Abstract

This article proposes a controller design that takes into account the control input dimension to be use in damping control of suspended load for crane systems. Many researches on transporting and anti-swaying control of cranes have been reported. However, most of those researches deals with overhead cranes. Only few studies deal with truck cranes since in the truck cranes, the suspended load should be controlled by using booms that have physical nonlinearity. Also, when introducing a new control system, the users would like to use the same control input dimension as the previous controller. For this purpose, a crane model is extended with a hydraulic control valve model, and a controller is designed based on this extended model. This allows to generate control inputs in the same dimension as the purchased valve controller. To show the validity of the proposed method, experiments using a truck crane has been conducted. The experimental results showed that the proposed controller has been successfully worked and the sway of the suspended load has been damped well.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Recently, cranes have been widely used in steel industry, port transportation industry, construction industry. However, load swaying occurs during transportation of suspended loads, and skillful handling techniques are required to control load fluctuations [1, 2]. Therefore, in order to solve this problem, various researches on damping control of suspended loads are being conducted. For example, for three-dimensional overhead cranes, studies on damping control of suspended loads have been reported [3,4,5]. In previous researches, existing controllers of crane systems were not explicitly incorporated into the control system [6, 7]. Many users want to introduce a new control method without changing the existing system. To solve these problems, the authors proposed a design method of control systems that provide an interface to use the same operational commands of the servo controller, and have realized a damping control of the suspended load by using a robot manipulator with a wireless motion sensor [8]. In this paper, the proposed design method is applied to track cranes so that the existing valve controller can be used as it is. The validity of the proposed method is evaluated by experiment using an actual truck crane.

2 Modeling

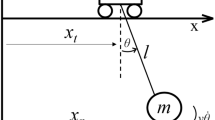

2.1 Modeling of Crane Boom

This chapter describes a modeling of a load suspended by a crane boom. Figure 1 shows a crane model and parameters. Table 1 shows the definition of the parameters and variables of the crane to be controlled. Where, in Table 1, BTP stands for Boom Top Position, and BFP stands for Boom Fundamental Position. In addition, each sway angle of the load is positive with respect to the X and Y axes forming the right-handed screw. Based on the above definitions, an equation of motion of the load in the lateral and longitudinal directions are derived by the Lagrange’s method. Taking the generalized coordinate \( q \) as \( \theta_{1} \), \( \theta_{2} \) and the generalized force as \( \tau_{i} \) (to be zero), Lagrange’s equation of motion is given by

where \( T_{W} \) is the kinetic energy, \( V_{W} \) is the potential energy and \( U_{b} \) is the dissipated energy.

Details are omitted but the equations of motion of the sway angle \( \theta_{1} \) in the lateral direction and the sway angle \( \theta_{2} \) in the longitudinal direction are derived. Linearization of the equation of motion is obtained as

2.2 Augmented System of Crane Boom with Valve Controller

In order to adjust the dimension of the control input to the angular velocity, which is the dimension of the operational command of the valve controller, a model of the controlled plant, i.e. the crane boom, is augmented so as to include the valve controller. The model to be identified is a transfer function from the operational command in angler velocity to the angler velocity of the boom, and the parameter values are identified by experiment.

In the experiment, the angular velocity command was randomly given from the joystick under the condition that there was only a hook, the mass of which was 30 kg (no suspended load), the rope length \( L_{O} \) was 3.69 m, and the boom length \( L_{B} \) was 4.5 m. Then, angular velocities of the longitudinal direction and the lateral direction were measured from a gyro sensor. As an example, Fig. 2 shows the time responses of the lateral valve command and the measured lateral angular velocity. Assuming that the order of the identified model is two, the model parameters are identified by least square method. As a result, the transfer function \( G_{SW} \) from the lateral valve command to the measured lateral angular velocity has been obtained as

Similarly, the transfer function \( G_{DC} \) from the longitudinal valve command to the measured longitudinal angular velocity has been obtained as

Using the identified transfer functions of Eqs. (3) and (4), the angular velocity in the longitudinal direction and the angular velocity in the lateral direction are calculated from the crane’s longitudinal angular velocity command \( \dot{\theta }_{BO} \) and the lateral angular velocity command \( \dot{\phi }_{BO} \) as follows:

The blue solid line in Fig. 3 shows the time response of the calculated output from the identified model by inputting the lateral angular velocity command \( \dot{\phi }_{BO} \) to it. In Fig. 3, the time response of the measured lateral angular velocity (red dotted line) is also plotted for comparison. From Fig. 3, it has been confirmed that the augmented system of the crane boom with the valve controller is well represented by the identified model.

