Abstract

Persimmon production has continued to increase in recent years. It is now being cultivated in more countries and new varieties are also reaching markets. One important feature that differentiates persimmon from other fruit crops is that the fruits from some cultivars are astringent at harvest, while other cultivars produce non-astringent fruits. Therefore, from a postharvest point of view, some cultivars require specific treatments being applied to remove astringency before their commercialization. On the other hand, storage of persimmons is limited by their sensitivity to manifest chilling injury at low temperature; the main chilling injury symptoms are related to textural changes. This chapter presents the postharvest biology and technology aspects of persimmon fruits.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Persimmon fruit belongs to the botanical family Ebenaceae, in the genus Diospyros (‘the fruit of the Gods’ in ancient Greek). This genus, with more than 2000 species, originated from China, and there is evidence for its existence some centuries before Christ. It was introduced to Japan and Europe in the seventh and seventeenth centuries respectively. Most of the cultivars whose fruits are edible belong to the species Diospyros kaki L.f., and species Diospyros lotus L.f. and Diospyros virginiana L.f. are relevant because they are used as rootstocks .

According to the FAO statistical databases (2014), persimmon is cultivated at an area of 1,025,989 ha, with a worldwide production of 5,190,624 tons. China is the main producer, whose production has doubled in the last decade. In countries like Brazil, South Korea, and Japan, persimmon production has remained constant in the last decade, while other countries like Azerbaijan and Uzbekistan have tripled their production. In Spain, persimmon production is now five-fold higher than it was 10 years ago (MAPAMA 2017).

Persimmon fruit, which is also known as kaki , is a botanical berry. There are hundreds of persimmon cultivars of varying fruit shape from spherical to acorn, flattened or squarish, while size can be as small as 50 g and can reach as much as 300 g, depending on the cultivar . External fruit color varies from one cultivar to the next, from light yellow-orange to dark orange-red. Persimmon structure consists of a rather homogeneous parenchymatous pericarp surrounded by a thin skin covered by a waxy cuticle (Pérez-Munuera et al. 2009a). The parenchyma cells of the mesocarp are irregularly shaped, but are basically round with a diameter ranging from 100 to 130 μm. The inside of cells is almost completely taken up by a large vacuole (Salvador et al. 2007).

Persimmons are considered a good source of readily available carbohydrates and a high content of bioactive compounds , such as tannins, polyphenols, steroids, dietary fiber, organic acids, minerals, and carotenoids , which contribute to the high antioxidant potential of these fruits (Santos-Buelga and Scalbert 2000). Recently, several studies have focused on persimmon fruit components and related them to various physiological functions. Indeed, it has been demonstrated that persimmons possess hypolipidemic and antioxidant properties , which are attributed to their water-soluble dietary fiber , carotenoids , and polyphenols (Gorinstein et al. 1998), with persimmon phenols being mainly responsible for the antioxidant effect of this fruit (Gorinstein et al. 2011). Persimmon peel has also been shown to be a valuable source of antioxidants, which under diabetic conditions, can reduce the oxidative stress induced by hyperglycemia (Yokozawa et al. 2007).

An important feature that differentiates persimmon from other fruit trees is that fruits from some cultivars are astringent at harvest, while other cultivars produce non-astringent fruits. The high soluble tannins content in fruit pulp is responsible for the astringency sensation when bitten. Astringency is the sensation that results when tannins bind salivary proteins and cause them to precipitate or aggregate, which leaves a rough ‘sandpapery’ or dry sensation in the mouth. Removal of astringency while preserving fruit quality has been one of the main challenges of food scientists working on persimmon. Moreover, persimmon fruit are sensitive to manifest chilling injury when stored at low temperatures. Therefore, the application of treatments to prolong the shelf life of persimmon fruit is a key step of postharvest technology.

Fruit Growth, Maturation, and Ripening

Fruit Growth

Persimmon fruits have a double sigmoidal growth curve : two periods of rapid growth (stages I and III), separated by a period of slow growth (stage II). Temperature plays an important role in both the growth and ripening of persimmon fruits (Sugiura et al. 1991), and climatic differences between persimmon-growing regions cause a wide variety in persimmon fruit growth rates (Mowat and George 1996). Candiret al. (2009) described the duration of stages I, II, and III as being 105–119, 21–35, and 21–42 days, respectively, at low and high altitudes. The cell division of persimmon fruits occurs actively at full bloom and the number of cells is significantly related to fruit size at harvest (Hamada et al. 2008). On average, increased fruit weight has been reported to be approximately2 g per day (Choi et al. 2013). At the end of stage II, fruits begin to turn yellow-orange, which indicates the occurrence of color break .

Like pruning , flower or fruit thinning are important cultural practices that affect fruit growth (Choi et al. 2014), as it improves fruit size and color. Thinning is also used to reduce biennial bearing , particularly if it is carried out in the flowering stage. Fruit set and fruit growth are sensitive to water stress (Buesa et al. 2013; Naor 2006), which may be the major cause of low fruit yields.

Maturation and Ripening

Based on their respiration and ethylene pattern, persimmon fruits are categorized as climacteric fruit . They produce a small but significant amount of ethylene during the ripening period (Itamura et al. 1991). Indeed, a low but evident peak in ethylene production is linked to the fruit maturation process (Salvador et al. 2007). Persimmons are also very sensitive to exogenous ethylene exposure and are induced to ripen with autocatalytic ethylene production by being exposed to exogenous ethylene (Wills et al. 1998; Kubo et al. 2003; Besada et al. 2010a).

Like many other fruits, change in external color is the most evident feature to take place during persimmon maturation . Thus, fruit external color changes from green to yellow-pale orange and then becomes an intense orange-red color. These changes are related to chlorophyll degradation and to carotenoids accumulation . β-Cryptoxanthin, zeaxanthin, antheraxanthin , and violaxanthin are the main carotenoids detected in persimmon skin (Ebert and Gross 1985; Niikawa et al. 2007). According to Niikawa et al. (2007), lutein mainly accumulates in the green stages, while β-cryptoxanthin and zeaxanthin abundantly accumulate in the coloring stages. The fact that skin turns to dark orange-red tones have been linked to a drastic increment in lycopene content in the most advanced maturity stages.

Changes in skin to achieve the characteristic orange-red color have often been linked to loss of firmness and to a reduction in the soluble tannins responsible for astringency (Salvador et al. 2007; Del Bubba et al. 2009; Tessmer et al. 2016). In fact, a strong and negative correlation has been observed between color and firmness values (Tessmer et al. 2016). Gradual fruit softening during ripening is related to microstructural changes in flesh, such as progressive parenchyma degradation with less swollen and more deformed cells. As maturity advances, degradation of cell walls and membranes takes place, and intercellular spaces are filled with solutes, which leads to a generalized loss of intercellular adhesion in the most advanced maturity stages. As explained later on, reduction in tannins during maturation differs between astringent and non-astringent cultivars .

The predominant sugars in persimmon are glucose, fructose, and sucrose, and a gradual increment in total sugars content generally takes place from the green stages to the mature ones (Zheng and Sugiura 1990; Senter et al. 1991; Del Bubba et al. 2009). However, in astringent cultivars, such an increase in sugars is not reflected in the measurement of total soluble solids because soluble tannins are included in the measurement of soluble solids. Therefore, the content of soluble tannins decreases, while the values of soluble solids remain constant, which indicates a parallel increase in sugars. Del Bubba et al. (2009) reported a gradual reduction in total vitamin C from values of 0.18 g/100 g to 0.8 g/100 g during both the growth and maturation periods of two astringent cultivars. Such a drop in vitamin C does not seem to be related to a degradation process, but to increased fruit weight.

In parallel to the skin color changes exhibited by persimmon fruits during maturation, the flesh color also evolves from white to orange. Similarly to that observed in loquat cultivars, in which red-fleshed and white-fleshed fruits are distinguished, some persimmon cultivars depict a much more intense orange-colored flesh at the time of commercial harvest than others (Zhou et al. 2011). β-Cryptoxanthin has been reported as the predominant carotenoid found in the flesh of different persimmon cultivars (Del Bubba et al. 2009; Zhou et al. 2011). Lutein, violaxanthin, zeaxanthin, and β-carotene are flesh persimmon carotenoids , and their levels vary greatly among cultivars.

