Abstract

The review of composite scintillators for cost-efficient large area detectors is presented. Design features of composite scintillator depending on the applications are discussed. Scintillation and optical materials for their production are considered. Along with single crystals scintillation powders obtained by sol-gel method as well as by solid state synthesis can be used for composites fabrication. Regularities of the light collection in composite layer are described. Composite scintillators can be a base for neutron and gamma detectors for medical radiography as well. For high energy physics (HEP) the optimum design with the maximum light output and high radiation hardness is proposed. It is shown that the composite scintillator with quartz light conducting layer and YAG:Ce wavelength shifting light guide can provide the optimal solution.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

1 Introduction

When implementing different scintillation detectors technological and economical issues become important. Nowadays there are a number of special require large area detectors with a relatively small scintillator thickness. The use of single-crystal or plastic scintillators for this purpose claims for special material and detector design to satisfy the economic limitations.

The production of single crystal scintillators is related to the crystals growth so these materials are expensive. There are many problem of manufacturing large area detectors on the base of single crystal also limited these developments. Plastic scintillator is an acceptable and cheap material for large area detector design, but these materials have low light output and low registration efficiency. Scintillation ceramics are fabricated without the stage of crystal growth using high-temperature compression technique. This technology guarantees the obtainment of the sufficiently large area plates with acceptable parameters and reasonable cost. But they are still too expensive for many applications. Composite scintillators are a compromise solution for fabrication high effective low-cost large area detectors. Composites detectors combine high performance of inorganic scintillators and cost effectiveness of plastic scintillators, ensure an optimal balance between the good scintillation quality and the reasonable price of the detector. The composite scintillator is a multicomponent system based on scintillation granules placed in an optical medium [1]. For the fabrication of composites different types of powders can be used: fine powders obtained by mechanical grinding of single crystals, of solidified melts or solid-state synthesis powders (mainly by sol-gel method). This allows to exclude the single crystals growth from the production cycle and to reduce the cost of composite scintillators if compared with bulk scintillators.

2 Composite Scintillators as an Alternative to Homogeneous Scintillation Materials

One of potential applications for composite scintillators are the X-ray detectors for technical, security and medical purposes preferably for imaging systems. Thin-layer detectors based on inorganic scintillation granules [1] can be inexpensive analogues of luminescent CsI(Tl) screens of columnar morphology [2,3,4]. Depending on the scintillators used, effective composite beta detectors can be fabricated as an alternative to plastic scintillator, as well as large area detectors for low activity radionuclide identification, and for neutron detection [5]. Composite scintillators based on radiation hard materials can be used in high energy physics (HEP) among other as scintillation elements of megatiles or calorimetric modules “shashlyk” type [6, 7].

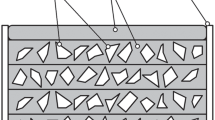

Composite scintillators consist of scintillation granules distributed in an optically transparent medium (Fig. 1).

The scintillator type, the granules size and the medium material are selected depending on the particles that have to be registered. Composite scintillators can be attributed to micro heterogeneous systems with granules size from 100 nm to 1000 μm. The content of granules may reach 95 volume percent. Due to the presence of optical boundaries between the granules and the medium, the scintillation light can be refracted, reflected, absorbed or diffused differently depending on the characteristics of the medium. It also depends on the correlation between the scintillation granules size and the incident light wavelength.

In this connection, composite scintillators have limitations in respect of optical transparency comparing to homogeneous mediums. A potential solution that allows reducing light losses is the use of light guides or light conducting layers over the composite layer or inside it. Such a design can be the basis for solving problems of collecting light from a large area of the detector (Fig. 2). This is typical for neutron and gamma-radiation detectors.

It is possible to improve the light collection in the composite scintillator in two ways: by using scintillation granules with sizes smaller than the luminescence wavelength or by selecting the optical medium and scintillation granules with similar refractive index.

3 Design of the Composite Scintillator

3.1 Optical Medium Materials

There are certain requirements specified as optical medium for the scintillator layer:

-

high optical transparency;

-

stability of properties over time and under environments (climatic loads, operating atmosphere, radiation impacts);

-

manufacturability.

