Abstract

Two important objectives of the automotive industry are the decrease in car weight and improvement in safety. High strength steels (HSS) especially advanced high strength steels (AHSS) and the third-generation HSS are the main measures to reduce automotive weight and improve safety in steel industry. Quenching and partitioning (Q&P) has been recently proposed by Speer as a fundamentally new way of producing martensite steels containing a considerable amount of retained austenite, it possesses good balance properties between tensile strength and elongation. In order to produce Q&P steel, a special thermal treatment is required, it consists of a two step thermal treatment. A special line designed by Baosteel especially for UHSS production was launched in March 2009, it is easy to implement the annealing cycle of Q&P. The industry trails with conventional C–Si–Mn TRIP780 composition by Q&P concept were carried out in this line. The results show that a good balance property is achieved, the microstructure and other properties are measured and discussed. A component of B pillar is made successfully by Q&P1000.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Increasing requirements for automotive weight reduction and safety have led to continuous growth in application of high strength steels (HSS) especially advanced high strength steels (AHSS) and the third-generation HSS in steel industry. Quenching and partitioning (Q&P) steel has been recently proposed by Speer [1–3] as a fundamentally new way of producing martensite steels containing a considerable amount of retained austenite. In order to produce Q&P steel, a special thermal treatment is required, it consists of a two step thermal treatment. It is difficult to carry out with this special annealing cycle in the conventional continuous annealing line (CAL) or continuous galvanized line (CGL). The good balance properties between strength and ductility can be achieved of Q&P steel in the experiments of laboratory [4–6], however, the properties results of industrialized Q&P steel have never been reported.

In this paper, the steels with conventional C–Si–Mn TRIP780 composition were carried out by Q&P concept at special line designed by Baosteel especially for UHSS production. It shows that 1000MPa grade cold rolled (CR) can be achieved by C–Si–Mn TRIP780 composition. X-ray diffraction, optical and scanning electron microscopy have been applied to characterize the microstructures. It includes ferrite martensite and retained austenite. The formability of Q&P steel is also studied by hole-expanding and cold-bending test. A component of B pillar is made successfully by Q&P1000.

2 Experimental Procedure

The chemical composition of the C–Si–Mn steel used is shown in Table 1. Si addition is used to suppress the formation of carbide [7], and Mn is used to enhance the stability of austenite. The slabs were reheated to a temperature of 1,250°C and hot rolled to a thickness of 3.5 mm. The finishing temperature was about 860°C and coiling temperature was about 600°C. The thickness of cold rolled steel sheets is 2 mm.

The heat treatment was conducted in the special UHSS line on cold rolled sheet. Figure 1 shows the schematic of production line for UHSS in Baosteel, the main characteristics and advantages of this line are as follows:

-

(1)

The tensile strength of 340–1,500 MPa for cold-rolled and 340–1,200 MPa tensile strength for hot-dip galvanizing sheet steel can be produced in this line. This unit particularly suitable for the production of ultra-HSS, it is the only one line for ultra-HSS in China.

-

(2)

Production line with multi-functional, and produces cold-rolled sheets and hot-dip galvanizing sheets. Cold-rolled sheets can be produced by high concentrations of hydrogen cooling and water quenching. Hot-dip galvanized sheets can be produced by conventional cooling (5% H2 + 95% N2) and high concentration of hydrogen cooling, the highest concentration of hydrogen is about 75%.

-

(3)

Laser welding machine to ensure that the ultra-HSS welding and the production quality and stable operation of the strip.

-

(4)

The direct fire is adopted in the heating furnace; it is conducive to improve the zinc coating performance of HSS.

-

(5)

The cooling rate of sheet is fast, when using more than 60% concentration of hydrogen for cooling, the cooling rate can be reach 140°C/s or more for 1 mm thick sheet; when the water quenching is used, the steel sheet cooling rate can exceed 500°C/s.

-

(6)

Cold-rolled steel sheet surface coating has a good performance, especially for water quenching sheet steel. Because the sheet is pickled after water quenching, and the Mn-rich elements of surface will be reduced, thus further improving the corrosion resistance of cold-rolled steel sheet and painting performance.

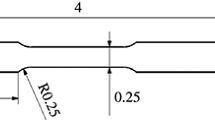

The mechanical properties are measured using JIS5# in the transverse direction. The samples are two-step etched with 2% Nital and sodium metabisulfite (Na2S2O5 + H2O) [8] for optical microscopy analysis and etched with 2% Nital for observation using JEM-2100F Scanning Electron Microscopy (SEM). The amount of retained austenite is quantified by X-ray diffractometry using Mo–Ka radiation. Hole-punching and hole-expanding tests are conducted using disc specimens of 50 mm in diameter with oil lubricant. The cold-bending property is measured in the transverse and longitudinal direction.

3 Results and Discussion

3.1 Mechanical Properties

The mechanical properties of the TRIP780 steels treated by Q&P process in the special UHSS line of Baosteel are presented in Table 2, there are nine coils. With the typical TRIP780 steel composition, higher tensile strength (1000–1200 MPa grade) can be achieved by Q&P treatment, and the ductility is also good (9.3–21.2%). Comparison with the same grade of DP and Martensite sheet steels, Q&P steels possess excellent balance tensile strength and elongation (see Fig. 2). Although TRIP1000 possess good balance between tensile strength and elongation, the carbon content is very high, it is about 0.3 wt% [9]. So the weldability of Q&P steels are better than the same grade of TRIP steel.