Differences Between Astringent and Non-astringent Cultivars

According to the level of astringency at harvest, persimmon cultivars are classified into two general categories: astringent and non-astringent (the latter is also called ‘sweet’ persimmons ) (Yonemori et al. 2003). In both categories, the fruit astringency of some cultivars is influenced by pollination (pollination variant) and cultivars whose fruits are not affected by pollination (pollination constant). Therefore, persimmon fruits can be classified into four groups: (1) the pollination constant non-astringent (PCNA) group, which is non-astringent irrespective of seeds being present, and fruits can be eaten at harvest when they are as crisp as apples; (2) the pollination variant non-astringent (PVNA) group, which is non-astringent at harvest if fruits have seeds, and fruits are not edible when firm if they have been not pollinated; (3) the pollination constant astringent (PCA) group, which is always astringent when firm; (4) the pollination variant astringent (PVA) group, which is also astringent if pollinated, and is non-astringent only around seeds, where there are dark tannin spots.

The cultivars that belong to the PCNA group can be eaten with high firmness, since their soluble tannins content is low enough not to be sensory-detected. On the contrary, the other cultivars show a high soluble tannins content at harvest; thus, they must be subjected to postharvest deastringency treatments before being marketed. Otherwise, they must be left on trees until they overripen and can, consequently, be eaten as soft persimmons.

Fruits of both the astringent and non-astringent types are highly astringent during the immature stages . Differences in astringency between them appear during the growth and ripening stages. Non-astringent cultivars show a gradual decrease in soluble tannins, which becomes sensorially non-detectable in the first coloring stages. Thus, in non-astringent cultivars like ‘Jiro ’ and ‘Harbiye ’, values close to 0.03% of soluble tannins have been reported at harvest (Taira et al. 1998; Candir et al. 2009). Astringent cultivars also display a gradual reduction of soluble tannins , but it is much less marked. Therefore, the fruits of astringent cultivars have high soluble tannins content even when fully colored and astringency becomes undetectable only in overripened stages, when fruits are completely soft. Astringent cultivars , such as ‘Hiratanenashi’, ‘Rojo Brillante’, or ‘Tipo’, contain a soluble tannins content that comes close to 0.5–1% (Taira et al. 1998; Salvador et al. 2007; Del Bubba et al. 2009) during the stage when fruits are completely colored and show marked firmness. Astringency is only lost in overripened stages, when soluble tannins content decrease to values of around 0.03% (Tessmer et al. 2016).

Early cessation of tannin cell development is thought to be the main cause of natural astringency loss in PCNA fruits, as it results in a diluted tannins concentration in flesh as fruits grow (Yonemori and Matsushima 1985). Yonemori and Suzuki (2009) described how tannin cells are densely distributed and interconnected as a continuous mass of tannin cells in astringent and non-astringent cultivars in cell division stages, while tannin cells distribute in a scattered manner in PCNA-type fruits and densely in PCA-type ones in late fruit development stages. Studies which have involved measuring the expression of the genes involved in flavonoid biosynthesis support this theory. According to Ikegami et al. (2005a, b), flavonoid biosynthesis genes are expressed at high levels in both PCA and PCNA types in early development stages. However, in the PCA-type cultivars, it remains high until the late development stages of fruit, which coincides with continuous tannin accumulation in fruits, while the expression of such genes in PCNA-type cultivars declines to become undetectable in late development stages, in parallel to tannins accumulation terminating.

Recently, Tessmer et al. (2016) observed the evolution of soluble tannin in two astringent and two non-astringent cultivars from the green to the overripened stages by light microscopy (LM) . This technique allowed a much higher content of soluble tannins present in the flesh of astringent fruits to be viewed compared to the non-astringent ones in green stages, which must be related to the early cessation of tannins accumulation. This study also revealed that the tannins insolubilization process takes place inside tannin cells in both astringent and non-astringent cultivars. Therefore, loss of astringency in PCNA cultivars seems to be a combination of an early cessation of tannins accumulation, followed by a later process of soluble tannins that remain in flesh. However, more studies are needed in order to understand the natural insolubilization process .

Soluble tannins are well known for having a high antioxidant capacity . Therefore, the differences in soluble tannins content during the development and maturity of astringent and non-astringent fruits are also manifested in this sense. Thus, antioxidant capacity is much higher in astringent fruits than in non-astringent ones. Although, all persimmon cultivars show a declining antioxidant capacity during maturation, it is more marked in astringent than in non-astringent fruits (Tessmer et al. 2016).

Another feature that seems to be conditioned by cultivar type is the sugar accumulation. PCNA cultivars have been reported to share a common pattern, in which the glucose and fructose concentration lowers from the green stage to color break and then increases again as fruits gain their orange color, while the sucrose concentration remains at relatively constant values (Novillo et al. 2015a).However, in non-PCNA cultivars, different sugar evolution trends are observed, depending on the cultivar: (1) glucose and fructose increase with maturation, while sucrose shows slight changes (Novillo et al. 2015a) or an increasing–decreasing parabolic-like evolution (Del Bubba et al. 2009); (2) a gradual increase in glucose, fructose, and sucrose as the maturity process advances (Senter et al. 1991; Zheng and Sugiura 1990).

Different sugar accumulation trends have been related to invertase activity (Giordani et al. 2011). Gallic and tannins acids have been reported to inhibit the activity of this enzyme (Chen et al. 2003), and, therefore, it is possible that the tannins present in persimmon also have an effect on the enzyme activity. This would explain why PCNA cultivars share a similar sugar accumulation pattern, which depends on the cultivar in astringent ones.

Factors That Affect the Maturity Process

The persimmon season is quite short, as it does not generally last more than 2or 3 months. Therefore, extending the harvest period has been one of the aims of postharvest technologists. Plant regulators have proven to be a useful tool to advance and delay fruit maturation. Preharvest applications of ethephon and paclobutrazol have been commercially applied in different cultivars to advance the maturity period. Ethephon , when metabolized by the plant, is converted into ethylene and its effect on advancing persimmon maturation has been extensively observed (Kim et al. 2004). Paclobutrazol , which is an inhibitor of gibberellin biosynthesis , is applied to soil in spring and has also been found to be effective in advancing fruit ripening (Ben-Arie et al. 1997). It is noteworthy that the application of both ethephon and paclobutrazol negatively affects the postharvest life of fruit as the postharvest softening rate is enhanced (Ben-Arie et al. 1997). Therefore, this fruit should be rapidly commercialized, given its short shelf life period.

Gibberellic acid (GA3) has been applied to different cultivars, such as ‘Triumph’, ‘Fuyu’, and ‘Hiratanenashi’, to delay fruit maturation (Ben-Arie et al. 1997; Agustí et al. 2003; Lee et al. 1997; DanielI et al. 2002; Nakano et al. 1997). This growth regulator is applied by spraying the tree upon fruit color breaking. Contrarily to that mentioned for ethephon and paclobutrazol, applying GA3 has a positive effect on preserving fruit quality during the postharvest life. It lowers the postharvest deterioration rate and allows longer fruit storage (Ben-Arie et al. 1997; Besada et al. 2008a). Ben-Arie et al. (1997) reported that the combined use of paclobutrazol and GA3 enables precocious harvesting, followed by an extended shelf life.

The maturity process can also be affected by environmental stress situations. The application of short-term regulated deficit irrigation (50% of the recommended amount of water) has been reported to induce the fruit maturation of cultivars ‘Rojo Brillante’ (Intrigliolo et al. 2011) and ‘Triumph’ (Ben-Arie et al. 2008). Maturity advance has been shown as increased skin color and reduced flesh firmness. Such an effect seems to depend on the fruit growth stage when water is restricted. While restricted irrigation carried out in phases II or III of ‘Rojo Brillante’ growth induced fruit maturation, this effect was not observed when water restriction took place in phase I of fruit growth.

Chloride stress is another environmental stress that has been recently reported to induce persimmon maturation. Besada et al. (2016) reported that fruits from trees grown under salinity conditions accumulated chloride in the calyx, which stimulated ethylene production in this tissue. In the fruits affected by slight and moderate salt stress, calyx ethylene production accelerated the maturity process, which was reflected as increased fruit color and as reduced fruit firmness. When salinity stress levels were severe, the high levels of ethylene produced by the calyx triggered autocatalytic ethylene production in other fruit tissues, which resulted in a drastic advance in fruit maturity . Besides the effect of advancing maturity, both water restrictions and salinity conditions have been reported to reduce the final fruit size.

Postharvest Handling

Harvest

Harvesting of persimmon fruit takes place in October to November. Clipping fruits from trees with cutters and leaving the calyx and a short stem attached to fruits are recommended practices. Snapping fruits from trees is an option, but only if skilled pickers have enough knowledge to avoid any kind of fruit injury.

As with many other commodities, the maturity index used to decide the harvest of persimmons is external color. Fruits need to be well developed and display the cultivar’s characteristic color before being harvested. Most persimmon cultivars are considered ready for harvest when they display a full orange to orange-red color, with no visible green background . Depending on the cultivar and the seasonal conditions, the number of pickings done to complete the harvest varies from one to three.

