Abstract

As Europe seeks to retain its leading position for industrial competitiveness, there is an urgent need to establish Additive Manufacturing (AM) skills at European, National and Regional levels. AM processes enable economic component production through efficient use of materials and increased design freedom as compared to conventional manufacturing. AM also raises the level of digital literacy among workers and contributes to the digitization of the European Industry. EU initiatives such as ADMIRE and CLLAIM aim to create and support an industry-led European Qualification System for Metal Additive Manufacturing that will tackle skills and qualification needs from an operator to engineer level.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Additive Manufacturing (AM)

- European Qualification System

- Metal AM

- Increased Design Freedom

- Describe Learning Outcomes

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The mobility of professionals specializing in welding technology was established long before the European Union advocated the need for international recognition of professional qualifications. This need for international recognition of qualifications by employers and local authorities was the starting point for designing the training and qualification systems initiated by the European Federation for Welding, Joining and Cutting (EWF) intended to qualify professionals in welding technology from blue- to white-collared workers. Today, with a fast-growing interest and implementation of Additive Manufacturing (AM), there is a high demand and a clear opportunity to deliver a training programme for workers in AM through a European and International qualification system, similar to existing EWF schemes that are closely aligned with industry requirements. By doing so, it is expected to increase the uptake of national diplomas that are recognized, and at the same time, to prepare the AM workforce with the necessary skills at both European and International levels. The ‘ADMIRE’ (ADMIRE 2017) and ‘CLLAIM’ (CLLAIM 2017) projects that were funded by the Erasmus + framework, was set up to attain this goal by creating a European Qualification System for Metal Additive Manufacturing, being the first to create EU qualification standards for AM Engineers and the latter one for EU AM operators, designers and inspectors.

2 Demand for Personnel Training in Additive Manufacturing

Education and employment are intrinsically tied to each other, and this statement is more prevalent in AM; here, there is a lack of qualified personnel, as evident from the EY 3D Printing report from April 2016, in which the lack of qualified experts was identified as the second highest barrier on the implementation of AM, and the first barrier being high costs associated with AM. This is one out of many reports and studies that have been conducted over the previous years that highlight the paramount need to fill the gap between the AM market and Vocational and Educational Training (VET) at a European level. Refer to Fig. 1 (Ernst and Young 2016).

Barriers of implementing AM (N = 900 companies) (Ernst and Young 2016)

Despite these constraints, the growth of AM technology continues to increase and the scale of potential applications have become wider, adding onto the pressures of an unpredictable future workforce. As a consequence, the delivery of timely and fit for purpose training is a need, as recommended in the Strategic Research Agenda released in 2014 by the Additive Manufacturing Platform (AM-Platform 2018). The recommendations include the following:

-

Developing training programmes for industry practitioners certified by professional bodies;

-

Catering for events based on specific industrial case studies, technology transfer support and supply chain assistance;

-

Developing AM specific training modules encompassing design, modelling, processes, materials and applications.

3 Tackling AM Training at a European Level

The European landscape in terms of training and qualification for AM personnel is fragmented in which small and separates blocks of training are being delivered across countries in different directions. There is an absence of a comprehensive and all-encompassing curricula for education, training and the provision of schemes to retrain and requalify the existing workforce in AM. The EWF is developing a European harmonized system for VET/Professional Training that would encompass qualifications ranging from an upper secondary level to a Postgraduate degree (Masters) level. The development of the European harmonized system is done in collaboration with current European funded projects CLLAIM and ADMIRE. Some of the tools included in the training are as follows: (i) the European Qualifications Framework (EQF 2018), which is structured into levels (from 1 to 8) encompassing specific descriptors for each level, known as Learning Outcomes; (ii) the European Credit System for Vocational Education and Training (ECVET 2018) and the European Skills, Competences, Qualifications and Occupations (ESCO 2018). The gaps are required to be analysed in detail to ensure that the developed European Qualification answers the industry requirements for each stage of the AM value chain, starting with the AM Designer and Specialist for the Numerical Modelling and Design and Materials; followed by the Specialist and Operator for the Processing stage, and finally, by Inspector for the Non-Destructive Testing and the Testing phases. Initially, to bridge the gap between job offers and job seekers in the professions related with AM, it became crucial to identify the skills needs in Europe. To have an overview on the relevance of technical skills gaps/topics for each professional profile (Operator, Inspector/Quality Assurance Supervisor, Designer, Supervisor and Engineer) identified in a market research conducted by EWF.

