Abstract

Scientific optimization has become a popular term in the modern design of electrical machines. Due to the current completive and dynamic market, and the increasing importance of energy efficiency and energy conservation, the design optimization of electrical machines has become an essential strategy for research and development. Yet the multi-disciplinary, multiobjective, high-dimensional, nonlinear, and coupled nature of the electrical machines’ design optimization poses a great challenge to the research communities. Nevertheless, the recent advanced algorithms for multiobjective optimization and multiple-criteria decision analysis have been empowering designers to push the existing boundaries of electrical machines design in dealing with the complexity for the novel concepts and innovative designs. This paper presents a state of the art survey on the advancements of the novel optimization tools and applications, and further demonstrates the progress of the academic research in this realm.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The task of solving optimal engineering design problems of electrical machines is considered as a demanding decision-making process where the real-life design problems have to be considered simultaneously from very different perspectives [1, 2]. In fact the design objectives of the electrical machines are often in contradiction as described in literature [3]. In addition, due to the large number of design parameters and constraints of the machines’ performance, finding an optimal solution which can simultaneously satisfy the design objectives can be an overwhelming task [4]. Even though there exists a number of case studies utilizing classical optimization algorithms, e.g. [5], their applicability is heavily constrained. For instance the objective function needs to be continuous and derivable.

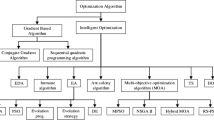

Many electrical machines models are based on finite element models, without analytical expressions for the optimization model itself. Thus, various intelligent optimization algorithms using non-analytical machine models have been employed, particularly in multiobjective optimization problems, such as those based on the popular genetic algorithms (GAs) [6], and particle swarm optimization (PSO) algorithms [7].

2 Optimization of Electrical Machines

A general workflow for finite element analysis (FEA) for electrical machines optimization was presented by Stipetic et al. [8]. According to their proposed workflow the process of optimization starts with the description of the problem i.e., identifying the boundary conditions, objectives and a set of constant model parameters e.g., topology of the motor, number of slots on the rotor and stator, number of poles, and type of winding. After setting the optimization algorithm, the following steps are performed iteratively in a loop: (1) the optimization algorithm generates variables (e.g. vectors of design variables), (2) the variables are converted to model parameters, (3) the model is converted into a FEA environment, (4) the FEA model is solved, (5) the performance of the model is extracted, (6) constraint functions and objective functions values are calculated, (7) the values of these constraint and objective functions are given back to the optimization algorithm. After the termination of the algorithm a set of optimal solutions or so called Pareto optimal front is created. According to Lei et al. [6], differential evolution algorithm (DEA), nondominated sorting genetic algorithm (NSGA) [9], Kriging-model based optimization [10], and PSO [7], follow the similar principle design optimization workflow with the widest usage in electrical machines design.

2.1 Genetic Algorithms

Lei et al. [6] well describe the potential and drawbacks of using GAs in optimal design of the electrical machines. The algorithm starts with a set of population represented by chromosomes. Solutions from one population (known as parent population) are taken and used to form a new population (known as offspring or children population) by three genetic operations of crossover, mutation and selection. The solutions which are used to generate new solutions are selected in terms of their fitness. This means that the more suitable the solutions are, the more opportunities they have to reproduce in the evolution process. This strategy of optimization is repeated until the design objectives are satisfied [11]. GAs are popular and are widely used due to their capabilities to find global optimum and not get trapped in the local minima [8]. However they are not considered the most computationally efficient [11]. In a recent study [9] the reluctance network of a synchronous reluctance motor (SynRM) was successfully optimized by means of a GA. With some modifications the GAs can be well adapted for solving multiobjective optimization problems of electrical machines [12]. Multiobjective genetic algorithm (MOGA) [10], the nondominated sorting algorithm (NSGA/NSGA-II) [11,12,13], and the strength Pareto evolutionary algorithms (SPEA/SPEA2) [14], are a number of real-life case studies.

2.2 Differential Evolution

Differential evolution (DE) algorithms [15] are among the widely used algorithms in designing the electric machines [16]. Like the genetic algorithms, the DE method works on a population which is a set of individuals, where each individual presents one machine design configuration [17]. Initial population is randomly initialized within the constraints of the design boundary. The candidate population is obtained by crossover and mutation processes from the existing population. As Zhang [16] describes in a case study the next generation of the design solutions is obtained by comparing the existing and candidate population by choosing members that satisfy boundary functions and as well as objective functions. Mutluer and Bilgin [17] utilize an effective DE algorithm in solving a number of real-life problems in electric machines design optimization where the effectiveness of the DE algorithm is compared with the stochastic methods.