Sugar content can be a good maturity index for non-astringent cultivars, but it is not adequate for astringent ones. This is because the measurement of soluble solids includes not only sugar, but also soluble tannins. It must be taken into account that, even for non-astringent cultivars, the content of total soluble solids required for harvest depends on the climatic conditions where cultivated. For the cultivar ‘Fuyu’, a soluble solid content of 15°Brix is recommended at harvest in New South Wales, while in Japan, the ‘Fuyu’ cultivar is harvested at 18°Brix (Agfacts 2003). Color maturity charts , which link external color with internal maturity, are useful tools to facilitate harvesting decisions.

Treatments to Remove Astringency

The postharvest application of deastringency treatments is a necessary requirement to commercialize fruits from astringent cultivars. As previously mentioned, natural astringency loss in this kind of cultivar only occurs on trees in overripened stages. Therefore, one of the traditional methods to remove astringency at harvest consists of treating fruit with ethylene (10 ppm at 20 °C) or ethephon (50–500 ppm) to enhance the maturity process. In these cases, astringency removal occurs in parallel to a drastic loss of firmness; therefore, fruits are commercialized when very soft. This implies many postharvest handling limitations, and also shortens the fruit’s postharvest life. Thus, fruit submitted to astringency removal by overripening is usually commercialized in local markets.

Different methods (exposing fruits to alcohol, CO2, N2, or warm water) allow persimmon astringency to be removed, while preserving fruit firmness. The effectiveness of these treatments relies on exposing fruits to anaerobic conditions . Acetaldehyde accumulates in flesh under anaerobic conditions and polymerizes soluble tannins (responsible for astringency) to form insoluble compounds, which are non-astringent (Matsuo and Itoo 1982; Taira et al.1997). Accordingly, many studies have related the rate of soluble tannins insolubilization to the amount of accumulated acetaldehyde in the flesh (Taira et al. 1989; Sugiura and Tomana 1983; Pesis et al. 1988). The process of tannins insolubilization induced by increasing acetaldehyde production has been observed at the microstructural level as insoluble material appearing inside the vacuoles of some tannic cells, which were initially filled with soluble material (Salvador et al. 2007).

Among the treatments based on exposing fruits to anaerobic conditions, carbon dioxide and alcohol methods are stressed for their effectiveness and for being commercially adopted. The application of these treatments consists in enclosing fruits in specialized chambers with high CO2 concentrations or with ethanol vapors. In both cases, the deastringency process rate is influenced by both intrinsic and extrinsic factors . With CO2 treatment, which has been more extensively studied, temperature, CO2 concentration, and treatment duration are the main intrinsic factors that affect its efficiency. Several studies have dealt with optimizing these parameters according to the cultivar; nowadays, the habitual conditions range from 80 to 95% CO2 applied for 1–3 days (20 °C and 90% RH).

It is necessary to keep in mind that the process followed to remove astringency consists of two phases : an induction phase in which fruits must be maintained for a minimum period at high CO2 concentrations and a series of reactions are triggered, and a second phase in which astringency gradually disappears and the presence of CO2 is not essential (Gazit and Adato 1972). Matsuo and Ito (1977) determined that these two phases were temperature-dependent. The optimum temperature at which to apply treatment has been widely investigated for the astringent varieties that are mainly commercialized. However, less attention has been paid to determine the effect of temperature on astringency loss which occurs once fruits no longer remain in the presence of CO2. Thus, more studies are needed to optimize this process phase.

Treatment duration depends not only on the applied temperature and CO2 concentration , but also on the extrinsic treatment factors. Apart from variety (Novillo et al. 2013), treatment efficiency strongly depends on the fruit’s physiological status (Taira et al. 1990). It can be generally stated that the more advanced is maturity, the more difficult it is to remove astringency and, therefore, applications need to last for more hours (Besada et al. 2010b). Apart from maturity status, it has also been reported that the previous conditions to which fruits have been exposed can also affect their response to CO2. In this sense, the effectiveness of the astringency removal treatment with CO2 has been shown to diminish in the fruits that have been previously stored at 15 °C for longer duration. This phenomenon has been related to structural changes at the cell level that the flesh undergoes during storage at that temperature. As storage at 15 °C is prolonged, degradation of the initial cell structure of flesh happens and intercellular spaces , which were initially empty, are progressively filled by cell material. It has been hypothesized that CO2 diffusion through intercellular spaces becomes more difficult and leads to a low anaerobic respiration rate and, consequently, to lesser acetaldehyde accumulation. Therefore, it results in incomplete tannins insolubilization, with the subsequent residual astringency sensation (Salvador et al. 2008).

Several preharvest stresses have also been observed to affect deastringency treatment effectiveness. Thus, fruit from trees exposed to extreme water stress or to intense salinity conditions does not properly respond to deastringency treatment (Besada et al. 2016).

Of all the aforementioned factors, the treatment duration is the easiest handled in fruit and vegetable centers. With major varieties like ‘Rojo Brillante’ and ‘Triumph’, the standard duration is considered to be 24 h. Depending on factors such as temperature, CO2 concentration, and the fruit maturity stage, this duration could be shorter or longer. Optimum treatment duration is the minimum duration needed to ensure that astringency-free fruits reach consumers.

Most research that has compared the effectiveness of ethanol and CO2 methods revealed that CO2 treatment is significantly more effective in removing astringency than applying ethanol (Taira et al. 1992a, b). This is linked to faster acetaldehyde accumulation in CO2-treated fruit compared to fruit treated with ethanol (Taira et al. 1992a; Tanaka et al. 1994; Yamada et al. 2002). Slow ethanol penetration through the skin and/or slow alcohol metabolism to acetaldehyde can explain this fact (Taira et al. 1992b; Itamura et al. 1991; Tanaka et al. 1994). It has also been demonstrated that the combined use of high levels of CO2 and ethanol treatments may increase deastringency process efficiency (Taira et al. 1992a). This can be a good alternative in those cases in which CO2 treatment has to be prolonged to ensure complete astringency removal (e.g., when treating fruits in an advanced maturity stage at temperatures below 20 °C). It is important to note that exposing fruits to CO2 deastringency treatment for excessively long periods may result in internal flesh browning being manifested (Fig. 1). This browning type becomes visible around the core of fruits, mainly in the area that surrounds the calyx. It has been observed that the intensity of this disorder associated with CO2 application increases if fruits are stored at low temperature after removing astringency . In order to avoid this browning, fruits were submitted to the CO2 treatment for the number of hours required to remove astringency. Therefore, planning the treatment application so that fruits in a CO2 chamber are in a similar physiological stage is highly recommended because, in this way, CO2 overexposure is avoided, as all the fruits in the chamber require similar treatment duration.

Storage

Low Temperature and Chilling Injury

Storage at low temperature is the predominant method used to preserve the postharvest life and to extend the marketing span of most perishable fruits. In temperature management during cold storage, it is important to take into account that persimmon fruits, as well as other tropical and subtropical commodities, are susceptible to chilling injury (CI) development during cold storage when held below a critical temperature.

The sensitivity of persimmon to CI is cultivar-dependent; cultivars like ‘Fuyu’, ‘Suruga’, or ‘Rojo Brillante’ are very chilling-sensitive, whereas others like ‘Triumph’ or ‘Hachiya’ are less susceptible to this disorder (Collins and Tisdell 1995; Arnal and Del Rio 2004).

CI symptoms, as well as their incidence and severity, depend on the cultivar, storage temperature, and duration. Nevertheless, firmness disorders are reported as one of the main CI manifestations in all sensitive cultivars. In the cultivar ‘Fuyu’, CI is initially expressed by flesh gelling (development of a gel-like consistency in flesh) and increased skin transparency through which the characteristic gel can be seen (MacRae 1987a) (Fig. 2a). In other cultivars, such as ‘Suruga’ or ‘Rojo Brillante’, the main CI symptom is a drastic loss of firmness (Collins and Tisdell 1995; Arnal and Del Rio 2004) (Fig. 2b). Other symptoms that have been associated with CI development are loss of fruit flavor, compacted flesh areas, and internal browning in ‘Rojo Brillante’ persimmons (MacRae 1987b; Woolf et al. 1997a; Collins and Tisdell 1995; Salvador et al. 2005). In general, CI symptoms became more severe after transferring fruits from low to ambient temperatures, although they can also be exhibited during cold storage (Woolf et al. 1997a; Zhang et al. 2010).

CI symptom development during cold storage also depends on factors such as fruit maturity and harvest time, apart from variety and storage temperature. A higher CI incidence has been reported for cultivars ‘Rojo Brillante’ (Salvador et al. 2005, 2006) and ‘Fuyu’ (Krammes et al. 2006) when fruits were picked in early maturity stages.