The technical skills gaps/topics marked in light blue (0–30%) are considered slightly relevant, whilst the ones in blue (31–75%) are considered relevant and those in dark blue (76–100%) are considered very relevant. Looking at the top row (‘Operator’), it is suggested that the topics ‘AM Processes’, ‘Post-Processing’ and ‘Pre-Processing and Material Handling’ are relevant and ‘Health, Safety and Environment (HS&E)’ is very relevant for development of the Operator’s professional qualification standards. Based on those skill needs, the design of a EU sector-specific curricula which is competence-based would be written according to the expected learning Outcomes (LOs) of the EQF. The recognition and certification of the respective LOs establish the formal, non-formal and informal learning pathways so that more flexible routes to learning are addressed, as well as, improving the entry and progress of the labour market (European Commission 2014; Flourentzouen 2012). The recognition of non-formal and informal learning often referred to as ‘Recognition of Prior Learning’ (RPL). The European harmonized scheme for Recognition of Prior Learning (RPL) and work-based recognition at the workplace would be designed such that it could enable lifelong learning and to disclosure flexible pathways/routes for the learners, especially for mature students. Some of the advantages of prior learning include giving formal recognition to the knowledge and skills that people already possess as a route to new employment; increasing the number of people with formal qualifications; and reducing training time by avoiding repetition of what candidates already know.

The RPL of both formal and informal learning is also supported by implementing ECVET principles by means of credits. This is carried out to ensure that the implementation is at a European level and at the same time, national and regional implementation through private training, education organizations and also public organizations. Another important aspect is to facilitate the mobility of workers in the European labour market, in which the CLLAIM project is contributing to this by referencing qualifications in EQF, and by setting up a framework for the creation of an ‘International Qualifications’ system for AM. The creation of a competency matrix for the qualification of levels according to the LOs detailed with the core knowledge, skills and competencies are expected to contribute to the ESCO classification, allowing the characterization and creation of new occupations and qualifications. Within AM, some profiles that have a higher priority such as those in Fig. 2 and the ones mentioned in the European Economic and Social Committee report on AM include machine operators who are able to deal with the process-specific software (Fornea and Van Laere 2015), personnel involved in curricula and training in AM for activities such as engineering design, software, materials processing, materials supply, post-processing, heat treatment, non-destructive testing and final finishing (Vallés 2015), and AM professionals and specialists such as design technicians and manufacturing inspectors (CECIMO 2015).

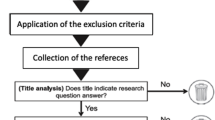

At the moment, the market is absent of any formal recognized qualification on metal AM in Europe. The majority of training cover aspects of AM in general and do not really explore topics in depth. The CLLAIM project, however, is at the forefront of curricular provision for AM based on the EWF System, which is a European qualification body supported by a quality assurance system, allowing the qualification and training process of personnel to be done in a harmonized way across Europe. The way the harmonization and implementation of the EU AM Qualification System are achieved pictured in Fig. 3.

The EU recognition is guaranteed by applying the same rules for quality assurance in each country, by overseeing the quality of the courses and making use of the necessary EU tools. At the same time, national recognition is achieved by engaging relevant AM stakeholders, including national accreditation organizations. For the implementation and provision of training at local level, the partners shall be approved beforehand to deliver the AM training courses. The contents of the European AM System would be maintained up to date, as the local providers of training would be closely engaged with industry, students and trainees. The new requirements captured by the local providers across countries would be, then, reflected in the learning outcomes descriptors. The learning outcomes are structured according to modular Learning Units, comprising of specific learning descriptors (KSC—knowledge, skills and competences). Another part will rely on a VET harmonized scheme for assessment and recognition of prior learning/work-based learning recognition within the scope of AM.

4 Conclusions

The European Skills Panorama (2014) described ‘Europe is a world leader in developing advanced manufacturing techniques. Advanced manufacturing is the use of cutting-edge skills or technologies to generate efficiencies and improvements to production processes. These techniques include the use of advanced robotics and 3D printing’. Therefore, one of the biggest challenges in tackling AM skill needs and shortages is related to the higher speed of technology development when compared with the speed of education/training provision. To tackle this, a systemic and sound methodological approach for skills monitoring and a deployment system of education and training to be delivered on time, involving all relevant stakeholders shall include the following:

-

Sector Skills Strategy at a European Level by developing and engaging stakeholders covering all sectors, technologies and the entire value chain; supported by a European Qualification System in AM;

-

A forecast methodology for assessing current and future needs to ensure that the demands of the industry are recorded and addressed;

-

A methodology to design and revise professional profiles and developing skills that will enable upskilling/reskilling of professionals. This is critical to accelerate the implementation of AM in the industry;

-

The creation of business–education–research partnerships to ensure that all key stakeholders are involved in the identification and creation of necessary skills.

