Abstract

Additive manufacturing technologies (AM) have become a production technology during the last years. Originally, the only field of application for AM was the time-efficient production of prototypes—also known as Rapid Prototyping. During the last 5 years, a significant increase of applications for Direct part production can be observed, especially in Aerospace and Medical industry as well as in General Engineering. For this reason, there is a strong demand for experts in AM today that cannot be met by university graduates because AM has, most of the time, not been represented in their curriculum. In addition, AM industry is highly dynamic which leads to a significant amount of new knowledge and relevant progress every year. So, continuing education and part-time training on Additive Manufacturing for people in employment is crucial for economic sustainable growth and application of AM in industry. This contribution aims to introduce a learning quality focused and didactically sound concept for part-time training in AM.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Part-time Training

- Additive Manufacturing

- Time-efficient Production

- Problem-based Learning Environment

- Electron Beam Melting

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Background

Additive manufacturing technologies (AM) have gained significance as production technologies during the last years. According to Wohlers Report as of 2017 (Wohlers Report 2017) total additive manufacturing market volume has exceeded the 6 billion US$ mark in the year 2016. As a result, total market volume has increased sixfold within 7 years, referred to 1 billion US$ in the year 2009. Several institutions provide forecasts for the additive manufacturing market growth. A summary is provided in Fig. 1. Based on Fig. 1, a compound annual growth rate of 31% until the year 2020 appears to be the most probable forecast for the development of the total additive manufacturing market volume, because this equals the average of all forecasts provided in Fig. 1.

Originally, the only field of application for AM was the time-efficient production of prototypes—also known as Rapid Prototyping. During the last 5 years, a significant increase in applications for direct part production can be observed, especially in Aerospace industry, Medical industry and in General Engineering (Wohlers Report 2017). This extension in application from prototyping to manufacturing is crucial to realize the forecasted growth rates provided in Fig. 1, because prototyping does often not require the production of more than one or ten parts. However, for realizing a compound annual growth rate of 31%, it is necessary to identify and exploit business cases within small- and medium-scale series. As a result, machine and material sales will increase and additive manufacturing technologies will further establish as production technologies. Today, skilled workers are, alongside some technological challenges, such as process robustness, etc., a bottleneck for this development. So, there is a need for specialists in, e.g. design (Computer-Aided Design) and dimensioning (Computer-Aided Engineering) for additive manufacturing, process development, quality assurance but also for skilled workers to, e.g. operate the machines. Figure 2 illustrates a puzzle of skills and institutions needed to enable strong future growth in additive manufacturing with a focus on personnel.

Today, challenges in terms of skilled labour exist on two different levels: On the one hand, there is a lack of professionals on all qualification levels, such as machine operator, engineer incl. designers or management. This is because today’s professionals typically have not had additive manufacturing covered during their education. On the other hand, the education of our ‘next generation’ professionals is a challenge because for example setting up a new curriculum for a university degree does take a lot of time and effort. Consequently, it can happen even today that a recent graduate engineer has hardly had any lectures on additive manufacturing. For this reason, there is a need to set up new curriculums that consider additive manufacturing on all qualification levels (school, apprenticeship, universities, etc.) so that our ‘next generation’ work force is knowledgeable about additive manufacturing. Obviously, this will take several years to be in place. For immediate assistance, continuing education can be seen as key enabler to meet the current demand for skilled employees in additive manufacturing.

Continuing education or further education is the generic term for post-secondary learning activities and programs for adults. In Germany, there is a more specific term called quaternary education. It comprises all learning activities after the first education phase, which includes school education and university or a first qualifying professional training. In the context of this chapter, the focus is on a specific aspect of continuing vocational education: part-time training after a first professional qualification, what is defined in the following paragraph. Part-time training comprises courses that professionals can join alongside their regular job in order to support lifelong learning and development on the job. The learners are already working with a company and sign up for extra classes to boost their skills in a specific field. In this context, part-time trainings are typically 0.5- to 4-day programs but can be combined to form a whole certifiable program, such as a Master of Engineering for additive manufacturing. The general advantage of part-time training is more flexibility for the participants to combine learning activities with their professional and family obligations. The employer has also the benefit that employees have briefer absences on their job.

