristics it is found that the most possible value of all these fuzzy random variables follow a normal distribution, i.e, \(\rho \sim N(\mu ,\sigma ^{2})\). To deal this situation the triangular fuzzy random variables \((a,\rho ,b)\), where \(\rho \sim N(\mu ,\sigma ^{2})\) is applied to deal with these uncertain parameters by combining fuzziness and randomness. As a consequence, it is appropriate to consider production cost, product demand, transportation cost and delivery time as a fuzzy random variables.

3 Modeling

In this section, a multi objective programming model for the PD planning considering fuzziness and randomness is constructed. The mathematical description of the problem is given as follows:

-

Index Sets

-

\(k\): index for source, for all \(i=1,2,\cdots ,K\),

-

\(l\): index for kind of product, for all \(l=1,2,\cdots ,L\),

-

\(j\): index for destinations of delivery, for all \(j=1,2,\cdots ,J\).

-

Parameters

-

\(U_{w}\): maximum inventory that can be store in warehouse,

-

\(\widetilde{\overline{C}}_{kl}\): Fuzzy random total cost of production per unit for product \(l\) by source \(i\),

-

\(y_{kl}\): inventory level of product \(k\) by source \(i\),

-

\(h_{kl}\): inventory holding cost per unit of product \(k\) by source \(i\),

-

\(\widetilde{\overline{t}}_{kl}\): delivery cost per unit of product \(k\) by source \(i\),

-

\(S_{kl}\) setup cost per unit of product \(k\) by source \(i\),

-

\(\widetilde{\overline{P}}_{kl}\): production cost per unit of product \(k\) by source \(i\),

-

\(r_{kl}\): rate of production of product \(k\) by source \(i\),

-

\(M_{l}\): maximum level of production of source \(i\),

-

\(p_{t}\): delivery time period lengths,

-

\(\widetilde{\overline{T}}_{kl}\): per unit delivery time.

-

Decision Variables

-

\(X_{kl}\): production volume of product \(k\) by source \(i\),

-

\(p_{t}\): delivery time periods length.

The multi objective optimization model of PD planing under fuzzy random environment is mathematically formulated as follow:

Objective function 1:

The first objective of PD plan is to minimize the total cost. The total cost of PD planing is composed by three parts namely total production cost which included regular production cost and setup cost, inventory holding cost and product delivery cost. The mathematical expression is as follow: \(\min ~ F_{1}=\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{C}}_{kl}+\sum _{l}\sum _{k}I_{kl}h_{kl}+\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{t}}_{kl}\), where \(\widetilde{\overline{C}}_{kl}=\sum _{k}\sum _{l}S_{kl}+\sum _{k}\sum _{l}\widetilde{\overline{P}}_{kl}\). There are some uncertain parameters in the objective function namely fuzzy random variables, \(\widetilde{\overline{C}}_{kl}\) and \(\widetilde{\overline{t}}_{kl}\), so it will be difficulty for decision makers to obtain the minimal cost accurately. Therefore, the decision makers usually only consider the average minimum cost by using the fuzzy random expected value model by Xu and Zhou as follow: \(\min ~ F_{1}=E\big [\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{C}}_{kl}+\sum _{l}\sum _{k}I_{kl}h_{kl}+\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{t}}_{kl}\big ]\).

Constraint:

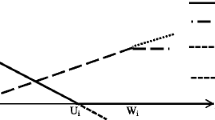

Sum of total available product is greater then sum of total demand of product: \(\sum _{k}\sum _{l}X_{kl}\ge \widetilde{\overline{D}}_{kl}\). There is uncertain parameter in the constraint namely fuzzy random variable \(\widetilde{\overline{D}}_{kl}\). Therefore, decision maker use fuzzy random expected value model to deal this as follow: \(E\big [\sum _{k}\sum _{l}X_{kl}\ge \widetilde{\overline{D}}_{kl}\big ]\). The sources are working at maximum level: \(\sum _{k}\sum _{l}r_{kl}X_{kl}\le M_{k}\). Inventory level of product is less then the upper bound of warehouses: \(0\le \sum _{k}\sum _{l}I_{kl}\le U_{w}\).

Objective function 2:

The second objective of PD plan is to minimize the delivery time, which is mathematically formulated as follow: \(\min ~ F_{2}=\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{T}}_{kl}\). There is uncertain parameter in the constraint namely fuzzy random variable \(\widetilde{\overline{T}}_{kl}\). Therefore fuzzy random expected value model is used to minimize as follow: \(\min F_{2}=E\big [\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{T}}_{kl}\big ]\).