2.3 Particle Swarm Optimization

The standard particle swarm optimization (PSO) is an evolutionary population-based optimization technique inspired by the behavior of bird flocks searching for food, widely used in designing of the electric machines [18]. As Sankardoss and Geethanjali [7] describe a PSO algorithm begins with the population of individuals called particles. Each particle constitutes a number of parameters to be optimized known as a candidate solution in a multidimensional space. The population of particles is called the swarm. The PSO then starts with the random initialization of swarm size and particle of the swarm. The swarm starts searching for the optimal solution in a multidimensional parameter space with random position and zero velocity. The swarm then moves in the search space depending on the fitness value estimated from the defined objective function [2]. The particles in the swarm drive toward the best solution by adjusting the velocity based on own experience and other particles’ experience known as neighborhood solutions at every time step in the parameter search solution. The velocity and hence the position of each particle are updated over a time in a number of iterations by evaluating the fitness function and comparing current solution with the personal best position of the particle and the group’s best solution [11]. Along with its multiobjective version (MOPSO) the algorithm’s many variants, e.g. the dynamic particle swarm optimization (DPSO) [18], and distance-based intelligent particle swarm optimization (DiPSO) [19], were utilized widely in numerous electrical machines design optimization.

2.4 Comparisons

In a study conducted by Mutluer and Bilgin [17], the design optimization of 16-poles/18-slots concentrated winding surface-mounted PMSM was investigated by using GA, simulated annealing (SA), and DE. The results showed that DE was more reliable than the other two methods. In two recent articles by Rebahi [20, 21], PSO, GA, and DE was compared in the optimization of a doubly salient 8/6 switched reluctance machine (SRM) aiming at the best results for the chosen objective functions. Computation cost or running time of algorithms was not considered. They concluded that GA and DE gave almost equally sufficient values, better than the results found by PSO. Though, ranking attempts between the different algorithms are not truly appropriate outer the framework of an optimization problem, their performance is therefore strongly case-dependent [22]. Furthermore it has been reported that the integration of PSO algorithms with GAs would result robust and efficient algorithms [21].

A brushless DC motor benchmark problem was presented in [23] and the MATLAB source code created for computing the objective function of a single objective optimization. A multiobjective problem definition for the same motor utilizing SPEA2, NSGA-II and sequential quadratic programming (SQP) algorithms are presented in [24]. The optimization problem was characterized by five continuous design variables subjected to six inequality constraints which are related to technological, and operational considerations regarding the wheel motor. The brushless DC motor benchmark problem was further used to test advanced algorithms suitable for electrical machine optimization e.g. modified social spider optimization (MSSO) algorithms [25], multiobjective symbiotic organism search (MOSOS) and improved multiobjective symbiotic organism search algorithms [26], the multiobjective krill herd algorithm (MOKH) [27], improved teaching-learning-based-optimization (ITLBO) technique [28], multiobjective firefly optimization (MOFO) and modified multiobjective firefly optimization (MOBFO) in [29].

2.5 Surrogate Models, Multi-level and Hybrid Methods

Because of the high computational cost of FEM, methods based on approximate models can present an effective way to solve optimization problems [30]. By using design of experiments (DoE) techniques [11, 31], and statistical analysis methods [32], approximate models [33] can be established as surrogate models for FEM or circuit models, to reduce the high computation cost of the iterative optimization process [34]. Though in problems with high number of design variables the number of FEM samples required for the DoE techniques is comparable to those required for a direct optimization with an evolutionary algorithm [35]. The two popular surrogate models in electrical machine design are the response surface (RS) [36], and the Kriging model [37]. Abbaszadeh [28] combined DoE and the RS method in a single-objective optimization problem to reduce cogging torque in a surface mounted permanent magnet motor. Similar methodology was used in a study by Zhu [29] for multiobjective optimization of magnetic planetary geared permanent magnet brushless machines. A recent example for application of a Kriging model based optimization can be found in [38], where the waveform of air-gap flux density was optimized in a flywheel motor. To do so Bu [9] combines DoE, surrogate model and a multiobjective evolutionary optimization algorithm (NSGA-II). A similar Kriging model was adopted by Tan [10] where the output power of a doubly-fed induction generator (DFIG) was optimized by means of DoE, Kriging-model construction and a PSO algorithm.