Such materials like optical epoxies and polyurethanes change their color at long-term use as a result of oxidation, and when exposed to UV and gamma radiation [8,9,10]. Using of plastic polymers is limited by their radiation hardness (not more than 10 Mrad) which is also related to oxidation processes [11].

Optical polysiloxanes are suitable materials for the fabrication of composite layers. These materials are resistant to all types of radiation especially if there are phenyl groups in their structures [12, 13]. Work [14] shows the radiation hardness of Dow Corning and “SUREL, Ltd” commercial polysiloxanes up to 90 Mrad. When exposed to radiation, groups of free radicals are formed within the elastomer matrix. Free radicals connect to other polymers and form densely crosslinked structures with increased resistance to radiation due to higher hardness, elasticity and a small elongation. Polysiloxanes’ advantages are easy operation, possible polymerization at room temperature, two-component composition, wide range of viscosities. It is also possible to introduce organic or inorganic additives into the polysiloxane matrix. It allows to increase the scintillation efficiency of the composite layer.

Commercially produced polysiloxanes can be divided into three groups: casting, optical and molding. The basic of casting polysiloxanes is dimethylsiloxane [15]. This group includes low-cost dielectric gels and elastomers with the refractive index of 1.4 at 25 °C for the 598 nm wavelength. Due to good physical and mechanical properties, casting polysiloxanes are used to protect electronic components against external influence [16]. Besides methyl groups of optical polysiloxanes also contain phenyl radicals in their structure. It results in the increase of the refractive index from 1.4 to 1.6 at 25 °C for the wavelength of 598 nm [17]. Polymethylphenylsiloxanes have higher chemical purity and transparency, however they are more expensive. Papers [12, 13] also show that the presence of phenyl groups in the –Si–O– chain increases the resistance to the polyphenylsiloxane degradation at radiation, as well as increases their hardness and permeability if compared with the polymethylsiloxanes. The field of application of molding siloxanes is the manufacture of optical fibers and lenses for products with LEDs. This material has high transparency, light stability and, potentially, radiation hardness. Therefore, molding polysiloxanes are a promising optical material for binding of scintillation granules and manufacture of optical fibers and fibers with a wavelength shifting additives.

Polysiloxanes are polymers resistant to oxidation with atmospheric oxygen. However, they are permeable to gaseous oxidizing impurities with high concentration. Simulation experiment on the iodine vapor effects on the composite scintillator based on Sylgard 184 silicon elastomer (Dow Corning) showed that over time there is a visual color change (Fig. 3).

The light output of composite detector also decreases, to 90% of the initial value (Fig. 4).

The iodine vapor is not a normal operating atmosphere for composite detectors. However, the experiment showed that when using polysiloxanes and especially casting and optical ones, it is necessary either to control the composition of the atmosphere in which the detector will operate, or to encapsulate the scintillator.

3.2 The Light Collection in the Composite Scintillator

The search of the best parameters of the composite scintillator claims for the optimal size and shape of the granules, their concentration in the optical medium, proper media and surface conditions.

Monte Carlo simulation was used for the light collection forecast. The approximation of geometrical optics was used, since in the studied systems the granules sizes exceed the wavelength of the scintillation light. The entire volume of the sample was divided into cubic cells with the disposition of the given shape granule in each cell (random size and random disposition). For the granules of spherical shape it is possible to obtain the coefficient of fullness of 0.51 (dense volume centric package). For the granules of cubic shapes (generally, parallelepipeds) the coefficient of fullness can approach to 1. Such version is used in [18] to simulate the light collection in the scintillators production by press forging. In this model, the phase function of scattering is not used. It is provided that the scattering occurs not in the volume of the granule, but on its border. This model takes into account the light absorption coefficient and the refractive indexes for the particles and for optical medium. For single crystal, including the particles in the composite scintillator, they are known from the literature or experiments.