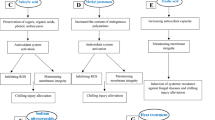

In different studies, CI manifestation has been related to changes in the cellular structure. Accelerated cell wall solubilization of chilling-injured fruit has been reported in persimmon cv. Fuyu (Grant et al. 1992). A microstructural study in cv. ‘Rojo Brillante’ showed that the drastic flesh softening, as a CI symptom, was associated with cell wall material degradation and the loss of intercellular adhesion (Pérez-Munuera et al. 2009b). Likewise, Luo and Xi (2005) reported that the primary cell wall and the middle lamella could not normally be dissolved in chilling-injured fruit when transferred to normal temperatures after cold storage. On the other hand, it has been recently reported that the low-temperature storage of persimmon leads to gradual oxidative stress, as well as major H2O2 accumulation, and sharp increases in catalase, peroxidase, and lipoxygenase (LOX) activities were linked to the manifestation of CI symptoms (Novillo et al. 2015b; Khademi et al. 2014).Many studies have focused on finding solutions to control CI in sensitive persimmon cultivars. Some tested postharvest strategies to alleviate CI symptoms and to allow cold storage to be prolonged in persimmon include using controlled atmospheres, heat treatments (hot water and hot air treatments), and pretreatments with 1-methylcyclopropene.

Modified Atmospheres and Controlled Atmospheres

Modified atmospheres (MA) or controlled atmospheres (CA) have become a common technology to prolong cold storage and to preserve the quality of some commodities like pears or apples (Kader 2004). In MA or CA, gases are removed or added to create an atmospheric composition around the commodity that differs from that of air. It usually involves reducing oxygen and/or increasing carbon dioxide concentrations. Using MA or CA should be considered to complement storage at proper temperatures. The benefit from using this technology depends on the commodity, cultivar, maturity stage, atmospheric composition, storage temperature, and duration (Kader 2004).

In persimmon fruits , most research has focused on using MA packages, inside which the desired atmosphere is generated passively during cold storage of fruit. Good results have been obtained with polyethylene or low-density polyethylene bags in ‘Fuyu’ and ‘Rama Forte’ cultivars (Brackmann et al. 1997). One of the main factors that limit longer storage life under MA conditions is the accumulation of ethanol and acetaldehyde , which causes off-flavors to develop and may also result in tissue browning (Ben-Arie et al. 1991).

The effect of CA on extending storage has been widely studied in some cultivars, like Fuyu. Although some atmospheres have resulted in reducing CI, they may lead to fruits that manifest external or internal browning (Burmeister et al. 1997; Brackmann et al. 2006). The incidence of skin and flesh disorders is the main limitation to storing ‘Fuyu’ in CA, and such disorders are reported to be due mainly to low O2 levels and not to high CO2 levels (Park and Lee 2008; Woolf and Ben Arie 2011). A recent study in ‘Fuyu’ has reported that the short-term high CO2 treatments based on fruit exposure to high CO2 concentrations relieve CI symptoms by preserving the integrity of cell walls and plasmalemma (Besada et al. 2015).

Studies into CA storage in other cultivars are limited. In the last few years, much interest has been shown in introducing the use of CA to some cultivars like ‘Rojo Brillante’. One example is an atmosphere based on 97% N2 + 3% air, which led ‘Rojo Brillante’ fruits to lose astringency and allowed fruit conservation for 30 days at 14 °C (Arnal et al. 2008). The use of an ultralow oxygen (ULO) atmosphere (1.3–1.8% O2) removed astringency in ‘Rojo Brillante’ when applied at 14.5 °C, but did not control CI at 1 or 10 °C (Orihuel-Iranzo et al. 2010). Other CAs based on 4–5% O2 + N2offered no additional benefit for retarding CI in ‘Rojo Brillante’, but prolonged the storage of ‘Triumph’ by alleviating fruit softening and flesh gelling (Besada et al. 2014). Other authors have reported that CA (1–1.5% O2 and 1.5–3% CO2) storage offers the benefit of delaying softening and retarding decay development in ‘Triumph’; nevertheless, fruit shelf life became inversely proportional to the storage period length (Tsviling et al. 2003).

According to the information provided above, optimum CA conditions do not seem to have been completely elucidated to prolong persimmon conservation and still depend basically on the cultivar. This is why CA conditions are rarely used commercially for persimmon fruits , and more studies are needed to optimize CA conditions in different persimmon cultivars.

Heat Pretreatments

Other treatments reported as being effective for alleviating CI in persimmon fruits are hot water or hot air applications prior to cold storage (Lay-Yee et al. 1997; Woolf et al. 1997b; Besada et al. 2008b). The response of fruit to heat treatments strongly depends on the cultivar. Before cold-storing cv. Fuyu, hot air and hot water treatments (HWTs) reduced the flesh gelling and flesh softening associated with CI (Woolf et al. 1997a, b; Burmeister et al. 1997; Lay-Yee et al. 1997). However, heat damage (mainly external and internal browning) was associated with heat treatments being applied (Woolf et al.1997b). In other cultivars, such as ‘Rojo Brillante’, the effectiveness of HWTs has been reported to depend on the maturity stage of fruits at harvest (Besada et al. 2008b). HWTs applied to fruits in an early maturity stage reduced CI and preserved fruit firmness and quality . However, when these treatments were applied to fruits in more advanced maturity stages, they caused irreversible epidermal breakage and external browning.

Tolerance to chilling temperatures that HWTs confer to persimmon fruits has been associated with relevant changes in cell wall degrading and antioxidant system enzymes. In cv. Rojo Brillante, HWTs have been reported to downregulate pectin methyl esterase and polygalacturonase activity, which results in greater cell wall integrity and, therefore, in fruit softening symptom alleviation. Moreover, the changes observed in peroxidase and catalase enzymes suggest that HWTs confer greater reactive oxygen scavenging capacity to fruits, and may also be implicated in alleviating CI symptoms (Khademi et al. 2014).

1-Methylcyclopropene (1-MCP)

A very positive effect of the postharvest application of 1-methylcyclopropene (1-MCP) on reducing CI symptoms has been widely reported in different persimmon cultivars. 1-MCP applied prior to cold storage has been shown to alleviate softening and gelation, which are the main symptoms in cultivars sensitive to low temperatures (Salvador et al. 2004; Kim and Lee 2005; Zhang et al. 2010). This effect of 1-MCP has been associated with preserving both the integrity of cell walls and adhesion between adjacent cells (Pérez-Munuera et al. 2009b), and reduces membrane permeability (Zhang et al. 2010) not only throughout cold storage, but also when fruits are transferred to shelf life temperatures. Reducing CI symptoms in persimmon achieved by 1-MCP treatment has also been attributed to modulate reactive oxygen species (ROS) scavenging enzymes. In 1-MCP-treated persimmons, cv. Rojo Brillante, alleviation of CI symptoms was linked to lower peroxidase activity levels and also to enhanced catalase enzyme activity, which resulted in slower H2O2 accumulation (Novillo et al. 2015b; Khademi et al. 2014). Similarly, Zhang et al. (2010) have reported, in cv. Fuyu, that the application of 1-MCP maintains greater antioxidant enzymes activity, such as superoxide dismutase (SOD), catalase, and also contributed to lowering the activity of oxidative enzymes, such as polyphenol oxidase (PPO) and peroxidase.

Nowadays, 1-MCP treatment is routinely applied in industry when fruits are cold-stored. Moreover, the combined use of 1-MCP and MA storage has been shown to prolong the retention of firmness and to reduce CI in ‘Fuyu’ persimmon (Kim and Lee 2005; Argenta et al. 2009). The combination of GA3 preharvest treatment with postharvest 1-MCP application allowed ‘Rojo Brillante’ persimmon to be stored for longer than when each treatment was singly applied and, thus, delayed CI symptoms injury and extended storage time (Besada et al. 2008a).

Pathological Disorders

One of the most important postharvest diseases in persimmon is black spot disease caused by Alternaria alternata . This is manifested as black, firm, dry stains of varying sizes and shapes, found below the calyx or on any point of the fruit skin surface. Under field conditions, A. alternate develops saprophytically on dead organic matter, leaves, shoots, and plants. Under suitable rain and high humidity conditions, fruits are infected in the field via the cuticle on the epidermis or via lesions and microlesions located beneath sepals (Kobiler et al. 2011; Palou et al.2012). Black spot rot incidence is determined by latent A. alternate infections caused in the field before harvest, and later develop during postharvest fruit conservation (Prusky et al. 1981). Under high humidity conditions, the fungus can even develop at low temperature. That is why disease symptoms often develop during prolonged conservation periods.

