Abstract

This paper presents a novel geometric simulation technique for multi-axis Additive Manufacturing (AM). In the proposed methodology, additive swept volume elements, which are represented with Tri-dexel models, are formulated for updating the virtual additive material. Triangular meshes are extracted from the Tri-dexel models using Marching Cube Algorithm for visualization. With the proposed methodology, either three-axis or five-axis AM tool paths of sculpture surfaces can be simulated before actually manufactured. Workpieces after additive manufacturing can be used as blanks for further Subtractive Manufacturing(SM). We developed a geometric simulation software based on the multi-axis AM simulation algorithm, and we carried out an actual three-axis AM experiment to compare with the simulation results. Computer implementation and practical example demonstrate the feasibility of the proposed multi-axis AM simulation method.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Additive Manufacturing (AM) [1], also known as 3D printing or metal deposition, refers to create a three-dimensional object in which successive layers of material are formed, provides a novel and productive method for producing freeform parts relative to Subtractive Manufacturing (SM, also known as machining or cutting). There have been many AM technologies according to different material feeding method [1,2,3], such as Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Electron Beam Melting (EBM) based on powder bed, and Laser Engineered Net Shaping (LENS), Direct Metal Deposition (DMD) and Selective Laser Cladding (SLC) with simultaneous material delivering.

In recent years, Hybrid Manufacturing technologies in which AM methods are incorporated with SM methods in a traditional machine tool or industrial robot environment have been a trend. Before actual manufacturing, geometric simulation uses virtual manufacturing to simulate and verify the actual processing, which can reduce error probability of programs, save costs and improve efficiency in actual manufacturing. Geometric simulation of multi-axis SM is a mature technology, but there are fewer researches about geometric simulation of AM, especially for five-axis AM. Most AM geometric simulation solutions adapt the similar swept volume discretion method as SM methods.

Theoretically, the virtual sculpting systems have two types. One is derived from surface-based deformable geometric object modeling, which may be vertex-based, spline-based, particle based, FEM (finite element modeling)-based, etc. The other one is based on swept volume models, e.g., Voxel or Dexel models.

For geometric simulation solutions of SM, Dexel model, first proposed by Tim Van Hook in [4] in 1986, is used for swept volume discretion. Hui [5] proposed an algorithm for sweeping a 3D object in image space used for simulating the material removal process in an NC machining operation. The proposed method does not suit for five-axis machining, and using a Dexel model alone could not achieve very good modeling accuracy. Zhu et al. [6] gives a detail description of Dexel model updating processes for virtual sculpting. They gave detailed description of Dexel-based tool swept volume and some interaction methods. Mullel et al. [7] proposed multi-Dexel volume for representation of a solid and used the method in milling simulation. Ren et al. [8] proposed a virtual prototyping and manufacturing planning method by using Tri-dexel models and haptic force feedback. Ren et al. [9] presented a detailed algorithm for eliminating inconsistency in a Tri-dexel volumetric models and reconstructing a water-tight polyhedral surface model from the Tri-dexel volumetric model.

For geometric simulation solutions of AM, Choi and Chan [10] proposed two new simulation methodologies, namely the Dexel-based and the layer-based fabrication approaches to simulate the powder-based and the laminated sheet-based Rapid Prototyping (RP) processes. Gao et al. [11] proposed a method of Tri-dexel model of polyhedrons and its application in RP simulation. The methods are only suit for three-axis RP simulation.

Although there are few literatures about geometric simulation of multi-axis AM, two commercial software products have the geometric simulation function for multi-axis AM. NX software [12] provides support for DMG MORI Lasertec Hybrid machines with new hybrid-manufacturing technologies. Nevertheless, this module is bound with hardware. SKM software [13] has the function of tool simulation and mechanism simulation to confirm tool paths in AM processing but lack of material growth visualization.

In this study, we propose a geometric simulation technique for multi-axis AM based on LENS technology. The proposed AM geometric simulation method uses Tri-dexel model to represent the swept volume and triangular meshes for material growth visualization. The reminder of this paper is organized as follows. Section 2 reviews some related works about geometric simulation of multi-axis AM. Section 3 describes the Tri-dexel models of additive swept volume. Section 4 gives the flowchart of Tri-dexel model based geometric simulation algorithm. Section 5 describes two simulation examples and an actual experiment. At last, Sect. 6 is the conclusion.

2 Review of Related Works

This section reviews some basic algorithms relate to Tri-dexel model based AM geometric simulation algorithm. First of all, Sect. 2.1 introduces some multi-axis AM tool path generation methods. Then Sect. 2.2 describes data structures of Dexel model and Tri-dexel model. At last, Sect. 2.3 reviews Boolean operation used in AM simulation.