The dependencies of the light collection coefficient for granules of regular and irregular shapes were investigated. The regular-shaped granules were presented in the form of spheres with a diameter of 20, 40 and 80 μm with a refractive index of 1.5. For irregularly shaped granules optical “irregularity” was set by random orientation of reflecting faces on the spherical surface of the granules.

Figure 5 shows the dependencies of the light collection coefficients τ (LCC) on the distance to the output window for granules of various sizes of regular (spherical) shape (three top lines) and irregular shape (three bottom lines). The irregular shape was formed by random orienting of the faces on the spherical surface.

The light collection coefficient for the regularly shaped granules is higher than the corresponding coefficient for the irregularly shaped granules. This difference increases for small size granules when the number of granules layers and the number of scattering optical boundaries increases.

Simulation demonstrates that the change in the refractive index of the optical medium has a greater effect on the composite scintillator containing granules of irregular shape (Fig. 6).

At the same time, in case of the regularly shaped granules the light collection coefficient changes to a lesser extent with the change of the refractive index of the optical medium. For the irregularly shaped granules the number of reflections on the granules surface before exiting there from is large. A small difference in the refraction probability produced by different refractive indexes increases many times at the light “wandering” in the irregularly shaped particles.

The light collection coefficients on the distance of the flash out to the output window for different transparency of the granules and the optical medium were carried out (Fig. 7).

Obtained dependencies of the light collection coefficient for the composite scintillator with a high transparency of the granules and optical medium materials (the absorption coefficient of less than 0.01 cm−1) substantially coincide. Hereof we can conclude that the optical absorption in these systems makes no considerable contribution to the attenuation of the light flux through the output window of the composite scintillator. The systems of less transparent materials (the absorption coefficient of more than 0.05 cm−1) make a great contribution to the light attenuation.

It is possible to obtain another confirmation that the main contribution to the attenuation of the light flux through the output window of the composite scintillator is made by the scattering at the interfaces. For this purpose it is necessary to examine the dependence of the light collection coefficient on the number of “conventional” granules layers between the output window and the place of the scintillation origination. This can be done by changing proportionally the dimensional parameters of the composite scintillator.

Figure 8 shows the dependence of the light collection coefficient on the distance to the output window of the composite. LCC is expressed as the number of granules layers with different granules sizes and changes of other dimensional parameters of scintillator proportional to them.

It is evident that these dependencies are practically the same for quite a large range of granules sizes. Thus, the study of the light collection in composite scintillators with Monte Carlo simulation shows a significant influence of the granules shape. For the regularly shaped granules the system transparency may increase due to the reduction of the number of reflection at the interface. Furthermore, it is shown that the influence of particles size and their concentration can be characterized by a conditional parameter of the “number of scattering boundaries”. This parameter, along with the relative refractive index, determines the transparency of thin layers of the heterogeneous scintillator.

The obtained dependencies are useful for the selection of materials and scintillation layer parameters, determination of their size and concentration in the composite scintillator.

3.3 Experimental Data of the Light Collection in the Composite Scintillator

One of the main parameter of composite scintillators is the non-uniformity of the light collection on the layer surface when picking up the signal with a WLS fiber or a photodetector placed locally (Figs. 9 and 10).

Due to the small thickness of the scintillator layer the light output of the composite is also very dependent on the position of the light guide and photodetector (Fig. 11).

At the top position of the photodetector the light output does not almost depend on the size of the composite scintillator granules (see Table 1). On the contrary, in case of the side position of the photodetector a sharp drop in light output is observed. It is associated with light loss in the nontransparent composite layer with distance from the photodetector. This phenomena is particularly evident for small scintillation granules.

During the experimental studies it was found that good light output uniformity is provided by composite detector in the form of a plate consisting of a composite scintillator 0.5–2 mm thick and a light-conducting layer 2 mm thick above it (Fig. 12).

Depending on the material of the light conducting layer this parameter is at the level of the plastic scintillator of the similar size or better (Fig. 13).

Design features of the composite detector allow registering the light flash that originates at the distance of 30 mm and more to the WLS fiber at the level of 10% (Fig. 14).

