Abstract

Metallic glasses are known for their outstanding mechanical strength but limited plasticity. Significant progress has been made in recent years in how to optimize processing conditions for bulk glass formation, net-shape forming and the microscopic mechanism of failure. However, the details of the correlation between atomic structure, defects and thermo-mechanical treatments utilized for structure modification and their impact on shear band nucleation and propagation for achieving macroscopic ductility are still not well understood.

This talk attempts to shed light on structural (re)ordering, recovery and rejuvenation mechanisms, as well as nanocrystallization phenomena in different metallic glasses when they are subjected to different casting conditions, relaxation or thermoplastic net shaping. The findings will be discussed with respect to short- and medium-range order modulation, defect generation and annihilation, and precipitation of secondary phases. The structural changes will be correlated with changes in plastic deformability and failure mechanisms, and the effectiveness of composition tuning and thermo-mechanical processing for plasticity improvement will be analyzed in order to derive design aspects and processing guidelines for property optimization of metallic glasses.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Structure Modulation and Mechanical Properties

1.1 Motivation and Background

Metallic glasses (MGs) are an exciting class of materials due to their unique properties, such as high strength and good wear resistance [1]. A major drawback is their limited ductility caused by the formation of shear bands leading to catastrophic failure. While progress in the understanding of early stages of deformation localization was made using colloidal solids or molecular dynamics simulations [2], an experimental understanding is still lacking. The reason is the disordered nature of MGs inhibiting direct imaging of the fundamental deformation mechanisms. Another drawback is that the structure and properties of MGs strongly depend on their processing history [3] and thus the atomic structure and the resulting properties can be largely tuned through thermo-mechanical treatments utilized for structure modification [4, 5].

1.2 Influence of Thermal and Mechanical History on Properties of MGs

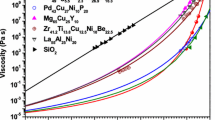

The influence of structural (re)ordering, recovery and rejuvenation mechanisms, as well as nanocrystallization phenomena has been tested for a variety of metallic glasses with different composition. The MGs were subjected to different casting conditions, as well relaxation treatment or thermoplastic net shaping in the supercooled liquid regime. These different treatments induce changes in the short- and medium-range order of the glass or may even lead to precipitation of secondary phases via crystallization at elevated temperatures. The structural changes are correlated with changes in plastic deformability and failure mechanisms, as revealed by detailed structure investigations and mechanical testing. Recent results on the effectiveness of composition tuning, microalloying and thermo-mechanical processing for plasticity improvement suggest that possible plasticity improvement is closely correlated with structural heterogeneities and the behavior of different structural motifs under localized stress and strain fields.

References

Ashby, M.F., Greer, A.L.: Metallic glasses as structural materials. Scripta Mater. 54, 321–326 (2006)

Cubuk, E.D., et al.: Structure-property relationships from universal signatures of plasticity in disordered solids. Science 358, 1033–1037 (2017)

Scudino, S., Shakur Shahabi, H., Stoica, M., Kaban, I., Escher, B., Kühn, U., Vaughan, G.B.M., Eckert, J.: Structural features of plastic deformation in bulk metallic glasses. Appl. Phys. Lett. 106, 1–4 (2015). 031903

Sarac, B., Zhang, L., Kosiba, K., Pauly, S., Stoica, M., Eckert, J.: Towards the better: Intrinsic property amelioration in bulk metallic glasses. Sci. Rep. 6, 1–8 (2016). 27271

Bian, X.L., Wang, G., Yi, J., Jia, Y.D., Bednarcik, J., Zhai, Q.J., Kaban, I., Sarac, B., Mühlbacher, M., Spieckermann, F., Keckes, J., Eckert, J.: Atomic origin for rejuvenation of a Zr-based metallic glass at cryogenic temperature. J. Alloy. Compd. 718, 254–259 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Eckert, J. (2019). Structure Modulation and Nanocrystallization of Metallic Glasses: How to Tune Mechanical Properties. In: Gdoutos, E. (eds) Proceedings of the First International Conference on Theoretical, Applied and Experimental Mechanics. ICTAEM 2018. Structural Integrity, vol 5. Springer, Cham. https://doi.org/10.1007/978-3-319-91989-8_81

Download citation

DOI: https://doi.org/10.1007/978-3-319-91989-8_81

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-91988-1

Online ISBN: 978-3-319-91989-8

eBook Packages: EngineeringEngineering (R0)