Abstract

Sulfide minerals are common minor constituents of the Earth’s crust. In some geological environments, sulfides constitute a major proportion of rocks. In particular, metallic ore deposits (Cu, Pb, Zn, Au, Ni, U, Fe), phosphate ores , coal seam s, oil shales , and mineral sands may contain abundant sulfides. Mining of these resources can expose the sulfides to an oxygenated environment. In fact, large volumes of sulfide minerals can be exposed in: tailings dams ; waste rock dumps; coal spoil heaps; heap leach piles ; run-of-mine and low-grade ore stockpiles; waste repository embankments; open pit floors and faces; underground workings ; haul roads; road cuts; quarries; and other rock excavations. When the sulfides are exposed to the atmosphere or oxygenated ground water, the sulfides will oxidize to produce an acid water laden with sulfate, heavy metal s and metalloids. The mineral pyrite (FeS2) tends to be the most common sulfide mineral present. The weathering of this mineral at mine sites causes the largest, and most testing, environmental problem facing the industry today – acid mine drainage (AMD ) (Scientific Issue 2.1).

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

2.1 Introduction

Sulfide minerals are common minor constituents of the Earth’s crust. In some geological environments, sulfides constitute a major proportion of rocks. In particular, metallic ore deposits (Cu, Pb, Zn, Au, Ni, U, Fe), phosphate ores , coal seam s, oil shales , and mineral sands may contain abundant sulfides. Mining of these resources can expose the sulfides to an oxygenated environment. In fact, large volumes of sulfide minerals can be exposed in: tailings dams ; waste rock dumps; coal spoil heaps; heap leach piles ; run-of-mine and low-grade ore stockpiles; waste repository embankments; open pit floors and faces; underground workings ; haul roads; road cuts; quarries; and other rock excavations. When the sulfides are exposed to the atmosphere or oxygenated ground water, the sulfides will oxidize to produce an acid water laden with sulfate, heavy metal s and metalloids. The mineral pyrite (FeS2) tends to be the most common sulfide mineral present. The weathering of this mineral at mine sites causes the largest, and most testing, environmental problem facing the industry today – acid mine drainage (AMD ) (Scientific Issue 2.1).

2.3 Weathering of Sulfidic Mine Wastes

Sulfidic mine wastes are in most cases polymineralic aggregates. The aggregates contain, apart from sulfides, a wide range of possible minerals including silicates, oxides, hydroxides, phosphates, halides, and carbonates. Silicates are the most common gangue mineral s , and the sulfides may represent ore or gangue phases. Thus, the mineralogy of sulfidic wastes and ores is highly heterogeneous and deposit specific.

When mining exposes sulfidic materials to an oxidizing environment, the materials become chemically unstable. A series of complex chemical weathering reactions are spontaneously initiated. This occurs because the mineral assemblages contained in the waste are not in equilibrium with the surface environment. Weathering of the minerals proceeds with the help of atmospheric gases, meteoric water and microorganisms .

The chemical weathering of an individual mineral within a polymineralic aggregate can be classified as an acid producing (i.e. generation of H+), acid buffering (i.e. consumption of H+), or non-acid generating or consuming reaction (i.e. no generation or consumption of H+). For example, the degradation of pyrite is an acid producing reaction, whereas the weathering of calcite is acid buffering, and the dissolution of quartz does not consume or generate any acid. The balance of all chemical reactions, occurring within a particular waste at any time, will determine whether the material will turn acid and produce AMD .

2.4 Acid Producing Reactions

2.4.1 Pyrite

Sulfides are stable under strongly reducing conditions. Exposure of these minerals to oxidizing conditions will destabilize them, and the sulfides will be destroyed via various oxidation mechanisms. Pyrite is the most abundant of the sulfide minerals, occurs in nearly all types of geological environments, and is commonly associated with coal and metal ore deposits. Thus, pyrite oxidation has been studied extensively from all scientific angles, and there is a vast literature on the subject (e.g. Evangelou 1995; Evangelou and Zhang 1995; Keith and Vaughan 2000; Liu et al. 2008c, 2009; Luther 1987). In contrast, the oxidation of other sulfides such as galena , sphalerite and chalcopyrite has received in comparison only limited attention.

Pyrite oxidation takes place when the mineral is exposed to oxygen (Rimstidt and Vaughan 2003). Oxidation which occurs in the presence of microorganisms is known as biotic. Pyrite oxidation may also occur without microorganisms as an abiotic or inorganic chemical oxidation process. Biotic and abiotic degradation can be caused by oxygen (i.e. direct oxidation ) or by oxygen and iron (i.e. indirect oxidation ) (Evangelou and Zhang 1995). Iron, both in its divalent and trivalent state, plays a central role in the indirect oxidation of pyrite. These different pyrite oxidation mechanisms can be summarized as:

-

1.

Oxidation by oxygen (abiotic direct oxidation );

-

2.

Oxidation by oxygen in the presence of microorganisms (biotic direct oxidation );

-

3.

Oxidation by oxygen and iron (abiotic indirect oxidation );

-

4.

Oxidation by oxygen and iron in the presence of microorganisms (biotic indirect oxidation).

Stoichiometric chemical reactions are commonly used to describe these different oxidation mechanisms. In the abiotic and biotic direct oxidation processes (mechanisms 1 and 2), oxygen directly oxidizes pyrite:

It is generally accepted, however, that pyrite oxidation is primarily accomplished by indirect oxidation (mechanisms 3 and 4). The indirect oxidation of pyrite involves the chemical oxidation of pyrite by oxygen and ferric iron (Fe3+), which occurs in three interconnected steps. The following chemical equations show the generally accepted sequence for such indirect oxidation of pyrite:

Oxidation of pyrite by oxygen (Step 1):

or,

Oxidation of ferrous iron to ferric iron (Step 2):

or,

Oxidation of pyrite by ferric iron (Step 3):

or,

Reactions 2.2, 2.3, and 2.4 release energy. Indirect pyrite oxidation is exothermic . In the initial step (Reaction 2.2), pyrite is oxidized by oxygen to produce dissolved ferrous iron (Fe2+), sulfate and hydrogen ions. The dissolved iron sulfate ions cause an increase in the total dissolved solids of the water. The release of hydrogen ions with the sulfate anions results in an acidic solution unless other reactions occur to neutralize the hydrogen ions. The second step (Reaction 2.3) represents the oxidation of ferrous iron (Fe2+) to ferric iron (Fe3+) by oxygen and occurs at a low pH. In the third reaction (Reaction 2.4) pyrite is oxidized with the help of Fe3+ generated in Reaction 2.3. Thus, Fe3+ acts as the oxidizing agent of pyrite. The oxidation of pyrite by Fe3+ in turn generates more Fe2+. This Fe2+ can then be oxidized to Fe3+ by oxygen via Reaction 2.3. The Fe3+ in turn oxidizes pyrite via Reaction 2.4, which in turn produces more Fe2+, and so on. Reactions 2.3 and 2.4 form a continuing cycle of Fe2+ conversion to Fe3+ and subsequent oxidation of pyrite by Fe3+ to produce Fe2+ (Fig. 2.1). This cyclic propagation of pyrite oxidation by Fe3+ continues until the supply of pyrite or Fe3+ to the reaction system is exhausted. While oxygen is not required for the Reaction 2.4 to occur, it is still needed to convert Fe2+ to Fe3+.

Simplified diagram illustrating the reaction pathways for pyrite oxidation (after Banks et al. 1997). Numbers 2.2 to 2.6 refer to Reactions 2.2, 2.3, 2.4, 2.5, and 2.6 in the text

The abundance of the oxidizing agent Fe3+ is influenced by the pH of the weathering solution. The solubility of Fe3+ is very low in neutral and alkaline waters. Hence, the concentrations of Fe3+ are very low in these solutions, and pyrite oxidation by Fe3+ in neutral to alkaline waters is slow and insignificant. Also, the concentration of dissolved Fe3+ decreases with increasing pH as Fe3+ solubility is limited by the precipitation of ferric hydroxide s (Fe(OH)3) and oxyhydroxides (FeOOH). In other words, if the pH increases to more than approximately 3 because of partial neutralization , for example, by carbonate minerals, then the following reactions will occur:

The precipitation of dissolved Fe3+ (Reactions 2.5 and 2.6) provides significant acidity to the solution by the release of hydrogen ions into water. This reaction lowers the pH and allows more Fe3+ to stay in solution. The Fe3+ is then involved in the oxidation of pyrite (Reaction 2.4) which results in a further reduction in pH.

The chemical precipitation of iron hydroxides in Reactions 2.5 and 2.6 is termed hydrolysis . Hydrolysis is the chemical process whereby water molecules react with dissolved cations; the cations become bonded to the hydroxy group and hydrogen ions are released. Consequently, hydrolysis results in the production of hydrogen ions, thereby causing the pH to fall. As mentioned above, the hydrolysis reaction of iron is controlled by pH. Under acid conditions of less than about pH 3, Fe3+ remains in solution. At higher pH values, precipitation of Fe3+ hydroxides occurs. Such a precipitate is commonly observed as the familiar reddish-yellow to yellowish-brown stain, coating, slimy sludge, gelatinous flocculant and precipitate in AMD affected streams and seepage areas (Chap. 3.5.7).