Constraint:

The total delivery time of product must be less than period time: \(\sum _{k}\sum _{l}X_{kl}\widetilde{\overline{T}}_{kl}\le ~p_{t}\).

4 Solution Method

To solve the previous multi objective PD planing problem, four step are proposed. First, a fuzzy random variables transform into fuzzy trapezoidal numbers. Secondly, fuzzy simulation is applied to calculate the expected value of objective functions. Third, weighted sum method is used to transformed the multi objective into single objective. At the end a genetic algorithm is proposed to solve the above describe multi objective problem.

4.1 Dealing with Fuzzy Random Variables

Generally we know that, it is difficult to directly obtain an optimal solution of fuzzy random variables. Therefore, the fuzzy random variables convert into deterministic ones by the proposed transformation method. At First, the fuzzy random variables are transformed into fuzzy numbers, and then Heilpern [9] expected value operator is applied to to drive the deterministic variables.

Transformation of fuzzy numbers variables into fuzzy numbers

Total Production Cost. Generally, a fuzzy random variable is denoted as \(\widetilde{\overline{\xi }}=([m]_{L},\rho (c),[m]_{R})\). From the previous section, \(\rho (\omega )\) is supposed to approximately follow a normal distribution \(N(\mu _{0},\sigma ^{2})\) with a probability density function of \(\varphi _{\rho }(x)\), so the expression of \(\varphi _{\rho }(x)\) should be \(\varphi _{\rho }(x)\)=\((1/\sqrt{2/pi\sigma _{0}}\exp [-(x-\mu _{0})^{2}/2\sigma ^{2}_{0}])\). Suppose that \(\sigma \) is a given probability level of random variable and \(\sigma \in [0,\sup \varphi _{\rho }(x)]\), \(r\) is a given possibility level for the fuzzy variable and \(r\in [r_{l},1]\), where \(r_{l}=([m]_{R}-[m]_{L})/([m]_{R}-[m]_{L}+\rho ^{R}_{\sigma }-\rho _{\sigma }^{L})\), both of them reflecting the decision maker’s degree of optimism. For an easy description, the probability level and the possibility level are called \(\sigma \) and \(r\), respectively. The transformation method consists of the following steps:

-

1.

Through historical data and professional experience using statistical laws, estimate the parameters \([m]_{L},~ [m]_{R},~ \mu _{0}\) and \(\sigma _{0}\);

-

2.

Obtain the decision maker’s degree of optimism, i.e., the values of probability level \(\sigma \in [0,sup ~\varphi _{\rho (x)}]\) and possibility level \(r\in [r_{l}, 1]\), where \(r_{l}= ([m]_{R}-[m]_{L})/[m]_{R}-[m]_{L}+\rho ^{R}_{\sigma }-\rho _{\sigma }^{L})\), which are often determined by using a group- decision-making approach;

-

3.

Let \(\rho _{\sigma }\) be the \(\sigma \)-cut of the random variable \(\rho (c)\), that is \(\rho _{\sigma }=[\rho _{\sigma }^{L},\rho ^{R}_{\sigma }=\{x\in R|\varphi _{\rho (x)}\ge \sigma \}]\), then, the value of \(\rho _{\sigma }^{L}\) and \(\rho ^{R}_{\sigma }\) can be expressed as

$$\begin{aligned} \rho _{\sigma }^{L}=inf\{x\in R|\varphi _{\rho (x)}\ge \sigma \}={inf\varphi _{\rho }^{-1}(\sigma )} =\mu _{0}-\sqrt{-2\sigma _{0}^{2}ln\sqrt{2\pi {\sigma _{0}}\sigma }}, \end{aligned}$$(52.1)$$\begin{aligned} \rho _{\sigma }^{R}=sup\{x\in R|\varphi _{\rho (x)}\ge \sigma \}={sup\varphi _{\rho }^{-1}(\sigma )} =\mu _{0}-\sqrt{-2\sigma _{0}^{2}ln\sqrt{2\pi {\sigma _{0}}\sigma }}. \end{aligned}$$(52.2) -

4.