In summary, continuing education can contribute, in synergetic coexistence with AM conferences, forums etc., to an economic sustainable growth and application of AM in industry. However, one should clarify any dependencies of the provider of continuing education before joining a program in order to enjoy a comprehensive and unbiased learning experience. Summarizing, two main drivers for the exceptional relevance of continuing education for AM can be derived:

-

Strong demand for experts in AM

A shortage of AM experts on the labour market can be observed which can hardly be met by, e.g. university graduates as AM has, most of the time, not been represented in their curriculum, see explanations above. Consequently, continuing education is a powerful tool for, e.g. mechanical engineers focused on production technology to develop further. Obviously, this is not only true for university graduates but also transferable on apprenticeship, etc.

-

Rapid and manifold progress in AM technologies

AM industry is highly dynamic which leads to a significant amount of new knowledge and relevant progress every year, month, or even day. Hence, continuing education and part-time training on AM for people in employment can be crucial to keep up-to-date reducing the need to provide cost-intensive capacity for internal forces to operate, e.g. a technology radar.

2 Fundamentals of Part-Time Training in Continuing Education

2.1 Relevance of Continuing Education for Today’s Industry

Recent analyses of the job market show a rising lack of qualified personnel. Technical jobs are particularly affected (Bundesagentur für Arbeit 2017). The time of vacancy increased from 90 to 100 days in the last year. The rising need for qualified employees is also visible in other European countries (Cedefop 2011). This is caused among others by the demographic change, a positively improving economic situation, and technological innovations. Especially, small and medium-sized companies are concerned by the lack of qualified personnel, because they are often not well versed in employer branding compared to big companies. One important approach to meet the need of qualified employees is continuing education. The results of the adult education survey confirm that the participation increases at continuing vocational training in the European average between 2007 and 2011 with 6 percentage points (Cedefop 2015) and in Germany between 1991 and 2014 with 14 percentage points (BMBF 2015). That is a clear hint for the increasing relevance of continuing education. Employers have a measurement against the rising lack of qualified employees by training their own workforce and they are able to strengthen their innovativeness. Furthermore, companies will get more attractive in the ‘war for talents’, if they offer their personnel opportunities for continuing education. Workers have the opportunity to secure their employability over their lifespan and they are enabled to make the next step in their career with learning and qualification.

Summarizing the arguments above, there is no discussion that continuing education is important and contains benefits for all parts involved. The question is whether all goals and demands connected with continuing education for professionals can be reached. Different authors claim that only 10% of training content can be transferred into practice and most of the trainings are bad investments (Ford et al. 2011; Gris 2008). The taught knowledge often stays inert and cannot be applied in the professional context. Following (Renkl et al. 1996), these phenomena of inert knowledge can be explained by three different reasons: The acquired knowledge has not an appropriate structure to put it into practice (structure deficit). The relevant knowledge is acquired in a suitable structure, but it cannot be transferred into practice because of accessibility problems (metaprocess deficit). The acquired knowledge is situated and connected to the learning situation. To apply knowledge it is necessary that the learning situation is quite similar to the application situation (situated cognition). Following these basic assumptions about practicable knowledge, learning settings and continuing education need to follow certain requirements to reach their goals. These requirements are explained in the next paragraph.

2.2 General Requirements of the Learning Psychology for Part-Time Training in Continuing Education

Against a background of part-time training and knowledge transfer in a job-related context, the learning psychology provides a relevant theoretical approach about learning and the design of learning environments: a moderate constructivist view of learning (Gerstenmaier and Mandl 2001). The moderate constructivist view of learning defines learning as process, in which the learner receives information and constructs his/her own knowledge based on his/her experiences, previous knowledge, emotional and motivational situation. Knowledge is not transportable from one person to the other. Knowledge has to be constructed by the learner individually (Mandl 2010). Furthermore, the learning process is characterized by six different aspects:

-

Active process: Learning is only possible with an active learner, who needs a minimum of motivation. Furthermore, cognitive activities but also motored operations are necessary by doing exercises or tasks.

-

Constructive process: Knowledge has to be integrated in available cognitive structures and prior knowledge. Existing experiences help to interpret and evaluate the new content.

