Abstract

Following the pioneering patent of Willey on Al–Sc alloys (1971), an extensive research program has started in the USSR in the 1970s, dedicated both to the fundamentals of interaction and mechanisms of Sc in Al and to the development of Sc-containing aluminum alloys. A number of very important phase diagrams of practically relevant systems have been experimentally studied and laid the foundation for the development of wrought and casting alloys with Sc. The unique equilibrium L12 Al3Sc phase has been characterized and its role in grain refinement, precipitation hardening and preventing recrystallization has been identified and explained. Interaction of Sc with other transition elements, in particular Zr, has been investigated. A number of alloys of Al–Mg, Al–Li–Mg, Al–Zn-Mg, Al–Cu systems with particular properties, e.g. high strength, weldablity, superplasticity, have been developed and commercialized in the 1980–1990s. This presentation gives an overview of those developments.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

The first patent on Sc-containing alloys is dated 1971 and was obtained by Willey of Alcoa [1]. This invention covered aluminum alloys containing up to 5% Sc (typically 0.2–0.6%) and also claimed hardening heat treatment in the temperature range 100–425 °C. This triggered huge interest to the mechanisms of Sc in Al alloys and to the phase diagrams of practically important Al systems with Sc. Russian schools of phase diagrams in particular in Baikov Institute of Metallurgy and Lomonosov Moscow State University became involved in studying the phase equilibria in these systems. This laid the foundation for the informed development and commercialization of Al–Mg, Al–Li and other aluminum alloys containing small additions of Sc as well as to the research in the phases formed at various stages of alloy processing, from casting to deformation; and eventually to the mechanisms of grain refinement , precipitation hardening and recrystallization control. These works were concentrated in the Baikov Institute of Metallurgy (IMET), All-Russia Institute of Light Alloys (VILS) and All-Russia Institute of Aviation Materials (VIAM).

Aluminum alloys containing scandium (frequently in combination with zirconium) use several mechanisms to control structure and properties. Primary particles of aluminides act as nucleants for the aluminum solid solution during solidification. Considerable amount of scandium is retained in the solid solution after solidification. This supersaturated solid solution decomposes at relatively high temperatures (250–350 °C) with the formation of coherent and semi-coherent particles that can either harden the alloy (this effect is used in Al–Mg alloys) or retard recrystallization (this is used in heat treatable aluminum alloys).

Phase Diagram Development

The first version of the Al–Sc phase diagram reported a peritectic reaction in the Al corner [2]. This was later proved to be wrong and the well-known eutectic reaction was established in Al-rich alloys, L → (Al) + Al3Sc at 655 °C with the eutectic point at 0.5–0.6 wt% Sc and the limit solubility of 0.4 wt% [3], which is very close to the later data of the eutectic temperature at 656–660 °C, eutectic point at 0.52–0.58 wt% Sc and limit solubility at 0.38 wt% [4, 5]. The solid solubility of Sc in (Al) rapidly decreases with temperature. The Al3Sc phase is formed at 1320 °C during a peritectic reaction, has a cubic ordered structure of L12 type with a = 0.4104 nm [5]. Interestingly enough, recently the peritectic nature of reaction between (Al) and Al3Zr came into question with a eutectic reaction suggested instead [6].

It was shown that on increasing the cooling rate, the solubility of Sc in Al significantly increases while the eutectic temperature decreases as shown in Fig. 1 [7, 8]. This created a base for the development of Sc-containing alloys that use supersaturation of the aluminum solid solution with scandium upon cooling during solidification.

Metastable phase diagrams of the Al–Sc system as 5 K/s (1); 102 K/s (2); 103 K/s (3) and 105 K/s (4). After [9]

The Al3Sc phase has been studied in detail, both the crystal structure [10] and mechanical properties [11].

Zirconium is an addition that is frequently used together with Sc to reduce the required amount of the latter and to increase the stability of the dispersion-hardened structure.

The Al–Sc–Zr phase diagram is considered as a combination of eutectic and peritectic transformations on the respective sides of the concentration triangle. In the aluminum corner of this system only binary Al3Sc and Al3Zr phases are in the equilibrium with (Al) (Fig. 2). The Al3Sc phase can dissolve Zr up to the composition Al3Sc0.6Zr0.4 (35 wt% Zr) [12,13,14]. The Al3Zr phase melts congruently at 1577 °C, has a tetragonal structure of D023 type with a = 0.4006–0.4014 nm and c = 1.727–1.732 nm, and dissolves Sc up to the composition Al3Zr0.8Sc0.2 (5 wt% Sc). These phases participate in the invariant reaction L + Al3Zr → (Al) + Al3Sc at 659 °C. Mutual equilibrium solubility of Zr and Sc in solid (Al) is 0.06% Zr, 0.03% Sc at 550 °C and 0.09% Zr, 0.06% Sc at 600 °C [9].