The Reactions 2.2, 2.3, 2.4, 2.5, and 2.6 show that in the presence of molecular oxygen, Fe2+ and S2– in pyrite are oxidized by oxygen to produce solid iron hydroxides and oxyhydroxides as well as dissolved sulfate and hydrogen ions. Clearly, oxygen and Fe3+ are the major oxidants of pyrite (Evangelou 1998; Singer and Stumm 1970). The oxidation of pyrite continues indefinitely unless one of the vital ingredients of pyrite oxidation is removed (i.e. Fe3+, oxygen or pyrite), or the pH of the weathering solution is significantly raised.

The reaction pathways of pyrite (Reactions 2.2, 2.3, 2.4, 2.5, and 2.6) have also been referred to as the AMD engine (Fig. 2.2). Pyrite , Fe3+ and oxygen represent the fuel, oxygen is also the starter engine, and Fe3+ hydroxides, sulfuric acid and heat come out of the exhaust pipe of the sulfidic waste. Such a simplified model of indirect oxidation of pyrite (Reactions 2.2, 2.3, 2.4, 2.5, and 2.6) can be summarized by one overall chemical reaction:

The self-sustaining, cyclic destruction of pyrite simplified as the “AMD engine”. The oxidation of pyrite is initiated through oxygen (“starter switch”). Pyrite , oxygen and iron (“fuel”) combust in the waste (“engine room”), and release Fe3+ hydroxides, sulfuric acid and heat into mine waters (“exhaust pipe”)

The above reaction describes the weathering of pyrite, highlights the need for water and oxygen, and illustrates the production of acid and iron hydroxide . However, there is little consensus in the literature on the precise reaction mechanisms describing the chemical oxidation of pyrite. Also, the chemical equations 2.2, 2.3, 2.4, 2.5, 2.6, and 2.7 are gross oversimplifications since: (a) the reactions do not explain that the Fe3+ hydroxides and sulfates are fictious, idealized solid phases; (b) they do not illustrate the range of iron hydroxide, oxyhydroxide and oxyhydroxysulfate minerals formed during pyrite oxidation; (c) they do not reflect the slow oxidation of Fe2+ in acid waters; (d) they disregard adsorption, desorption and neutralization reactions; (e) they disregard super-saturation of waters with iron and sulfate; (f) they do not consider the precipitation of elemental sulfur (S0) and the formation of polysulfide (\( \textrm{S}_{\textrm{n}}^{2-}\)), sulfite \( {\rm SO}_{3}^{2-}\); S: 4+), thiosulfate (\( {\rm S}_{3}{\rm O}_{3}^{2-}\); S: 2+), and polythionates (\( {\rm S}_n{\rm O}_{6}^{2-}\)) ions; and (g) they do not describe the rate or speed (i.e. kinetics) of pyrite oxidation (Nordstrom and Alpers 1999a; Ritchie 1994b). Hence, the above reaction paths (Reactions 2.1, 2.2, 2.3, 2.4, 2.5, 2.6, and 2.7) represent only approximations for actual field conditions.

How quickly pyrite weathers is influenced by its mineralogical properties and by external chemical, physical and biological factors. Mineralogical properties include the particle size , porosity , surface area , crystallography, and trace element content of pyrite. External factors are the presence of other sulfides, the presence or absence of microorganisms , as well as the oxygen and carbon dioxide concentration, temperature, pH and Fe2+/Fe3+ ratio of the weathering solution. Therefore, the rate of pyrite oxidation (i.e. the weathering kinetics of pyrite) is influenced by the following factors:

-

Pyrite particle size , porosity and surface area . The oxidation reactions occur on the surfaces of pyrite particles. Small particle sizes and large surface areas increase the reactivity of pyrite, and maximum oxidation of the pyrite surface occurs along pits, cracks, pores, and solid and liquid inclusions. For example, pyrite grains are exceptionally small in diameter in so-called framboidal pyrite . Framboidal pyrite refers to small-grained pyrite crystals with a grain size less than one micron. The grains are dispersed in the matrix or agglomerated to form a small spherical mass, typically several tens of micron in diameter. Such framboidal pyrite is more reactive than other pyrite morphologies – cubic pyrite crystals or coarse pyrite nodules – because of the greater surface area and porosity per volume of framboidal pyrite. Thus, pyrite oxidation is a surface controlled reaction (Evangelou 1995; Rose and Cravotta 1998). The quantity of a particle’s surface area is most decisive in determining reaction rates and its dissolution (Kuechler and Noack 2007; Liu et al. 2008d).

-

Mining , crushing and milling of pyrite-bearing rock to fine particle size s, for the purpose of metal extraction, vastly increase the pyrite surface area and potentially expose more pyrite to oxidation and weathering. However, crushing and milling of pyritic materials do not necessarily increase the oxidation rate of pyrite in waste rock dumps. This is because coarse-grained pyritic wastes have more pore space and allow greater oxygen movement into the wastes. Consequently, acid generation in coarse-grained wastes may occur to a greater depth than in fine-grained wastes.

-

Pyrite crystallography. Poorly crystalline pyrites or pyrites with structural defects have an imperfect or distorted crystal lattice. This leads to physical stress in the crystal structure which makes the mineral more susceptible to chemical attack (Hutchison and Ellison 1992; Rose and Cravotta 1998).

-

Trace element substitution . Trace elements can be present in pyrite in the form of minute mineral inclusions and as chemical impurities in the crystal lattice (Table 2.1). This puts strain on the crystal structure and diminishes the sulfide’s resistance to oxidation. For instance, the occurrence of arsenic in pyrite greatly decreases the resistance of pyrite to oxidation (Hutchison and Ellison 1992; Plumlee 1999). Pyrite with arsenic is thereby more reactive to oxidation than pyrite with either nickel or cobalt (Lehner and Savage 2008; Lehner et al. 2007).

-

Presence of other sulfides. Sulfidic wastes commonly contain sulfides other than pyrite. If there is direct physical contact between at least two different sulfide minerals, electrons move between the sulfides and a galvanic cell is formed. During weathering the sulfide mineral with the highest electrode potential is galvanically protected from oxidation, while the mineral with the lowest electrode potential is weathered more strongly. Selective oxidation of sulfide minerals occurs as one sulfide mineral is preferentially leached over another (Abraitis et al. 2004; Evangelou 1995; Evangelou and Zhang 1995; Hita et al. 2006; Kwong et al. 2003; Liu et al. 2008b; Nordstrom and Alpers 1999a; You et al. 2007). This galvanic protection process is the same as that for galvanized iron. The more electroconductive sulfide oxidizes at a slower rate than it would when not in contact with another sulfide. For example, among the three common sulfide minerals – pyrite, galena and sphalerite – pyrite has the highest electrode potential followed by galena and then sphalerite (Sato 1992). If these minerals are in contact with each other, sphalerite will be preferentially weathered and oxidation of pyrite is reduced. Hence, pyrite in direct contact with other sulfides does not react as vigorously as it does in isolation (Cruz et al. 2001a). Also, the oxidative dissolution of pyrite can be delayed, while other sulfides are preferentially oxidized (Hita et al. 2006; Kwong et al. 2003; You et al. 2007).

-

Temperature of the waste. The oxidation of pyrite is exothermic and generates heat as shown by the above equations. Such elevated temperatures are also advantageous to the growth of thermophilic bacteria . These bacteria use some of the released energy for their metabolic processes. However, most of the energy is released as heat and within the physical confines of waste dumps and tailings dams , there is little dissipation of the heat due to the abundance of gangue mineral s with poor heat conductivity. Thus, the pyritic waste gets warmer. Pyrite oxidation occurs faster as its oxidation rate nearly doubles with each 10°C increase in temperature (Smith et al. 1992) (Scientific Issue 2.2).