Transform the fuzzy random variable \(\widetilde{\overline{\xi }}=([m]_{L}), \rho (c), [m]_{R}\) into the \((r,\sigma )\) level trapezoidal fuzzy number \(\tilde{c}_{\widetilde{\overline{\xi }}(r,\sigma )}\) by using the following equation:

$$\begin{aligned} \widetilde{\overline{\xi }}\rightarrow \tilde{c}_{\widetilde{\overline{\xi }}(r,\sigma )}=([m]_{L},\underline{m},\overline{m}, [m]_{R}), \end{aligned}$$(52.3)so

$$\begin{aligned} \underline{m}=[m]_{R}-r([m]_{R}-{\rho _{\sigma }^{L}})=[m]_{R}-r([m]_{R}-\mu _{0}+\sqrt{-2\sigma _{0}^{2}ln\sqrt{2\pi {\sigma _{0}}\sigma }}), \end{aligned}$$(52.4)$$\begin{aligned} \overline{m}=[m]_{L}+r(\rho _{\sigma }^{R}-[m]_{L})=[m]_{L}+r(\mu _{0}-[m]_{L}+\sqrt{-2\sigma _{0}^{2}ln\sqrt{2\pi {\sigma _{0}}\sigma }}). \end{aligned}$$(52.5)\(\widetilde{\overline{\xi }}\) can be specified by \(\tilde{c}_{\widetilde{\overline{\xi }}(r,\sigma )}=([m]_{L},\underline{m},\overline{m}, [m]_{R}) \) with the following membership function:

$$\begin{aligned} \mu _{\tilde{c}_{\widetilde{\overline{\xi }}(r,\sigma )}}=\left\{ \begin{array}{lll} 0 &{}\quad {\text {for}} &{} x<[m]_{L}, {x} >[m]_{R}\\ \frac{x-[m]_{L}}{\underline{m}-[m]_{L}} &{} \quad {\text {for}} &{} [m]_{L}\le x <\underline{m}\\ 1 &{}\quad {\text {for}} &{} \underline{m}\le x \le \overline{m}\\ \frac{[m]_{R}-x}{[m]_{R}-\overline{m}} &{}\quad {\text {for}} &{} \overline{m} < x \le [m]_{R}. \end{array} \right. \end{aligned}$$(52.6)

The transformation process of fuzzy random variable \(\widetilde{\overline{\xi }}\) to the \((r,\sigma )\)-level trapezoidal fuzzy number \(\tilde{c}_{\widetilde{\overline{\xi }}(r,\sigma )}\) is described in Eqs. (52.1)–(52.6).

Let \(\widetilde{\overline{t}}_{kl}\) transportation cost, \(\widetilde{\overline{D}}_{kl}\) demand of product and \(\widetilde{\overline{T}}_{kl}\) per unit delivery time of product are also fuzzy random variables. Based on the previous method described for \(\widetilde{\overline{c}}_{kl}\) total cost of production, can be transformed into \((r,\sigma )\)-level trapezoidal fuzzy numbers.

4.2 Fuzzy Simulation for Expected Value

By using the fuzzy random simulation we can get the expected value of objective functions. The procedure is describe step by step as follow.

-

Step 1. Set \(E[f(C,Q,\xi )]=0\).

-

Step 2. Randomly generate \(\mu _{i},~ i=1,2,\cdots ,m\) from the \(\varepsilon \)-level sets of \(\xi \), where \(\varepsilon \) is a sufficiently small number.

-

Step 3. Set \(a=f(C,Q,\mu _{1}) \wedge f(C,Q,\mu _{2}) \wedge ,\cdots \wedge f(C,Q,\mu _{m})\), \(b= f(C,Q,\mu _{1}) \vee f(C,Q,\mu _{2}) \vee ,\cdots \vee f(C,Q,\mu _{m})\).

-

Step 4. Randomly generate \(r\) from \([a,b]\).

-

Step 5. If \(r\ge 0\), then \(E[f(C,Q,\xi )]\leftarrow E[f(C,Q,\xi )]+Cr[f(C,Q,\mu _{1})]\ge r\).

-

Step 6. If \(r< 0\), then \(E[f(C,Q,\xi )]\leftarrow E[f(C,Q,\xi )]-Cr[f(C,Q,\mu _{1})]\le r\).

-

Step 7. Repeat the fourth to sixth steps for \(m\) times.

-

Step 8. \(E[f(C,Q,\xi )]=a\vee 0+ b\wedge 0 + E[f(C,Q,\xi )].(b-a)/m\).

