Abstract

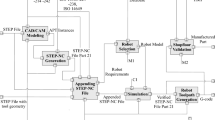

In the work the way of the virtual activating of the robotized production cell with use of the OPC server is presented. The use of CAD/CAE class systems allows simulation of the operation of an industrial robot as a part of the implementation of the modified technological process. Based on the conducted virtual tests, it is possible to verify the mechatronic function of the tested system and to predict the collision of robot elements with other elements of the system. It makes possible to eliminate collision events at the design stage of a given technological process. Robot models together with their work environment are prepared to simulate the mechatronic function of the robotized manufacturing workcell in the “Mechatronics Concept Designer” module of the PLM Siemens NX software. In the mentioned model, the “rigid body” components were created that map the geometric form of individual elements of the system, the “joint” components reflecting the nature of cooperation between the “rigid body” components, “position control” components affecting the system state and elements of the “Position sensor” type that monitors the state of the system. The OPC server is the element integrating the 3D model of the system functioning in the CAD/CAE system with the developed control application. In order to integrate the virtual model of the robotized manufacturing workcell, the objects of the “signal” type were also created, which are responsible for transmitting information about the state of the object to the control system and for reading information on the further work of the executive system.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Gawrysiak, M.: Mechatronics and mechatronics design. Wydawnictwo Politechniki Białostockiej, Białystok (1997). (in Polish)

Lückel, J.: The concept of mechatronics function modules applied to compound active suspension systems. In: Proceedings of Symposium “Research Issues in Automotive Integrated Chassis Control Systems”, International Symposium for Vehicle System Dynamics, Herbertov, pp. 1–6 (1992)

Bolton, W.: Mechatronics: Electronic Control Systems in Mechanical and Electrical Engineering. Pearson Education, Harlow (2016)

Banaś, W., Ćwikła, G., Foit, K., Gwiazda, A., Monica, Z., Sękala, A.: Experimental determination of dynamic parameters of an industrial robot. IOP Conf. Ser. Mater. Sci. Eng. 227, 1–8 (2017). https://doi.org/10.1088/1757-899X/227/1/012012

Banaś, W., Ćwikła, G., Foit, K., Gwiazda, A., Monica, Z., Sękala, A.: Modelling of industrial robot in LabView Robotics. IOP Conf. Ser. Mater. Sci. Eng. 227, 1–8 (2017). https://doi.org/10.1088/1757-899X/227/1/012011

Hryniewicz, P., Banaś, W., Foit, K., Gwiazda, A., Sękala, A.: Modelling cooperation of industrial robots as multi-agent systems. IOP Conf. Ser. Mater. Sci. Eng. 227, 1–8 (2017). https://doi.org/10.1088/1757-899X/227/1/012061

Banaś, W., Gwiazda, A., Monica, Z., Sękala, A., Foit, K.: Analysis of the position of robotic cell components and its impact on energy consumption by robot. IOP Conf. Ser. Mater. Sci. Eng. 145, 1–8 (2016). https://doi.org/10.1088/1757-899X/145/5/052017

Gołda, G., Kampa, A.: Manipulation and handling processes off-line programming with use of K-Roset. IOP Conf. Ser. Mater. Sci. Eng. 227, 1–8 (2017). https://doi.org/10.1088/1757-899X/227/1/012050

Gołda, G., Kampa, A., Paprocka, I.: Modeling and simulation of manufacturing line improvement. Int. J. Comput. Eng. Res. 6(10), 26–31 (2016)

Hetmańczyk, M., Michalski, P.: The aid of a mistake proofing with the use of mechatronic systems according to the Poka-Yoke methodology. Adv. Mater. Res. 837, 399–404 (2014). https://doi.org/10.4028/www.scientific.net/AMR.837.399

Hetmańczyk, M., Michalski, P.: The qualitative assessment of pneumatic actuators operation in terms of vibration criteria. IOP Conf. Ser. Mater. Sci. Eng. 95, 1–8 (2015). https://doi.org/10.1088/1757-899X/95/1/012056

Michalski, P., Hetmańczyk, M.: Implementation of the safety components base on industrial networks. IOP Conf. Ser. Mater. Sci. Eng. 95, 1–8 (2015). https://doi.org/10.1088/1757-899X/95/1/012085