As an alternative to the above surrogate models, multi-level optimization methodologies can be utilized to address the demanding and complexity of machines design optimization for a robust design [3]. According to Lei [39] a multi-level optimization is done via initially subdividing the design variables set in many subsets in such a way that the first part of the optimization is driven by the more sensitive variables for a better search. This subdivision is conducted in order to quickly approach the region of Pareto-optimal solutions, and then switching to the full set of variables, in order to focus on the details of the search region [40].

Although, one may find the multi-level optimization not time-efficient, a thorough case study by Bramerdorfer [41], investigates the possibilities of speeding-up the process. They clarify that combining surrogate modeling and evolutionary algorithms, generally would lead to a reduction of the required number of FE simulations needed to achieve high-quality Pareto fronts [42]. This would lead to the sophisticated optimization techniques of hybrid optimization algorithms [43]. Applications include the FE model simplification based on geometrical symmetry and the symmetry of the time course of machine parameters [12, 31]. A great number of such hybrid optimization methods have been developed and applied in electrical machine design [44,45,46,47]. Thorough investigation of these methods exceeds the framework of the recent survey and it is going to be the matter of further research. Figure 1 illustrates the annual progress of the number of academic publications considering the well-known algorithms/methods used in the context of design optimization of electric machines.

(source: village database www.engineeringvillage.com)

Growth of the major optimization algorithms used for electric machines design presented in the literature (2003–2016)

NSGA, DE, PSO, and Kriging, are considered as the major optimization algorithms widely used in the design optimization of the electric machines. These algorithms are seen as the essential but not sufficient tools to enhance creating the efficient global optimization approaches in dealing with dimensionality [12, 48, 49]. The dimensions of the real-life optimization problems due to the increasing number of variables, objectives, constraints and decision criteria are ever expanding. Yet, presenting a decision-maker with numerous representative solutions on a multidimensional Pareto-optimal set strongly reported to be impractical [13, 36, 50]. In fact dealing with the ever increasing dimensionality a supplementary decision-support system to enhance the existing optimization algorithms would be essential [51]. On the other hand in a number of studies e.g. [52, 53], it has been reported that performing the process of optimal design within the integrated design environment of a commercial optimization package [54], would be highly desirable. Via commercial optimization packages e.g. [55] the coupling and integration requirements are well customized, and it further fill the gap between optimization approaches and electric machines optimal design. Furthermore the true potential of machine learning [56, 57], and intelligent optimization [49], has still not been explored in the realm of electric machines design.

3 Conclusions

The design of the electrical machines has been dramatically revolutionized by utilizing the advanced optimization algorithms. A great number of methods have been introduced to solve the electrical machines optimization problems, and the research in this field has become a booming topic in recent years. The multiobjective and hybrid algorithms provide a solid platform for designers to explore the design space for a robust design and the global optimum options. In this article we surveyed the latest advancements in this realm and visualized the ever increasing progress of the applications of the novel optimization algorithms.

References

Pyrhonen, J., Jokinen, T., Hrabovcova, V.: Design of Rotating Electrical Machines, 2nd edn. Wiley, Hoboken (2013)

Mosavi, A.: Decision-making models for optimal engineering design and their applications. Doctoral Dissertation, University of Debrecen, Hungary (2013)

Khelifa, M., Mordjaoui, M., Medoued, A.: An inverse problem methodology for design and optimization of an interior permanent magnetic motor. Hydrog. Energy 3, 345–367 (2017)

Wang, W.: Rotor shape investigation and optimization of double stator switched reluctance machine. IEEE Trans. Magn. 51, 1–4 (2015)

Nguyen, T.D., Lanfranchi, V., Doc, C., Vilain, J.P.: Comparison of optimization algorithms for the design of a brushless DC machine. Electric Drives 78, 1–6 (2009)

Lei, G., Zhu, J.G., Guo, Y.: Multidisciplinary Design Optimization Methods for Electrical Machines and Drive Systems, pp. 73–159. Springer, Heidelberg (2016)

Sankardoss, V., Geethanjali, P.: PMDC motor parameter estimation using bio-inspired optimization algorithms. In: IEEE Access, pp. 1–11 (2017)

Stipetic, S., Werner M., Damir, Z.: Optimization in design of electric machines: methodology and workflow. In: Electrical Machines & Power Electronics, pp. 441–448 (2015)