Section of the Al–Sc–Zr phase diagram: a polythermal section from Al–0.4% Sc to Al–0.8% Zr and b isothermal sections at 550 °C (dashed lines) and 600 °C (solid lines). After [9]

The typical concentrations of scandium and zirconium in commercial aluminum alloys are lower than 0.3% Sc and 0.15% Zr or <0.45% in total. Depending on the Zr:Sc ratio, either Al3Sc (Zr:Sc < 1) or Al3Zr (Zr:Sc > 1) solidifies as primary phase. Some authors suggest the formation of a ternary Al3(ScZr) phase with the crystal structure similar to that of stable Al3Sc and metastable Al3Zr. However, there is no evidence in favor of the formation of a new phase in the Al–Sc–Zr system. Metallographic examination of primary particles in Al–Sc–Zr alloys show that Al3Sc phase forms a rim on primary Al3Zr particles [9]. This surface layer possesses very good refining ability of Al3Sc and “activates” Al3Zr, allowing strong grain refinement at relatively low Sc concentrations.

Another practically important phase diagram is of the Al–Mg–Sc system that is a foundation for a new class of precipitation hardened Al–Mg alloys. The invariant eutectic reaction L → (Al) + Al3Sc + Al8Mg5 occurs in the aluminum corner of the system at 447 ± 3 °C and 0.1–0.5% Sc [15]. Figure 3a gives a polythermal section of the Al-rich portion of the Al–Mg–Sc phase diagram. Under real casting conditions, the solidification continues down to 447–450 °C when the ternary (Al) + Al3Sc + Al8Mg5 eutectics is formed.

a A polythermal section from Al–17% Mg to Al–1% Sc of the Al–Mg–Sc phase diagram and b solid solubility of Mg and Sc in (Al). After [9]

Commercial alloys of 1570-type (5–6% Mg) usually contain less than 0.3% Sc (typical concentrations of Sc and Zr are less than 0.15% each). In this compositional range, the ternary Al–Mg–Sc alloy is on the border between primary solidification of either (Al) or Al3Sc. However, if we take into account the joint presence of Sc and Zr in commercial alloys and the mechanism of their formation (Fig. 2), it becomes clear that the typical concentration of Sc and Zr is sufficient for very good grain refining of Al–Mg alloy upon casting.

In addition to grain refinement , the main purpose of introduction of Sc to Al–Mg alloys is to assure the precipitation of coherent Al3Sc particles from the supersaturated solid solution. The precipitation hardening and structural hardening (due to the retarded recrystallization ) significantly add to the solid-solution hardening effect that is the typical mechanism of strengthening of Al–Mg alloys. Therefore, the solubility of Mg and Sc are of great importance in these alloys. It has been shown that the solubility of magnesium in solid aluminum considerably decreases in the presence of scandium . The limit solubility of Mg and Sc in solid aluminum at the temperature of the ternary eutectics is 10.5% Mg and 0.007% Sc as compared to 13.5–14% Mg in the binary system [9]. The solubility of Mg and Sc decreases with temperature as shown in Fig. 3b. These data are useful for the correct choice of annealing temperatures for homogenization or precipitation .

Another implication of adding Mg to Al–Sc alloys is the fact that magnesium increases the lattice parameter of the aluminum solid solution and, hence decreases the dimensional misfit between Al3Sc and the matrix (from 0.012 in a binary Al–Sc alloy to 0.00054 in a ternary Al–6.5% Mg–Sc alloy [16]). As a result, the coherency of Al3Sc is retained at higher temperatures and on longer exposures, providing for a higher thermal stability of Al–Mg–Sc alloys.

Other phase diagrams of commercially important systems such as Al–Cu–Sc, Al–Si–Sc, Al–Li–Sc, Al–Li–Mg–Sc, and Al–Cu–Mg–Zn–Sc–Zr have been thoroughly investigated by Russian research groups as well and the reviews can be found elsewhere [9, 17].

