Abstract

Fiber-reinforced polymer (FRP) jacketing or wrapping has become an attractive strengthening technique for concrete columns. Within this strengthening technique, FRP composites are wrapped around the concrete column with the fibers in the jacket being oriented in the hoop direction. In practice, the FRP jackets can be either continuous or discontinuous along the column height and thus the resulting column is referred to as fully or partially wrapped FRP-confined concrete columns. Existing research has demonstrated that the partially strengthening technique by discrete FRP strips is a promising and economic alternative to the fully FRP strengthening technique. Although a number of experimental investigations have been conducted on partially wrapped FRP-confined concrete columns, the stress-strain behavior of FRP-confined concrete in partially wrapped concrete columns is not yet understood. This paper presents an experimental program to investigate the axially compressive behavior of circular concrete columns partially wrapped with FRP strips. The test results are presented and compared with the predictions from a typical analysis-oriented stress-strain model to examine its reliability and accuracy. It has been demonstrated that the model provides reasonably accurate predictions of the ultimate axial stress of partially FRP-confined concrete while it usually underestimates the ultimate axial strain.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

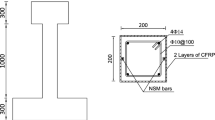

Existing research has demonstrated that the fully FRP confinement can significantly enhance the compressive strength and deformation capacities of circular concrete columns (Lam and Teng 2003; Matthys et al. 2005; Pham et al. 2013; Lin and Teng 2017). Alternatively, the concrete column can be wrapped with longitudinally discrete (i.e., spaced) FRP strips/hoops (Fig. 1), which is referred to as a partially FRP-confined concrete column. Although most of the existing studies are related to fully FRP-confined concrete columns, partially FRP-confined concrete columns have also been demonstrated to process an adequate increase in strength and a remarkable increase in axial deformation capacity compared with their counterparts (i.e., un-confined concrete columns) (e.g., Barros and Ferreira 2008; Park et al. 2008; Wei et al. 2009; Campione et al. 2015; Pham et al. 2015; Zeng et al. 2017). In addition, strengthening columns with discrete FRP strips is expected to be able to avoid FRP buckling failure which will easily occurred in concrete-filled FRP tubes as the axial stiffness of the FRP tube cannot be neglected. Also, less FRP materials are needed for partially FRP-confined concrete columns and thus partial FRP strengthening can be applied easier and faster than full FRP strengthening (Pham et al. 2015; Zeng et al. 2017).

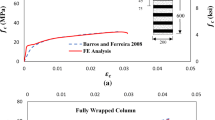

The interest to understand the behavior of partially FRP-confined concrete has led to a few experimental studies on the behavior of concrete in partially FRP-confined columns (Barros and Ferreira 2008; Park et al. 2008; Campione et al. 2015; Pham et al. 2015; Triantafyllou et al. 2015; Saljoughian and Mostofinejad 2016; Zeng et al. 2017). The confinement in the axially loaded circular columns fully wrapped by FRP jackets is uniform. However, as for the confined concrete in partially FRP-confined circular columns, the confinement is non-uniform (Fig. 1) for the section at a given horizontal level within the bare concrete between two FRP strips (Mander et al. 1988). The use of discrete FRP strips results in the less efficient confinement to the concrete between the two adjacent FRP strips. The confinement mechanism is similar to the concrete confined by steel hoops or spirals, in which the reduced confinement effect between two adjacent strips can be considered through the “arching effect”. Based on the arching action assumption, a parabola with an initial slope of 45° covering a clear vertical spacing (\( s_{f}^{\prime} \)) between two FRP strips is defined to separate the effectively confined part from the ineffectively confined part of the concrete core (Fig. 1). As illustrated in Fig. 2, the ineffective confinement area is located between two adjacent FRP strips. The difference of confinement mechanisms between fully and partially FRP-confined concrete implies different behavior between them, which may lead to the difference in stress-strain curves between the confined concrete in partially FRP-confined concrete columns and that in fully FRP-confined concrete columns. As a result, the reliability and accuracy of existing theoretical models for fully FRP-confined concrete need to be carefully examined for their applicability for partially FRP-confined concrete.