Bu, J.: Optimization for airgap flux density waveform of flywheel motor using NSGA-2 and Kriging model based on MaxPro design. IEEE Trans. Magn. 14, 1–7 (2017)

Tan, Z.: DFIG machine design for maximizing power output based on surrogate optimization algorithm. IEEE Trans. Energy Convers. 30(3), 1154–1162 (2015)

Mosavi, A.: Optimal engineering design. Technical report, University of Debrecen (2013)

Khaliq, S.: Rotor pole optimization of novel axial-flux brushless doubly fed reluctance machine for torque enhancement. IEEE Trans. Magn. 52(7), 1–4 (2016)

Kuznetcov, V.: Technique of evolutionary optimization permanent-magnet synchronous motors. Procedia Comput. Sci. 103, 198–204 (2017)

Beniakar, M.: Strength pareto evolutionary optimization of an in-wheel PM motor with unequal teeth for electric traction. IEEE Trans. Magn. 51(3), 1–4 (2015)

Zhang, P.: Saliency ratio and power factor of IPM motors optimally designed for high efficiency and low cost objectives. In: ECCE, pp. 3541–3547 (2014)

Zhang, P.: Establishing the relative merits of interior and spoke-type permanent magnet machines with ferrite. IEEE Trans. Ind. Appl. 9, 2940–2948 (2015)

Mutluer, M., Bilgin, O.: Comparison of stochastic methods for design optimization of permanent magnet synchronous motor. Neural Comput. Appl. 21, 2049–2056 (2012)

Lee, J.H.: Distance-based intelligent particle swarm optimization for optimal design of permanent magnet synchronous machine. IEEE Trans. Magn. 53(6), 1–4 (2017)

Mosavi, A., Vaezipour, A.: Reactive search optimization; application to multiobjective optimization problems. Appl. Math. 3, 1572–1582 (2012)

Rebahi, F.: Optimization design of a doubly salient 8/6 SRM based on three computational intelligence methods. Turk. J. Electr. Eng. Comput. Sci. 24, 4454–4464 (2016)

Rebahi, F.: Multi-objective optimization design of 8/6 switched reluctance motor using GA and PSO algorithms. Electr. Eng. 15, 86–99 (2015)

Brisset, S., Brochet, P.: Analytical model for the optimal design of a brushless DC wheel motor. Int. J. Comput. Math. Electr. Electron. Eng. 20(3), 829–848 (2005)

Moussouni, F., Brisset, S.: A benchmark for a mono and multi objective optimization of the brushless DC wheel motor (2008)

Klein, C.: Modified social-spider optimization algorithm applied to electromagnetic optimization. IEEE Trans. Magn. 52(3), 1–4 (2016)

Ayala, H.: Multiobjective krill herd algorithm for electromagnetic optimization. IEEE Trans. Magn. 52(3), 1–4 (2016)

Ayala, H., Klein, C., Mariani, V., Coelho, L.: Multi-objective symbiotic search algorithm approaches for electromagnetic optimization. IEEE Trans. 53(6), 1–4 (2017)

Bouchekara, H.R.E.H., Nahas, M.: Optimization of electromagnetics problems. Appl. Comput. Electromagn. 30(12), 1341–1347 (2015)

Abbaszadeh, K.: Torque optimization in surface-mounted permanent-magnet motors by using design of experiment. Convers. Manag. 52(10), 3075–3082 (2011)

Zhu, X.: Multiobjective optimization design of a magnetic planetary geared permanent magnet brushless machine. IEEE Trans. Magn. 50(11), 1–4 (2014)

Mosavi, A.: A multicriteria decision making environment for engineering design and production decision-making. Int. J. Comput. Appl. 69, 26–38 (2013)

Mosavi, A.: Decision-making in complicated geometrical problems. Int. J. Comput. Appl. 87(19), 22–25 (2014)

Mosavi, A.: Application of multi-objective optimization packages in design of an evaporator coil. World Acad. Sci. 4, 145–167 (2010)

Mosavi, A.: Decision-making software architecture; the visualization and data mining assisted approach. Int. J. Inform. Comput. Sci. 3, 12–26 (2014)

Mosavi, A.: The large scale system of multiple criteria decision making; pre-processing. Large Scale Complex Syst. Theory Appl. 9, 354–359 (2010)