3.2 Microstructure and Stability of Retained Austenite

Microstructures of Q&P1000 (Coil No. 5) is shown in Fig. 3. The microstructure includes ferrite (white), martensite (laths) and retained austenite (light near the grain boundary). With the increase of tensile strength, the amount of ferrite decrease.

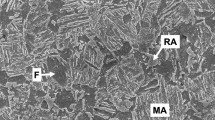

SEM is carried out to observe the characteristics of retained austenite. Figure 4 shows the microstructure of sample from Coil No. 5. The large gray grains are ferrite while the brighter phases are martensite and retained austenite. The retained austenite usually appears as a small gray block with smooth and rounded edges at the laths martensite boundaries. It concludes that a considerable amount of retained austenite is obtained by Q&P treatment at industry continuously annealing line.

Figure 5 shows the relationship between strain and retained austenite measured from Coil No. 5. The amount of retained austenite in annealed Q&P1000 steel is about 9%, with the increase of strain, the retained austenite of the sample decrease quickly. When the strain reach to 10%, the amount of retained austenite decrease to about 4%. This phenomenon is similar to TRIP steel.

3.3 Other Properties and Application

Table 3 shows the variations in hole expansion ratio and minimum relative bending radius of Q&P1000. The hole expansion ratio is about 30%, similar to the same grade DP steel. The minimum relative bending radius of perpendicular rolling direction is better than parallel rolling direction. Figure 6 shows the photograph of B pillar made by Q&P1000.

4 Conclusions

The steels with conventional C–Si–Mn TRIP780 composition are carried out by Q&P concept at a special commercial line designed by Baosteel, the following results are achieved:

-

(1)

The good balance properties between strength and ductility can be achieved of C-Si-Mn TRIP780 steel by Q&P treatment. It possesses both higher tensile strength and excellent total elongation. The tensile strength is from 1,000–1,200 MPa and the elongation is from 9.3 to 21.2%.

-

(2)

Q&P steels are composed of ferrite and carbon-depleted laths martensite and retained austenite.

-

(3)

Comparison with the same grade of DP, Mart and TRIP steel, the Q&P steels possess good balance properties between high tensile strength and excellent stretch-flangeability.

-

(4)

Q&P1000 are drawn successfully to a complex component (B pillar) of a domestic car.

References

J.G. Speer, A.M. Streicher, D.K. Matlock, F. Rizzo, G. Krauss, Quenching and Partitioning: A Fundamentally New Process to Create High Strength TRIP Sheet Microstructures, Austenite Formation and Decomposition ed. by E.B. Damm and M.J. Merwin, (TMS, Warrendale, PA, 2003), pp. 505–522

J.G. Speer, D.K. Matlock, B.C. DeCooman, J.G. Schroth, Carbon partitioning into austenite after martensite transformation. Acta Mater. 51, 2611–2622 (2003)

J.G. Speer, F.C. Rizzo, D.K. Matlock, D.V. Edmonds, The ‘Quenching and Partitioning’ Process: Background and Recent Progress, in Proceedings of 59th Annual ABM Congress, ABM, São Paulo, Brazil, 2004, pp. 4824–4836. Also published in Mater. Res. 8(4), 417–423 (2005)

A.M. Streicher, J.G. Speer, D.K. Matlock, B.C. De Cooman, International Conference on Advanced High Strength Sheet Steels for Automotive Applications Proceedings, ed. by J.G. Speer, Quenching and Partitioning Response of a Si-Added TRIP Sheet Steel, AIST, (Warrendale, PA, 2004), pp. 51–62

J.W. Jin, S.H. Byun, S.B. Lee, S.I. Kim, C.S. Oh, N. Kang, K.M. Cho. Mechanical Properties Comparison of DP, TRIP, Q&P Steels as a function of Heat Treatment Condition. In International Conference on New Developments in Advanced High-Strength Sheet Steel. Florida, USA, 2008, p. 169

S.C. Hong, J.C. Ahn, S.Y. Nam, S.J. Kim, H.C. Yang, J.G. Speer, D.K. Matlock, Mechanical properties of high-Si plate steel produced by the quenching and partitioning process. Met. Mater. Int. 13(6), 439–445 (2007)

M.F. Gallagher, J.G. Speer, D.K. Matlock, Microstructure Development in TRIP-Sheet Steels Containing Si, AI, and P, 44th MWSP Conference Proceedings, vol. XL, 2002

A.K. De, J.G. Speer D.K. Matlock, Color tint-etching for multiphase steels, Adv. Mater. Process, February 1, 2003

M. Takahashi, H. Yoshida, S. Hiwatashi, Properties of TRIP Type High Strength Steels International Conference on TRIP-Aided High Strength Ferrous Alloys, ed. by Prof. Dr. Ir. B.C. De Cooman, 2002, pp. 103–111

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer-Verlag Berlin Heidelberg and Metallurgical Industry Press

About this paper

Cite this paper

Wang, L., Feng, W. (2011). Development and Application of Q&P Sheet Steels. In: Weng, Y., Dong, H., Gan, Y. (eds) Advanced Steels. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-17665-4_25

Download citation

DOI: https://doi.org/10.1007/978-3-642-17665-4_25

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-17664-7

Online ISBN: 978-3-642-17665-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)