To this end, an experimental program was conducted to study the axially compressive behavior of circular columns wrapped with CFRP strips. In total 60 columns were prepared and tested. The main test variable examined in this experimental program included the clear spacing and width of FRP strips. The test results, in term of the effects of the clear spacing and width of FRP strips on the axial compressive behavior of partially FRP-confined concrete, were presented and discussed. A widely accepted analysis-oriented stress-strain model proposed by Teng et al. (2007) was used to predict the stress-strain behavior of partially FRP-confined concrete and its reliability and accuracy were examined by the comparisons between the test results and the model predictions.

2 Experimental Program

Totally sixty FRP-confined cylindrical column specimens were tested to investigate the effects of FRP strip width, clear spacing and FRP thickness. All specimens had a diameter of 150 mm and a height of 300 mm. Note that the clear spacing and width of FRP strips are the main parameters studied in the current study and they represent the coefficient of FRP vertical efficiency. Note that the vertical confinement effectiveness coefficient, which is a coefficient representing the coefficient of FRP vertical efficiency, is given by \( \left( {1 - s_{f}^{\prime} /2D} \right)^{2} \) where \( s_{f}^{\prime} \) is the clear spacing of two adjacent FRP strips and \( D \) is the diameter of the column (fib 2001). The design of strip number and strip width led to several different clear spacing ratios in present study. It is noted that the ratio between the clear spacing of two adjacent FRP strips and the column diameter is referred to as clear spacing ratio (i.e., \( s_{f}^{\prime} /D \)), as shown in Fig. 1. Each column has two nominally identical specimens.

The flat coupon tensile tests were conducted to determine the material properties of FRP sheets, following the recommends specified in the ASTM standard (ASTM D3039 2008). The average values of tensile strength, elastic modulus and rupture strain were determined as 4185.6 MPa, 259.7 GPa and 1.75%, respectively. Column compression test was conducted using a displacement controlled procedure with a rate of 0.4 mm/min.

3 Conclusions

The test results of 60 circular columns fully or partially wrapped with FRP strips are presented in this paper. A widely accepted analysis-oriented model proposed by Teng et al. (2007) is used to predict the stress-strain behavior of partially FRP-confined concrete, and the reliability and accuracy of the model are then examined through the comparisons between the test results and the model predictions. Based on the study presented in this paper, the following conclusions can be drawn:

-

(1)

Significant increases in the strength and axial deformation capacity are obtained for partially FRP-confined concrete. Similar to fully wrapped columns, partially wrapped columns are mostly failed due to the rupture of FRP strips. However, an increase in the clear FRP strip spacing may lead to the crushing failure of the bare concrete between two adjacent strips.

-

(2)

A three-segment stress-strain curve can predict the behavior of partially FRP-confined concrete better compared with a two-segment stress-strain curve which normally captures the behavior of fully FRP-confined concrete well. This three-segment stress-strain curve is consisted of a first linear ascending segment, a transition segment and a second ascending/descending segment.

-

(3)

The stress-strain curves of FRP-confined concrete in fully wrapped columns show monotonically ascending behavior owing to the sufficient FRP confinement. For partially FRP-confined concrete, the slope of the third segment is increased with the width of FRP strips while it is nearly independent to the FRP strip thickness. The normalized axial strength increases with the width of FRP strips for specimens confined with four or five FRP strips while it seems to be independent to the width of FPR strips for specimens confined with only three FRP strips. The ultimate axial strain of concrete increases with the width of FRP strips. The normalized axial strength and ultimate strain increase with the FRP thickness. An increase in the clear spacing of adjacent FRP strips leads to a decrease in the axial strength while the ultimate axial strain of concrete and the hoop rupture strain of FRP are approximately independent to the clear spacing of adjacent FRP strips.

-

(4)

The equation for calculating the minimum amount of FRP is conservative. There may exist an optimum value of \( s_{f}^{\prime} /d \) around 0.5, leading to the monotonic ascending stress-strain behavior not easily being obtained (i.e., \( f_{cu}^{\prime} /f_{co}^{\prime} > 1 \)).

-

(5)

Teng et al.’s (2007) model is reasonably accurate for predicting the axial strength of partially FRP-confined concrete, providing that the confinement effectiveness coefficients (fib 2001; CNR-DT 200 R1 2013) have properly been considered. However, the predicted ultimate strain is significantly underestimated and the stress at the turning point is also underestimated by Teng et al.’s (2007) model.

