Abstract

Recovery of uranium in conventional ion exchange circuits, using strong base or weak base resins containing quaternary or tertiary amine functional groups, is based on an anion exchange mechanism. In saline liquors, chloride competes with uranium for the active resin sites and reduces resin loading. This results in significant negative impacts on the IX process in terms of plant throughput and operating costs. In this paper we present the results of a study on the recovery of uranium from an acidic in situ leach liquor containing approximately 9 g/L chloride . A range of resins was tested, and a high capacity strong base resin was identified with significantly enhanced loading compared to conventional resins. Other process-relevant criteria such as loading kinetics and elution efficacy are also discussed. The process developed was successfully tested during a recent ion exchange pilot plant operated in conjunction with a field-leach trial.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

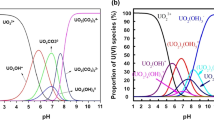

The Honeymoon Uranium Project is located in South Australia. A plant was operated on the site by Uranium One between 2011 and 2013 using an in situ recovery (ISR ) process. The pregnant leach solution (PLS ) contained relatively high chloride concentrations, up to 10 g/L Cl, and a novel process using a mixed solvent was adopted to address this challenge. The mixed solvent suffered from a number of drawbacks including a propensity for crud formation and poor phase disengagement in stripping [1], in part due to iron transfer combined with the need for an alkali stripping process [2]. Ion exchange (IX) technology is particularly well suited to address these problems.

The main challenge with the application of IX to saline liquors is the resultant depression in uranium loading on the resin. For example, 23–30 g/LWSR U3O8 loading was reported on strong base resin Duolite A101 DU for a fluidised CIX pilot plant trial, using a feed of ~250 mg/L U3O8 [3]. Experimental studies performed more recently with macroporous SBA resin Dow Ambersep® 920, have indicated that at equilibrium, a 50 mg/L U3O8 feed achieves a loading of 28 g/LWSR U3O8 with Ambersep® 920U SO4, and 21 g/LWSR U3O8, with the larger size bead Ambersep® 920 U XL [4]. When chloride is present, the loading is severely affected as highlighted by a study using SBA Dowex® 21 K XLT, where equilibrium loading at 7.5 g/L Cl and 50 mg/L U3O8 was reported as <10 g/LWSR U3O8 [5].

Fainerman et al. studied the potential of weak base anion (WBA) exchange resins for the extraction of uranium from saline liquors and found that they are more chloride tolerant than strong base anion exchange (SBA) resins that are routinely applied for uranium recovery [6]. The study identified that whilst WBA resins containing tertiary amines were effective up to chloride concentrations of approximately 12 g/L, WBA resins containing more complex amine functionality were effective at higher chloride concentrations (22 g/L Cl). For applications of moderate salinity, ANSTO proposed a process combining the use of tertiary amine WBA resins with NaCl elution and nanofiltration for eluant recycle [7].

Boss Resources has taken over the Honeymoon Project and is currently investigating options to restart the operation. The company has recently completed a Pre-Feasibility Study [8] and carried out a Field-Leach Trial with an continuous counter-current ion exchange (CCIX) pilot plant operated in parallel [9]. This paper outlines results from a test work program conducted by ANSTO for BOSS Resources, aimed at determining the most suitable resin for the extraction of uranium from the saline ISR liquors. A range of resins was screened and their performance with respect to loading, elution and kinetics assessed. The work culminated with the operation of the ion exchange pilot plant at Honeymoon in September 2017.

Materials and Methods

For the laboratory tests, a synthetic leach liquor was produced to simulate the Honeymoon ISR leach liquor . The liquor composition is outlined in Table 1. Commercially available resins were used, with properties as described in Table 2. Resins were converted to sulfate form by contact with 1 M H2SO4 and not screened prior to the tests.

Resins were measured on a ‘wet settled resin’ basis [10]. For the chemical equilibrium tests, the resin and aqueous solutions were contacted by bottle roll at 30 °C for 24 h at varying resin to liquor volumes. Uranium was doped into solution in some points. For extraction kinetics experiments, a single bottle roll contact was used with liquor sampled at regular intervals. A 27 mm inner diameter column (80 mLWSR bed volume) was used for the loading experiments with pre-heated feed liquor (30 °C) pumped down-flow. In the column based elution experiments, a 16 mm inner diameter jacketed column (15 mLWSR bed volume) was used and the eluant was pumped down-flow. Liquors were analysed by ICP-OES, and resins were analysed for uranium by Delayed Neutron Activation (DNA) analysis using the OPAL reactor at ANSTO. Chloride concentrations in liquors and resin strip solutions were determined by titration with AgNO3. During the pilot plant at Honeymoon, liquors and resins were analysed by a portable XRF unit (Olympus Innov-X X-5000). Selected liquor /resin samples were sent to ANSTO for analysis.