2.3 Augmented Crane System Including Suspended Load Dynamics

Finally, an augmented crane system including suspended load dynamics is defined so as to derive a state space expression of the whole system. The augmented crane system consists of the augmented system of the crane boom with the valve controller derived in Sect. 2.2 and the suspended load dynamics. Figure 4 shows the whole block diagram of the augmented crane system. Based on the block diagram, by taking the state vector as \( \varvec{x} = \left[ {\begin{array}{*{20}c} {\theta_{1} } & {\theta_{2} } & {\theta_{B} } & {\phi_{B} } & {\dot{\theta }_{1} } & {\dot{\theta }_{2} } & {\dot{\theta }_{B} } & {\dot{\phi }_{B} } & {\ddot{\theta }_{B} } & {\ddot{\phi }_{B} } \\ \end{array} } \right]^{T} \) and the input as \( \varvec{u} = \left[ {\begin{array}{*{20}c} {\dot{\theta }_{Bo} } & {\dot{\phi }_{Bo} } \\ \end{array} } \right]^{T} \), a state space expression is derived (see [9] for the detail).

3 Control System Design

The damping control system to be designed consists of a full-order observer and a state feedback controller. Also, the state feedback controller is designed using an optimal regulator.

Assuming a zero order hold, and the state space representation of the crane including the valve derived in Chap. 2 is discretized as follows:

For the system of Eq. (7), let the weighting matrix \( \varvec{Q}_{d} \in \Re^{10 \times 10} \) for state and \( \varvec{R}_{d} \in \Re^{2 \times 2} \) be the weighting matrix for input. Find the state feedback gain that minimizes the evaluation function

The weighting matrix is set to

and the state feedback gain \( \varvec{F}_{d} \) is derived.

For the states necessary for state feedback control that cannot be observed, the state estimate value of the observer was used. By choosing the state vector as \( \varvec{x} = \left[ {\begin{array}{*{20}c} {\hat{\theta }_{1} } & {\hat{\theta }_{2} } & {\hat{\theta }_{B} } & {\hat{\phi }_{B} } & {\dot{\hat{\theta }}_{1} } & {\dot{\hat{\theta }}_{2} } & {\dot{\hat{\theta }}_{B} } & {\dot{\hat{\phi }}_{B} } & {\ddot{\hat{\theta }}_{B} } & {\ddot{\hat{\phi }}_{B} } \\ \end{array} } \right]^{T} \), the observer is given by

The observer gain \( \varvec{K}_{d} \) is calculated according to a framework of the steady-state Kalman filter. For this time, weighting matrix \( \varvec{Q}_{o} \in \Re^{10 \times 10} \), \( \varvec{R}_{o} \in \Re^{4 \times 4} \) for estimated state and observation output are selected as

Figure 5 shows a block diagram of the proposed control system described above.

4 Experiment of Load Damping Control of Truck Crane

4.1 Experimental Procedure

In this experiment, the cargo crane of TADANO Ltd., is used as an actual machine (Fig. 6). For detection of sway angular velocity of suspended load, a small 9-axis wireless motion sensor (logical product LP-WS 1102) was attached to the upper side of the suspended load. Crane longitudinal angle and lateral angle are measured by using a potentiometer attached to each motion axis. All the states necessary for the state feedback are estimated from the gyro sensor and the potentiometer, and the controller generates the angular velocity command. The sampling time of the control system is 60 ms. The experimental conditions are listed in Table 2. Table 3 summarizes the specifications of the small 9-axis wireless motion sensor. As the contents of the experiment, damping control is carried out respectively in the longitudinal direction and the lateral direction. Specifically, the lateral direction generates a target trajectory from the state of the lateral angle of 25° from the reference coordinate system of the crane to the target angle of 40° and moves the boom. After that, confirm the response when entering step input such as returning to the original place. In the same way as the lateral direction described above, the boom is moved in the longitudinal direction, the angle of which is between 55° and 65°.

Also, as a comparative subject, experiments without damping control are performed in the same way.