This disease must be controlled by applying antifungal treatments or resistance inducers in both the field and postharvest periods. Applying GA3 has proven to be effective in lowering its incidence (Pérez et al. 1995), and the efficacy of this treatment is associated with greater fruit firmness. The most effective postharvest treatments are modified atmospheres (30% of CO2) and sodium troclosene or hydrochloric acid baths, either alone or combined with the fungicide prochloraz (Prusky et al. 2001, 2006; Kobiler et al. 2011).

Gray mold , caused by Botrytis cinerea , can also become a serious problem during persimmon postharvest life, as it grows even at low temperature, so it multiplies in fruits stored under cold conditions for long periods (Woolf et al. 2008; Palou et al. 2009). The symptoms noted during cold storage consist of very soft lesions of varying sizes, which discolor fruit skin. Lesions appear from below the calyx and spread over the peduncular region, but are also found occasionally on other fruit regions. Infected fruits that come into contact with adjacent fruits can cause rotting nests. Hot water postharvest treatments have proven to be effective for controlling the disease during long storage periods (Woolf et al. 2008).

Persimmon fruits can also display peduncular molding caused by several fungi. One of them is known as Pestalotiopsis clavispora , which causes dry molding that commences below the calyx and spreads all over the peduncular region. In some cases, symptoms can be seen in other fruit regions. In central regions of lesions, a white-colored cotton-like fungal mycelium develops (Palou et al. 2013b). Another peduncular mold type that has been recently detected in persimmon fruits in the Mediterranean region is caused by Lasiodiplodia theobromae (Palou et al. 2013a). This pathogen produces a cotton-like white mycelium on soft, irregular light brown-colored lesions, which gradually darken when they spread from the calyx to the rest of the fruit. Symptoms are also observed, but less frequently, in the equatorial and stylar fruit regions. These diseases commence mainly in the field from latent infections, and their incidence does not tend to be high and no specific control measures are required.

Anthracnose , which is caused by Colletotrichum gloeosporioides and by Colletotrichum acutatum, may also affect persimmon fruits. Lesions are rounded and their color varies from dark brown to black (Palou et al. 2013c). They appear more frequently in equatorial fruit regions, but can also be displayed in the peduncular region. Colletotrichum horii also causes anthracnose symptoms in the field, and affects young shoots and fruits even before they are ripe for commercial reasons. Anthracnose caused by C. horii is one of the main diseases in leading persimmon production countries like Japan, China, South Korea, and New Zealand (Weir and Johnston 2010; Kwon et al. 2013).

Other fungi that can affect persimmon , but to a lesser extent, are Penicillium expansum, Rhizopus stolonifer, Cladosporium spp., Trichoderma spp., and Mucor piriformis (Crisosto 2004; Palou et al. 2009; Kwon and Park 2004).

Grading and Packing

Fruit grading is a common step to commercialize fruits according to their quality category. This step is carried out by passing fruits on a packing line, where they were previously cleaned by soft roller brushes. Then, fruits are graded mainly by size, but most modern packing lines also include shape, firmness, degree of blemish, and color as grading parameters. At the end of the line, fruits are generally packed by hand and the use of single-layer trays is recommended.

The persimmon surface is naturally covered by a waxy cuticle (Pérez-Munuera et al. 2009a), so it is important to keep the roller brushes in good condition to avoid natural wax from being removed. Moreover, persimmons are highly sensitive to mechanical damage and, therefore, special care must be taken to design and maintain packing line operations. The number and height of drops upon equipment transitions should be minimized, and unavoidable impacts should be prevented by cushioning with foam rubber and other materials.

The mechanical damage that fruits are exposed to during packing operations has been reported as one of the main causes of persimmon flesh decoloring (Novillo et al. 2014). Such disorders have been studied in depth in the astringent cultivar ‘Rojo Brillante’. It has been observed that two different alterations are manifested, depending on the level of astringency of fruits when mechanically impacted: ‘flesh browning ’ or ‘pinkish bruising ’. The former is manifested as large browned areas of the flesh that extend around the fruit; browning starts on the surface and then spread to inner regions. This disorder appears on fruits that have undergone a mechanical impact after astringency was removed by high CO2 treatment. The latter (pinkish bruising) is seen as isolated areas of pulp (close to the skin) on which habitual orange color has turned pinkish, and is detected in fruits that have suffered mechanical damage when astringent (Novillo et al. 2014).

Oxidative stress has been reported as the key mechanism that lies behind these alterations (Novillo et al. 2014). Not only mechanical damage itself but also CO2 deastringency treatment results in ROS accumulation in the flesh of fruit. Under such oxidative conditions, tannins, which are initially uncolored, undergo an oxidation process and become colored. When the insoluble tannins of fruits that are submitted to the deastringency treatment are oxidized, they acquire a brown coloring, while the oxidation of soluble tannins present in astringent fruits allows them to acquire a pinkish color. The former are observed by the naked eye as flesh browning, while the soluble tannins are seen as ‘pinkish bruising’. This pattern of response to mechanical damage is shared by most astringent cultivars. Although the intensity of these disorders depends on the cultivar, they all seem to manifest browning (Fig. 3) or pinkish bruising, depending on the level of astringency at the time of the mechanical impact. Non-astringent cultivars, however, show less sensitivity to manifesting such alterations associated with mechanical damage (Novillo et al. 2015c).

As fruit is very sensitive to manifesting such alterations, proper conditions on packing lines to avoid impacts will mean better quality fruit. From a commercial point of view, flesh browning manifestation implies greater loss of quality than pinkish bruising, as the former spreads all around fruits, while the pinkish disorder is manifested only in located areas that have suffered strong impacts. Therefore, in order to reduce fruit sensitiveness to browning, applying a deastringency treatment is recommended after carrying out packing operations.

Conclusion

The level of astringency and the degree of sensitiveness to chilling injury are the main characteristics that will condition the postharvest handling of persimmon fruit. Treatments based on high CO2 concentrations are the most commonly applied in order to remove astringency while preserving fruit firmness, and the conditions of the treatment must be optimized for each cultivar, having also to take into account factors such as the maturity stage at harvest and the preharvest stresses.

Nowadays, fruit storage is carried out by applying 1-MCP to reduce chilling injury. Moreover, combining 1-MCP with other technologies like controlled or modified atmospheres allows to further extend the storage period.

During postharvest handling of persimmon, it is also important to bear in mind that fruits are very sensitive to manifesting disorders associated with mechanical damages. Therefore, avoiding mechanical impacts is essential to preserving fruit quality.

References

Agfacts. (2003). Persimmon growing in New South Wales. Agfact H3.1.17. Elizabeth Macarthur Agricultural Research Institute, Camden, NSW, Agriculture. Industry & Investment. NSW Government. Retrieved from http://www.dpi.nsw.gov.au/agriculture/horticulture/other/other/persimmon

Agustí, M., Juan, M., Yagüe, B., Mesejo, C., Martínez-Fuentes, A., & Almela, V. (2003). Tratamientos para retrasar la maduración del fruto del caqui (Diospyros kaki L.) Comunidad Valenciana Agraria, 24, 27–33.

Argenta, L. C., Vieira, M. J., & Tomazini, A. M. (2009). Conservação da qualidade de caqui ‘Fuyu’ em ambiente refrigerado pela combinação de 1-MCP e atmosfera modificada. Revista Brasileira de Fruticultura, 31(2), 323–333. (In Portuguese with English abstract).

Arnal, L., & Del Rio, M. A. (2004). Effect of cold storage and removal astringency on quality of persimmon fruit (Diospyros kaki, L.) cv. Rojo Brillante. Revista de Agaroquimica y Tecnologia de Alimentos, 10(3), 179–185.

Arnal, L., Besada, C., Navarro, P., & Salvador, A. (2008). Effect of controlled atmospheres on maintaining quality of persimmon fruit cv. “Rojo Brillante”. Journal of Food Science, 73(1), 26–30.

Ben-Arie, R., Zutkhi, Y., Sonego, L., & Klein, J. (1991). Modified atmosphere packaging for long-term storage of astringent persimmons. Postharvest Biology and Technology, 1(2), 169–179.

Ben-Arie, R., Zhou, H. W., Sonego, L., & Zutkhi, Y. (1997). Plant growth regulator effects on the storage and shelf-life ‘Triumph’ persimmons. Acta Horticulturae, 436, 243–250.

Ben-Arie, R., Zilkah, S., Klein, I., & Gamrasni, D. (2008). Persimmon and environment: Soil and water management for high quality fruit production. Advances in Horticultural Science, 22(4), 286–293.

Besada, C., Arnal, L., & Salvador, A. (2008a). Improving storability of persimmon cv. Rojo Brillante by combined use of preharvest and postharvest treatments. Postharvest Biology and Technology, 50(2), 169–175.