-

Self-regulated process: Parts of the learning process need the engagement of the learner him-/herself to organize and monitor the own activities.

-

Emotional process: The learning process is influenced by emotions. Especially performance-orientated emotions (i.e. exam nerves) and social emotions (i.e. proud) are relevant. To foster learning processes, positive emotions have to be strengthened and negative emotions have to be avoided.

-

Social process: Knowledge acquisition always takes place in a social context with interaction between several persons. Besides facts and contents, attitudes and values are negotiated.

-

Situated process: Knowledge is always connected to a specific situation. If you learn, the acquired knowledge will be linked with the context.

To facilitate such an ideal learning process, which takes all various aspects mentioned above into account, it is necessary to design a learning environment with a balance between construction and instruction (Reinmann and Mandl 2006). Traditional learning environments emphasize the role of the teacher as instructor, who teaches the relevant knowledge. S/he has the most active part in the learning setting and passes on the content to the learners by explanations, instructions and presentations. The learners are first of all in a receiving role and less active. A learning environment oriented on the moderate constructivist view pays attention to the balance between construction by the learners and instruction by the teacher (see Fig. 3). Induced by a problem-based approach, the learners have an active role. They construct their knowledge in a social group; they are emotionally involved and act self-regulated. The teacher is more reactive by supporting, coaching, counselling and encouraging the learners. S/he has the task to switch between reactive and active parts depending on the situation and learning phase.

Balance between construction and instruction (based on Reinmann and Mandl 2006)

To design such a problem-based learning environment which facilitates a balance between construction and instruction four aspects have to be noticed:

-

Authentic context: Ideal learning environments are authentic situations, in which the learner needs new knowledge and skills to master the situation. In order to design such situations real problems, cases and simulations of authentic situations should be used. The authentic context creates relevance for the learner, motivates, generates interest and produces relevance to practical application. Consequently, it is one important factor for successful knowledge transfer since the learning situation is quite similar to the application situation at the job.

-

Multiple contexts: As knowledge is acquired in a specific situation, it is also linked to the situation in its cognitive representation (Renkl et al. 1996). To get flexible and more general available knowledge, it has to be put into multiple contexts. The learner should get the opportunity to use and practice his/her knowledge in different situations. Taking different perspectives into account supports the acquisition of flexible and applicable knowledge, too.

-

Social context: Although learning looks like an individual process, social aspects are really relevant. Knowledge acquisition happens in interaction between several persons. Learning environments should enable collaboration and problem solving in groups. The contact to experts and a community is an important aspect, too.

-

Instructional context: Besides authenticity, multiple contexts and social interactions, teacher’s instruction and support are also significant. The instructional context should be adaptive to the learner’s needs to support him/her mastering authentic problems in multiple contexts with other learners. Learning environments without suitable construction are threatened to fail because of overtaxing and a missing structure.

A meta-analysis of 43 empirical studies shows robust effects from problem-based learning environments on learners’ skills and their practical knowledge (Dochy et al. 2003). That endorses the theoretical assumptions about knowledge transfer mentioned above. In summary, the balance between construction and instruction with problem-based learning settings enables the application of knowledge to job-related contexts. Further results confirm that learners acquire a smaller amount of knowledge in problem-based learning environments in comparison to traditional settings. But the sustainability and the applicability are higher (Dochy et al. 2003). An additional factor is the learners’ previous knowledge. The more the learners know before the more they profit from problem-based learning scenarios. Consequently, the learners’ preconditions have to be taken into account. For beginners, the instructional context should predominate. The authentic context can be realized with examples and realistic cases to provide more details and starting points for learners.