4.2 Experimental Result

The time response of the lateral angle \( \phi_{B} \) of the crane is shown in Fig. 7, and that of the sway angle \( \theta_{2} \) in the lateral direction is shown in Fig. 8. The time response of the longitudinal angle \( \theta_{B} \) of the crane is shown in Fig. 9, and that of the sway angle \( \theta_{1} \) in the longitudinal direction is shown in Fig. 10. As shown in Fig. 7, the target value of the step of setting the crane lateral angle from 40° to 25° is given. Further, as shown in Fig. 9, the target value of the step for setting the crane longitudinal angle from 65° to 55° is given. As can be seen from Figs. 8 and 10, when the damping control is not performed in both the lateral direction and the longitudinal direction, the load continues to sway, but it can be suppressed in the case where the damping control is performed. As shown in Figs. 7 and 9, it was found that the settling time of both the lateral angle and the longitudinal angle with the proposed damping control was longer than that without control. This is because the movement of the lateral angle and the longitudinal angle of the crane is also used for damping control. To calculate the damping ratio from the time response of the sway angle, the responses acquired by the experiment are numerically fitted to a function given by

Comparison of time responses of lateral angle \( \theta_{2} \) of the load without (blue dotted line) and with (red solid line) proposed control systems corresponding to Fig. 7.

Comparison of time responses of longitudinal angle \( \theta_{1} \) of the load without (blue dotted line) and with (red solid line) proposed control systems corresponding to Fig. 9.

so as to minimize the least square error. The calculated damping ratio \( e^{{ - \alpha \frac{2\pi }{\omega }}} \) is listed in Table 4.

From Table 4, it can be seen that the sway of the load can be suppressed in the case of the case with the damping control compared with the case of no damping control. In addition, it can be seen that in the longitudinal direction, the sway of the load is not attenuated without damping control. This is because the resonance of the higher frequency modes, mainly due to the second bending mode of the load-lope pendurum system occurd. To solve this problem, the controlled plant model should be expanded so as to include the second mode, and it would be one of the future work.

5 Conclusion

This paper proposes a method for designing control inputs in the same dimension as the purchased valve controller generally installed in a crane, and showed its effectiveness by actual machine experiments. The attenuation rate of the suspended load swaying could be halved by the proposed method. However, the oscillation of the second bending mode occurring in the load cannot be attenuated. The future work would be to suppress this second mode oscillation.

References

Yano, K., Yamada, M., Terashima, K.: Development of operator support system for rotary crane considering positioning and sway-suppression. Trans. Soc. Instrum. Control Eng. 42(10), 1158–1167 (2006). (in Japanese)

Honda, H., Yoshida, T.: Estimating the sway angle of an overhead crane by an observer using angular velocity sensors. Trans. Jpn. Soc. Mech. Eng. 72(722), 131–136 (2006)

Cho, S., Lee, H.: An anti-swing control of a 3-dimensional overhead crane. In: Proceedings of the 2000 IEEE American Control Conference, pp. 1037–1041, June 2000

Kaneshige, A., Terashima, K., Munetoshi, H., Sadamori, T.: Modeling and transferring control of an overhead traveling crane based on the information of object position. Trans. Jpn. Soc. Mech. Eng. Series C 64(628), 4777–4782 (1998)

Cho, S., Lee, H.: A fuzzy-logic antiswing controller for three-dimensional overhead cranes. ISA Trans. 41(2), 235–243 (2002)

Wu, X., He, X., Wang, M.: A new anti-swing control law for overhead crane systems. In: Proceedings of the 2014 IEEE 9th Conference on Industrial Electronics and Applications (ICIEA), pp. 678–683, June 2014

Shah, U.H., Piao, M., Hong, K.S.: Command-shaping control of quayside cranes with eight-pole reeving mechanism. In: Proceedings of the International Conference on Mechatronics and Automation, pp. 2030–2035, August 2016

Iwatani, A., Ishikawa, J.: Damping control of suspended load based on position command. In: Proceedings of the 34th Annual Conference of the Robotics Society of Japan, 3C1-05 (2016). (in Japanese)

Yoshikawa, M., Iwatani, A., Ishikawa, J.: Damping control of suspended load for cranes in consideration of control input dimension. In: Proceedings of the 2017 JSME Conference on Robotics and Mechatronics (Robomech 2017), pp. 1P2-C06(1)–1P2-C06(4), May 2017. (in Japanese)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Yoshikawa, M., Iwatani, A., Ishikawa, J. (2018). Damping Control of Suspended Load for Truck Cranes in Consideration of Control Input Dimension. In: Duy, V., Dao, T., Zelinka, I., Kim, S., Phuong, T. (eds) AETA 2017 - Recent Advances in Electrical Engineering and Related Sciences: Theory and Application. AETA 2017. Lecture Notes in Electrical Engineering, vol 465. Springer, Cham. https://doi.org/10.1007/978-3-319-69814-4_42

Download citation

DOI: https://doi.org/10.1007/978-3-319-69814-4_42

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-69813-7

Online ISBN: 978-3-319-69814-4

eBook Packages: EngineeringEngineering (R0)