4 Composite Scintillators Applications

4.1 Neutron Detection

The search for new and optimization of existed materials for neutron detection is a topic of interest in detector developments. A potential solution could be inexpensive large area scintillators based on the materials sensitive to thermal and fast neutrons. For thermal neutrons detection composite scintillators based on ZnS:Ag with 6Li or 10B isotopes having the detection efficiency of not more than 20% are often used [5]. An alternative to this material are composite scintillators based on 6LiI(Eu) single crystal granules (Fig. 15).

It was shown that thermal neutrons detection efficiency of 6LiI(Eu) composite detectors up to 70% of the single crystal sample of the same thickness (Table 2).

If compared with the composite scintillators based on ZnS:Ag with 6Li or 10B isotopes, the scintillator based on 6LiI(Eu) granules is more promising. In case of ZnS:Ag the formation of secondary charged particles takes place in the converter stage, and the scintillation origination—in ZnS:Ag phase in which the particles lose different parts of their original energy. For 6LiI(Eu) these processes occur within one scintillator granule with equal total loss of the particles energy. The problem of the scintillation light scattering in 6LiI(Eu) composite scintillator is solved by selecting the granules size, the optical medium and the ratio of the system components, basing on the results of experimental and computer simulations. The stability of the hygroscopic dispersed phase of the scintillator within the detector is provided by glue-free connection of detector parts. For the optimal composition detectors the resolution of better than 40% was obtained in the line of 4.78 meV. In this case the registration of gamma rays with the energy above 2.6 meV takes place in the region below the threshold of thermal neutrons detection (Fig. 16).

4.2 X-ray Detection

Composite scintillators can also be used for X-ray introscopy. For this purpose the detector’s area should be comparable to the size of the object. Composites meet this requirement. So it is possible to fabricate scintillation and screens on their base without limitation of linear dimensions and with sufficient spatial resolution. Currently there is a need for X-ray detectors at both low energy (20–40 keV) and high energy (60–160 keV or more). To ensure the required X-ray detection efficiency, the maximum of spectral sensitivity of photodetector must correspond to the composite emission. For “soft” radiation detection composites based on materials with low density and atomic number but with high light output are suitable. CsI(Tl) composite film potentially can work with photodiode array fabricated in CMOS technology [19]. Such films should be cheaper then CsI(Tl) columnar scintillation screens. To register higher energy composite detectors based on Gd2O2S:Pr,Ce, GAGG:Ce and ZnSe (see Fig. 17) are appropriate.

These scintillators have high density, high effective atomic number, they are non-hygroscopic, radiation and chemically stable, have sufficiently high light output and good spatial resolution. Parameters for ZnSe composite are presented at Table 3.

Composite scintillators for X-ray scanners are base on the material with low transparency. This disadvantage is because of the large number of scintillation granules layers which is required to provide the necessary level of X-ray absorption [20, 21]. This problem can be solved by using of alternating thin composite layers and light guides that allow obtaining a three-dimensional structure of “zebra” type. Another way is uniform distribution of granules in the composite of the required thickness. The experiment on the examples of YSO:Ce composites showed the possibility to fabricate composite scintillator more than 10 mm thick (Fig. 18) with sufficiently uniform distribution of granules in the volume.

4.3 Gamma Detectors

One of typical application of plastic scintillators is radiation portal monitors. The disadvantage of this material is low registration efficiency of low energy gamma rays. To improve registration efficiency it is possible to cover plastic scintillator by composite layer that registers gamma rays with the energies less than 100 keV. CsI(Tl) or YSO(Ce) layers can be used for this task (Fig. 19).

The composite scintillator absorbs low energy gamma rays emitting the light with the wavelength for which the scintillation plastic is a transparent material. In this case high energy radiation does not linger in the small thickness of the composite layer, and is registered directly by the plastic. It was found that the minimum detection activity and the registration efficiency of gamma photons in the line of 33 keV of 137Cs radionuclide and in the line of 59.5 keV of 241Am radionuclide for the combined detector with the composite layer are higher than ones for plastic scintillator (Figs. 20, 21 and 22).

Scintillation characteristics of combined detector UPS-923A with YSO:Ce and CsI(Tl) composite layer are shown at Tables 4 and 5.