Besada, C., Salvador, A., Arnal, L., & Martínez-Jávega, J. M. (2008b). Hot water treatment for chilling injury reduction of astringent ‘Rojo Brillante’ persimmon at different maturity stages. HortScience, 43(7), 2120–2123.

Besada, C., Jackman, R. C., Olsson, S., & Woolf, A. B. (2010a). Response of ‘Fuyu’ persimmons to ethylene exposure before and during storage. Postharvest Biology and Technology, 57(2), 124–131.

Besada, C., Salvador, A., Arnal, L., & Martínez-Jávega, J. M. (2010b). Optimization of the duration of deastringency treatment depending on persimmon maturity. Acta Horticulturae, 858, 69–74.

Besada, C., Novillo, P., Navarro, P., & Salvador, A. (2014). Effect of a low oxygen atmosphere combined with 1-MCP pretreatment on preserving the quality of ‘Rojo Brillante’ and ‘Triumph’ persimmon during cold storage. Scientia Horticulturae, 179, 51–58.

Besada, C., Llorca, E., Novillo, P., Hernando, I., & Salvador, A. (2015). Short-term high CO2 treatment alleviates chilling injury of persimmon cv. Fuyu by preserving the parenchyma structure. Food Control, 51, 163–170.

Besada, C., Gil, R., Bonet, L., Quiñones, A., Intrigliolo, D., & Salvador, A. (2016). Chloride stress triggers maturation and negatively affects the postharvest quality of persimmon fruit. Involvement of calyx ethylene production. Plant Physiology and Biochemistry, 100, 105–112.

Brackmann, A., Mazaro, S. M., & Saquet, A. A. (1997). Cold storage of persimmons (Diospyros kaki L.) cultivars Fuyu and Rama Forte. Ciencia-Rural, 27(4), 561–565.

Brackmann, A., Vilela, J. A., Silveira, A. C., Steffens, C., & Sestari, I. (2006). Storage conditions of ‘Fuyu’ persimmon. Revista Brasileira de Agrociência, 12, 183–186.

Buesa, I., Badal, E., Guerra, D., Ballester, C., Bonet, L., & Intrigliolo, D. S. (2013). Regulated deficit irrigation in persimmon trees (Diospyros kaki) cv. ‘Rojo Brillante’. Scientia Horticulturae, 159, 134–142.

Burmeister, D. M., Ball, S., Green, S., & Woolf, A. B. (1997). Interaction of hot water treatments and controlled atmosphere storage on quality of ‘Fuyu’ persimmons. Postharvest Biology and Technology, 12(1), 71–81.

Candir, E. E., Ozdemir, A. E., Kaplankiran, M., & Toplu, C. (2009). Physico-chemical changes during growth of persimmon fruits in the East Mediterranean climate region. Scientia Horticulturae, 121(1), 42–48.

Chen, J., Ni, H., Sun, J., & Cheng, D. (2003). Effects of major secondary chemicals of wheat plants on enzyme activity in Sitobion avenae. Kunchong Xuebao, 46, 144–149. (In Chinese).

Choi, S. T., Park, D. S., Son, J. Y., Park, Y. O., Hong, K. P., & Cho, K. S. (2013). Climate-related changes in fruit growth of ‘Fuyu’ persimmon during the harvest season. Korean Journal of Horticultural Science and Technology, 31(1), 32–37.

Choi, S. T., Park, D. S., Kim, E. S., Shin, H. Y., & Kang, S. M. (2014). Seasonal growth and characteristics of fruits developed from delayed flowers of ‘Fuyu’ persimmon. Scientia Horticulturae, 177, 108–111.

Collins, R. J., & Tisdell, J. S. (1995). The influence of storage time and temperature on chilling injury in Fuyu and Suruga persimmon (Diospyros kaki L.) grown in subtropical Australia. Postharvest Biology and Technology, 6(1–2), 149–157.

Crisosto, C. (2004). ‘Persimmon’. In K. C. Gross, C. Y. Wang, & M. Salveit (Eds.), Agriculture handbook number 66. The commercial storage of fruits, vegetables, and florist and nursery stocks. Retrieved from https://www.ars.usda.gov/ARSUserFiles/oc/np/CommercialStorage/CommercialStorage.pdf

DanielI, R., Girardi, C. L., Parussolo, A., Ferri, V. C., & Rombaldi, C. V. (2002). Effect of the application of gibberellic acid and calcium chloride in the retardation of harvest and conservability of persimmon, Fuyu. Revista Brasileira de Fruticultura, 24(1), 44–48.

Del Bubba, M., Giordani, E., Pippucci, L., Cincinelli, A., Checchini, L., & Galvan, P. (2009). Changes in tannins, ascorbic acid and sugar content in astringent persimmons during on-tree growth and ripening and in response to different postharvest treatments. Journal of Food Composition and Analysis, 22(7), 668–677.

Ebert, G., & Gross, J. (1985). Carotenoid changes in the peel of ripening persimmon (Diospyros kaki) cv Triumph. Phytochemistry, 24(1), 29–32.

FAOSTAT. (2014). Retrieved from http://faostat.fao.org/site/339/default.aspx

Gazit, S., & Adato, I. (1972). Effect of carbon dioxide atmosphere on the course of astringency disappearance of persimmon (Diospyros kaki Linn.) fruits. Journal of Food Science, 37(6), 815–817.

Giordani, E., Doumett, S., Nin, S., & Del Bubba, M. (2011). Selected primary and secondary metabolites in fresh persimmon (Diospyros kaki Thunb.): A review of analytical methods and current knowledge of fruit composition and health benefits. Food Research International, 44(7), 1752–1767.

Gorinstein, S., Bartnikowska, E., Kulasek, G., Zemser, M., & Trakhtenberg, S. (1998). Dietary persimmon improves lipid metabolism in rats fed diets containing cholesterol. The Journal of Nutrition, 128(11), 2023–2027.

Gorinstein, S., Leontowicz, H., Leontowicz, M., Jesion, I., Namiesnik, J., Drzewiecki, J., & Trakhtenberg, S. (2011). Influence of two cultivars of persimmon on atherosclerosis indices in rats fed cholesterol-containing diets: Investigation in vitro and in vivo. Nutrition, 27(7–8), 838–846.

Grant, T. M., Macrae, E. A., & Redgwell, R. J. (1992). Effect of chilling injury on physicochemical properties of persimmon cell walls. Phytochemistry, 31(11), 3739–3744.

Hamada, K., Hasegawa, K., Kitajima, A., & Ogata, T. (2008). The relationship between fruit size and cell division and enlargement in cultivated and wild persimmons. The Journal of Horticultural Science and Biotechnology, 83(2), 218–222.

Ikegami, A., Yonemori, K., Kitajima, A., Sato, A., & Yamada, M. (2005a). Expression of genes involved in proanthocyanidin biosynthesis during fruit development in a Chinese Pollination-constant, Nonastringent (PCNA) Persimmon, ‘Luo Tian Tian Shi’. Journal of American Society for Horticultural Science, 130, 830–835.

Ikegami, A., Kitajima, A., & Yonemori, K. (2005b). Inhibition of flavonoid biosynthetic gene expression coincides with loss of astringency in pollination-constant, non-astringent (PCNA)-type persimmon fruit. Journal of Horticultural Science and Biotechnology, 80(2), 225–228.

Intrigliolo, D. S., Bonet, L., Ferrer, P., Besada, C., & Salvador, A. (2011). Short-term effects of regulated deficit irrigation of ‘Rojo Brillante’ persimmon (Diospyros kaki)—Yield, fruit quality and post-harvest performance. Acta Horticulturae, 922, 113–120.

Itamura, H., Kitamura, T., Taira, S., Harada, H., Ito, N., Takahashi, Y., & Fukushima, T. (1991). Relationship between fruit softening, ethylene production and respiration in Japanese persimmon ‘Hiratanenashi’. Journal of the Japanese Society for Horticultural Science, 60(3), 695–701.

Kader, A. (2004). Postharvest technology of horticultural crops (2nd ed.). Oakland: Division of Agriculture and Natural Resources University of California.

Khademi, O., Besada, C., Mostofi, Y., & Salvador, A. (2014). Changes in pectin methylesterase, polygalacturonase, catalase and peroxidase activities associated with alleviation of chilling injury in persimmon by hot water and 1-MCP treatments. Scientia Horticulturae, 179, 191–197.

Kim, Y. K., & Lee, J. M. (2005). Extension of storage and shelf-life of sweet persimmon with 1-MCP. Acta Horticulturae, 685, 165–174.