The digitization of the manufacturing sector heralds the beginning of the Fourth Industrial Revolution. One of the key pillars is the use of AM that will change qualifications at three levels—manufacturing technologies, control systems and digital technologies. As trends such as the Internet of Things and connected machines become pervasive, we need to ensure that our workforce is ready to embrace this challenge and to drive the industry forward by having reskilled, retrained and newly qualified personnel. Also, to be taken into account is the changing nature of work and the emergence of new roles that have the potential to benefit existing workers by enabling them to work beyond what would be expected given the physical requirements of the job such as through Artificial Intelligence and Robotic Assistance. Companies, universities, training institutions and governments must work together to address these new changes by aligning formal and informal qualifications, boosting a modular delivery and embracing lifelong learning in all of its dimensions.

References

ADMIRE. (2017). European master degree in metal additive manufacturing (A.M.). Retrieved March 27, 2018, from http://admireproject.eu.

AM Platform. (2018). European technology platform in additive manufacturing. Retrieved March 27, 2018, from http://www.rm-platform.com.

CECIMO. (2015). Additive manufacturing on its way to industrialisation—A game changer? Retrieved March 27, 2018, from http://www.cecimo.eu/site/fileadmin/Magazine/CECIMO_magazine_AM_edition_2015.pdf.

CLLAIM. (2017) European AM qualification body and European harmonized qualification system. Retrieved March 27, 2018, from http://cllaimprojectam.eu.

ECVET. (2018). The European credit system for vocational education and training (ECVET). Retrieved March 27, 2018, from https://ec.europa.eu/education/policy/vocational-policy/ecvet_en.

EQF. (2018). Descriptors defining levels in the European Qualifications Framework (EQF). Retrieved March 27, 2018, from https://ec.europa.eu/ploteus/en/content/descriptors-page.

Ernst & Young. (2016). EY GLobal 3D Printing Report, 2016. Retrieved March 27, 2018, from ey-global-3d-printing-report-2016-full-report.pdf.

ESCO. (2018). European skills/ competences, qualifications and occupations. Retrieved March 27, 2018, from https://ec.europa.eu/esco/portal/home.

European Commission. (2014). Advancing manufacturing—advancing Europe’—Report of the task force on advanced manufacturing for clean production. Retrieved March 27, 2018, from https://ec.europa.eu/digital-single-market/news/advancing-manufacturing-advancing-europe-report-task-force-advanced-manufacturing-clean.

EU Skills Panorama (2014). Analytical highlight—focus on advanced manufacturing. Retrieved March 27, 2018, from http://skillspanorama.cedefop.europa.eu/sites/default/files/EUSP_AH_AdvManufacturing_0.pdf.

Flourentzouen, E. (2012). Official journal of the European union—council recommendation of 20 December 2012 on the validation of non-formal and informal learning. Retrieved March 27, 2018, from eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012H1222(01)&from=EN.

Fornea, D., & Van Laere, H. (2015). OPINION of the European economic and social committee on living tomorrow. 3D printing—a tool to empower the European economy. Retrieved March 27, 2018, from http://edz.bib.uni-mannheim.de/edz/doku/wsa/2014/ces-2014-4420-en.pdf.

Vallés, J. L. (2015). Additive manufacturing in FP7 and horizon 2020—Report from the EC workshop on additive manufacturing held on 18 June 2014. Retrieved March 27, 2018, from http://www.rm-platform.com/linkdoc/EC/AMWorkshopReport2014.pdf.

Acknowledgements

The ADMIRE project has been funded with support from the European Commission. This publication reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. No. 575938-EPP-1-UK-EPPKA2-KA. The CLLAIM project has been funded with support from the European Commission. This publication reflects the views only of the author, and the Commission cannot be held responsible for any use which may be made of the information contained therein. No. 591838-EPP-1-2017-1-ES-EPPKA2-SSA

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Assunçao, E.G., Silva, E.R., Pei, E. (2019). Professional Training of AM at the European Level. In: Pei, E., Monzón, M., Bernard, A. (eds) Additive Manufacturing – Developments in Training and Education. Springer, Cham. https://doi.org/10.1007/978-3-319-76084-1_14

Download citation

DOI: https://doi.org/10.1007/978-3-319-76084-1_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-76083-4

Online ISBN: 978-3-319-76084-1

eBook Packages: EngineeringEngineering (R0)