Precipitation in Sc-Containing Aluminum Alloys

The aluminum solid solution tends to supersaturate with transition metals upon cooling after solidification. Al–Sc alloys are vivid representatives of this behavior (see Fig. 1). Of course the supersaturated solid solution can be obtained also by quenching after high-temperature anneal. The decomposition of supersaturated solid solutions with Sc is the foundational mechanism for precipitation hardening and recrystallization retarding in aluminum alloys as was extensively studied by Drits et al. [16, 18, 19].

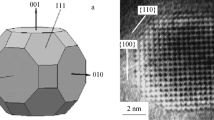

It was established that the decomposition occurs with precipitation of fine, spherical, coherent particles of the equilibrium Al3Sc phase. This is the unique characteristic of Al–Sc alloys as in most of precipitation hardened alloys, intermediate metastable phases precipitate and cause hardening . It was also demonstrated that the effective temperature range of hardening in between 250 and 350 °C with the maximum strength achieved after several hours of annealing. The equilibrium Al3Sc phase has a cubic structure with the lattice parameter very close to that of aluminum, which enables homogeneous nucleation of particles just a few nm in diameter as illustrated in Fig. 4 [9]. The selected area diffraction pattern shows only superstructure reflections, while the particles give a distinct Ashby-Brown deformation contrast from the surrounding elastic field. The coherent precipitates are quite stable at temperatures below 350 °C for over 100 h. On increasing the annealing temperature above 400 °C, the particles loose coherency and become semi-coherent after 50 h [9]. The main mechanisms of hardening are shearing of small coherent precipitates at the maximum strength stage (e.g. 250 °C, 50 h) followed by Orowan hardening by dislocation loop formation after the coherency loss. The strengthening in the Al–Sc system is the highest among aluminum alloys , reaching 1000 in terms of the increase in the yield strength normalized to the total amount of alloying elements as compared to 191 in Al–Li–Mg alloys, 77 in Al–Cu–Mg alloys, and only 48 in Al–Zn–Mg–Cu alloys [9].

Precipitation of coherent Al3Sc particles in an Al–0.6% Sc alloy at 350 °C, 100 h: a microstructure showing particles 13 nm in diameter and b (100) electron diffraction pattern showing superstructure reflections. After [9]

The Al–Sc system is often used as a model system for studying nucleation, growth and hardening during decomposition of a supersaturated solid solution; owing to the unique features such as precipitation of the equilibrium phase, its homogenous nucleation, spherical shape of the particles, and their uniform distribution in the matrix.

One of the most common group of alloys, i.e. Al–Mg AA5XXX series, acquires the ability to harden via precipitation thanks to alloying with Sc. Conventionally, these alloys are subjected to solution hardening due to the high solubility of Mg in Al. The addition of Sc and its supersaturation in the Al solid solution during solidification makes it possible to combine the solution hardening of Mg with precipitation hardening by Al3Sc at 250–300 °C. This combination is not possible or is not beneficial in other Al alloys that are usually aged at 130–195 °C for precipitation of hardening metastable phases. In these alloys, the strengthening effect of conventional precipitation will be lost upon higher-temperature precipitation of Al3Sc. Figure 5a illustrates the benefits of alloying Al–Mg alloys with Sc.

Effects of precipitation in Al–Mg–Sc alloys: a hardening in binary Al–Sc and ternary Al–Mg–Sc alloys and b evolution of Al3Sc radius during aging of an Al–6.5% Mg–0.4% Sc alloys at different temperatures. After [9]

The studies of precipitate evolution showed that Al3Sc precipitates are rather stable in Al–Mg alloys and preserve their coherency up to radii of 65 nm (anneals at 400–450 °C for 10 h), which is 2–3 times larger than in binary Al–Sc alloys [20]. This is related to the reduced misfit between the precipitates and the Al–Mg matrix.

It was already mentioned that Sc and Zr are commonly used jointly in Al alloys. This has an advantage of reducing the required amount of expensive Sc but also has another advantage of increasing the stability of the hardening effect. Figure 6 shows that ternary Al–Sc–Zr alloys may have a lower absolute hardening effect but it is more stable at longer holding times and at higher temperatures. This is a result of joint precipitation of two L12 phases, i.e. equilibrium Al3Sc and metastable Al3Zr. It is demonstrated that the former precipitates are larger while the latter much finer as shown in Fig. 7. The concurrent precipitation of two similar and coherent phases slows down the softening of the alloy and preserves high hardening effect to higher temperatures and exposures. It should be noted that the precipitation of Al3Sc phase starts at a lower temperature than Al3Zr, therefore the positive synergetic effect is observed at aging at 350–400 °C [21].