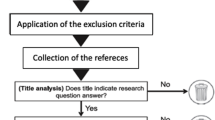

2.3 Design of a Part-Time Training in Continuing Education

Taking the theoretical and empirical considerations above into account several aspects for designing a part-time training is relevant. First of all, the input of the training has to be analysed. In the context of training conception input means the target group or the potential learners and their preconditions. Relevant questions to investigate the input are related to previous knowledge and experience with the topic, motives to participate, former learning experiences, demographical characteristics and job-related context. Second, the output of the training has to be defined. The output can be described with learning goals or competences the participants acquire (Bloom and Krathwohl 1956). Learning goals give an important orientation during the design process. They describe, what participants should know, understand and can apply in different fields, for example, cognitive and motor goals. Bringing input and output together, the produced gap determines the content of the training. Taking the concept of part-time trainings into account, the challenge is to structure and reduce the content suitable to digestible snacks. The selection and arrangement of content use different heuristics. Following the idea of brief part-time trainings with content-related excellence, the horizontal reduction is a relevant heuristic by focusing on one topic and neglect familiar topics.

3 Fraunhofer’s Modular Network Approach for Continuing Education and Part-Time Training in the Field of Additive Manufacturing

3.1 Introducing Fraunhofer IGCV and Fraunhofer Academy

Fraunhofer IGCV, Fraunhofer Research Institution for Casting, Composite and Processing Technology IGCV, is a production-focused research institution with headquarter in Augsburg and an additional location in Garching (both Munich Area, Southern Germany). Fraunhofer IGCV has a strong focus on additive manufacturing and conducts research on both direct processes, such as laser-based powder bed fusion of metals, Directed Energy Deposition—processes or extrusion-based processing of fibre-reinforced plastics, and indirect processes, such as binder jetting-based printing of moulds and cores for sand casting. In its so-called ‘AMLab’ (cf. www.amlab.de), a joint laboratory between Fraunhofer IGCV and the Institute for machine tools and industrial management of the Technical University of Munich, one of Germany’s largest additive manufacturing machine parks has been available for wide-ranged research on additive manufacturing since more than 20 years.

Fraunhofer Academy is the Fraunhofer-Gesellschaft’s specialist provider of continuing education and part-time training for people in employment. The Fraunhofer Academy offers specialists and managers several courses of study, certificate courses and seminars based on the research activities of the Fraunhofer institutes in collaboration with selected and prestigious partner universities (https://www.academy.fraunhofer.de/en.html). In October 2016, Fraunhofer IGCV and Fraunhofer Academy decided to join forces in order to set up a modular framework for part-time training and continuing education in additive manufacturing.

3.2 Modular Framework for Continuing Education and Part-Time Training Within Fraunhofer Gesellschaft Under the Umbrella of Fraunhofer Academy

According to DIN EN ISO/ASTM 52900:2017-06, seven process categories for additive manufacturing exist today, Fig. 4.

They exhibit significant differences in terms of their technological principle to generate parts. Within each process category, several processes are available on the market. Processes described in VDI-guideline 3405 (2014), such as polymer-focused laser-sintering, or metal-focused laser or electron beam melting are all part of process category ‘Powder Bed Fusion’. Hence, it can be concluded that additive manufacturing covers a wide range of different technologies to generate parts out of polymers, metals, ceramics, paper, concrete, etc. via different technological principles (e.g. melting, chemical bonding). For that reason, a modular approach for part-time training and continuing education exhibits two core advantages: Participants can choose courses that have a focus on their relevant topics. For instance, if one were interested in metal processing technologies, a comprehensive course, which covers technologies for ceramic, polymer and metal processing, would not be a perfect fit. In contrast, a course on all metal processing technologies out of the seven process categories might be a perfect fit. Through modularization, the institution responsible for certain modules can have in-depth practical experience in the technology or topic covered by the course. For a certain combination of modules, knowledgeable institutions can join forces in order to ensure best possible quality of the offered continuing education. For that reasons, Fraunhofer IGCV developed a modular network approach for continuing education for additive manufacturing as shown in Fig. 5.