-

Microbiological activity ( Bacteria , Archaea, fungi, algae, yeasts, and protozoa). AMD environments commonly contain an abundance of microorganisms . Some of these microorganisms thrive under aerobic or anaerobic conditions and favour acid or neutral pH regimes. Archaea, Eukarya and Bacteria isolated from AMD environments are diverse and include Acidithiobacillus thiooxidans (previously Thiobacillus; Kelly and Wood 2000), Acidithiobacillus ferrooxidans (previously Thiobacillus), Leptospirillum ferrooxidans, Thiobacillus thioparus and Ferroplasma spp. (e.g. Bernier and Warren 2007; Blowes et al. 1998; Bond et al. 2000; Bryan et al. 2006; Fowler et al. 1999; Gleisner et al. 2006; Gould and Kapoor 2003; Gould et al. 1994; Hallberg and Johnson 2005; Johnson 1998a, b; Kock and Schippers 2006, 2008; Ledin and Pedersen 1996; Natarajan et al. 2006; Sánchez España et al. 2008a; Schippers and Sand 1999; Schippers et al. 2007; Schrenk et al. 1998). Certain bacteria grow particularly well in pH 2 –3 environments. These acidophilic (i.e. acid loving) bacteria and Archaea participate in the conversion of Fe2+ to Fe3+ and the oxidation of sulfur and sulfur compounds. They utilize the oxidation of the metal component (i.e. predominantly Fe) and sulfur compounds to obtain energy for their growth. Consequently, some bacteria and Archaea significantly accelerate the rate of Fe2+ oxidation to Fe3+. In fact, these bacteria and Archaea accelerate the rate of Fe2+ oxidation, which is relatively slow under abiotic, acid (pH < 4) conditions (Reaction 2.3), by a factor of hundreds to as much as one million times (Singer and Stumm 1970). In turn, the increased concentrations of Fe3+ oxidize the pyrite and accelerate acid formation. A so-called self-perpetuating or autocatalytic reaction develops whereby the microorganisms serve as a reaction catalyst for Fe2+ oxidation (Reaction 2.3). Iron oxidizing bacteria such as Acidithiobacillus ferrooxidans, Leptospirillum ferrooxidans and Ferroplasma spp. oxidize Fe2+ to Fe3+ whereas sulfur oxidizing thiobacteria such as Acidithiobacillus thiooxidans oxidize sulfides and other sulfur compounds. These aerobic bacteria and Archaea speed up the chemical oxidation rate of Fe2+ and sulfur compounds when molecular oxygen is present.

2.6 Acid Buffering Reactions

The oxidation of pyrite, the precipitation of iron and aluminium hydroxides, and the dissolution of some secondary minerals release hydrogen to solution. These processes increase the solution’s acidity unless the hydrogen is consumed through buffering reactions. Much of the buffering of the generated acidity is achieved through the reaction of the acid solution with rock-forming minerals in the sulfidic wastes. These gangue mineral s have the capacity to buffer acid; that is, the minerals will react with and consume the hydrogen ions. Acid buffering is largely caused by the weathering of silicates, carbonates and hydroxides.

The buffering reactions occur under the same oxidizing conditions, which cause the weathering of sulfide minerals. However, unlike sulfide oxidation reactions, acid buffering reactions are independent of the oxygen concentration of the gas phase or water in which the weathering reactions take place. The individual gangue mineral s dissolve at different pH values, and buffering of the solution pH by individual minerals occurs within certain pH regions (Fig. 2.3). As a consequence, depending on the type and abundance of gangue minerals within the waste (i.e. the buffering capacity of the material), not all sulfide wastes produce acidic leachates and the same environmental concerns.

Stepwise consumption of buffering capacity in a hypothetical sulfidic waste dump. (Reprinted from Salomons (1995) with permission from Elsevier Science)

2.6.1 Silicates

The major reservoir of buffering capacity in the environment are the silicate minerals which make up the majority of the minerals in the Earth’s crust. Chemical weathering of silicate minerals consumes hydrogen ions and occurs via congruent or incongruent weathering. Congruent weathering involves the complete dissolution of the silicate mineral and the production of only soluble components (Reaction 2.8). Incongruent weathering is the more common form of silicate weathering whereby the silicate mineral is altered to another phase (Reaction 2.9). The chemical composition of most silicates such as olivines, pyroxenes, amphiboles, garnets, feldspars, feldspathoids, clays and micas is restricted to a range of elements. Thus, the two types of silicate weathering can be represented by the following reactions:

Chemical weathering of silicates results in the consumption of hydrogen ions, the production of dissolved cations and silicic acid, and the formation of secondary minerals (Puura and Neretnieks 2000). For example, the incongruent destruction of the sodium-rich plagioclase feldspar albite (NaAlSi3O8) may produce montmorillonite (simplified as Al2Si4O10(OH)2) or kaolinite (Al2Si2O5(OH)4), depending on the amount of leaching:

The incongruent destruction of other feldspars such as the calcium-rich plagioclase anorthite (CaAl2Si2O8), and that of orthoclase, sanidine, adularia or microcline (KAlSi3O8) can be written as follows:

In most natural environments, the surface water contains dissolved carbon dioxide. The following reaction represents the incongruent weathering of K-feldspar under such conditions more accurately (Ollier and Pain 1997):

In the above chemical reactions (Reactions 2.10, 2.11, 2.12, 2.13, and 2.14), plagioclase and K-feldspar consume hydrogen ions in solution or generate bicarbonate ions. In addition, the by-products of feldspar and chlorite weathering are Na+, K+, Ca2+, silicic acid (H4SiO4) and the clay minerals kaolinite (Al2Si2O5(OH)4), illite (K2Al4(Si6Al2O20)(OH)4), or montmorillonite (simplified as Al2Si4O10(OH)2). The silicic acid or silica may precipitate as opaline silica or cryptocrystalline chalcedony (SiO2). New quartz is only rarely formed, and then it usually overgrows on pre-existing quartz grains. Clay minerals such as smectite, illite and kaolinite may weather, and their dissolution consumes hydrogen ions as the minerals dissolve (Rozalén et al. 2008; Shaw and Hendry 2009). For example, the dissolution of kaolinite can be represented by the following reaction:

If the dissolved Al3+ is allowed to precipitate as gibbsite (Al(OH)3), this neutralizing mechanism is lost because an equal amount of hydrogen will be released into solution (Deutsch 1997):

On the other hand, if gibbsite already exists as a solid phase in the waste rocks , it provides additional neutralizing ability because it can consume dissolved hydrogen ions. Similarly, ferric hydroxide solids (Reaction 2.17) previously precipitated during pyrite oxidation can be redissolved in acidic waters, thereby consuming hydrogen ions:

Quartz (SiO2), chalcedony (SiO2), opal (SiO2 · nH2O), and other silica minerals do not consume hydrogen when they weather to form silicic acid (Reaction 2.18). Silicic acid is a very weak acid and does not contribute significant hydrogen ions to solution. The acid is unable to donate protons to a solution unless the pH is greater than 9 (Deutsch 1997).

2.6.2 Carbonates

Carbonate minerals play an extremely important role in acid buffering reactions. Minerals such as calcite (CaCO3), dolomite (CaMg(CO3)2), ankerite (Ca(Fe,Mg)(CO3)2), or magnesite (MgCO3) neutralize acid generated from sulfide oxidation. Calcite is the most important neutralizing agent, because of its common occurrence in a wide range of geological environments and its rapid rate of reaction compared to dolomite. Similarly to pyrite weathering, grain size , texture and the presence of trace elements in the crystal lattice of carbonates may increase or decrease their resistance to weathering (Plumlee 1999; Strömberg and Banwart 1999). Calcite neutralizes acid by dissolving and complexing with hydrogen ion to form bicarbonate (HCO3 –) and carbonic acid (H2CO3) (Al et al. 2000; Blowes and Ptacek 1994; Strömberg and Banwart 1999; Stumm and Morgan 1995). Depending on the pH of the weathering solution, acidity is consumed either by the production of bicarbonate in weakly acidic to alkaline environments (Reaction 2.19) or by the production of carbonic acid in strongly acidic environments (Reaction 2.20).

Overall, the dissolution of calcite neutralizes acidity and increases pH and alkalinity in waters. A reversal of the Reactions 2.19 and 2.20 is possible when there is a change in temperature, loss of water or loss of carbon dioxide. Reprecipitation of carbonates will occur, which in turn releases hydrogen ions, causing the pH to fall.

The presence or absence of carbon dioxide strongly influences the solubility of calcite (Sherlock et al. 1995; Stumm and Morgan 1995). Calcite dissolution can occur in an open or closed system, depending on whether carbon dioxide is available for gas exchange. If water is in contact with a gas phase, then carbon dioxide can enter the solution and calcite dissolution occurs in a so-called open system (Reaction 2.21). In the open system, there is an increased solubility of calcite (Stumm and Morgan 1995). The unsaturated zones of sulfidic waste rock piles represent such open systems. In contrast, in the water saturated zone of sulfidic waste rock piles or tailings, there is no carbon dioxide gas phase. Here, calcite dissolves in a closed system (Reaction 2.22):

Therefore, in an open mine waste environment there is increased calcite dissolution because the calcite is exposed to a carbon dioxide gas phase. More bicarbonate is generated and more hydrogen ions are consumed than it would be the case in a closed mine waste environment (Sherlock et al. 1995).

Dissolution of other carbonates such as dolomite , ankerite or magnesite will similarly result in the consumption of hydrogen ions and in the release of bicarbonate, calcium and magnesium ions and carbonic acid. However, calcite is more easily dissolved than dolomite or ankerite. Siderite (FeCO3) is a common gangue mineral in coal deposits and various metal ores. The neutralizing effect of siderite depends on the redox conditions of the weathering environment. Under reducing conditions, siderite dissolves to form bicarbonate and Fe2+ ions. In contrast, in an open system with abundant oxygen, the dissolution of siderite has no neutralizing effect. While the generation of bicarbonate consumes hydrogen ions, any Fe2+ generated will undergo hydrolysis and precipitation (Reactions 2.5 and 2.6). This in turn generates as much hydrogen ions as are consumed by the generation of bicarbonate (Blowes and Ptacek 1994; Ptacek and Blowes 1994; Rose and Cravotta 1998). Hence, under well oxidized conditions, the net neutralizing effect of siderite dissolution is zero (Skousen et al. 1997).