4.3 Weighted Sum Method

The weight sum method is one of the technique which is mostly applied to solve the multi-objective programming problem. By applying the weighted sum method we can convert the multi objective into single objective giving the weight of each objective function.

Assume that the related weight of the objective function \(f_{i} (x )\) is \(w_{i}\) such that \(\sum _{i=1}^{m}w_{i}=1\) and \(w_{i}\ge 0\). So we can construct the evaluation function as follows: \(u(f(x))=\sum _{i=1}^{m}w_{i}f_{i}(x)=w^{t}f(x)\), where \(w_{i}\) expresses the importance of the object \(f_{i}(x)\) for decision maker. Then we get the following weight problem, \(\min _{x\epsilon {X}}u(f(x))=\min _{x\epsilon {X}}\sum _{i=1}^{m}w_{i}f_{i}(x)=\min _{x\epsilon {X}}w^{t}f(x)\).

4.4 Genetic Algorithm

In this subsection we have applied a stochastic search methods for optimization problems based on the mechanics of natural selection and natural genetics, genetic algorithms (GAs), which have received remarkable attention regarding their potential as a novel approach to multi objective optimization problems. GAs do not need many mathematical requirements and can handle any types of objective functions and constraints. GAs have been well discussed and summarized by several authors, e.g., Holland [11], Goldberg [8], Michalewicz [19], Fogel [6], Gen and Cheng [7] and Liu [3].

This section attempts to present a fuzzy random simulation and weighted sum method-based genetic algorithm to obtain a solution of multi objective programming with fuzzy random coefficients.

1. Representation structure: We use a vector \(x = (x_{1}, x_{2}, \cdots , x_{n})\) as a chromosome to represent a solution to the optimization problem.

2. Handling the constraints: To ensure the chromosomes generated by genetic operators are feasible, we can use the technique of fuzzy random simulation to check them.

3. Initializing process: Suppose that the DM is able to predetermine a region which contains the feasible set. Generate a random vector \(x\) from this region until a feasible one is accepted as a chromosome. Repeat the above process \(N_{pop\_size}\) times, then we have \(N_{pop\_size}\) initial feasible chromosomes \(x^{1}, x^{2},\cdots , x^{N_{pop\_size}}\).

4. Evaluation function: The regret value of each chromosome \(x\) is calculated, then the fitness function of each chromosome is computed by

5. Selection process: The selection process is based on spinning the roulette wheel \(N_{pop\_size}\) times. Each time a single chromosome for a new population is selected in the following way: Calculate the cumulative probability \(q_{i}\) for each chromosome \(x^{i}\)

Generate a random number \(r\) in \([0,q_{N_{pop\_size}}]\) and select the \(ith\) chromosome \(x^{i}\) such that \(q_{i-1}< r \le q\Gamma _{i},~ 1 \le i \le N_{pop\_size} \). Repeat the above process \(N_{pop\_size}\) times and we obtain \(N_{pop\_size}\) copies of chromosomes.

6. Crossover operation: Generate a random number \(c\) from the open interval \((0, 1)\) and the chromosome \(x^{i}\) is selected as a parent provided that \(c < P_{c}\), where parameter \(P_{c}\) is the probability of crossover operation. Repeat this process \(N_{pop\_size}\) times and \(P_{c}.N_{pop\_size}\) chromosomes are expected to be selected to undergo the crossover operation. The crossover operator on \(x^{1}\) and \(x^{2}\) will produce two children \(y^{1}\) and \(y^{2}\) as follows: \(y^{1}=cx^{1}+(1-c)x^{2}, y^{2}=cx^{2}+(1-c)x^{1}\).

If both children are feasible, then we replace the parents with them, or else we keep the feasible one if it exists. Repeat the above operation until two feasible children are obtained or a given number of cycles is finished.

7. Mutation operation: Similar to the crossover process, the chromosome \(x^{i}\) is selected as a parent to undergo the mutation operation provided that random number \(m < P_{m}\), where parameter \(P_{m}\) as the probability of mutation operation. \(P_{m}\,\cdot \, N_{pop\_size}\) chromosomes are expected to be selected after repeating the process \(N_{pop\_size}\) times. Suppose that \(x^{1}\) is chosen as a parent. Choose a mutation direction \(d\epsilon R^{n}\) randomly. Replace \(x\) with \(x + M \,\cdot \, d\) if \(x + M\,\cdot \, d\) is feasible, otherwise we set \(M\) as a random number between 0 and \(M\) until it is feasible or a given number of cycles is finished. Here, \(M\) is a sufficiently large positive number.