Mosavi, A.: Data mining for decision making in engineering optimal design. J. AI Data Min. 2(1), 7–14 (2014)

Esmaeili, M., Mosavi, A.: Variable reduction for multiobjective optimization using data mining techniques. Comput. Eng. Technol. 5, 325–333 (2010)

Han, Z.: Surrogate-based optimization. In: Real-World Applications of Genetic Algorithms, pp. 343–362 (2012)

Silva, R.: Visualization and analysis of tradeoffs in many-objective optimization. IEEE Trans. Magn. 52(3), 1–4 (2016)

Lei, G.: Techniques for multi-level design optimization of permanent magnet motors. IEEE Trans. Energy Conver. 30(4), 1574–1584 (2015)

Di, B.: Magnetic design optimization approach using design of experiments with evolutionary computing. IEEE Trans. Magn. 52(3), 1–4 (2016)

Bramerdorfer, G.: Possibilities for speeding up the fe-based optimization of electrical machines. IEEE Trans. 52(6), 4668–4677 (2016)

Ma, C., Qu, L.: Multiobjective optimization of switched reluctance motors based on design of experiments and particle swarm. Energy Convers. 30, 1144–1153 (2015)

Xia, B.: A novel subregion-based multi-dimensional optimization of electromagnetic devices assisted by kriging surrogate model. IEEE Trans. Magn. 53(6), 1–4 (2017)

Mohammadi, M.: A computationally efficient algorithm for rotor design optimization of synchronous reluctance machines. IEEE Trans. Magn. 52(3), 1–4 (2016)

Mosavi, A., Varkonyi-Koczy, A.R., Fullsack, M.: Combination of machine learning and optimization for automated decision-making. In: MCDM (2015)

Mosavi, A., Rabczuk, T.: Learning and intelligent optimization for material design innovation. In: Theoretical Computer Science and General Issues, LION11 (2017)

Zhang, B.: Multi-objective optimization of a transverse flux machine with claw-pole and flux-concentrating structure. IEEE Trans. Magn. 52(8), 1–10 (2016)

Mosavi, A.: Application of data mining in multiobjective optimization problems. Int. J. Simul. Multi. Design Optim. 5, A15 (2014)

Mosavi, A., Vaezipour, A.: Developing effective tools for predictive analytics and informed decisions. Technical report, University of Tallinn (2013)

Mosavi, A.: Multiple criteria decision-making preprocessing using data mining tools. Int. J. Comput. Sci. Issues 7, 26–34 (2010)

Santos, C.: A multiobjective firefly approach using beta probability distribution for electromagnetic optimization problems. IEEE Trans. Magn. 49(5), 2085–2088 (2003)

Lopez, T.: Rotor of Synchronous Reluctane Motor optimization (2016)

Mosavi, A.: On engineering optimization the splined profiles. In: Proceedings of International modeFRONTIER (2010)

Bramerdorfer, G., Zavoianu, C.: Surrogate-based multi-objective optimization of electrical machine designs facilitating tolerance analysis. IEEE Trans. 8, 1–11 (2017)

Mosavi, A: Predictive decision model (2015). https://doi.org/10.13140/RG.2.2.21094.63047

Mosavi, A., Varkonyi-Koczy, A.R.: Integration of machine learning and optimization for robot learning. In: Advances in Intelligent Systems and Computing, vol. 519, pp. 349–355 (2017)

Mosavi, A.: Multiple criteria decision making integrated with mechanical modeling of draping for material selection of textile composites. In: Composite Materials (2012)

Acknowledgement

This work has partially been sponsored by the Research & Development Operational Program for the project “Modernization and Improvement of Technical Infrastructure for Research and Development of J. Selye University in the Fields of Nanotechnology and Intelligent Space”, ITMS 26210120042, co-funded by the European Regional Development Fund.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Baranyai, M., Mosavi, A., Vajda, I., Varkonyi-Koczy, A.R. (2018). Optimal Design of Electrical Machines: State of the Art Survey. In: Luca, D., Sirghi, L., Costin, C. (eds) Recent Advances in Technology Research and Education. INTER-ACADEMIA 2017. Advances in Intelligent Systems and Computing, vol 660. Springer, Cham. https://doi.org/10.1007/978-3-319-67459-9_27

Download citation

DOI: https://doi.org/10.1007/978-3-319-67459-9_27

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-67458-2

Online ISBN: 978-3-319-67459-9

eBook Packages: EngineeringEngineering (R0)