2.6.3 Exchangeable Cations

A final neutralizing source in the subsurface are the cations (Ca2+, Mg2+, Na+, K+) present on the exchange sites of micas, clays and organic matter (Deutsch 1997; Strömberg and Banwart 1999). These exchangeable cations can be replaced by cations dissolved in weathering solutions. During sulfide oxidation, dissolved hydrogen and Fe2+ ions are produced which will compete for the cation exchange sites. The newly generated hydrogen and Fe2+ ions are removed from solution and temporarily adsorbed onto the exchange sites of the solid phases. Such reactions of clays with dissolved Fe2+ and hydrogen ions, respectively, can be represented as (Deutsch 1997; Rose and Cravotta 1998):

Clays may also undergo solid transformations during acid leaching whereby a potassium-bearing illite consumes hydrogen and is thereby transformed to a potassium-free smectite clay mineral (Puuru et al. 1999):

2.6.4 Reaction Rates

The weathering rate (i.e. weathering kinetics ) of individual minerals in sulfidic wastes is influenced by: (a) the mineral’s composition, crystal size, crystal shape, surface area , and crystal perfection; (b) the pH and dissolved carbon dioxide content of the weathering solution; (c) temperature; (d) redox conditions; and (e) access of weathering agent and removal of weathering products (Hodson 2006; Salmon and Malmström 2006; Sherlock et al. 1995). For example, there is a large difference in weathering rates between fine-grained waste and larger waste rock particles (diameters >0.25 mm). Smaller particles (diameters <0.25 mm) with their larger surface areas contribute to the great majority of sulfide oxidation as well as silicate and carbonate dissolution (Strömberg and Banwart 1999).

Different minerals reacting with acidic solutions have a variable resistance to weathering (Table 2.3). Minerals such as olivine and anorthite are more reactive and less stable in the surficial environment than K-feldspar, biotite, muscovite and albite (Fig. 2.4). The rates of the different acid buffering reactions are highly variable, and the major rock-forming minerals have been classified according to their relative pH-dependent reactivity (Table 2.4). Compared with the weathering rates of even the most reactive silicate minerals, the reaction rate s of carbonates are relatively rapid, particularly that of calcite (Strömberg and Banwart 1999). Carbonates can rapidly neutralize acid. In an extreme case, calcite may even be dissolved at a faster rate than pyrite. As a consequence, drainage from a calcite-bearing waste may have a neutral pH, yet the quality of the mine drainage can eventually deteriorate and turn acid as the calcite dissolves faster than the pyrite.

The stability of minerals during weathering (Sherlock et al. 1995)

Silicate minerals are abundant in sulfidic wastes, and their abundance may suggest that a waste rich in silicates has a significant buffering capacity . However, silicates do not necessarily dissolve completely, and the chemical weathering rate of silicates is very slow relative to the production rate of acid by pyrite oxidation. Therefore, rock-forming silicates do not buffer acid to a significant degree, and they only contribute token amounts of additional long-term buffering capacity to sulfidic wastes (Jambor et al. 2000c). Nonetheless, silicate mineral dissolution can maintain neutral conditions if the rate of acid production is quite slow and if abundant fine-grained, fast weathering silicates are present.

2.7 Coal Mine Wastes

Coal mining and processing generate the largest quantity of mine wastes (Fig. 2.5). The environmental issues related to coal wastes are attributable to the exposure of reduced earth materials (coal, sulfides, and Fe2+-bearing carbonates) to oxygen (Younger 2004). The consequences of oxidation of coal and associated strata range from the release of acid waters due to pyrite oxidation to the spontaneous combustion of the wastes.

Coals were initially deposited in reduced environments such as swamps and peat bogs. This depositional environment also resulted in the presence of fine-grained sedimentary rocks enclosing the coal seams (i.e. mudstones, sandstones). Hence, coals and their associated sediments commonly contain iron sulfides including major pyrite and possible traces of marcasite, galena, chalcopyrite and sphalerite. Oxidation of these sulfides may lead to AMD and metal and metalloid release (Kolker and Huggins 2007).

Coals are readily combustible sedimentary rocks, possessing significant carbon, hydrogen and sulfur contents. The total sulfur content of coals vary, ranging from a few 0.1 wt.% to extreme examples reaching 10 wt.%. Sulfur in coal occurs in three sulfur forms: (a) pyritic sulfur, (b) sulfate sulfur, and (c) organic sulfur. Much of the sulfur is organically bound within solid carbonaceous materials (i.e. the coal macerals), and this form of sulfur does not contribute to the acid generation of coal wastes. Sulfate sulfur is generally the result of oxidation of pyrite in the coal and is an indicator of weathering of the coal before or after mining. Thus, it is important to determine what percentage of the total sulfur is incorporated into acid-generating pyrite. Such knowledge allows an evaluation of the acid production of coal seams and associated rock types. At coal mines, AMD is commonly brought about by the oxidation of pyrite which is finely disseminated through the coals and associated sedimentary rocks.

Pyrite is not the only Fe2+-bearing mineral that undergoes oxidation when coal-bearing rocks are exposed to the atmosphere (Younger 2004). Carbonate minerals such as siderite (FeCO3) and ankerite (Ca(Mg,Fe)(CO3)2) are common gangue minerals of coal-bearing strata and these carbonates contain Fe2+. The weathering of siderite consumes hydrogen ions as long as the released Fe2+ does not undergo oxidation and hydrolysis because the hydrolysis of Fe3+ releases hydrogen protons. Thus, siderite dissolution in an oxidizing environment has no neutralizing effect on acid waters (Sect. 2.4.2). By contrast, the dissolution of ankerite consumes more hydrogen protons than the subsequent oxidation and hydrolysis of the released iron (Younger 2004). Consequently, ankerite possesses a net neutralization potential for acid waters.

Sulfide-bearing coal and associated sediments possess distinct geochemical compositions. Trace elements that are commonly enriched in coals and associated strata include trace metals (e.g. Cu, Pb, Zn, Ni, Co, Cd, Hg, U) and metalloids (e.g. As, Sb, Se). These elements are contained in sulfides, silicates, carbonates and organic matter (e.g. Kolker and Huggins 2007; Qi et al. 2008; Yang 2006; Zheng et al. 2007). Oxidation of sulfides and organic matter, weathering of silicate and carbonate minerals, and leaching of trace elements and other metals from coal mine wastes may impact on the receiving environment (Sect. 3.4.4).

2.7.1 Spontaneous Combustion of Pyritic Wastes

Coal and certain base metal, uranium, iron and phosphate ore deposits are hosted by sedimentary sequences, some of which contain pyritic, carbonaceous shales and mudstones. The exothermic oxidation of sulfides and organic matter in these rock types can lead to a significant increase in temperature in pyritic, carbonaceous rocks. The elevated temperatures have the potential to cause premature detonation of explosives in a charged blasthole with catastrophic consequences (Briggs and Kelso 2003). This is particularly the case for ammonium nitrate-based explosive products.

The development of even higher temperatures may lead to the spontaneous ignition of coal and carbonaceous, pyritic shales and mudstones, which has been observed naturally (Mathews and Bustin 1984). It can also occur in underground workings , open pit faces, waste rock dumps, and slag heaps (Bullock and Bell 1997; Puura et al. 1999; Sidenko et al. 2001). It is visible as smoke, comprising a variety of gases such as water vapour, sulfur dioxide, carbon dioxide, carbon monoxide, and methane. In particular, colliery spoil and carbonaceous, pyritic waste rock dumps have the tendency to burn and smoke. Vent sites are commonly coated with condensate minerals such as sulfates, halides and native sulfur (Masalehdani et al. 2009).

Coal and carbonaceous rocks often contain abundant very fine-grained, micrometer sized framboidal pyrite. Spontaneous combustion of this material is initiated through its exposure to atmospheric oxygen or oxygenated ground water. This leads to the slow exothermic oxidation of pyrite, carbon and organic matter which in turn results in a gradual rise in temperature of the rock. Any fine-grained rock materials will act as heat insulators, and the heat will not be able to escape. At some stage, enough heat is generated to ignite the carbon or organic matter . The oxidation reactions are significantly accelerated as soon as significant amounts of atmospheric oxygen or oxygen dissolved in water are supplied to the carbonaceous material, and large surface area s are exposed, for example, as a result of mining. Next, rapid oxidation of this hot pyritic, carbonaceous rock is initiated, and spontaneous combustion occurs. The organic carbon and sulfur begin to burn. Smoke and steam are released resembling volcanic fumaroles. The combustion of carbon and organic matter increases the heat of the rock which in turn increases the rate of sulfide oxidation. If there is sufficient oxygen during the combustion process, the pyrite is converted to hematite and sulfur oxides:

If there is not enough oxygen for complete oxidation, hydrogen sulfide is formed. In extreme cases of oxidation, temperatures reach 1200°C and localized melting of the rocks and wastes occurs. In such cases, the outer dump layer cracks, and surface venting of gases from sulfidic materials becomes significant. The spontaneous combustion and subsequent cooling of coal spoil and pyritic waste rock dumps produce waste materials of complex mineralogical composition, including slag -type phases, thermal metamorphic or pyrometamorphic minerals, and weathering related minerals (Dokoupilová et al. 2007; Puura et al. 1999; Sidenko et al. 2001).