References

ASTM D3039: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials (D3039M), West Conshohocken, USA (2008)

Barros, J.A.O., Ferreira, D.R.S.M.: Assessing the efficiency of CFRP discrete confinement systems for concrete cylinders. J. Compos. Constr. 12(2), 134–148 (2008)

CNR-DT 200 R1: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures, Advisory Committee on Technical Recommendations For Construction, National Research Council, Rome, Italy (2013)

Campione, G., La Mendola, L., Monaco, A., Valenza, A., Fiore, V.: Behavior in compression of concrete cylinders externally wrapped with basalt fibers. Compos. Part B Eng. 69, 576–586 (2015)

fib: Externally Bonded FRP Reinforcement for RC Structures. The International Federation for Structural Concrete, Lausanne, Switzerland (2001)

Hadi, M.N.S., Pham, T.M., Xu, L.: New method of strengthening reinforced concrete square columns by circularizing and wrapping with fiber-reinforced polymer or steel straps. J. Compos. Constr. 17(2), 229–238 (2013)

Lam, L., Teng, J.G.: Design-oriented stress-strain model for FRP-confined concrete. Constr. Build. Mater. 17(6–7), 471–489 (2003)

Lin, G., Teng, J.G.: Three-dimensional finite-element analysis of FRP-confined circular concrete columns under eccentric loading. J. Compos. Constr. 21(4), 04017003 (2017)

Mander, J.B., Priestley, M.J., Park, R.: Theoretical stress-strain model for confined concrete. J. Struct. Eng. 114(8), 1804–1826 (1988)

Matthys, S., Toutanji, H., Audenaert, K., Taerwe, L.: Axial behavior of large-scale columns confined with fiber-reinforced polymer composites. ACI Struct. J. 102(2), 258–267 (2005)

Park, T.W., Na, U.J., Chung, L., Feng, M.Q.: Compressive behavior of concrete cylinders confined by narrow strips of CFRP with spacing. Compos. Part B Eng. 39(7–8), 1093–1103 (2008)

Pham, T.M., Doan, L.V., Hadi, M.N.: Strengthening square reinforced concrete columns by circularisation and FRP confinement. Constr. Build. Mater. 49, 490–499 (2013)

Pham, T.M., Hadi, M.N.S., Youssef, J.: Optimized FRP wrapping schemes for circular concrete columns under axial compression. J. Compos. Constr. 19(6), 04015015 (2015)

Saljoughian, A., Mostofinejad, D.: Axial-flexural interaction in square RC columns confined by intermittent CFRP wraps. Compos. Part B Eng. 89, 85–95 (2016)

Teng, J.G., Huang, Y.L., Lam, L., Ye, L.P.: Theoretical model for fiber-reinforced polymer-confined concrete. J. Compos. Constr. 11(2), 201–210 (2007)

Triantafyllou, G.G., Rousakis, T.C., Karabinis, A.I.: Axially loaded reinforced concrete columns with a square section partially confined by light GFRP straps. J. Compos. Constr. 19(1), 1–15 (2015). 04014035

Wei, H., Wu, Z., Guo, X., Yi, F.: Experimental study on partially deteriorated strength concrete columns confined with CFRP. Eng. Struct. 31(10), 2495–2505 (2009)

Zeng, J.J., Guo, Y.C., Gao, W.Y., Li, J.Z., Xie, J.H.: Behavior of partially and fully FRP-confined circularized square columns under axial compression. Constr. Build. Mater. 152, 319–332 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Zeng, JJ., Li, LJ., Guo, YC. (2019). Stress-Strain Behavior of Circular Concrete Columns Partially Wrapped with FRP Strips. In: Gdoutos, E. (eds) Proceedings of the First International Conference on Theoretical, Applied and Experimental Mechanics. ICTAEM 2018. Structural Integrity, vol 5. Springer, Cham. https://doi.org/10.1007/978-3-319-91989-8_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-91989-8_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-91988-1

Online ISBN: 978-3-319-91989-8

eBook Packages: EngineeringEngineering (R0)