2.1 Multi-axis Additive Manufacturing Tool Path Generation

In AM, the quality of deposition depends on the choice of AM tool paths. AM tool paths need to fulfill some requirements such as avoiding collapse and deposition voids [14], saving time and cost, axes constraint and dimensional accuracy [15].

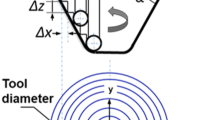

There are different tool path patterns for different parts and applications. (1) For three-axis AM tool path generation, contour-parallel offsetting pattern and zigzag pattern are two common patterns for general parts. The contour-parallel offsetting pattern results in better deposition for circular geometries and the zigzag pattern can avoid deposition voids [14]. Furthermore, staggered zigzag pattern is used for avoiding collapse and regional zigzag pattern is used for parts with inner voids. (2) For five-axis AM tool path generation, spiral pattern and regional zigzag pattern can be used, we should noting that the tool axes should be planed following surface feature. (3) For some special parts, for example, thin-wall parts, follow pattern and helical pattern can be used either for three-axis or five-axis AM tool path generation. Figure 1 shows some AM tool path patterns.

2.2 Tri-Dexel Model

Dexel model uses a series of small cubes in a specific direction (usually the Z-axis direction) to represent a volume. The single direction Dexel model has deviation in expressing a complex shape. Comparing with the single direction DEXEL model, three direction DEXEL model could express a solid more precisely [11]. Tri-dexel rays are extracted in three directions. By Tri-dexel rays, the entity’s bounding box is divided into a series of voxels. The neighbor voxels with same attributes can be merged into a big voxel to save memory.

Figure 2 shows data structures of a Dexel model and a Tri-dexel model [9]. The Dexel model is defined relative to an origin point \( O \) with a grid interval \( \delta \). As shown in Fig. 2(a), each Dexel segment \( D_{i,j,k} \) consists of two node \( \xi_{i,j,k}^{l} \) and \( \xi_{i,j,k}^{u} \) as the lower and the upper ends of a Dexel segment. A Tri-dexel model is defined relative to three direction Dexel(Dexel-X, Dexel-Y, Dexel-Z), as shown in Fig. 2(b). \( N_{x} ,N_{y} ,N_{z} \) are the numbers of grid cells along the three edges of a 3D-grid.

2.3 Boolean Operations of Tri-Dexel Model

Boolean operations include union, intersection and subtraction. Union operation is used in the process of material deposition in AM. As Tri-dexel model is formed by three single direction Dexel, the union operation of Tri-dexel can be decomposed to three single direction Dexel. Figure 3 gives three types of Dexel union operations. In Fig. 3(a) and (b),, the union of Dexel A, B is C. the union operation of more than two Dexels can transform to union of two Dexels. For example, in Fig. 3(c), the union of A1, A2 with B is the union result of A1, B then union with A2.

For material deposition in AM, the whole additive swept volume is the union of all micro swept volume. Current swept volume after deposition is the union of current micro volume with deposited swept volume. The additive swept volume can be expressed as Tri-dexel models. The union operation of swept volume is based on Tri-dexel models which is linear, precise, and fast. In Sect. 3, we will introduce the method to generate the Tri-dexel model of additive swept volume. In Tri-dexel model, the Marching Cube Algorithm [16] could be easily used to extract triangles for visualization.

3 Tri-Dexel Models Generation of Additive Swept Volume

In this section, we will introduce a method of building additive volume and Tri-dexel models of swept volume. The whole swept volume are formed of many micro swept volume. The swept volume in this section is based on micro swept volume between two GOTO points.

3.1 Additive Swept Volume Model

In LENS processing, powders are deposited with the movement of laser tool. In our algorithm, the deposited volume between two GOTO points \( \varvec{P}_{i} \varvec{P}_{i + 1} \) can be simplified as a cuboid, which the length is the distance of \( \varvec{P}_{i} \varvec{P}_{i + 1} \), the width is the laser spot diameter, and the height is the deposition thickness. As shown in Fig. 4(a).

The cuboid model is only suit for straight line type tool paths (such as Fig. 1(b)). There may be gaps at the corner of two segments. So we change the cuboid model to cylindrical model to get optimization results. The deposited shape between two GOTO points \( \varvec{P}_{i} \varvec{P}_{i + 1} \) can be simplified as cylinder swept volume. As shown in Fig. 4(b).

After building the swept volume model, the micro swept volume can be transformed to Tri-dexel model, the following sections introduce Tri-dexel model of cylinder-shaped swept volume.