If combustion has already begun in mine waste dumps, disturbing the burning heap – by excavating or reshaping it – will only provide additional atmospheric oxygen to the waste, and the rate of combustion will increase. Various methods are used to combat combustion in mine wastes, including: (a) covering the entire surface of burning spoil heaps including the batters with a thick layer of inert material; (b) compaction of the near-surface material; (c) application of a final cover layer with good water retention properties; (d) injection of water; and (e) water spraying (Fig. 2.6). However, compaction may eventually lead to cracking of the seal by pressurized gases. Also, the use of excessive amounts of water may generate steam and eventually cause steam explosions.

In order to prevent premature detonation of explosives or spontaneous combustion in carbonaceous, pyritic rocks, the rocks need to be characterized for their pyrite and organic carbon contents and their temperature. Such characterization should occur before or during mining. This will ensure that any high-risk material will undergo special handling prior to their finite disposal. Disposal options include dumping small heaps of wastes and leaving them to oxidize and cool prior to finite capping with benign wastes.

2.8 Formation and Dissolution of Secondary Minerals

The weathering of sulfides releases sulfate, metals, metalloids and other elements into solution. This water can contact more sulfide minerals and accelerate their oxidation (i.e. acid producing reactions). Alternatively, it can contact gangue mineral s , some of which react to neutralize some or all of the acid (i.e. acid buffering reactions). Above all, the reactive sulfide and gangue minerals will contribute various ionic species to the weathering solution. In fact, in many sulfidic materials the acid producing, acid buffering and non-acid generating reactions release significant amounts of dissolved cations and anions into pore water s. As a result, the waters become highly saline. Some ions will remain in solution in ionic form, where they can interact with minerals and be adsorbed. Sheet silicates such as chlorite, talc, illite and smectite are especially able to adsorb metal ions from pore solutions (Dinelli and Tateo 2001). Few ions will remain in solution indefinitely and enter ground or surface water s. Other ions will interact in the weathering solution, reach saturation levels and precipitate as secondary minerals in the waste. The formation of secondary minerals is the most common form of element fixation in pore waters of sulfidic wastes. A significant fraction of the metals released by sulfide oxidation is retained in the wastes as secondary mineral precipitates (Farkas et al. 2009; Lin 1997; Lin and Herbert 1997; Smuda et al. 2007). Such secondary mineral formation is not exclusive to the wastes themselves; numerous salts approach saturation in ground waters, streams and leachates associated with the weathering of sulfidic wastes. Therefore, a wide range of secondary minerals are known to precipitate in oxidizing sulfidic wastes and AMD environments (Table 2.5). Also, the formation of secondary minerals is not exclusive to sulfidic wastes and AMD waters. It may occur in any saline water regardless of its pH.

2.8.1 Pre-mining and Post-mining Secondary Minerals

Secondary minerals are defined as those that form during weathering. Weathering of sulfides may occur before, during or after mining. Thus, a distinction has to be made between secondary minerals formed by natural processes prior to mining and those formed after the commencement of mining (Nordstrom and Alpers 1999a).

Sulfide oxidation prior to mining results in the formation of secondary minerals . For example, if a sulfide orebody has been exposed by erosion and weathered by surface water s descending through the unsaturated zone, a near-surface oxidized layer of secondary minerals forms (Courtin-Nomade et al. 2009; Gomes and Favas 2006; Williams 1990). Some of these secondary minerals are relatively insoluble in ground and surface waters. They effectively capture the metals and reduce the release of metals into the environment. Hence, leaching of completely oxidized wastes can produce non-acid mine waters. Nonetheless, an abundance of relatively soluble sulfates such as gypsum may still result in saline, sulfate-rich drainage waters.

Sulfide oxidation during and after mining results in the formation of secondary minerals . Post-mining secondary minerals form because waste and ore have been exposed to the atmosphere and subsequently weathered. Such post-mining oxidation products occur as cements and masses within the waste and as crusts at or near the waste’s surface. The surface precipitates are commonly referred to as efflorescences. They are particularly common in waste piles, underground workings, stream beds and seepage areas, and on pit faces (Figs. 2.7, 2.8 and 2.9).

Face of the Río Tinto smelting slag dump, Spain. Mineral efflorescences commonly occur as white sulfate salt precipitates (gypsum, epsomite, hexahydrite, bloedite, copiapite, roemerite) in protected overhangs and at seepage points at the base of the slag dump. The slags generate ephemeral drainage, which runs from the dump into the Río Tinto and contributes to its acidification and metal load

The distinction of pre- from post-mining secondary minerals can be a challenging task because some minerals, particularly the soluble sulfates, may have formed during the pre- and post-mining stage. Stable isotope analyses coupled with textural analyses have proven useful in differentiating pre- and post-mining sulfates (Campbell and Lueth 2008). The precipitation of post-mining secondary minerals takes place in response to one of these following processes (Nordstrom and Alpers 1999a):

-

Oxidation and hydrolysis of the dissolved cation (Fe2+);

-

Hydrolysis of the dissolved cation (e.g. Fe3+, Al3+);

-

Reaction of acid mine waters with acid buffering minerals or alkaline waters;

-

Mixing of acid mine waters with neutral pH waters;

-

Oxidation of sulfides in humid air;

-

Concentration of the mine water due to evaporation .

Evaporation is an important mechanism in the formation of mineral salts. This process concentrates any cations and anions in mine waters until they reach mineral saturation, forming secondary minerals . Not all precipitates are crystalline, and many solids are of a poorly crystalline or even amorphous nature. The initial minerals that precipitate tend to be poorly crystalline, metastable phases that may transform to more stable phases over time (Murad et al. 1994; Nordstrom and Alpers 1999a). Consequently, the collection and identification of metastable phases using conventional laboratory techniques are troublesome, and materials should be collected and stored in airtight containers at temperatures resembling field conditions. By contrast, airborne and ground infrared spectrometry can be used to identify and map secondary iron minerals. This approach allows the discrimination and mapping of different iron minerals in exposed outcrops, waste dumps, watersheds, and streams impacted by tailings spillages (Ackman 2003; Dalton et al. 2000; Ferrier et al. 2009; Sams and Veloski 2003; Sams et al. 2003; Swayze et al. 2000; Williams et al. 2002; Velasco et al. 2005). In turn, the pH value of mine drainage waters can be inferred from the colour and spectral reflectance of the precipitates because the occurrence of different iron minerals is controlled by pH as well as other parameters.

2.8.2 Solubility of Secondary Minerals

Secondary minerals can be grouped into sulfates, oxides, hydroxides and arsenates, carbonates, silicates, and native elements (Table 2.5). The type of secondary minerals formed in mine wastes is primarily controlled by the composition of the waste. For example, coal spoils commonly possess iron, aluminium, calcium, magnesium, sodium, and potassium sulfates (e.g. Zielinski et al. 2001), whereas metalliferous waste rocks tend to contain abundant iron, aluminium and heavy metal sulfate salts.

Some of the secondary minerals are susceptible to dissolution, whereby a wide range in solubility has been noted. For example, simple hydrous metal sulfates are very soluble in water, whereas the iron and aluminium hydroxysulfates are relatively insoluble. In addition, there are a number of secondary sulfates and carbonates which are poorly soluble such as barite (BaSO4), anglesite (PbSO4), celestite (SrSO4), and cerussite (PbCO3). As a result, once these minerals are formed, they will effectively immobilize the contained elements. The minerals act as sinks for sulfate, barium, strontium, and lead in oxidizing sulfidic wastes, and their precipitation controls the amount of sulfate, barium, strontium, and lead in AMD solutions.

The water soluble hydrous metal sulfates with divalent cations (Me2+SO4 · nH2O) are the most dominant secondary mineral types (Jambor et al. 2000a, b). These hydrous sulfates may redissolve in water and release their ions back into solution:

Alternatively, the hydrous sulfates may dehydrate to less hydrous or even anhydrous compositions. For example, melanterite (FeSO4 · 7H2O) may precipitate first, which may then dehydrate to rozenite (FeSO4 · 4H2O) or szomolnokite (FeSO4 · H2O). Also, the hydrous Fe2+ sulfates may oxidize to Fe2+-Fe3+ or Fe3+ sulfate salts. For instance, the Fe2+ mineral melanterite (FeSO4 · 7H2O) may oxidize to the mixed Fe2+-Fe3+ mineral copiapite (Fe5(SO4)6(OH)2 · 20H2O) (Frau 2000; Jerz and Rimstidt 2003). The newly formed secondary minerals are more stable and resistant to redissolution compared to their precursors. Thus, secondary minerals may exhibit a paragenetic sequence whereby the minerals formed in a distinct order. The general trend for the simple hydrous sulfate salts is that the Fe2+ minerals form first, followed by the mixed Fe2+-Fe3+ minerals, and then the Fe3+ minerals (Jambor et al. 2000a, b).