Kim, Y. H., Lim, S. C., Youn, C. K., Yoon, T., & Kim, T. S. (2004). Effect of ethephon on fruit quality and maturity of ‘Tone Wase’ astringent persimmons (Diospyros Kaki L.) Acta Horticulturae, 653, 187–191.

Kobiler, I., Akerman, M., Huberman, L., & Prusky, D. (2011). Integration of pre- and postharvest treatments for the control of black spot caused by Alternaria alternata in stored persimmon fruit. Postharvest Biology and Technology, 59(2), 166–171.

Krammes, J. G., Argenta, L. C., & Vieira, M. J. (2006). Influences of 1-methylcyclopropene on quality of persimmon fruit cv. ‘Fuyu’ after cold storage. Acta Horticulturae, 727, 513–518.

Kubo, Y., Nakano, R., & Inaba, A. (2003). Cloning of genes encoding cell wall modifying enzymes and their expression in persimmon fruit. Acta Horticulturae, 601, 49–55.

Kwon, J. H., & Park, C. S. (2004). Ecology of disease outbreak of circular leaf spot of persimmon and inoculum dynamics of Mycosphaerella nawae. Research in Plant Disease, 10(4), 209–216.

Kwon, J. H., Kim, J., Choi, O., Gang, G. H., Han, S., & Kwak, Y. S. (2013). Anthracnose caused by Colletotrichum horii on sweet persimmon in Korea: Dissemination of conidia and disease development. Journal of Phytopathology, 161(7–8), 497–502.

Lay-Yee, M., Ball, S., Forbes, S. K., & Woolf, A. B. (1997). Hot-water treatment for insect disinfestation and reduction of chilling injury of ‘Fuyu’ persimmon. Postharvest Biology and Technology, 10(1), 81–87.

Lee, Y. M., Jang, S. J., & Lee, Y. J. (1997). Effect of preharvest application of MGC-140 and GA3 on the storability of ‘Fuyu’ persimmon (Diospyros kaki L.) Journal of the Korean Society for Horticultural Science (Korea Republic), 38(2), 157–161.

Luo, Z. S., & Xi, Y. F. (2005). Effect of storage temperature on physiology and ultrastructure of persimmon fruit. Journal of Zhejiang University Agriculture and Life Sciences, 31(2), 195–198.

MacRae, E. A. (1987a). Development of chilling injury in New Zealand grown ‘Fuyu’ persimmon during storage. New Zealand Journal of Experimental Agriculture, 15(3), 333–344.

MacRae, E. A. (1987b). Storage and shelf life of Fuyu and Flat Fuyu persimmon in New Zealand 1984–1986. Division of Horticulture and Processing. DSIR, Postharvest.

MAPAMA. (2017). Retrieved from http://www.mapama.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/superficies-producciones-anuales-cultivos/

Matsuo, T., & Ito, S. (1977). On mechanisms of removing astringency in persimmon fruits by carbon dioxide treatment I. Some properties of the two processes in the de-astringency. Plant and Cell Physiology, 18(1), 17–25.

Matsuo, T., & Itoo, S. (1982). A model experiment for de-astringency of persimmon fruit with high carbon dioxide treatment: In vitro gelation of kaki-tannin by reacting with acetaldehyde. Agricultural and Biological Chemistry, 46(3), 683–689.

Mowat, A. D., & George, A. P. (1996). Environmental physiology of persimmons. In B. Schaffer & P. Andersen (Eds.), Handbook of environmental physiology of fruit crops (pp. 195–202). Boca Raton: CRC Press Inc..

Nakano, R., Yonemori, K., Sugiura, A., & Kataoka, I. (1997). Effect of gibberellic acid and abscisic acid on fruit respiration in relation to final swell and maturation in persimmon. Acta Horticulturae, 436, 203–214.

Naor, A. (2006). Irrigation scheduling and evaluation of tree water status in deciduous orchards. Horticultural Reviews, 32, 111–166.

Niikawa, T., Suzuki, T., Ozeki, T., Kato, M., & Ikoma, Y. (2007). Characteristics of carotenoid accumulation during maturation of the Japanese persimmon ‘Fuyu’ [Diospyros kaki]. Horticultural Research (Japan), 6(2), 251–256.

Novillo, P., Besada, C., Gil, R., & Salvador, A. (2013). Fruit quality and response to deastringency treatment of eight persimmon varieties cultivated under Spanish growing conditions. Acta Horticulturae, 996, 437–442.

Novillo, P., Salvador, A., Llorca, E., Hernando, I., & Besada, C. (2014). Effect of CO2 deastringency treatment on flesh disorders induced by mechanical damage in persimmon. Biochemical and microstructural studies. Food Chemistry, 145, 454–463.

Novillo, P., Besada, C., Tian, L., Bermejo, A., & Salvador, A. (2015a). Nutritional composition of ten persimmon cultivars in the “ready-to-eat crisp” stage. Effect of deastringency treatment. Food and Nutrition Sciences, 6(14), 1296.

Novillo, P., Salvador, A., Navarro, P., & Besada, C. (2015b). Involvement of the redox system in chilling injury and its alleviation by 1-methylcyclopropene in ‘Rojo Brillante’ Persimmon. HortScience, 50(4), 570–576.

Novillo, P., Salvador, A., Navarro, P., & Besada, C. (2015c). Sensitivity of astringent and non-astringent persimmon cultivars to flesh disorders induced by mechanical damage. Acta Horticulturae, 1079, 605–610.

Orihuel-Iranzo, B., Miranda, M., Zacarías, L., & Lafuente, M. T. (2010). Temperature and ultra low oxygen effects and involvement of ethylene in chilling injury of ‘Rojo Brillante’ persimmon fruit. Food Science and Technology International, 16(2), 159–167.

Palou, L., Montesinos-Herrero, C., Guardado, A., Besada, C., & Del Río, M. A. (2009). Fungi associated with postharvest decay of persimmon in Spain. Acta Horticulturae, 833, 275–280.

Palou, L., Taberner, V., Guardado, A., & Montesinos-Herrero, C. (2012). First report of Alternaria alternata causing postharvest black spot of persimmon in Spain. Australasian Plant Disease Notes, 7(1), 41–42.

Palou, L., Montesinos-Herrero, C., Besada, C., & Taberner, V. (2013a). Postharvest fruit rot of persimmon (Diospyros kaki) in Spain caused by Lasiodiplodia theobromae and Neofusicoccum spp. Journal of Phytopathology, 161(9), 625–631.

Palou, L., Montesinos-Herrero, C., Guardado, A., & Taberner, V. (2013b). First report of Pestalotiopsis clavispora causing postharvest fruit rot of loquat in Spain. Journal of Plant Pathology, 95(Suppl. 4), S4.69.

Palou, L., Montesinos-Herrero, C., Tarazona, I., & Taberner, V. (2013c). Postharvest anthracnose of persimmon fruit caused by Colletotrichum gloeosporioides first reported in Spain. Plant Disease, 97(5), 691–691.

Park, Y. M., & Lee, Y. J. (2008). Induction of modified atmosphere-related browning disorders in ‘Fuyu’ persimmon fruit. Postharvest Biology and Technology, 47(3), 346–352.

Pérez, A., Ben-Arie, R., Dinoor, A., Genizi, A., & Prusky, D. (1995). Prevention of black spot disease in persimmon fruit by gibberellic acid and iprodione treatments. Phytopathology, 85(2), 221–225.

Pérez-Munuera, I., Quiles, A., Larrea, V., Arnal, L., Besada, C., & Salvador, A. (2009a). Microstructure of persimmon treated by hot water to alleviate chilling injury. Acta Horticulturae, 883, 251–256.

Pérez-Munuera, I., Hernando, I., Larrea, V., Besada, C., Arnal, L., & Salvador, A. (2009b). Microstructural study of chilling injury alleviation by 1-methylcyclopropene in persimmon. HortScience, 44(3), 742–745.

Pesis, E., Levi, A., & Ben-Arie, R. (1988). Role of acetaldehyde production in the removal of astringency from persimmon fruits under various modified atmospheres. Journal of Food Science, 53(1), 153–156.

Prusky, D., Ben-Arie, R., & Guelfat-Reich, S. (1981). Etiology and histology of Alternaria rot of persimmon fruits. Phytopathology, 71(11), 1124–1128.

Prusky, D., Eshel, D., Kobiler, I., Yakoby, N., Beno-Moualem, D., Ackerman, M., & Arie, R. B. (2001). Postharvest chlorine treatments for the control of the persimmon black spot disease caused by Alternaria alternata. Postharvest Biology and Technology, 22(3), 271–277.

Prusky, D., Kobiler, I., Akerman, M., & Miyara, I. (2006). Effect of acidic solutions and acidic prochloraz on the control of postharvest decay caused by Alternaria alternata in mango and persimmon fruit. Postharvest Biology and Technology, 42(2), 134–141.