5 Composite Scintillators in High Energy Physics

High energy physics experiments require large areas detectors that maintain the stability of the scintillation parameters up to 25 Mrad at the average dose rate of 6.5–10.4 Mrad/h [6, 22]. Plastic scintillators lave radiation hardness under conditions of ultra-large flux of ionizing radiation. Therefore, plastic elements with radiation damage must be periodically replaced, which requires labor-intensive technical measures. It increases the cost of scientific experiments considerably. The use of radiation hard large size single crystals in calorimeters is limited by their high cost first of all. Inexpensive semiconductors require large additional expenses for the development of cooling systems. Therefore the use of composite scintillators as the component of hadron calorimeter “wedges” might be a compromise solution.

5.1 Design of Composite Detectors for HEP

For the HEP detectors the following requirements are specified: radiation hardness, short decay times, possibility of mass production of large area detectors, reasonable cost. The scintillators currently used for HEP meet only physical requirements of the radiation hardness more than 30 Mrad. The main problem in their application is the difficulties of complying with technological and economic conditions. The suggestion to use composite scintillators in HEP detectors is promising. For production of large areas composite detectors commercially available materials can be used.

Basic design of composite detector, discussed in the Chap. 2, is suitable for HEP application. It provides the direct contact of the scintillator with the photodetector if the photodetector can withstand high radiation loads.

An additional option element is the use of WLS fibers in cases when it is impossible to use a photodetector in the radiation field near the scintillator. This construction can be implemented in “Megatile” design for the operation at high radiation doses (Fig. 23) and medium radiation doses (Fig. 24), as well as in “Shashlyk” design (Fig. 25).

Scintillators in the detectors for HEP must contain a minimum of activatable elements, must have minimum phosphorescence and decay times of up to 100 ns. Ce3+ doped silicates and garnets meet the specified requirements to a greater or lesser degree. The radiation hardness of these materials has been widely studied [23,24,25,26]. Potentially, they must be radiation hard at the doses of more than 30 Mrad. Optical, scintillation, luminescence and kinetic properties of silicates and garnets are represented in details in [27,28,29,30,31].

The rare-earth metals silicates doped with cerium (Y2SiO5, Gd2SiO5 Gd2Si2O7, Lu2(1−x)Y2x SiO5) luminesce in the violet region. It is consistent with the spectral sensitivity of the UV photodetectors and allows registering the light at the direct contact with the detector. However, this group of crystals has a number of disadvantages. Gadolinium has a large thermal neutron capture cross section [32]. The use of lutetium silicates is limited by the effective energy store which appears at the thermoluminescence or afterglow [33], as well as by the high cost of raw materials. The most suitable scintillator for the proposed radiation hard detector is Ce3+ doped yttrium silicate. This material consists of light inactivatable elements and has the lowest phosphorescence among the silicates.

Ce3+ doped yttrium aluminum garnets (Y3Al5O12, Y3AlGaO12, Gd3Al2.5Ga2.5O12) make a part of the second group of crystals potentially interesting for HEP. The scintillators have the luminescence in the green region, which is convenient for matching to silicon photodetector.

Good coordination of excitation and luminescence spectra of YSO:Ce and YAG:Ce crystals (Fig. 26) allows using commercially available crystalline YAG fibers with low concentrations of Ce3+ activator as the radiation hard scintillators.

Use of YAG:Ce fiber increases the light collection efficiency in the scintillation composites. But in this case it is necessary to use additional shifters re-emitting the light to the wavelength of silicon photomultipliers operation and also to deduct the intrinsic gamma background of the fiber.

Scintillation materials obtained by the solid-state synthesis are candidates for composite scintillators since their synthesis excludes the expensive stage of single crystals growth. However, in the solid-state synthesis there are problems with the penetration of the activator into the crystal lattice. Therefore its scintillation efficiency is lower than the efficiency of single crystals. Another way to manufacture scintillating materials without crystals growth is a sol-gel method.