Secondary minerals, be they relatively soluble or insoluble, possess large surface area s. Consequently, they adsorb or coprecipitate significant quantities of trace elements including metals and metalloids. The precipitates effectively immobilize elements in acid mine waters and hence provide an important natural attentuation and detoxification mechanism in mine waters (Berger et al. 2000; Lin 1997; Nordstrom and Alpers 1999a). However, this immobilization of metals is only temporary as many mineral efflorescences, particularly the simple hydrous metal sulfates, tend to be soluble and release their stored metals back into mine waters upon dissolution.

The presence of soluble secondary minerals in mine wastes is strongly influenced by the prevalent climatic conditions. In humid climates, soluble sulfate minerals may not accumulate because of extensive leaching. In arid and semi-arid climates, soluble minerals may persist because of high evaporation rates and a lack of rainfall.

2.8.3 Acid Consumption and Production

The precipitation of some secondary minerals may influence the mine water pH as their formation generates or consumes hydrogen ions. Generally, the formation of Fe3+ or Al3+ hydroxides generates acid, whereas the precipitation of Fe2+, Mn2, Fe3+ and Al3+ sulfate salts such as jarosite (KFe3(SO4)2(OH)6), alunite (KAl3(SO4)2(OH)6), coquimbite (Fe2(SO4)3 · 9H2O), jurbanite (Al(SO4)(OH) · 5H2O), halotrichite (FeAl2(SO4)4 · 22H2O), or melanterite (FeSO4 · 7H2O) consumes acid. However, this consumption of acidity is only temporary as these minerals, particularly the simple hydrous metal sulfates, tend to be soluble and release their stored acidity upon dissolution (Cravotta 1994) (Table 2.2). A generalized reaction for this temporary acid consumption can be written as follows:

The precipitation and redissolution of secondary minerals in sulfidic wastes may greatly influence the acidity and chemical composition of ground, surface and pore water s (Chap. 3). As a consequence, the amounts and types of secondary salts need to be determined in sulfidic mine wastes.

2.8.4 Coatings and Hardpans

The formation of secondary minerals does not only influence the mine water chemistry but it also impacts on potential water-rock reactions. For example, rapid precipitation of secondary minerals – during sulfide oxidation or carbonate dissolution – may coat or even encapsulate the acid producing or buffering mineral. Such coatings will make the mineral less susceptible to continued weathering and dissolution. Coatings developing on oxidizing sulfide grains can be exceptionally fine-grained (i.e. nm sized phases) and can consist of complex assemblages of amorphous, poorly crystalline and crystalline secondary phases (Petrunic et al. 2009).

Prolonged precipitation of secondary minerals may occur at the surface or at a particular depth of tailings dams and waste rock piles. Such continuous precipitation results in the formation of laterally extensive or discontinuous surface or subsurface layers (Alakangas and Öhlander 2006a; Boorman and Watson 1976; Blowes et al. 1991; Graupner et al. 2007; Hakkou et al. 2008a; Holmström et al. 1999; McGregor and Blowes 2002; McSweeney and Madison 1988; Moncur et al. 2005) (Fig. 2.10). Precipitated minerals include hydroxides (e.g. goethite , ferrihydrite, lepidocrocite ), sulfates (e.g. jarosite , gypsum, melanterite ), or sulfides (e.g. covellite), which fill the intergranular pores and cement the waste matrices.

In waste rock piles and tailings dams , secondary minerals typically precipitate below the zone of oxidation and at the interface between oxic and anoxic layers (Fig. 2.11). A distinct vertical colour change in the waste, from reddish-brown-yellow at the top to grey below, generally indicates the transition from an oxidized layer to reduced material. If the precipitation layer dries out and cements, it forms a so-called hardpan . This layer acts as horizontal barrier to the vertical flow of pore water s. A hardpan may also form within the zone of oxidation at a depth where the pore water reacts with acid neutralizing carbonates. The pH of the pore water rapidly rises due to carbonate dissolution, and iron precipitates as iron hydroxides which cement the waste.

Simplified diagram illustrating the formation of a hardpan layer in sulfidic wastes (after Jambor et al. 2000b). In this example, hardpan formation occurs at the water table between the saturated and unsaturated zone. A hardpan layer may also form within the unsaturated zone due to chemical reactions between an acidic leachate and a neutralizing layer

The formation of hardpans in sulfidic wastes can be induced in order to control sulfide oxidation. The addition of limestone , lime (Ca(OH)2), magnesite (MgCO3), brucite (Mg(OH)2), or other neutralizing materials, at or just below the surface of sulfidic waste, will help to generate artifical hardpans or so-called chemical covers or chemical caps of gypsum, jarosite and iron hydroxides (Chermak and Runnells 1996, 1997; Ettner and Braastad 1999; Pérez-López et al. 2007a, b; Shay and Cellan 2000). Regardless whether the hardpan is naturally formed or chemically induced using neutralizing materials, a hardpan reduces the extent of wind and water erosion at the tailings surface, limiting dust dispersion. It also protects the underlying materials from further oxidation and limits AMD generation through various processes: (a) it prevents ingress of oxygenated ground and pore water into water saturated parts of the sulfidic waste; (b) it limits the movement of atmospheric oxygen through reactive unsaturated sulfidic wastes; (c) it reduces the waste’s porosity ; and (d) it accumulates heavy metal s and metalloids through mineral precipitation, and adsorption and coprecipitation processes. However, elements not permanently fixed in insoluble minerals are susceptible to dissolution and mobilization back into pore waters. Such hardpans do not protect the sulfidic materials from further oxidation nor do they cause permanent sequestration of trace elements (Lottermoser and Ashley 2006a).

2.9 Acid Generation Prediction

AMD generation can result in surface and ground water contamination that requires expensive water treatment and involves potential liability in perpetuity. An accurate prediction of the acid producing potential of sulfidic wastes is, therefore, essential. A prediction of acid generation requires a good understanding of the physical, geological, geochemical and mineralogical characteristics of the sulfidic wastes. Data acquisition for acid generation prediction includes the completion of:

-

Geological modeling;

-

Geological, geochemical, mineralogical and petrographic descriptions;

-

Geochemical static and kinetic tests; and

-

The use of computer models for oxygen movement and geochemical processes.

2.9.1 Geological Modeling

Geological modeling is a basic technique for assessing the acid generation potential of sulfidic wastes. It involves classification of the deposit and deduction of potential acidity problems (Table 2.6). The reasoning behind this method is that ore deposits of the same type have the same ore and gangue mineral s and accordingly, the same acid producing and acid buffering materials (Kwong 1993; Plumlee 1999; Seal et al. 2000). However, the method has very limited application because it assumes that factors influencing acid generation such as pyrite surface area , abundance of sulfides or waste dump characteristics are constant for the mine sites and ore deposits being compared. The comparisons are very unreliable, yet they may provide some initial insight in the overall likelihood of acid generation. The technique may be applied to stratigraphically equivalent coal mines or ore deposits in volcano-sedimentary sequences. Thus, geological modeling and classification of an ore deposit is an initial crude step in ranking the deposit in terms of its potential to produce AMD .

2.9.2 Geological, Petrographic, Geochemical and Mineralogical Descriptions

A prediction on acid generation should begin well before sulfidic wastes are produced at mine sites. Preliminary evaluations can be performed as early as the exploration drilling and early mining of an orebody. Fundamental basic data for waste characterization and acid generation prediction include: existing lithologies; structural features; ore and gangue textures and mineralogy; particle size distribution; depth of oxidation; and whole rock geochemistry. Geological data such as pyrite content, geochemical analyses (S, C, CO3, metals), and static test data can be used to construct a three-dimensional block model of different waste rock units prior to mining (Bennett et al. 1997).

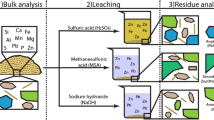

Characterization of sulfidic waste materials involves mineralogical, mineral chemical and geochemical investigations (Lin 1997; Marescotti et al. 2008). Mineralogical observations (using X-ray diffraction, optical microscopy, scanning electron microscopy, and transmission electron microscopy) should note the size, shape, surface area s, degree of crystallinity, distribution, and oxidation state of sulfides, gangue mineral s , and weathering products. As the abundance of pyrite and other sulfides in mine wastes is a crucial aspect of AMD generation, their quantity can be determined using advanced X-ray diffraction techniques (Oerter et al. 2007). Textural descriptions are also important as they can reveal protective encapsulation of sulfides in weathering resistant gangue minerals such as quartz .