We illustrate the fuzzy random simulation-based genetic algorithm procedure as follows:

-

Step 1. Input the parameters \(N_{pop\_size}\), \(P_{c}\) and \(P_{m}\).

-

Step 2. Initialize \(N_{pop\_size}\) chromosomes whose feasibility may be checked by fuzzy random simulation.

-

Step 3. Update the chromosomes by crossover and mutation operations and fuzzy random simulation is used to check the feasibility of offspring.

-

Step 4. Compute the fitness of each chromosome based on the regret value.

-

Step 5. Select the chromosomes by spinning the roulette wheel.

-

Step 6. Repeat the second to fourth steps for a given number of cycles.

-

Step 7. Report the best chromosome as the optimal solution.

5 Numerical Example

A numerical example is proposed in this section which illustrate the practical application of the proposed optimized model.

-

Number of production plant (source): 1

-

Numbers of distribution places: 4

-

Fuzzy random cost of production: (140,\(\rho (c),160\)); where \(\rho (c)\sim N(150,4)\).

-

Fuzzy random cost of transportation: \({\widetilde{\overline{t}}}_{11}=(4,\rho (t),8)\); \(\rho (t)\sim N(7,1)\), \({\widetilde{\overline{t}}}_{12}=(3.5,\rho (t),7)\); \(\rho (t)\sim N(6, 0.8)\), \({\widetilde{\overline{t}}}_{13}=(4.2,\rho (t),8.4)\); \(\rho (t)\sim N(7,.9)\), \({\widetilde{\overline{t}}}_{14}=(4,\rho (t),\) \(6.1)\); \(\rho (t)\sim N(7,1)\).

-

Fuzzy random delivery time: \({\widetilde{\overline{T}}}_{11}=(8,\rho (T),12)\);\(\rho (T)\sim N(11,1)\), \({\widetilde{\overline{T}}}_{12}=(6.5,\) \(\rho (T),10)\); \(\rho (T)\sim N(8, 0.8)\), \({\widetilde{\overline{T}}}_{13}=(8.5,\rho (T),13)\); \(\rho (T)\sim N(11,.95)\), \({\widetilde{\overline{T}}}_{14}=(6,\rho (T),12)\); \(\rho (T)\sim N(9.5,1)\).

-

Fuzzy random demand: \({\widetilde{\overline{D}}}_{11}=(80,\rho (D),100)\); \(\rho (D)\sim N(90,4)\), \({\widetilde{\overline{D}}}_{12}=(60,\) \(\rho (D),90)\); \(\rho (D)\sim N(80,3.5)\), \({\widetilde{\overline{D}}}_{13}=(85,\rho (D),100)\); \(\rho (D)\sim N(94,4.1)\), \({\widetilde{\overline{D}}}_{14}=(65,\rho (D),\) \(90)\); \(\rho (D)\sim N(80,3.5)\).

-

Inventory Holding cost per unit: 2.

In the view of final solution of GA in Table 52.1, the producer can rationally allocate the production and save cost and delivery time. We have considered the fuzziness and randomness at the same time when making planing which assist decision makers to make more accurate and well informed planing. Suppose the decision maker is not satisfied with the current solution when \(w_{1} =0.6\) and \(w_{2} = 0.4\), so he can get the satisfied approximate solution by changing the weight coefficients of \(w_{1}\) and \(w_{2}\).

6 Conclusion

In this paper, we have proposed the multi objective production-distribution programming problem with fuzzy random coefficients. For a special type of fuzzy random variables, we have applied a method to transfer into fuzzy number and expected value operator was applied to get the deterministic variables. A fuzzy random simulation-based genetic algorithm using weighted sum method approach which is effective to solve the general fuzzy random multi objective programming problem. Though the fuzzy random simulation-based genetic algorithm proposed in this paper usually spends more CPU time than traditional algorithms, it is a viable and efficient way to deal with complex optimization problems involving randomness and fuzziness.In the future, fuzzy random simulation-based multi objective genetic algorithm is another field that we will consider.