5.2 Materials for the Light Guide (Light Conducting Layer)

Using the light guide (light conducting layer) over the composite scintillator helps to increase the number of registrations of the light that occurs in the nontransparent composite medium. Polysiloxane, quartz glass and leucosapphire meet these requirements for light guides. The advantages and disadvantages of polysiloxanes were discussed at Sect. 3.1. The quartz glass is radiation hard up to 45 MGy [34], but after irradiation its transparency decreases in the wavelength region of up to 350 nm. The leucosapphire also has the good radiation hardness [34, 35] but its threshold of the transparency decrease is limited by 350 nm.

To increase the scintillation efficiency by the wavelength shifter use is selected according to the emission range of the scintillating material. In HEP experiments Kuraray plastic WLS fibers are commonly used [36]. They offers WLS fibers for different wavelengths depending on the desired spectrum shift (e.g., from 485 to 607 nm). Disadvantages of plastic fibers are low radiation hardness (up to 20 Mrad), expensive replacement of damaged fibers during of HEP experiments. Radiation hard YAG fibers with small Ce3+ concentrations that have higher light collection efficiency are an alternative to plastic WLS fibers. The disadvantage of these fibers is the need to deduct intrinsic gamma background.

5.3 Radiation Tests of Materials for Composite Detector

Radiation hardness tests of the materials for the fabrication of composite scintillators were carried out as in our earlier study [14]. The samples were irradiated with electrons E0 = 8.3 meV at room temperature. The total integral dose made up 130 ± 0.5 Mrad (1000 ± 5 kGy). The list of the materials is represented in Table 6.

After irradiation of 50 Mrad the decrease of the light output to 2% was observed (Figs. 27 and 28) and the decrease of the transparency of single crystals, polysiloxanes, quartz and leucosapphire to 5% (Figs. 29, 30, 31, 32, 33 and 34) in the 400–700 nm was also revealed. The extent of the radiation damage of YSO:Ce base composite scintillators, obtained by the solid-state synthesis, was at the level of single crystal composites at the irradiation of up to 50 Mrad as well. All the tested materials also withstood the radiation doses of 100–130 Mrad except composite scintillators based on YSO:Ce obtained the by the solid-state synthesis.

The radiation tests showed that in HEP experiments detectors from YSO:Ce single crystal can be used in high radiation fields. Composite detectors on the base of YSO:Ce single crystal granules and YSO:Ce granules obtained by the solid-state synthesis are suitable for medium and low radiation loads.

5.4 Scintillation Parameters of Composite Detector

Scintillation parameters of composite detector with different materials of lightguides and light conducting layers (Figs. 35 and 36) were tested. The technology of manufacture of detectors with polysiloxane light conducting layer is described in [37].

For the fabrication of the scintillation layer YSO:Ce single crystal granules (0.1 at.%) (ISMA, Ukraine) and Sylgard 184 (Dow Corning, USA) were used. As the materials for the light conducting layer we used Sylgard 184 optical elastomer as well as quartz glass KU-1 (Poltava, Ukraine) and leucosapphire (ISMA, Ukraine). The light collection was carried out with Y-11 WLS fiber (Kuraray) or with YAG:Ce single crystal fiber (Institute of Light and Matter, Lyon, France). Composite scintillators manufactured according to designs represented at the Figs. 35 and 36 are shown in the Figs. 37 and 38, respectively.

To calculate the light output of the composite detector we measured the count rates of the elements and the reference sample of the plastic scintillator UPS-923A both with dimensions 14 × 60 × 4 mm. The relative light output of the elements was calculated as (1):

- where \( {\text{LO}}_{\text{relative}} \) :

-

relative light output of the composite detector,

- \( {\text{LO}}_{\text{detective}} \) :

-

light output of the composite detector (number of pulses per second),

- \( {\text{LO}}_{\text{plastic}} \) :

-

light output of the standard sample of the plastic scintillator UPS-923A (number of pulses per second).

The detector tests were carried out according to the schema shown at Fig. 39.

Test results are shown at the Table 7. The optimum design providing the maximum light output corresponds to the composite with quartz light conducting layer and YAG:Ce wavelength shifting light guide.

