Abstract

This paper described an optimization method of deciding the location of RTS (robotic total station) in tunnel deformation monitoring of a series of points. Normally the method of resection and polar coordinate was utilized in deformation monitoring by RTS, in which two datum points should be installed in immovable location and the robotic total stations could be installed in movable location. Usually the locations were decided from human experience. This paper presented methods of evaluating the systematic accuracy, which were functions of the locations of the RTS and two datum points. Then the systematic accuracy could be optimized by some optimization methods. This method was applicable in installation of the RTS system in tunnel deformation monitoring.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

RTS (Robotic total stations) are widely utilized in the engineering measuring such as tunneling engineering, structural engineering, etc. The method of resection and polar coordinate is a usual method in the installation of the robotic total stations, in which one robotic total station and two datum points are installed. In this method two datum points should be installed in immovable location and the robotic total stations could be installed in movable positions. Usually the two datum points and the robotic total stations were installed based on human experience. This paper presents a method of evaluating the systematic accuracy of the installation of the RTS and two datum points. Based on the evaluating method, a method of minimizing the systematic errors was presented based on the optimization method.

Usually only the position of the RTS and two datum points need to be determined before engineering measuring. For each point there are x, y and z positions, thus there are 9 unknowns in the measuring systems. Generally, for a RTS, the measuring error of the distance is A mm ± 1 ppm form and the error of the angle is B” form (as for one commercial robotic total station, the measuring error of the distance is 0.6 mm ± 1 ppm and the measuring error of the angle is 0.5”). Thus, there a best position, which has minimum system error during measuring for one project.

There are two possible evaluating methods for the total systematic error of measuring projects. First is that the total adding together error is minimum of all measuring points. Second is that the maximum error of one single measuring point is minimum of the system. This paper gives the possible methods of calculating the two different optimized installing points for RTS and datum points.

2 Method

Assume the positions of all the measuring points are already known. The position of the RTS and two datum points needs to be determined. Also assume the total systematic error of the measuring project is only related to the measuring distances and angles. Other errors such as temperature, sunlight, wind etc. are not considered in this paper. The measuring process of one single point has two steps: first, is the decision of the position of the RTS and the initial direction of the horizontal dial by resection method from two datum points; second, is the decision of the measuring point by polar coordinate method from the RTS.

While S means slope distance and D means horizontal distance. α and β mean horizontal and vertical angles. α0 means an initial angle and C is a constant. O represented the position of RTS, A and B represented two datum points, and i represented each of the measuring points. The position of all the points was shown in Fig. 1. Coordinates of unknowns could be expressed from the known parameters. The total differential could be calculated. The mean square error could be determined by the total differential.

Then, the error of position of measuring points could be determined,

Also, the mean square errors are,

Thus, the mean square of each direction of position of every single measuring point could be determined. There are two possible methods of evaluation of the overall error of all the measuring points. Assume the mean error of single measuring point is

The overall systematic error of the measuring system could be evaluated by

Or by

Basically, this optimization problem is a constrained optimization problem of 9 degrees of freedom. The best position of total station and two datum points could be calculated by optimization method [1, 2].

3 Application

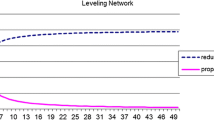

This paper chose the least square method to be applied to the decision of the position of total station and two datum points in tunnel engineering. Since total station and the two datum points are always installed on the side wall of the tunnel and the problem could be simplified into a one-dimension problem, i.e. only the X coordinates (Assuming the X direction is the tunnel direction) of the three points needed to be decided. The testing case is as follows: Width of the tunnel is assumed to be 6 m; The deformation extent is from 0–150 m; Inside measuring points should be installed every 10 m at both sides of the tunnel (totally 30 points); Two datum points should be installed outside the deformation zone; Total station could be install in deformation zone; All measuring points, datum points and total station are assumed to be the same height. The calculated positions of the total station and two datum points were illustrated in Fig. 2. The calculated mean square errors are 4.28 mm2.

4 Conclusion

This paper presented methods of evaluating the systematic error of deformation measuring by RTS, which were functions of the locations of the RTS and two datum points. The error could be optimized by some optimization methods. This method was preliminary tested in installation of the RTS system in tunnel deformation monitoring and valid result could be obtained.

References

Nelder, J., Mead, R.: A simple method for function minimization. Comput. J. 7(4), 308–313 (1965)

Yan, H., Yang, W.: Surveying Principles and Methods. Science Press, Beijing (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Switzerland AG

About this paper

Cite this paper

Liu, B., Wei, Y. (2018). Optimization of Location of Robotic Total Station in Tunnel Deformation Monitoring. In: Wu, W., Yu, HS. (eds) Proceedings of China-Europe Conference on Geotechnical Engineering. Springer Series in Geomechanics and Geoengineering. Springer, Cham. https://doi.org/10.1007/978-3-319-97112-4_158

Download citation

DOI: https://doi.org/10.1007/978-3-319-97112-4_158

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97111-7

Online ISBN: 978-3-319-97112-4

eBook Packages: EngineeringEngineering (R0)