Aging curves for Al–0.3% Sc (solid lines) and Al–0.3% Sc–0.17% Zr (dashed lines) at 200 °C (○); 300 °C (●); 300 °C (Δ); 350 °C (▲); 400° (×); and 450 °C (□). After [9]

Precipitation in an Al–0.3% Sc–0.17% Zr alloy: a 350 °C, 200 h; b 400 °C, 200 h; and c 450 °C, 10 h. Larger particles in b are the equilibrium Al3Sc phase while smaller particles in c are the metastable Al3Zr phase. After [9]

There are some peculiarities in precipitation hardening in Al–Si and Al–Li alloys alloyed with Sc. It was shown that not Al3Sc phase but rather a metastable AlSiSc phase with spherical or ellipsoid-shaped particles precipitate in Al–Si–Sc alloys and effectively harden these alloys at 200–250 °C [22]. In Al–Li alloys two L12 phases, i.e. Al3Li and Al3Sc, precipitate. It is possible to perform two stage aging, with the first stage at 400 °C to form Al3Sc followed by a lower temperature stage at 200 °C to form Al3Li [23]. Composite particles with the Al3Sc core and the Al3Li envelope are typically observed in these alloys, driven by the reduction of interfacial and elastic energies.

Recrystallization Control

Transition metals are common additions to aluminum alloys to control recrystallization via pinning of dislocations and grain boundaries by dispersoids precipitating upon homogenization or hot deformation. As a result the temperatures of recrystallization onset and completion are increased. Ti and Zr increase the latter by 180 °C and 240 °C, respectively [9].

The precipitates of Al3Sc retain their coherency to high temperatures and also grow rather slowly, so it is prudent to suggest that their effect on recrystallization development may be pronounced. The recrystallization of Al–Sc alloys has been studied for different starting conditions before cold rolling (annealed and forged; quenched in water, aged, or hot extruded) and for different Sc concentrations [9, 18]. It has been shown that even small additions of Sc (0.1–0.15%) sharply increase the recrystallization temperature. The temperature of recrystallization onset is increased to 350–375 °C at 0.15–0.3% Sc and the temperature of recrystallization completion can be as high as 640 °C in a hot extruded Al–0.4% Sc alloy [9]. Figure 8 illustrated these effects.

Effect of Sc additions on the recrystallization temperature of aluminum: a recrystallization onset and b recrystallization completetion. After [18]

The size and distribution of Al3Sc particles play the crucial role in the recrystallization control. Precipitates finer than 10 nm with the spacing smaller than 300 nm increase the onset of recrystallization by 125–175 °C and shift the completion of recrystallization by 125–250 °C [24]. On reaching the final recrystallization temperature the precipitates grow to 130–190 nm with a spacing of 1.3–2.5 µm [9].

The hindering of recrystallization is even more pronounced in Al–Mg–Sc alloys where, as it has been already mentioned, the stability of the precipitates is greater than in binary alloys. The maximum recrystallization onset temperature is achieved at Sc concentrations above 0.2% with no complete recrystallization possible at these concentrations as shown in Fig. 9. Particles with a diameter of 15–16 nm and spacing lesser than 170 nm are most efficient. A subgrain structure is typical with the cell size of 2–4 µm [25].

Effect of Sc concentration of the recrystallization temperatures in an Al–6.5% Mg alloy. After [9]

Additional alloying with Zr further increases the temperature stability of dispersoids and subgrain (polygonized) structure of deformed alloys [26]. This is illustrated in Fig. 10.

Grain structure of an AA6XXX alloy after homogenization at 480 °C, hot rolling at 400 °C and quenching from 500 °C: a an alloy without Sc and Zr and b an alloy with Sc and Zr. After [32]

Grain Refinement upon Solidification

Primary Al3Sc particles are almost ideal substrates for Al as their crystal structure is very close to that of solid Al. The great grain refining ability of Sc in Al was first reported in the 1960s [27] and was later justified and confirmed on many occasions. In binary alloys, the grain refining is observed at hypereutectic compositions, i.e. above 0.5% Sc (Fig. 11). In ternary Al–Sc–Zr alloys, the grain refining effect is observed at lower concentrations of Sc. One of the possible explanations is that Al3Sc forms an envelope onto the primary Al3Zr particles, which requires much less Sc. Mutual additions of Sc and Zr (0.15% each) can even deliver a nondendritic structure in Al–Li–Mg, Al–Mg and Al–Zn–Mg alloys with the grain size as small as 20 µm [28, 29]. This grain refining is particularly important upon welding as it helps avoiding hot cracking and reducing residual stresses, making the welding joint much stronger.