The ‘Input’-element covers an analysis of participants’ existing skills and field of work needed to enter the modular network. If there is no prior knowledge on additive manufacturing, a participant should enter the network by joining the ‘Basic module’, which covers fundamentals of additive manufacturing. The ‘Basic module’ will be explained in more detail below. If there is sufficient prior knowledge, a participant can directly join one or more of the ‘In-depth modules’. The ‘Output’-element highlights the importance of having SMART (specific, measurable, accepted, reasonable, time-bound) learning objectives for every course module and path through the network. So far, three modules have been developed: First, the ‘Basic module’ which covers fundamentals of additive manufacturing and is provided by Fraunhofer IGCV in Augsburg, second an in-depth module on laser beam melting, which is also provided by Fraunhofer IGCV, and third an in-depth module on electron beam melting, which is provided by Fraunhofer IFAM in Dresden. According to the definitions provided in the section above, the current focus of the developed network is to provide high-quality part-time training. For this reason, the content of the three modules is free of overlap and follows a similar and by Fraunhofer Academy approved structure. As a result, participants can join every module and will thereby continuously add new knowledge in the field of AM. The objective for the years 2018 and 2019 is to integrate more Fraunhofer Institutes and possibly excellent universities into the network illustrated in Fig. 5 to be able to provide more part-time trainings within element ‘In-depth modules’. In collaboration with designated certification bodies and universities, it will then be possible to issue both certificates such as an ‘Additive Manufacturing Specialist’ on design, metal/polymer/ceramic processing, etc. and Master degrees on additive manufacturing.

3.3 Developed Modules

Within this section, the general idea of the developed part-time trainings is presented. On the one hand, the set-up of the ‘Basic module’ will be described, on the other hand, the common set-up of both the laser and electron beam melting part-time training will be presented. An example for an input–output chart for part-time trainings is shown in Fig. 6. This chart has been developed for the ‘Basic module’.

To participate in the part-time training ‘Basic module’, learners shall have a specific education, which means they should hold a university degree on a, at least partly, technical subject. Alternatively, participants should have been foremen or equivalent in the production environment for more than 3 years. Hence, a technological basic knowledge of the learners is guaranteed. As the content of the ‘Basic module’ is chosen very broad, learners active in development, production, business development and innovation, as well as technically focused management can participate in this course, given that the educational prerequisites are fulfilled. The overall objective of the part-time training ‘Basic module’ is to enable participants to establish a team within their company that is able to systematically identify company-specific potentials for additive manufacturing and to derive corresponding exploitation plans. To achieve this overall objective after a 2-day part-time training, the output as described in Fig. 6 needs to be achieved.

Figure 6 gives an overview on the input–output chart for the ‘in-depth modules’ on laser or alternatively electron beam melting. As there is a certain similarity amongst this two powder bed fusion technologies, a similar set-up was foreseen for the two-day part-time training. As described in Fig. 7, learners who want to join this ‘in-depth modules’ need to fulfil more demanding requirements in terms of their education level compared to the ‘Basic module’. Also, required department affiliations are more precise compared to the ‘Basic module’. This is necessary to reach the overall objective that participants shall be enabled to optimize the technology, which is in scope of the part-time training (either laser or electron beam melting) in terms of, e.g. achievable surface roughness, minimal wall thicknesses etc.

Besides input–output charts, which are supposed to give a brief overview on what is going on in each element of the modular network (Fig. 5) more detailed class schedules need to be developed in order to maximize the quality of the part-time trainings. Within these class schedules, it shall be specified:

-

What is the market-driven motivation to set-up this part-time training?

-

What are the objectives in terms of cognitive, affective or hands-on skills?

-

What are the prerequisites for participation? (This question is basically sufficiently answered with the input section of an input–output chart.)

-

What is the qualification needed for the teachers?

-

What are the boundary conditions of the part-time training and how does the overall concept look like?

-

Duration

-

Proportion of theory and practice

-

Actions before the part-time training, such as app-based preparation of learners

-

Actions after the part-time training, such as control of learning progress by means of regular tests during the first 6 months after the completion of the part-time training

-

What is the theoretical and practical content of the part-time training?

Following Table 1 gives an overview on the objectives, which were defined for Fraunhofer IGCVs ‘Basic module’.

Tables 2 and 3 give an overview on the timetable developed for the first and second day of the ‘Basic module’. Tables 2 and 3 do also include didactical methods, which are defined in the following for clarification reasons:

-

Demonstration: something is demonstrated by the teacher, such as how to prepare an additive manufacturing machine for a build job.

-

Discussion: a certain topic is discussed within the group; the teacher can be part of the discussion or only the moderator.

-

Group work: teams of, e.g. three participants are formed to solve a given problem. The teams should not remain the same for all group works.