3.2 Tri-Dexel Model of Additive Swept Volume

To generate Tri-dexel models of additive swept volume, the first step is to compute the minimum bounding box of swept volume (as shown in Fig. 5(a)). Then the bounding box is divided into grids by grid interval (as shown in as shown in Fig. 5(b)). The grid vertexes can form all the rays to get the Tri-dexel model.

The grid interval will determine the simulation accuracy. The more intense, the higher the accuracy of the simulation, but the computing time and memory space will rise sharply. So the ideal Tri-Dexel model of discrete space should be as large as possible under the premise of satisfying simulation error.

The cylinder-shaped swept volume is formed by some regular surfaces, as shown in Fig. 5(a): The left side and right side are cylindrical surfaces; the front side, back side, top side and bottom side are planes. The Tri-dexel swept volume is formed by computing the interaction of the rays and regular surfaces. The interaction algorithms is simple and can refer to [8].

4 Tri-Dexel Model Based Geometric Simulation Algorithm

As shown in Fig. 6, the flowchart of Tri-dexel model-based geometric simulation algorithm includes six main steps.

-

(0)

For the input data, the input tool paths are generated by any kind tool path pattern introduced in Sect. 2.1. The input geometry models is used to check the validity of input tool paths and compare the simulation result model with the original model.

-

(1)

In step 1, the micro swept volume and minimum bounding box is built for each segment formed by two GOTO points. The method is introduced in Sects. 3.1 and 3.2.

-

(2)

In step 2, the micro swept volume is transformed to Tri-dexel model. The method is introduced in Sect. 3.2.

-

(3)

In step 3, the micro swept volume and deposited material model are expressed in Tri-dexel models. Union operation of Tri-dexel models introduced in Sect. 2.3 is used for computing new deposited material models.

-

(4)

In step4, triangles meshes could be extracted by Marching Cube Algorithm [16]. Before extracting, the deposited material model expressed by Tri-dexel model should be transform to Voxel model because the Voxel model could express complex inner attributes.

-

(5)

The last step is the visualization of triangles meshes using display engine.

5 Simulation and Experiments

5.1 Software Implementation and Simulation

A software framework is built to implement the multi-axis AM geometric simulation algorithm. The software is developed based on NX Open platform. The AM tool paths in this study are generated by software HybridCAM (the software has got China’s compute software copyright registration certificate). The development of HybridCAM and simulation in this study is based on NX 9.0.

In this study, we use two parts to demonstrate the simulation process. The two parts come from real parts in aviation industry. The size of two parts are shown in Table 1, and the CAD models of two parts are shown in Fig. 7.

Before the AM simulation processing, we use software HybridCAM to generate tool paths of the two parts. Tool paths of the first part “Vane” is generated by three-axis helical pattern, and tool paths of the second part “Impeller” use five-axis follow pattern. Processing parameters in Table 1 give two parameters in tool path generation and simulation. Figure 8(a) shows the generating tool paths of the part “Vane”. Figure 8(b) shows the generating tool paths of one blade in the part “Impeller”.

In the AM simulation processing, the deposition models are first demonstrated by Tri-dexel models, and then transformed to triangular meshes for visualization. Figure 9(a) and (b) show Tri-dexel models of the two parts generated in the deposition processing. In the two models, grid interval for computing Tri-dexel model of swept volume is set to 1 mm. From partial magnification in Fig. 9, we can see that the Tri-dexel models are smooth.

After the AM simulation processing, the deposition models are visualized by triangular meshes. As shown in Fig. 10. In the figures, we can clear see the layered deposition material and the deposition model is basically consistent with the CAD models. In Fig. 10, we can see the layer is smooth. We also notice that the laser tool axes are always perpendicular to the surface. In the two deposition models, there are some ladder shapes obviously on boundary but not obviously inside. The smaller the layer thickness, the smoother the deposition model. Comparing with the Dexel method in reference [11], the deposition results in this study are better with less ladder shapes and more overall smoothness.

5.2 Additive Manufacturing Experiment

To evaluate that the AM simulation results are consistent with actual manufacturing results, we did the actual experiment of part “vane”. The experiment of part “impeller” was not realized due to limitations of experimental equipment.

The experimental equipment is modified by a three-axis machining tool. As shown in Fig. 11. The powder feeder equipment (Fig. 11(a)) is connecting with the three-axis AM equipment (Fig. 11(b)). Actual AM deposition experiment parameters are shown in Table 2. The tool paths are generated similar with Fig. 8(a), the only difference is that the layer thickness is set to 0.3 mm. Considering the generated tool paths have more than 300 layers, the tool paths are not displayed here, and we only manufactured about 100 layers considering efficiency.