Investigations using electron microprobe and synchrotron based analyses demonstrate the abundance, siting and speciation of metals, metalloids and other elements in solid waste phases (Lu et al. 2005; Schuwirth et al. 2007). The potential mobility of metals and metalloids in mine wastes and waste contaminated soils and sediments can be evaluated using partial and sequential extraction techniques (Álvarez-Valero et al. 2009; Cappuyns et al. 2007; Dold 2003; Falk et al. 2006; Heikkinen and Räisänen 2009; Hudson-Edwards and Edwards 2005; Ibrahim and Jaber 2007; Lavergren et al. 2009; Ostergren et al. 1999; Pérez-López et al. 2008; Slowey et al. 2007). Sequential leaching tests demonstrate that heavy metals may be present as cations: (a) on exchangeable sites; (b) incorporated in carbonates; (c) incorporated in easily reducible iron and manganese oxides and hydroxides; (d) incorporated in moderately reducible iron and manganese oxides and hydroxides; (e) incorporated in sulfides and organic matter ; and (f) incorporated in residual silicate and oxide minerals. The successive extractions are assumed to remove individual phases of the material selectively, while causing relatively insignificant dissolution of other phases. However, it is obvious that these differentiated wet chemistry analyses are associated with several problems. (a) the reactions involved in the leaching procedures are not selective; (b) readsorption and precipitation processes may occur; and (c) sample preparation, including drying, commonly causes transformation of labile phases to more stable components (e.g. Conesa et al. 2008).

Moreover, the bioavailability of metals and metalloids in mine wastes and their potential transfer to plants, animals and humans can be established using various extraction tests. These tests also allow an evaluation of the risk associated with the exposure of humans and animals to contaminated materials (Bruce et al. 2007; Schaider et al. 2007).

Thus, geological, petrographic, mineralogical and geochemical descriptions of sulfidic wastes provide important information on: (a) the nature and distribution of acid producing and acid buffering minerals; (b) the mineralogical siting of metals and metalloids; (c) the potential release and mobility of elements during weathering; and (d) the bioavailability of elements in mine wastes and the risk associated with human and animal exposure.

2.9.3 Sampling

The distribution of acid producing and acid consuming minerals is generally heterogeneous on micro- to macroscopic scales. Different ore lenses, coal seam s and waste materials may represent acid producing or acid buffering units. Sulfidic wastes cannot be treated as a homogeneous mass, and the accurate prediction of AMD requires an appropriate samping strategy and sampling density (Modis and Komnitsas 2007).

Waste samples can be obtained during exploration drilling and mining. However, representative sampling from drill cores is very difficult to achieve. The properties of vein deposits highlight the problems of sampling from drill cores for acid generation prediction (Dobos 2000). For example, a mesothermal gold vein deposit comprises of a rock mass, which is non-acid generating, and a series of acid generating veins with abundant pyrite (Fig. 2.12). Drilling and sampling of a composite over the entire drill section will yield a sample, largely comprising of the non-acid generating host rock. By contrast, blasting of this material will cause the rock to break along the veins, resulting in the exposure of a disproportionate amount of pyrite veins. If this mined material is dumped, it will generate more acid than the initially drilled and geochemically tested material. Therefore, geologically controlled sampling is most important in order to ensure that the analyzed samples are representative of the type and distribution of acid producing and acid buffering minerals (Dobos 2000). Otherwise, significant errors may occur when averages of static or kinetic test data are used: (a) to predict the likelihood of acid generation from a particular waste pile; or (b) to forecast the composition of seepage waters emanating from waste dumps.

Schematic diagram showing a macroscopic ore texture of a mesothermal gold deposit (after Dobos 2000). Acid producing pyrite veins are hosted by non-acid producing country rocks. The traces of drill holes into the veined rock are also indicated

Waste rock piles and coal spoil heaps of historic mining operations commonly require characterization and acid prediction . It has been suggested that the most economic sampling strategy to adequately characterize existing waste rock piles is a homogeneous composite of 15–30 samples (Munroe et al. 1999; Smith et al. 2000). However, sulfidic waste piles, particularly those dumped some time ago, may have developed a vertical mineralogical and chemical zonation. Sampling restricted to dump surfaces will disregard sulfidic, partly oxidized or secondary mineral enriched wastes at depth. Hence, drilling and profile sampling may be required to obtain sample materials representative of the entire waste dump (Farkas et al. 2009).

2.9.4 Geochemical Tests

Geochemical tests should not be conducted without detailed mineralogical and geochemical investigations of the material. Particularly, the acquisition of pure static and kinetic test data without a detailed knowledge of the mineralogical composition of the waste represents a waste by itself. Detailed procedures for various static and kinetic tests, and instructions on how to interpret them, are found in Morin and Hutt (1997). Laboratory methods for the geochemical analysis of environmental samples, including sulfidic wastes, are given by Crock et al. (1999).

2.9.4.1 Static Tests

Static tests are geochemical analyses of sulfidic waste which are used to predict the potential of a waste sample to produce acid. Details of these tests are documented in the literature (Jambor 2003; Jambor et al. 2007; Mitchell 2000; Morin and Hutt 1997; Sobek et al. 1978; Smith et al. 1992; White et al. 1999). Static tests are empirical procedures, and there is a confusing array of tests to measure and to document acid production and acid neutralization . In addition, static tests and reporting conventions vary (North America: AP, NP, NNP, NPR; Australia and the Asia Pacific region: MPA, ANC, NAPP). Fortunately, static tests can be assigned to three major categories:

-

Saturated paste pH and electrical conductivity. A representative fine-grained or crushed waste sample is saturated with distilled water to form a paste. The pH and electrical conductivity (EC) of the paste can be determined in the field or after a period of equilibration (12 –24 hours) (Morin and Hutt 1997). Paste pH measurements conducted in the field allow a rapid distinction of acid generating rocks from acid neutralising rocks. Hughes et al. (2007) recommend the use of paste pH and a simple portable carbonate dissolution test in the field for distinguishing rocks that are potentially acid forming from those that are acid neutralising. A pH value of less than 4 generally indicates that the sample is acid generating, and an EC value of greater than 20 μScm–1 indicates a high level of total dissolved solids in the waste’s leachate. Paste pH and EC values of wastes and soils forming on waste rock dumps may change over time because sulfide minerals within the materials weather and release ions into solution and the materials are flushed by infiltration and runoff waters (Borden 2001).

-

Acid Base Accounting (ABA ). Acid Base Accounting refers to the numerical data used to predict acid generation. The three components of the ABA are: (1) determination of acid production; (2) determination of acid consumption; and (3) calculation of net acid production or consumption using the data from (1) and (2).

-

1.

Determination of acid production. The Acid Potential (AP), Acid Production Potential (APP), or Maximum Potential Acidity (MPA) tests establish the maximum amount of sulfuric acid produced from sulfidic wastes. This is measured by analyzing the sample for its sulfur content. For the MPA and APP, the weight per cent sulfur is then converted to kilograms of sulfuric acid per tonne of waste (MPA value in kg H2SO4t–1=wt.% S×30.625). For the AP, the weight per cent sulfur is converted to kilograms of calcium carbonate per tonne of waste that would be required to neutralize the acidity (AP value in kg CaCO3t–1=wt.% S×31.25).

-

2.

Determination of acid consumption. The Neutralization Potential (NP), Acid Neutralizing Capacity (ANC) or Acid Consumption (AC) tests measure the amount of acid the sample can neutralize. This is determined by analyzing the acidity consumption of a sample in acid (HCl or H2SO4). Consequently, the tests establish the buffering capacity of a sample due to dissolution and weathering of gangue mineral s , or in other words, the ability of a sample to neutralize acid generated from sulfide oxidation. The NP and ANC are determined by adding acid to a sample, and then back titrating with hydroxide to determine the amount of acid the sample has consumed. The ANC value is reported in the form of kilograms of sulfuric acid consumption per tonne of waste (kg H2SO4t–1), whereas the NP value is given in the form of kilograms of calcium carbonate consumption per tonne of waste (kg CaCO3t–1).

-

3.

Calculation of net acid production or consumption. The Net Acid Producing Potential (NAPP) represents the theoretical balance of a sample’s capacity to generate acid. By contrast, the Net Neutralization Potential (NNP) gives the waste’s capacity to neutralize any acid generated.

-

3.1

NAPP calculations are based on the net acidity of samples (i.e. kilograms of H2SO4 per tonne of waste) (Environment Australia 1997). The NAPP is defined as being the difference between the Maximum Potential Acidity (MPA) and the Acid Neutralizing Capacity (ANC), whereby the MPA value is subtracted from the ANC value. A positive NAPP value indicates the sample should generate acid, whereas a negative value indicates the potential for acid neutralization (Fig. 2.13).

$${\rm{NAPP}} = {\rm{MPA}}-{\rm{ANC}}$$or

$${\rm{NAPP }}\;({\rm{kg}}{\rm{H}}_{\rm{2}} {\rm{SO}}_{\rm{4}} {\rm{t}}^{-{\rm{1}}} ) = {\rm{S}}\;({\rm{wt.}}\% )\;{\rm{3}}0.{\rm{625}}-{\rm{ANC }}\;({\rm{kg}}{\rm{H}}_{\rm{2}} {\rm{SO}}_{\rm{4}} {\rm{t}}^{-{\rm{1}}} ) $$((2.29)) -

3.2

NNP calculations are based on the net neutralizing potential available in the samples (i.e. kilograms of CaCO3 per tonne of waste) (Mitchell 2000; Skousen et al. 2002; White et al. 1999). The NNP or ABA is defined as being the difference between the Acid Potential (AP) and the Neutralization Potential (NP). In theory, the NNP value is the net amount of limestone required to exactly neutralize the potential acid-forming rock.