-

Guided dialog: in contrast to a lecture, slides are presented by utilizing questions, such as ‘Why is this aspect important and therefore mentioned on this slide?’. Obviously, slides need to be prepared in a way that this didactical method can be applied.

-

Lecture: giving a presentation to inform about a certain topic.

-

Practical work: something is created by the learners.

-

Single work: each participant has to solve the same problem on his/her own.

It is obvious from Tables 2 and 3 that both training days start with a hands-on activity. This is recommendable to ‘awake’ learners and highlight that they are a crucial part of the event. On the first day, all AM processes are introduced to the learners, which means a significant amount of information. This is both tough and relevant. However, in order not to give a 3-h lecture on AM-processes in a row, a lightweight design hands-on training was foreseen to interrupt this set following the principles of learning psychology described in Sect. 2.2. In general, by utilizing varying didactical methods, the attention of the learners can be kept on a high level. By foreseeing test for the learn progress during the training, teachers get feedback, which content should be repeated and to which extent. Also, these tests do help learners to independently repeat the content and to put it into a new context by themselves. More details and most recent information on the modules are available: www.academy.fraunhofer.de/additivefertigung

So far, in total 5 runs with the three developed part-time training modules have been performed. Overall, 16 person have been educated (1 run ‘Basic module’, 3 runs ‘In-depth—laser beam melting’, 1 run ‘In-depth—electron beam melting’) resulting in an average evaluation of 4.6 points, whereas 5 is the upper end (excellent) and 1 (very poor) the lower end of the applied range. For the pilot evaluation, a more detailed feedback from the four participants (n = 4) was collected which is shown in Fig. 8. It can be concluded that both the didactical design and the content received very good grades. The didactical design including the idea of problem-based learning could be put into practice very well and the participants estimated it as suitable. The output was estimated above average by the participants themselves immediately after the training.

It is assumed that the weaker results for the output are caused by a heterogeneous prior knowledge of the participants. Possibly, learners with a more profound pre-knowledge rated the output rather average. Therefore, a pre-knowledge-test should be done beforehand to prove this assumption. Measurements to handle heterogeneous prior knowledge, what is quite common in continuing education, are identified in the following fields:

-

Try to find out as much as possible about prior knowledge on AM of the participants and their special interests in the field of AM before the part-time training takes place. This can be done by providing an online questionnaire before the event. Expectations should be collected, too. If a questionnaire is not possible before the training, at least the participants’ expectations and experiences should be collected at the beginning of the training. The trainer can carry out a fine tuning concerning content by integrating suitable examples or by shifting priorities between topics.

-

Prepare extra modules on certain topics as a back-up in order to be responsive if participants want to also learn about something, which is not completely included in your course material. Foresee time slots in your timetable for these extra topics. The training concept should be flexible for adjustments.

-

Group work is a suitable didactical method to handle heterogeneous prior knowledge. Two scenarios are possible: Groups with different knowledge and experiences work together, therefore the participants learn from each other and the principle of multiple perspectives is realized (see Sect. 2.2). In the second scenario, groups are built with similar knowledge and experience. Then the groups can work on different tasks related to their skills.

Besides a Continual Improvement Process, further investigations could focus on the knowledge transfer into job-related contexts. This could provide evidence for more improvements of the didactical design and also the content. Additionally, insights would be collected for future developments in the field of AM and the need for training.

References

Ark Invest (2017). 3D Printing Market—Analysts Are Underestimating the Future. https://ark-invest.com/research/3d-printing-market.

Bitkom (2017). 3D Printing—Erfolgsgeschichte für den Digitalstandort. [3D Printing—Success Story for the Digital Location].

Bloom, B. S., & Krathwohl, D. R. (1956). Taxonomy of educational objectives: The classification of educational goals, by a committee of college and university examiners. New York: Longmans, Green.

Bundesagentur für Arbeit (2017). Statistik/Arbeitsmarktberichterstattung, Berichte: Blickpunkt Arbeitsmarkt– Fachkräfteengpassanalyse, Nürnberg, Juni 2017 [Federal Employment Agency, Statistics/Labour Market Reporting, Reports: Focus on the labour market—skilled worker bottleneck analysis, Nuremberg, June 2017].