Herbuś, K., Kost, G., Reclik, D., Świder, J.: Integration of a virtual 3D model of a robot manipulator with its tangible model (phantom). Adv. Mater. Res. 837, 582–587 (2014). https://doi.org/10.4028/www.scientific.net/AMR.837.582

Herbuś, K., Ociepka, P., Gwiazda, A.: Conception of the integration of the virtual robot model with the control system. Adv. Mater. Res. 1036, 732–736 (2014). https://doi.org/10.4028/www.scientific.net/AMR.1036.732

Banaś, W., Herbuś, K., Kost, G., Nierychlok, A., Ociepka, P., Reclik, D.: Simulation of the Stewart platform carried out using the Siemens NX and NI LabVIEW programs. Adv. Mater. Res. 837, 537–542 (2014). https://doi.org/10.4028/www.scientific.net/AMR.837.537

Herbuś, K., Ociepka, P.: Analysis of the Hexapod work space using integration of a CAD/CAE system and the LabVIEW software. IOP Conf. Ser. Mater. Sci. Eng. 95, 1–8 (2015). https://doi.org/10.1088/1757-899X/95/1/012096

Herbuś, K., Ociepka, P.: Integration of the virtual 3D model of a control system with the virtual controller. IOP Conf. Ser. Mater. Sci. Eng. 95, 1–8 (2015). https://doi.org/10.1088/1757-899X/95/1/012084

Herbuś, K., Ociepka, P.: Mapping of the characteristics of a drive functioning in the system of CAD class using the integration of a virtual controller with a virtual model of a drive. Appl. Mech. Mater. 809/810, 1249–1254 (2015). https://doi.org/10.4028/www.scientific.net/AMM.809-810.1249

Herbuś, K., Ociepka, P.: Determining of a robot workspace using the integration of a CAD system with a virtual control system. IOP Conf. Ser. Mater. Sci. Eng. 145, 1–8 (2016). https://doi.org/10.1088/1757-899X/145/5/052010

Herbuś, K., Ociepka, P.: Integration of the virtual model of a Stewart platform with the avatar of a vehicle in a virtual reality. IOP Conf. Ser. Mater. Sci. Eng. 145, 1–8 (2016). https://doi.org/10.1088/1757-899X/145/4/042018

Herbuś, K., Ociepka, P.: Verification of operation of the actuator control system using the integration the B&R Automation Studio software with a virtual model of the actuator system. IOP Conf. Ser. Mater. Sci. Eng. 227, 1–8 (2017). https://doi.org/10.1088/1757-899X/227/1/012056

Herbuś, K., Ociepka, P.: Designing of a technological line in the context of controlling with the use of integration of the virtual controller with the mechatronics concept designer module of the PLM Siemens NX software. IOP Conf. Ser. Mater. Sci. Eng. 227, 1–8 (2017). https://doi.org/10.1088/1757-899X/227/1/012057

Herbuś, K., Ociepka, P., Gwiazda, A.: Application of functional features to the description of technical means conception. Adv. Mater. Res. 1036, 1001–1004 (2014). https://doi.org/10.4028/www.scientific.net/AMR.1036.1001

Ociepka, P., Herbuś, K.: Application of CBR method for adding the process of cutting tools and parameters selection. IOP Conf. Ser. Mater. Sci. Eng. 145, 1–8 (2016). https://doi.org/10.1088/1757-899X/95/1/012100

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Herbuś, K., Ociepka, P., Gwiazda, A. (2019). Virtual Activating of a Robotized Production Cell with Use of the Mechatronics Concept Designer Module of the PLM Siemens NX System. In: Burduk, A., Chlebus, E., Nowakowski, T., Tubis, A. (eds) Intelligent Systems in Production Engineering and Maintenance. ISPEM 2018. Advances in Intelligent Systems and Computing, vol 835. Springer, Cham. https://doi.org/10.1007/978-3-319-97490-3_41

Download citation

DOI: https://doi.org/10.1007/978-3-319-97490-3_41

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97489-7

Online ISBN: 978-3-319-97490-3

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)