The composite scintillators with Sylgard 184 light conducting layer also have high light output. This is due to the use in the scintillator and the light conducting layers with the same refraction index. However, the detector design with the quartz light conducting layer is more preferable due to better operational characteristics.

6 Conclusion

In conclusion it should be note that the general trend to cheap detector with the reasonable price claim for new technical and technological solutions. Composite scintillators are a promising solution. Their development will allow manufacturing inexpensive detecting devices for a wide range of applications. The need to search and develop technological solutions increasing the transparency, uniformity and light output of composite scintillators is obvious. This will allow to significantly expand the range of scintillators, and using in detectors production the materials that have the limitations related with manufacture of the large size bulk scintillators.

References

A. Gektin, N. Shiran, N. Pogorelova et al., Inorganic-organic rubbery scuntillators. Nucl. Instr. Meth. Phys. Res. Sect. A 486, 191–195 (2002)

S.L. Miller, V. Gaysinsiy, I. Shestakova, V. Nagarkar, Recent advances in columnar CsI (Tl) scintillator screens, in Penetrating Radiation Systems and Applications VII, Vol. 5923 (2005)

van Eijk Carel.W.E., Inorganic scintillators in medical imaging detectors Nucl. Instr. Meth. A. 509, 17–25 (2003)

V.V. Nagarkar, T.K. Gupta, S.R. Miller et al., Structured CsI (T1) scintillators for x-ray imaging applications. IEEE Trans. Nucl. Sci. 492, 492–496 (1998)

V.S. Litvin, A.D. Belayev, S.M. Ignatov et al., ZnS(Ag)/6LiF and LiI(Eu) Scintillators and silicon photomultipliers for thermal neutron detectors with high space and time resolution. Bull. Rus. Acad. Sci. Phys. 73, 219–221 (2009)

S. Afanasiev, P. de Barbaro, A. Boyarintsev, HE upgrade beyond phase 1. Finger scintillator option. CMS Note, V. 3 (2014)

G.S. Atoyan, V.A. Gladyshev, S.N. Gninenko et al., Lead-scintillator electromagnetic calorimeter with wavelength shifting fiber readout. Nucl. Instr. Meth. Phys. Res. Sect. A A320, 144–154 (1992)

M.C. Celina, A.R. Dayile, A. Quintana, A perspective on the inherent oxidation sensitivity of epoxy materials. Polymer 54, 3290–3296 (2013)

C.L. Hunks, D.J. Hunzmun, in Radiation Effects Design Handbook, Section 3. Electrical Insulating Materials, NASA (1971)

G. Lee, Radiation resistance of elastomer. IEEE Trans. Nucl. Sci. 32, 3806–3808 (1985)

C. Zorn, S. Majewski, R. Wojcik, K.F. Johnson, Progress in the design of a radiation-hard plastic scintillator. IEEE Trans. Nucl. Sci. 38, 194–199 (1991)

A. Quaranta, S. Carturan, M. Cinausero et al., Characterization of polysiloxane organic scintillators produced with different phenyl containing blends. Mat. Chem. Phys. 137, 951–958 (2013)

A. Quaranta, S. Carturan, T. Marchi et al., Radiation hardness of polysiloxane scintillators analyzed by ion beam induced luminescence. Nucl. Instr. Meth. A. 385, 3155–3159 (1997)

A. Boyarintsev, N. Galunov, N. Karavaeva et al., Study of radiation resistant gel bases for composite detectors. Func. Mat. 28, 271–276 (2013)

A. Norrisa, J. DeGroot, F. Nishidaa Jr. et al., Silicone materials for optical applications. www.dowcorning.com

J. McDonald, Advanced silicone materials for LED lighting, in Dow Corning Corporation for the DOE SLL Workshop, January 28th, 2015

T.E. Gorbacheva, V.A. Tarasov, N.Z. Galunov, Light collection simulation when determining light yield of single crystal and polycrystalline organics scintillators. Func. Mat. 22, 408–415 (2015)