Bundesministerium für Bildung und Forschung (BMBF) (2015). Weiterbildungsverhalten in Deutschland 2014. [Federal Ministry of Education and Research (BMBF) (2015). Continuing Education Behaviour in Germany 2014.] https://www.bmbf.de/pub/Weiterbildungsverhalten_in_Deutschland_2014.pdf.

CEDEFOP (2011). What next for skills on the European labour market? www.cedefop.europa.eu/files/9059_en.pdf.

Cedefop (2015). Job-related adult learning and continuing vocational training in Europe: A statistical picture. Luxembourg: Publications Office. Cedefop research paper no 48. https://doi.org/10.2801/392276.

DIN EN ISO/ASTM 52900:2017-06 Additive manufacturing—General principles—Terminology (ISO/ASTM 52900:2015); German version EN ISO/ASTM 52900:2017.

Dochy, F., Segers, M., Van den Bossche, P., & Gijbels, D. (2003). Effects of problem-based learning: A meta-analysis. Learning and instruction, 13(5), 533–568.

EY’s Global 3D Printing Report (2016). How will 3D printing make your company the strongest link in the value chain? Ernst & Young 2016.

Ford, J. K., Yelon, S. L., Billington, A. Q. (2011). How much is transferred from training to the job? The 10% delusion as a catalyst for thinking about transfer. Performance Improvement Quarterly, 24(2), 7–24.

Gerstenmaier, J.; Mandl, H. (2001). Constructivism in cognitive psychology. In N. J. Smelser & P. Baltes (Eds.), International Encyclopedia of the Social and Behavioral Sciences (pp. 2654–2659). Oxford: Elsevier.

Gris, R. (2008). Die Weiterbildungslüge. Warum Seminare und Trainings Kapital vernichten und Karrieren knicken.[The training lie. Why seminars and training courses destroy capital and kink careers] Frankfurt a. M.: Campus.

Langefeld, B. (2016): Additive Manufacturing—Next Generation. In: Mobility Goes Additive.

Mandl, H. (2010). Lernumgebungen problemorientiert gestalten—Zur Entwicklung einer neuen Lernkultur. [Design problem-oriented learning environments—To develop a new learning culture.] In: E. Jürgens & J. Standop (Eds.), Was ist “guter” unterricht? Namhafte expertinnen und experten geben antwort [What is “good” teaching? Renowned experts provide answers] (pp. 19–38). Bad Heilbrunn: Klinkhardt.

Reinmann, G., Mandl, H. (2006). Unterrichten und Lernumgebungen gestalten. [Teaching and designing learning environments] In: A. Krapp & B. Weidenmann (Hrsg.), Pädagogische psychologie [Educational Psychology] (S. 613–658). Weinheim: Beltz.

Renkl, A., Mandl, H., & Gruber, H. (1996). Inert knowledge: Analyses and remedies. Educational Psychologist, 31(2), 115–121.

VDI 3405: VDI-guideline 3405:2014: Additive Manufacturing Processes, Rapid Manufacturing—Basics, Definition, Processes. https://www.vdi.de/uploads/tx_vdirili/pdf/2244181.pdf.

Wohlers Report (2017). 3D Printing and Additive Manufacturing State of the Industry. Annual Worldwide Progress Report. Wohlers Associates, Inc., Colorado.

Wohlers Report (2016). 3D Printing and Additive Manufacturing State of the Industry. Annual Worldwide Progress Report. Wohlers Associates, Inc., Colorado.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Seidel, C., Schätz, R. (2019). Continuing Education and Part-Time Training on Additive Manufacturing for People in Employment—an Approach Focused on Content-Related and Didactical Excellence. In: Pei, E., Monzón, M., Bernard, A. (eds) Additive Manufacturing – Developments in Training and Education. Springer, Cham. https://doi.org/10.1007/978-3-319-76084-1_2

Download citation

DOI: https://doi.org/10.1007/978-3-319-76084-1_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-76083-4

Online ISBN: 978-3-319-76084-1

eBook Packages: EngineeringEngineering (R0)