Commercial Alloys with Sc

In the USSR the fundamental research in the mechanisms of Sc in aluminum alloys resulted in the development and then commercialization of a number of wrought alloys.

Addition of Sc to Al–Mg alloys allowed engineers to improve their weldability and significantly increase the strength (yield strength increment is 120 MPa), fracture toughness and thermal stability of properties (up to 250 °C and down to −196 °C) due to the precipitation of Al3Sc. These alloys are typically homogenized at 400 °C, and extruded or rolled at 250–300 °C. A combination of refined as-cast grain structure, polygonized deformation structure and precipitation hardening results in a very advantageous combination of properties [9, 30]. Commercial alloys containing 6% Mg (1570: 6% Mg, 0.2% Sc, 0.1% Zr), and smaller amounts of Mg (1545, 1535, 1523, 1515) have been developed and used in welded aerospace (e.g. fuel tanks, space platforms, heat exchangers, structural components) and marine (structural components) applications [30].

In heat-treatable aluminum alloys the effects of precipitation hardening with Al3Sc are hard to combine with the major processes of conventional aging due to the large difference in required annealing temperatures, i.e. 250–300 °C versus 150–190 °C. In these alloys alloying with Sc aims at the fine grain structure during solidification and welding as well on the restricting recrystallization .

An Al–Zn–Mg–Sc (1970) alloy was developed to substitute for AA2324 in aerospace applications, having advantages in corrosion resistance and weldability. Less alloyed 1935 and 1975 alloys can be used as extrusions in automotive and railway applications, to substitute AA6063-type alloys, being much stronger, tougher and weldable [30].

An important group of Sc-containing alloys is based on the Al–Li–Mg system. These alloys are intended for fuel tanks, aircraft structural parts and are used in some of MiG fighter jets and Beriev hydroplanes [31]. The grades include 1421 (0.16–0.21% Sc) and 1430 (0.01–0.1% Sc). Also Sc was added to some of Al–Cu–Li alloys (1460, 1461, 1430, 1469) in order to improve their strength, corrosion resistance and weldability. These alloys substitute for Al–Cu–Mg alloys with 10–15% weight reduction.

Table 1 gives some examples of tensile properties for Sc-bearing aluminum alloys .

Concluding Remark

This overview shows a solid foundation laid by Russian scientists for the development and application of Sc-containing aluminum alloys . Main phase diagrams, specifics of precipitation , mechanisms of grain refining, hardening and recrystallization control have been developed in the 1970–1990s and have not lost value in the XXI century. Also commercialization of Sc-containing aluminum alloys has been started in Russia in the 1980s and some of these examples are still unique despite growing globally interest to application of Sc in Al.

References

Willey LA (1971) Aluminum Scandium Alloy, USA Patent US3619181 A.

Naumkin OP, Terekhov VT, Savitskii EM (1965) Izv. Akad. Nauk SSSR, Met. (4): 176–179.

Drits ME, Kadaner ES, Dobatkina TV, Turkina NI (1973) Izv. Akad. Nauk SSSR, Met. (4):213–217.

Murray J L (1998) J. Phase Equilibria 19(4): 380–384.

Cacciamani G, Riani P, Borzonea G, Parodi N, Saccone A, Ferro R, Pisch A, Schmid-Fetzer R (1999) Intermetallics 7: 101–108.

Wang F, Eskin DG, Khvan AV, Starodub KF, Lim JJH, Burke MG, Connolley T, Mi J (2017) Scr. Mater. 133: 75–78.

Drits ME, Toropova LS, Bykov YuG (1983) Izv. Akad. Nauk SSSR, Met. (1): 179–182.

Toropova LS, Kamardinkin AN (1989) Tzvetn. Met. (5): 104–106.

Toropova LS, Eskin DG, Kharakterova ML, Dobatkina TV (1998) Advanced Aluminum Alloys Containing Scandium, Gordon & Breach OPA, Amsterdam.

Rechkin VN, Lamikhov LK, Samsonova TI (1964) Kristallografiya 9(3): 405–408.

Drits ME, Toropova LS, Gushchina FL, Fedotov SG (1984) Izv. Vyssh. Uchebn. Zaved., Tsvetn. Met. (1): 123–124.