Results and Discussion

Laboratory Extraction Isotherms

The extraction of uranium by several resins was characterised using loading curves spanning a range of uranium concentrations encompassing the feed tenors expected at the Honeymoon ISR operation. The resins selected included both a conventional tertiary amine WBA resin (WBA 1) and a complex amine WBA resin (WBA 2). The two SBA resins tested had different capacities and back-bones and did not have conventional quaternary ammonium functional groups. The resins were selected based on previous experience and all have shown an advantage in loading when compared with conventional SBA resins. SBA 2 had only just been released at the start of the project and had not previously been tested. It was included due to its high capacity.

The results for the equilibrium extraction isotherms are shown in Fig. 1. SBA 2 exhibits a clear advantage in loading performance compared with the other resins, reaching 57 g/Lwsr U3O8 at 100 mg/L U3O8 in solution, compared with the other resins which loaded around 18–20 g/Lwsr U3O8. The resin loaded about 0.2–0.45 g/Lwsr Fe, which shows that it is highly selective for uranium over Fe3+. The fact that the resin is capable of loading that much uranium in the presence of almost 9 g/L Cl represents a significant breakthrough for uranium processing using saline water sources.

The shape of the SBA 2 isotherm is quite steep, suggesting a strong interaction between uranium and the resin in addition to the high capacity. While this is advantageous in extraction , it also means that elution would be expected to be more difficult. Of the other resins examined, SBA 1 and WBA 2 performed best at elevated tenors (>100 mg/L U3O8), while SBA 1 and WBA 1 were better at lower tenors. Thus, SBA 1 was the best performing of the other resins examined with respect to equilibrium uranium extraction .

Laboratory Extraction Kinetics

Another important consideration for the ion exchange process is the kinetics of extraction . The kinetics of extraction for the various resins tested is illustrated in Fig. 2. Experiments were conducted as batch bottle roll experiments over a 24 h period with liquor sampled at regular intervals during the first 8 h. The results show that the order of decreasing extraction kinetics in terms of approach to equilibrium extraction was SBA 1 > WBA 1 > SBA 2 > WBA 2.

Generally speaking, SBA resins extract uranium faster than WBA resins [11, 12], macroporous resins are kinetically quicker than gel resins [13] and resins with smaller beads load faster than those with larger beads [11, 14]. SBA 1 and WBA 1 are both monodisperse resins with similar bead sizes (~550 μm, with a uniformity coefficient 1.1–1.2). Of the two, SBA 1 would be expected to be better kinetically due to the strong base functionality. The other two resins are more polydisperse, with uniformity coefficient of ~1.7. SBA 2 and WBA 2 will therefore contain a greater proportion of kinetically slow larger beads. The elongated tails evident in the high loading tests for SBA 2 and WBA 2 could be due to slow penetration of the larger beads.

Bench Scale Breakthrough Curve

Column -based breakthrough curves were obtained for each of the resins at a flow rate of approximately 5 BV/h. The results are shown in Fig. 3, and highlight the superior performance of SBA 2, which took approximately 360 BV to break through to 5% of the feed concentration versus 130 BV for the next best performing resin (SBA 1). The slope of the breakthrough curve was greatest for SBA 1, followed by WBA 1, SBA 2 and WBA 2. This is consistent with the order of extraction rate.

Bench Scale Column Elution

Ion exchange processes using SBA resins commonly use H2SO4 and NaCl for elution [11, 12, 14]. Of the two, NaCl is more effective; but its use can introduce chloride into recirculating liquors, which will have a deleterious impact upon uranium extraction if not properly controlled. Nitrate elution is very effective and has also been used in uranium IX circuits [14]. However, its use introduces similar problems as chloride elution, with additional complications associated with nitrate waste liquor disposal due to environmental concerns.

Fixed bed column elution experiments were conducted to explore potential options for SBA 2, for which the elution characteristics were not known. Various eluants were tested and the results are presented in Fig. 4. The results show that elution with 1 M H2SO4 is ineffective, highlighting the very strong interaction between uranium and the resin in a sulfate environment . Elution with a total of 1 M chloride (i.e. 0.1 M HCl + 0.9 M NaCl) was more effective, with a peak uranium tenor of 4.0 g/L U3O8 for a loaded resin containing 38.6 g/Lwsr U3O8. However, the elution profile was quite broad, and even after 20 BV the elution was not complete (0.94 g/Lwsr U3O8 remaining on the resin).