The deposition model is shown in Fig. 12. We can see that the deposition model is intact, no collapse, no distortion and deformation. The actual manufacturing results are consistent with simulation results. The outer surface covers an oxide layer which can be knocked out. To get more smooth and high precision part, the deposition model can be used as blank for furthermore finishing.

6 Conclusion and Future Work

This paper presents a novel geometric simulation technique for multi-axis Additive Manufacturing. The proposed method can be used for three-axis and five-axis AM processing geometric simulation. The cylinder-shaped additive swept volume model can simulate the deposition models lively, and simulation examples and actual manufacturing experiment demonstrate the feasibility of the proposed simulation method.

Currently we are working on an algorithm to simulate the AM processing more lively using new swept models. In addition, we plan to do more actual experiments using industrial robot to further verify and improve our algorithms.

References

Bikas, H., Stavropoulos, P., Chryssolouris, G.: Additive manufacturing methods and modelling approaches: a critical review. Int. J. Adv. Manuf. Technol. 83(1), 389–405 (2016)

Griffith, M.L., Keicher, D.M., Atwood, C.L.: Free form fabrication of metallic components using laser engineered net shaping (LENS{trademark}). Office of Scientific & Technical Information Technical Reports (1996)

Thompson, S.M., Bian, L., Shamsaei, N., et al.: An overview of direct laser deposition for additive manufacturing; part I: transport phenomena, modeling and diagnostics. Add. Manuf. 8, 36–62 (2015)

Van Hook, T.: Real-time shaded NC milling display. In: 13th Annual Conference on Computer Graphics and Interactive Techniques, p. 15. ACM, New York (1986)

Hui, K.C.: Solid sweeping in image space—application in NC simulation. Visual Comput. 10(6), 306–316 (1994)

Zhu, W., Lee, Y.S.: Dexel-based force-torque rendering and volume updating for 5-DOF haptic product prototyping and virtual sculpting. Comput. Ind. 55(2), 125–145 (2004)

Muller, H., Surmann, T., Stautner, M., et al.: Online sculpting and visualization of multi-dexel volumes. In: Eighth ACM Symposium on Solid Modeling and Applications, pp. 258–261 (2003)

Ren, Y., Lai-Yuen, S.K., Lee, Y.S.: Virtual prototyping and manufacturing planning by using tri-dexel models and haptic force feedback. Virtual Phys. Prototyping 1(1), 3–18 (2006)

Ren, Y., Zhu, W., Lee, Y.S.: Feature conservation and conversion of tri-dexel volumetric models to polyhedral surface models for product prototyping. Comput.-Aided Des. Appl. 5(6), 932–941 (2013)

Choi, S.H., Chan, A.: A virtual prototyping system for rapid product development. Comput. Aided Des. Cad 36(5), 401–412 (2004)

Gao, X., Zhang, S., Hou, Z.: Three direction DEXEL model of polyhedrons and its application. In: International Conference on Natural Computation, vol. 5, 145–149 (2007)

SKM Homepage, http://www.skm-informatik.com/skm/home.html

Ren, L., Sparks, T., Ruan, J., et al.: Integrated process planning for a multiaxis hybrid manufacturing system. J. Manuf. Sci. Eng. 132(2), 237–247 (2010)

Gao, W., Zhang, Y., Ramanujan, D., et al.: The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 69(C), 65–89 (2015)

Lorensen, W.E., Cline, H.E.: Marching cubes: a high resolution 3D surface construction algorithm. In: Conference on Computer Graphics & Interactive Techniques, vol. 21(4), pp. 163–169 (1987)

Acknowledgement

The authors gratefully acknowledge National Natural Science Foundation of China(51575386). The authors would also like to thank the experimental supporting from Wuhan HuaGong Laser Engineering Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

He, S., Zeng, X., Yan, C., Gong, H., Lee, CH. (2017). Tri-Dexel Model Based Geometric Simulation of Multi-axis Additive Manufacturing. In: Huang, Y., Wu, H., Liu, H., Yin, Z. (eds) Intelligent Robotics and Applications. ICIRA 2017. Lecture Notes in Computer Science(), vol 10464. Springer, Cham. https://doi.org/10.1007/978-3-319-65298-6_73

Download citation

DOI: https://doi.org/10.1007/978-3-319-65298-6_73

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-65297-9

Online ISBN: 978-3-319-65298-6

eBook Packages: Computer ScienceComputer Science (R0)