J. Silva, S. Lanceros-Mendes, G. Minas, J.G. Rocha, CMOS X-ray image sensor array, in 14th IEEE International Conference on Electronics, Circuits and Systems. pp. 1067–1070 (2007)

E.F. Voronkin, Digital X-ray imaging using matrix detectors and composite screens. Func. Mat. 21, 112–118 (2014)

V. Litichevskyi, Composite scintillation panels and elements based on fine-grained granules of crushed crystals. Func. Mat. 20, 259–265 (2013)

S.V. Afanasiev, A.Yu. Boyarintsev, M.V. Danilov, “Finger” structure of tiles in CMS endcap hadron calorimeters. CMS Note. 2 (2015)

E. Auffray, A. Fedorov, M. Korjik et al., The impact of proton induced radioactivity on the LSO:Ce, YSO:Ce scintillation detectors. IEEE 2013 NSS/MIC

E. Auffray, A. Borisevitch, A. Gektin et al., Radiation damage effects in Y2SiO5:Ce scintillation crystals under γ-quanta and 24 GeV protons. Nucl. Instr. Meth. A. 783, 117–120 (2015)

M.V. Derdzyan, K.L. Ovanesyan, A.G. Petrosyan et al., Radiation hardness of LuAG:Ce and LuAG:Pr scintillator crystals. J. Cryst. Growth 361, 212–216 (2012)

T. Butaeva, I. Ghambaryan, M. Mkrtchyan, Recharging processes of Ce3+ in gamma-irradiated YAG:Ce single crystals. Opt. Spec. 118, 247–254 (2015)

M. Kapusta, M. Moszynski, M. Balcerzyk, J. Pawelke, Comparison of the scintillation properties of LSO:Ce and YSO:Ce as detectors for high resolution PET. Ann. Rep. 73–74 (1999)

Ya. Gerasymov, Technology for obtaining large size complex oxide crystals for experiments on muon-electron conversion registration in high energy physics. Sci. Innovation 10, 26–33 (2014)

E. Miholova, M. Nikl, J.A. Mares, Luminescence and scintillation properties of YAG:Ce single crystal and optical ceramics. J. Lum. 126, 77–88 (2007)

X. Zenga, G. Zhaoa, J. Xua et al., Effect of air annealing on the spectral properties of Ce:Y3Al5O12 single crystals grown by the temperature gradient technique. J. Cryst. Growth 274, 495–499 (2005)

Yu. Zorenko, J.A. Mares, P. Prusa et al., Luminescence and scintillation characteristics of YAG:Ce single crystalline films and single crystals. Rad. Measur. 45, 389–391 (2010)

G. Leinweber, D.P. Barry, M.J. Trbovich et al., Neutron capture and total cross-section measurements and resonance parameters of gadolinium. Nucl. Sci. Eng. 154, 261–279 (2006)

A. Masalov, O. Viagin, I. Ganina, Yu. Malyukin, Mechanisms of charge interaction in co-doped Lu2SiO5:Ce3+ crystals. Func. Mat. 17, 311–316 (2010)

D.V. Orlinski, V.T. Gritsyna, Radiation resistance investigation of quartz glass KU-1. Probl. Atom. Sci. Tech. 5, 60–63 (2000)

E. Colby, G. Lum, T. Plettner et al., Gamma radiation studies on optical materials. IEEE Trans. Nucl. Sci. 49, 2857–2867 (2002)

A.Yu. Boyarintsev, T.A. Nepokupna, Yu.D. Onufriev, N.L. Karavaeva, A.V. Krech, M. Galunov, Scintillation element and its manufacturing method. Ukraine patent 111455 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Boyarintsev, A.Y., Nepokupnaya, T.A., Onufriyev, Y.D., Tarasov, V.A. (2017). Composite Scintillator. In: Korzhik, M., Gektin, A. (eds) Engineering of Scintillation Materials and Radiation Technologies. ISMART 2016. Springer Proceedings in Physics, vol 200. Springer, Cham. https://doi.org/10.1007/978-3-319-68465-9_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-68465-9_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68464-2

Online ISBN: 978-3-319-68465-9

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)