Additional experiments were conducted to assess whether a further increase in the feed chloride concentration would improve the uranium elution. The tests used 1.5 M total chloride with either 0.1 M HCl or 0.05 M H2SO4. The results (Fig. 4) show that for sulfate free eluants, the elution peak was reached in fewer bed volumes when using 1.5 M Cl than with 1.0 M Cl. This can most likely be ascribed to higher chloride concentrations in the initial period of elution, when chloride adsorption by the resin is strongest. It is also possible that the elution equilibrium is more favourable for 1.5 M Cl.

Interestingly, the acid used to acidify the eluant had a significant impact on the elution. The 0.05 M H2SO4 containing eluant was significantly less effective than the 0.1 M HCl eluant. It was suspected that the cause of the difference is the resin’s exceptional affinity for uranyl sulfate.

Continuous Counter-Current Ion Exchange Pilot Plant Site Trial

The Honeymoon Field Leach Trial CCIX Pilot Plant was operated continuously at site for a period of 10 weeks from Sep to Nov 2017, using live feed produced by the Honeymoon field leaching trial (FLT). The plant consisted of 3 modules each including 7 fluidised ion exchange contactors approximately 1 m in height. The contactors in each module were arranged as a cascade. The 21 contactors were divided into loading (14 contactors) and elution (7 contactors). Each contactor consisted of an annular space where the resin was fluidised, a central feed well and a screened launder for screening of resin and liquor .

The feed consisted of blended PLS containing 50 mg/L U3O8, a tenor which was historically typical for the site [1]. Later in the trial, a concentration of 75 mg/L U3O8 was also tested, but these results are not presented here. All the liquors produced were returned to the FLT operation. Loading was conducted continuously and in a counter current manner. The eluant consisted of 1.5 mol/L NaCl and 0.1 mol/L HCl. Elution was also operated in a counter-current mode. A short water wash of the resin in the lead contactor was conducted following loading to minimise contamination of the eluate.

The results of the laboratory test work presented in this paper were modelled to define the base case operating conditions. A summary of the operating conditions are presented in Table 3. The loading and elution liquor to resin flow rate ratios were 652 and 11, respectively. The elution circuit was operated for 0.83 h out of every 6 h period, to allow for fluidisation of the resin bed under the lower flow conditions of the elution circuit. The PLS generated by the FLT was blended to maintain a constant feed concentration. The pH of the feed was lower than tested in the laboratory work, but the chloride concentration was similar.

The results presented in Table 3 are based on 36 cycles, or approximately 9 days of operation. The barrens concentration during this period averaged 4 mg/L U3O8, equivalent to ~92% extraction . During an 84 cycle operating period, corresponding to 57% of the time the tenor of the feed to the plant was ~50 mg/L mg/L U3O8, higher extractions with barrens ≤1 mg/L were consistently achieved The loading achieved was 28 g/LWSR U3O8, which was approximately 60% of the equilibrium value.

The resin loading achieved in this trial (~28 g/LWSR U3O8) is comparable with previously published pilot plant trial results with feeds containing no chloride and in some cases higher uranium tenors.

A liquor and resin profile, sampled from the 14 contactors of the loading circuit is presented in Fig. 5. The measured concentrations in both liquor and resin displayed good use of the entire length of the circuit. Also presented in Fig. 5, alongside the sample profiles, are modelled results using equilibrium and kinetic parameters estimated from laboratory test work data. The model gave a reasonable fit of the plant data suggesting that pre-pilot plant modelling is very useful to predict and set operating conditions for the plant.

The degree of elution consistently achieved was >97%, demonstrating that uranium concentration <1 g/LWSR U3O8 on the eluted resin is possible. However, there was limited opportunity to increase the eluate concentration above 2 g/L U3O8 without increasing the residual uranium in the eluted resin. Table 4 provides eluate and eluted resin concentrations as a function of eluant to resin flow ratio for periods of relatively stable operation. Further decrease in the ratio of eluant to resin flowrate resulted in unacceptably high residual uranium remaining in the eluted resin. Future work will focus on optimising and improving elution protocols to achieve higher uranium concentrations in the eluate, while keeping the residual uranium in the eluted resin at acceptably low concentrations. Additionally, a concentration step such as nanofiltration can be employed prior to product recovery [15]. Interestingly, the exceptional loading characteristics of this resin allowed for relatively low barrens (<4 mg/L U3O8), at relatively high uranium in the eluted resin (2.4 g/LWSR U3O8).