Toropova LS, Kamardinkin AN, Kinzhibalo VV, Tyvanchuk AT (1990) Fiz. Met. Metalloved. 69–70(12) 108–111.

Kamardinkin AN, Dobatkina TV, Rostova TD (1991) Izv. Akad. Nauk SSSR, Met. (2): 214–216.

Toropova LS, Dobatkina TV, Kamardinkin AN (1992) Izv. Akad. Nauk SSSR, Met. (5): 140–143.

Turkina NI, Kuz’mina VI (1976) Izv. Akad. Nauk., Met. (4) 208–212.

Drits ME, Pavlenko SG, Toropova LS, Bykov YuG, Ber LB (1981) Dokl. Akad. Nauk SSSR 257 (2): 353–356.

Belov NA, Eskin DG, Aksenov AA (2005) Multicomponent Phase Diagrams. Applications for Commercial Aluminum Alloys, Elsevier, Amsterdam.

Drits ME, Toropova LS, Bykov YuG, Ber LB, Pavlenko SG (1982) Isv. Akad. Nauk SSSR, Met. (1) 173–178.

Drits ME, Ber LB, Bykov YuG, Toropova LS, Anastas’eva GK (1984) Fiz. Met. Metalloved. 57(6) 1172–1179.

Toropova LS, Bykov, YuG, Lazorenko VM, Platov YuM (1982) Fiz. Met. Metalloved. 54 (1): 201–203.

Belov NA, Alabin AN, Eskin DG, Istomin-Kastrovskii VV (2006) J. Mater. Sci. 41: 5890–5899.

Kharakterova ML, Eskin DG, Toropova LS (1994) Acta Metall. 42 (7) 2285–2290.

Miura Y, Horikawa K, Yamada K, Nakayama M (1994) In: Sanders, TH, Starke EA (eds) The 4th Int. Conf. on Aluminum Alloys: Their Physical and Mechanical Properties. Vol. 2, Atlanta: Georgia Institute of Technology, p 161–168.

Drits ME, Toropova LS, Bykov YuG (1985) Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall. (4): 80–84.

Royset J, Ryum N (1994) In: Sanders, TH, Starke EA (eds) The 4th Int. Conf. on Aluminum Alloys: Their Physical and Mechanical Properties. Vol. 1, Atlanta: Georgia Institute of Technology, p 194–201.

Yelagin VI, Zakharov VV, Rostova TD, Filatov YuA (1986) In: Metallovedenie, lit’e i obrabotka legkikh splavov. Moscow: Metallurgiya, p 180–189.

Lamikhov LK, Samsonov GV (1964) Tsvetn Met. (8): 79–82.

Turkina NI, Semenova EV (1992) Tekhnol. Legk. Spl. (1): 57–59.

Yelagin VI, Zakharov VV, Rostova TD, Filatov YuA (1986) In: Metallovedenie, lit’e i obrabotka splavov. Moscow: VILS, p 6–16.

Yelagin VI, Zakharov VV, Filatov YuA, Rostova TD (2006) In: Perspektivnye tekhnologii legkikh i spetsial’nykh splavov. Moscow: Fizmatlit, p 181–193.

Grushko O, Ovsyannikov B, Ovchinnikov V (2017) Aluminum–Lithium Alloys. Process Metallurgy, Physical Metallirgy and Welding, Boca Raton: CRC Press.

Kharakterova ML, Eskin DG, Rokhlin LL (1997) Metally (1): 123–128.

Ovsyannikov BV, Popov VI (2010) In: Proceedings of the 12th International Conference on Aluminium Alloys. Tokyo: Jpn. Inst. Light Metals, p 441–446.

Acknowledgements

Although this paper is a review of research done mostly by others, I would like to express gratitude to people that have been actively involved in studying Al–Sc alloys and whom I had an honor to meet and collaborate with: Dr. L. S. Toropova, Dr. Yu. A Filatov, Dr. T. V. Dobatkina, Dr. M. L. Kharakterova, Dr. A. N. Kamardinkin, Dr. B. V. Ovsyannikov.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Eskin, D.G. (2018). Sc Applications in Aluminum Alloys: Overview of Russian Research in the 20th Century. In: Martin, O. (eds) Light Metals 2018. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72284-9_204

Download citation

DOI: https://doi.org/10.1007/978-3-319-72284-9_204

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72283-2

Online ISBN: 978-3-319-72284-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)