Salvador, A., Arnal, L., Monterde, A., & Cuquerella, J. (2004). Reduction of chilling injury symptoms in persimmon fruit cv.‘Rojo Brillante’ by 1-MCP. Postharvest Biology and Technology, 33(3), 285–291.

Salvador, A., Arnal, L., Monterde, A., & Martínez-Jávega, J. M. (2005). Influence of ripening stage at harvest on chilling injury symptoms of persimmon cv. Rojo Brillante stored at different temperatures. Food Science and Technology International, 11(5), 359–365.

Salvador, A., Arnal, L., Carot, J. M., Carvalho, C. P., & Jabaloyes, J. M. (2006). Influence of different factors on firmness and color evolution during the storage of persimmon cv. ‘Rojo Brillante’. Journal of Food Science, 71(2), S169–S175.

Salvador, A., Arnal, L., Besada, C., Larrea, V., Quiles, A., & Pérez-Munuera, I. (2007). Physiological and structural changes during ripening and deastringency treatment of persimmon fruit cv. ‘Rojo Brillante’. Postharvest Biology and Technology, 46(2), 181–188.

Salvador, A., Arnal, L., Besada, C., Larrea, V., Hernando, I., & Pérez-Munuera, I. (2008). Reduced effectiveness of the treatment for removing astringency in persimmon fruit when stored at 15 C: Physiological and microstructural study. Postharvest Biology and Technology, 49(3), 340–347.

Santos-Buelga, C., & Scalbert, A. (2000). Proanthocyanidins and tannin-like compounds–nature, occurrence, dietary intake and effects on nutrition and health. Journal of the Science of Food and Agriculture, 80(7), 1094–1117.

Senter, S. D., Chapman, G. W., Forbus, W. R., & Payne, J. A. (1991). Sugar and nonvolatile acid composition of persimmons during maturation. Journal of Food Science, 56(4), 989–991.

Sugiura, A., & Tomana, T. (1983). Relationships of ethanol production by seeds of different types of Japanese persimmons and their tannin content [Diospyros kaki, pollination, astringency]. HortScience, 18, 319–321.

Sugiura, A., Zheng, G. H., & Yonemori, K. (1991). Growth and ripening of persimmon fruit at controlled temperatures during growth stage III. HortScience, 26(5), 574–576.

Taira, S., Itamura, H., Abe, K., & Watanabe, S. (1989). Comparison of the characteristics of removal of astringency in two Japanese persimmon cultivars, ‘Denkuro’ and ‘Hiratanenashi’. Journal of the Japanese Society for Horticultural Science, 58(2), 319–325.

Taira, S., Itamura, H., Abe, K., Oor, K., & Watanabe, S. (1990). Effect of harvest maturity on removal of astringency in Japanese persimmon (Diospyros kaki Thunb.), ‘Hratanenashi’ fruits. Journal of the Japanese Society for Horticultural Science, 58(4), 813–818.

Taira, S., Oba, S., & Watanabe, S. (1992a). Removal of astringency from ‘Hiratanenashi’ persimmon fruit with a mixture of ethanol and carbon dioxide. Journal of the Japanese Society for Horticultural Science, 61(2), 437–443.

Taira, S., Satoh, I., & Watanabe, S. (1992b). Relationship between differences in the ease of removal of astringency among fruits of Japanese persimmon (Diospyros kaki Thunb.) and their ability to accumulate ethanol and acetaldehyde. Journal of the Japanese Society for Horticultural Science, 60(4), 1003–1009.

Taira, S., Ono, M., & Matsumoto, N. (1997). Reduction of persimmon astringency by complex formation between pectin and tannins. Postharvest Biology and Technology, 12(3), 265–271.

Taira, S., Matsumoto, N., & Ono, M. (1998). Accumulation of soluble and insoluble tannins during fruit development in nonastringent and astringent persimmon. Journal of the Japanese Society for Horticultural Science, 67(4), 572–576.

Tanaka, T., Takahashi, R., Kouno, I., & Nonaka, G. I. (1994). Chemical evidence for the de-astringency (insolubilization of tannins) of persimmon fruit. Journal of the Chemical Society, Perkin Transactions, 1(20), 3013–3022.

Tessmer, M. A., Besada, C., Hernando, I., Appezzato-da-Glória, B., Quiles, A., & Salvador, A. (2016). Microstructural changes while persimmon fruits mature and ripen. Comparison between astringent and non-astringent cultivars. Postharvest Biology and Technology, 120, 52–60.

Tsviling, A., Nerya, O., Gizis, A., Sharabi-Nov, A., & Ben-Arie, R. (2003). Extending the shelf-life of ‘Triumph’ persimmons after storage, with 1-MCP. Acta Horticulturae, 599, 53–58.

Weir, B. S., & Johnston, P. R. (2010). Characterisation and neotypification of Gloeosporium kaki Hori as Colletotrichum horii nom. nov. Mycotaxon, 111(1), 209–219.

Wills, R., McGlasson, B., Graham, D., & Joyce, D. (1998). Postharvest: An introduction to the physiology and handling of fruit, vegetables and ornamentals (262 pp). Wallingford: CAB International.

Woolf, A. B., & Ben Arie, R. (2011). Persimmon (Diospyros kaki L.) In E. M. Yahia (Ed.), Postharvest biology and technology of tropical and subtropical fruits (pp. 166–193). Cambridge: Woodhead Publishing.

Woolf, A. B., MacRae, E. A., Spooner, K. J., & Redgwell, R. J. (1997a). Changes to physical properties of the cell wall and polyuronides in response to heat treatment of ‘Fuyu’ persimmon that alleviate chilling injury. Journal of the American Society for Horticultural Science, 122(5), 698–702.

Woolf, A. B., Ball, S., Spooner, K. J., Lay-Yee, M., Ferguson, I. B., Watkins, C. B., & Forbes, S. K. (1997b). Reduction of chilling injury in the sweet persimmon ‘Fuyu’ during storage by dry air heat treatments. Postharvest Biology and Technology, 11(3), 155–164.

Woolf, A., Jackman, R., Olsson, S., Manning, M., Rheinlander, P., Mowat, A., & Harker, R. (2008). Meeting consumer requirements from a New Zealand perspective. Advances in Horticultural Science, 22(4), 274–280.

Yamada, M., Taira, S., Ohtsuki, M., Sato, A., Iwanami, H., Yakushiji, H., & Li, G. (2002). Varietal differences in the ease of astringency removal by carbon dioxide gas and ethanol vapor treatments among Oriental astringent persimmons of Japanese and Chinese origin. Scientia Horticulturae, 94(1), 63–72.

Yokozawa, T., Kim, Y. A., Kim, H. Y., Lee, Y. A., & Nonaka, G. I. (2007). Protective effect of persimmon peel polyphenol against high glucose-induced oxidative stress in LLC-PK 1 cells. Food and Chemical Toxicology, 45(10), 1979–1987.

Yonemori, K., & Matsushima, J. (1985). Property of development of the tannin cells in non-astringent type fruits of Japanese persimmon (Diospyros kaki) and its relationship to natural deastringency. Journal of the Japanese Society for Horticultural Science, 54(2), 201–208.

Yonemori, K., & Suzuki, Y. (2009). Differences in three-dimensional distribution of tannin cells in flesh tissue between astringent and non-astringent type persimmon. Acta Horticulturae, 833, 119–124.

Yonemori, K., Ikegami, A., Kanzaki, S., & Sugiura, A. (2003). Unique features of tannin cells in fruit of pollination constant non-astringent persimmons. Acta Horticulturae, 601, 31–35.

Zhang, Y., Rao, J., Sun, Y., & Li, S. (2010). Reduction of chilling injury in sweet persimmon fruit by 1-MCP. Acta Horticulturae Sinica, 37(4), 547–552.

Zheng, G., & Sugiura, A. (1990). Changes in sugar composition in relation to invertase activity in the growth and ripening of persimmon (Diospyros kaki) fruits. Journal of the Japanese Society for Horticultural Science, 59(2), 281–287.

Zhou, C., Zhao, D., Sheng, Y., Tao, J., & Yang, Y. (2011). Carotenoids in fruits of different persimmon cultivars. Molecules, 16(1), 624–636.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Besada, C., Salvador, A. (2018). Postharvest Biology and Technology of Persimmon. In: Mir, S., Shah, M., Mir, M. (eds) Postharvest Biology and Technology of Temperate Fruits. Springer, Cham. https://doi.org/10.1007/978-3-319-76843-4_16

Download citation

DOI: https://doi.org/10.1007/978-3-319-76843-4_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-76842-7

Online ISBN: 978-3-319-76843-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)