The process showed good selectivity with respect to Fe, with concentration of Fe in the eluate measured at 4–6 mg/L iron as compared to total Fe of 1 g/L in the PLS . The eluate purity was reflective of the high selectivity of the resin towards uranium .

Conclusions

In the course of a targeted test work program for BOSS Resources, a SBA resin capable of effectively loading uranium in the presence of 9 g/L Cl was identified. The resin exhibited exceptional loading characteristics and good selectivity over ferric ions. Elution was tested and a mixed NaCl/HCl eluant was shown to be effective. The resin was not amenable to sulfuric acid elution.

A continuous counter current ion exchange pilot plant was operated for 10 weeks to test the process and proved to be successful in achieving low barrens (4 mg/L U3O8) and high resin loadings (28 g/LWSR U3O8). The eluate concentration was limited to ~2.5 g/L U3O8, under the conditions tested in the pilot plant .

The results represent a significant improvement in the processing of uranium ores using saline water sources.

References

Ballestrin S, Low R, Reynaud G, Crane P (2014) Honeymoon Mine Australia: commissioning and operation of the process plant using a novel solvent extraction reagent mixture in a high chloride environment. In: ALTA uranium conference. ALTA Metallurgical Services, Perth, Australia

Quinn JE, Wilkins D, Soldenhoff KH (2013) Solvent extraction of uranium from saline leach liquors using DEHPA/Alamine 336 mixed reagent. Hydrometallurgy 134–135:74–79

Haines AK (1978) The development of continuous fluidized bed ion exchange in South Africa, and its use in the recovery of uranium. J South Afr Inst Min Metall 78(12):303–315

Cheira MF, Atia BM, Kouraim MN (2017) Uranium(VI) recovery from acidic leach liquor by Ambersep 920U SO4 resin: Kinetic, equilibrium and thermodynamic studies. J Radiat Res Appl Sci 10(4):307–319

Soldenhoff K, Davidson J (2005) Uranium recovery from highly saline in situ leach solution by ion exchange. In: First extractive metallurgy operators’ conference. AUSIMM, Brisbane, Australia

Fainerman-Melnikova M, Soldenhoff K (2010) Uranium extraction from saline solutions using weak base anionic resins. In: Uranium 2010-the future is U. Saskatoon, Canada

Wilson A, Fainerman-Melnikova M, Soldenhoff K (2011) What are the options for an integrated IX process to recover uranium from saline and hypersaline liquors? In: ALTA uranium conference. ALTA Metallurgical Services, Perth, Australia

BOSS Resources Ltd. (2017) Honeymoon pre-feasibility study heralds near term production potential. https://bossresources.com.au/wp-content/uploads/2017/05/170531-1-Announcement-BOE-PreFeasibility-Study-5.pdf. Accessed 13 March 2018

BOSS Resources Ltd. (2017) Honeymoon field leach trial outright success. https://bossresources.com.au/wp-content/uploads/2017/11/HoneymoonField-Leach-Trial-Outright-Success.pdf. Accessed 13 March 2018

Ford MA, Lombaard LR (1986) Standard test methods for the strong-base resins used in the recovery of uranium. Mintek, South Africa

Merritt RC (1971) The extractive metallurgy of uranium. Colorado School of Mines Research Institute, USA, pp 138–182

Sole KA, Mooiman MB, Hardwick E (2016) Present and future applications of ion exchange in hydrometallurgy: an overview. In IEx 2016. Society of Chemical Industry, Cambridge, United Kingdom

McGarvey FX, Hauser EW, Kinetic studies on gel and macroporous anion exchangers using the uranyl sulfate/sulfate exchange. In: Liberti L, Millar JR (eds) Fundamentals and applications of ion exchange. Springer Netherlands, Dordrecht, pp 81–101

Himsley A (1986) Application of ion exchange to uranium recovery. Ion exchange technology in the nuclear fuel cycle. IAEA, Vienna, pp 53–85

Peacock M, McDougall S, Boshoff P, Butcher D, Ford M, Donegan S, Bukunkwe D (2016) Paladin Energy Ltd.—Nanofiltration technology for reagent recovery. In: ALTA uranium REE conference. ALTA Metallurgical Services, Perth, Australia

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Soldenhoff, K., Quinn, J.E., Safinski, T., Bowes, K., Ford, M. (2018). Breakthrough in Uranium Recovery from Saline Liquors by Ion Exchange. In: Davis, B., et al. Extraction 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-95022-8_179

Download citation

DOI: https://doi.org/10.1007/978-3-319-95022-8_179

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-95021-1

Online ISBN: 978-3-319-95022-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)