-

3.1

$${\rm{NNP\ or\ ABA = NP - AP}}$$or

$${\rm{NNP}}\,{\rm{or}}\,{\rm{ABA}}\,\left( {{\rm{kgCaCO}}_{\rm{3}} {\rm{t}}^{{\rm{ - 1}}} } \right) = {\rm{NP}}\left( {{\rm{kgCaCO}}_{\rm{3}} {\rm{t}}^{{\rm{ - 1}}} } \right) - {\rm{AP}}\left( {{\rm{kgCaCO}}_{\rm{3}} {\rm{t}}^{{\rm{ - 1}}} } \right)$$((2.30)) -

1.

Geochemical classification plot for mine wastes based on their wt.% sulfur and Acid Neutralizing Capacity (ANC) values. Wastes plot into the field of positive or negative Net Acid Producing Potential (NAPP) (after Smart et al. 2002). A higher ANC/MPA ratio may be used as a safety factor (2, 3 or 4 rather than 1) to classify waste samples as acid or non-acid generating

Theoretically, rocks with positive NNP values have no potential for acidification whereas rocks with negative NNP values do. In practice, a safety factor is applied and rocks with a significant positive NNP value are generally regarded as having no acidification potential (>+20 or +30 kg CaCO3t–1). Rocks with a significant negative NNP value (<–20 or –30 kg CaCO3t–1) are potentially acid generating. Materials with intermediate NNP values have uncertain acid generation potentials (–20 or –30 kg CaCO3t–1<NNP<+20 or +30 kg CaCO3t–1).

Alternatively, the ratio NP/AP, known as the Neutralization Potential Ratio (NPR), or the ratio NP/MPA can be used as the criterion to evaluate the capacity of the material to generate AMD (Heikkinen and Räisänen 2008; Price et al. 1997; Skousen et al. 2002) (Fig. 2.14). Theoretically, a NP/AP ratio less than 1 generally implies that the sample will eventually lead to acidic conditions (Sherlock et al. 1995). A ratio greater than 1 is indicative that the sample will not produce acid upon weathering. In practice, a safety factor is applied and rocks with a NP/AP ratio greater than 2, 3 or 4 are non-acid generating, whereas samples with a NP/AP ratio less than 1 have a likely acidification potential (Price et al. 1997).

Geochemical classification plot for mine wastes based on their wt.% sulfidic sulfur content and NP/AP ratio, showing the probable fields of AMD generation (after Price et al. 1997)

-

Net Acid Generation (NAG ) or Net Acid Production (NAP). The NAG test directly evaluates the generation of sulfuric acid in sulfidic wastes. It is based on the principle that a strong oxidizing agent accelerates the oxidation of sulfides. The test simply involves the addition of hydrogen peroxide to a pulverized sample and the measurement of the solution pH after 24 hours, when the oxidation reaction is thought to be complete (final NAG pH). If the NAG pH is below a critical value, then the sample has the potential to generate acid in the field (Liao et al. 2007; Schafer 2000). Variations of the NAG test procedure include the static, sequential and kinetic NAG test (Miller 1996, 1998a). A final NAG pH greater than or equal to 4.5 classifies the sample as non-acid forming. A final NAG pH result of less than 4.5 confirms that sulfide oxidation generates an excess of acidity and classifies the material as higher risk. The NAP test is similar to the NAG test and involves the addition of hydrogen peroxide and titration of the peroxide-sample slurry to a neutral pH using hydroxide . The amount of acidity consumed is reported in kilograms of calcium carbonate per tonne of waste (kg CaCO3t–1).

-

Results of NAG and NAPP tests will place a waste material into one of several categories including acid consuming (ACM), non-acid forming low sulfur (NAF-LS), non-acid forming high sulfur (NAF-HS), potentially acid forming low capacity (PAF-LC), and potentially acid forming high capacity (PAF-HC) (Table 2.7, Fig. 2.15) (Miller 1996, 1998a). If a site contains PAF-HC or PAF-LC material, then kinetic test data need to be acquired, and AMD management practices have to be established (Miller 1996, 1998a). However, attention must also be given to NAF-HS and ACM material if they host soluble secondary minerals such as gypsum. Drainage from such materials may be neutral to alkaline but exceptionally saline, thereby exceeding water quality guidelines for sulfate. In addition, neutral to alkaline drainage waters may carry exceptionally high contents of metals such as zinc, molybdenum or cadmium and metalloids such as arsenic , antimony , or selenium (Sect. 3.4.3).

Geochemical classification plot for mine wastes based on their Net Acid Producing Potential (NAPP) and NAG pH values. Wastes plot as NAF (non-acid forming), PAF (potentially acid forming) and UC (uncertain) wastes (after Smart et al. 2002)

The main advantage of these static tests is their simplicity, and most static tests can be perfomed at mine sites. However, the determination of the acid generating potential is not standardized. Also, the static tests are based on several assumptions and are, therefore, associated with many problems (Jambor 2000, 2003; Jambor et al. 2003; Miller 1996; Morin and Hutt 1997; Paktunc 1999; Weber et al. 2004; White et al. 1999):

-

The tests use powdered or crushed samples for analysis which artificially increase the grain size and expose more mineral grains to reactions.

-

Total sulfur analyses are not representative of the AP, APP or MPA because sulfur may also be present in non-acid producing sulfides or non-reactive or non-acid producing sulfates such as gypsum, anhydrite, barite or even organic material. Sulfur present in organic matter does not participate in acid generation (Casagrande et al. 1989). Organic matter is particularly common in coal spoils and washery wastes. Therefore, an acid generation prediction of such wastes using total sulfur analyses will be unreliable. Also, many sulfidic wastes contain non-acid generating sulfate minerals. It is possible to analyze for sulfidic sulfur contained in sulfides and for sulfate sulfur contained in secondary sulfate minerals (e.g. Yin and Catalan 2003). However, current bulk geochemical analytical techniques are not capable of distinguishing pyritic sulfur from sulfur present in acid producing sulfates or in other sulfides that may or may not generate acid.

-

Framboidal pyrite is more reactive than euhedral forms due to the greater specific surface area (Weber et al. 2004). As a result, NAPP testing is biased by the rapid acid generating oxidation of framboidal pyrite prior to and during the ANC test.

-

The possible coating of acid producing sulfides by secondary minerals is not taken into account, and it is assumed that the acid producing and acid consuming minerals will react completely.

-

Organic carbon is oxidized by hydrogen peroxide during NAG testing which interferes with the acidity of the solution.

-

The static tests do not allow the much slower acid buffering reactions of silicates to take place which, however, contribute only very minor amounts to the neutralization potential of sulfidic wastes (Heikkinen and Räisänen 2008; Jambor et al. 2000c).

Overall, static tests may under- or overestimate the acid production of a particular sample. As a result, numerous authors have proposed improvements and alternatives to existing static tests (e.g. Lawrence and Scheske 1997; Li et al. 2007a; Morin and Hutt 1997). These proposed methods seek to provide better estimates of sulfur speciation and acid producing minerals in the waste. Regardless of these modifications to existing laboratory protocols and the introduction of new field and laboratory tests, static tests only predict the acid potential of individual samples and not of entire waste dumps. The tests are adequate tools for preliminary evaluation of AMD and are best used as rapid screening tools to assess the likelihood of acid generation from particular sulfidic wastes (Miller 1996, 1998a).

2.9.4.2 Kinetic Tests

Kinetic tests simulate the weathering and oxidation of sulfidic waste samples. They are generally used to follow up the findings of static testing. Kinetic tests expose the sulfidic waste over time, from several months to several years, to moisture and air (e.g. Acero et al. 2007c; Alakangas and Öhlander 2006b; Falk et al. 2006; Hakkou et al. 2008b; Malmström et al. 2006; Mitchell 2000; Morin and Hutt 1997; Munk et al. 2006; Smith et al. 1992; Trois et al. 2007; Younger et al. 2002). The experiments can be accelerated to simulate long-term weathering of waste materials in a shorter time frame. Water is thereby added to the waste more frequently than it would occur under normal field conditions.

Generally, kinetic tests involve the addition of water to a known quantity of waste. Leach columns and humidity cells are the most frequently used laboratory test techniques, whereby water is dripped or trickled onto one kilogram to one tonne of sample. The acid producing and acid buffering reactions are allowed to proceed, and the leachate is periodically collected and analyzed for its composition including pH and EC as well as sulfate, metal and metalloid concentrations. Mineralogical and geochemical characterization of the sulfidic waste has to be carried out prior to and after experimentation. In laboratory kinetic tests, relatively small samples are monitored under controlled conditions (Fig. 2.16), whereas field kinetic tests monitor relatively large samples under less controlled conditions in large bins or drums (Fig. 2.17).