References

Aliev RA, Fazlollahi B et al (2007) Fuzzy-genetic approach to aggregate production-distribution planning in supply chain management. Inf Sci 177(20):4241–4255

Averbakh I (2010) On-line integrated production-distribution scheduling problems with capacitated deliveries. Eur J Oper Res 200(2):377–384

Liu B (2002) Theory and practice of uncertain programming. Physica-Verlag, Heidelberg pp 235–238

Bilgen B, Ozkarahan I (2004a) Strategic tactical and operational production-distribution models: a review. Int J Technol Manage 28(2):151–171

Erengüç ŞS, Simpson NC, Vakharia AJ (1999) Integrated production/distribution planning in supply chains: an invited review. Eur J Oper Res 115(2):219–236

Fogel DB (2006) Evolutionary computation: Toward a new philosophy of machine intelligence, vol 1. Wiley.com

Gen M, Cheng R (1997) Genetic algorithms and engineering design. Wiley, New Jersey

Glodberg DE (1989) Genetic algorithms in search, optimization, and machine learning. Addion Wesley, Reading

Heilpern S (1992) The expected value of a fuzzy number. Fuzzy Sets Syst 47(1):81–86

Hua G, Wang S, Chan CK (2009) A fractional programming model for internation facility location. J Ind Manage Optim 5:629–649 (in Chinese)

Holland J (1975) Adaptation in natural and artificial systems. University of Michigan Press, Ann Arbor

Kruse R, Meyer KD (1987) Statistics with vague data, vol 6. Springer.

Kwakernaak H (1978) Fuzzy random variables-I. definitions and theorems. Inf Sci 15(1):1–29

Kwakernaak H (1979) Fuzzy random variables-II, algorithms and examples for the discrete case. Inf Sci 17(3):253–278

Lee YH, Kim SH (2002) Production-distribution planning in supply chain considering capacity constraints. Comput Ind Eng 43(1):169–190

Liang TF (2008a) Fuzzy multi-objective production/distribution planning decisions with multi-product and multi-time period in a supply chain. Comput Ind Eng 55(3):676–694

Liang TF (2008b) Integrating production-transportation planning decision with fuzzy multiple goals in supply chains. Int J Prod Res 46(6):1477–1494

Liang TF, Cheng HW et al (2011) Application of fuzzy sets to aggregate production planning with multiproducts and multitime periods. IEEE Trans Fuzzy Syst 19(3):465–477

Michalewicz Z (1996) Genetic algorithms \(+\) data structures \(=\) evolution programs. springer.

Petrovic D, Roy R, Petrovic R (1998) Modelling and simulation of a supply chain in an uncertain environment. Eur J Oper Res 109(2):299–309

Sarmiento AM, Nagi R (1999) A review of integrated analysis of production-distribution systems. IIE Trans 31(11):1061–1074

Selim H, Araz C, Ozkarahan I (2008a) Collaborative production-distribution planning in supply chain: a fuzzy goal programming approach. Transp Res Part E: Logistics Transp Rev 44(3):396–419

Vidal CJ, Goetschalckx M (1997a) Strategic production-distribution models: A critical review with emphasis on global supply chain models. Eur J Oper Res 98(1):1–18

Wang RC, Liang TF (2004a) Application of fuzzy multi-objective linear programming to aggregate production planning. Comput Ind Eng 46(1):17–41

Xu JP, Pei W (2013) Production-distribution planing of construction supply chain management under fuzzy random environment for large-scale construction projects. J Ind Manage Optim 9(1):31–56 (in Chinese)

Acknowledgments

The authors wish to thank the anonymous referees for their helpful and constructive comments and suggestions. The work is supported by the National Natural Science Foundation of China (Grant No. 71301109), the Western and Frontier Region Project of Humanity and Social Sciences Research, Ministry of Education of China (Grant No. 13XJC630018), the Philosophy and Social Sciences Planning Project of Sichuan province (Grant No. SC12BJ05), and the Initial Funding for Young Teachers of Sichuan University (Grant No. 2013SCU11014).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Nazim, M., Hashim, M., Nadeem, A.H., Yao, L., Ahmad, J. (2014). Multi Objective Production–Distribution Decision Making Model Under Fuzzy Random Environment. In: Xu, J., Cruz-Machado, V., Lev, B., Nickel, S. (eds) Proceedings of the Eighth International Conference on Management Science and Engineering Management. Advances in Intelligent Systems and Computing, vol 280. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-55182-6_52

Download citation

DOI: https://doi.org/10.1007/978-3-642-55182-6_52

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-55181-9

Online ISBN: 978-3-642-55182-6

eBook Packages: EngineeringEngineering (R0)