Abstract

Joint clearance is a main cause of generating positioning error in industry robot and the low repeatability and uncertainty make it difficult to compensate. This paper mainly focus on SCARA robot and study the effect of revolute joint clearance in positioning accuracy. First, the positioning error model in XOY plane related to joint clearance is set up and analysis to obtain the extreme error value is made. Then a combined idea to study the joint clearance is presented. From this way, the seemingly random clearance error vector can be predicted by some rough deciding factors. Therefore, if the distribution pattern of clearance vector and the rough decided value are obtained, a compensation is possible. Finally, the Ball-Bar was applied to carry out experiment for invalidation and further correction. From the experiment, some patterns are obtained and show that the clearance is indeed rough decided by some factors.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As robot becomes more and more important in industry automation field, the investigation of its accuracy and characteristics become popular among researchers. A very crucial aspect for an industry robot is the positioning error which can be influenced by many factors, particularly, the joint clearance. For most mechanisms, joint clearance is inevitable and main sources of it usually from the manufacturing error, wearing, and bearing gap and deformation. Unlike existing structural error by manufacturing or compliance which can be compensated, the low repeatability of joint clearance made it difficult to compensate.

Some researchers focused on the kinematics when exist joint clearance which include assessment of mechanism accuracy, the repeatability and the mathematic model of end positioning error etc. There are mainly two possible approaches to the kinematic problems: deterministic way which determines the contact point position in joint clearance by supposed contact force model, and stochastic approach that handles the problem from a probabilistic way.

In order to obtain the mathematic model of end positioning error, Innocenti [1] had proposed a method based on the principle of the virtual work to get the relation of the joint contact configuration and the resulting displacement. Then Stefano and Vincenzo [5] modified this method. Some scholars considered the joint clearance as an additional massless link, like the work of Ting et al. [6] and Tsai and Lai [7], which used geometry method to get the maximum deviation region. For some simple specific robot mechanisms, some researchers just used coordinate transform to get the final error model caused by joint clearance. In the study of Nicolas and his fellows [3], a system way of displaying the end effector error by coordinate transformation had been proposed.

For investigating the kinematic effects, most scholars focused on the maximum and minimum positioning error of end effector so as to give a maximum allowable accuracy guarantee [3, 6, 7]. While some studied the working path deviation when joint clearance exist. They try to reduce and minimize the deviations from the target locations by properly selecting the working path when considering the clearance in the model [2, 4]. This study mainly focus on SCARA robot and investigates the effects of joint clearance in positioning error of XOY plane. First set up the positioning error model, then propose an idea of synthesizing deterministic way and stochastic approach. After that, the experiment is carried out for validation and correction. Finally, some conclusions are made.

2 Setting up Positioning Error Model

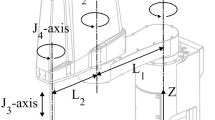

In general, SCARA robot has three revolute pairs and one prismatic pair and axes of the three revolute joints are in parallel with each other. Because of the compact structure and parallel axes feature, SCARA manipulator can realize high accuracy motion, which makes it widely used in electronic assembly field. However, this special structure feature also limits the workspace of SCARA to plane working only. Figure 1 is the 3-D model of YAMAHA YK600XG SCARA robot, the experimental object of this study provided by Dalian YUNMING Automation Technology Company. The mechanism diagram is shown as Fig. 2.

Joint R 01, R 12, R 34 are revolute joint and the axes of them are parallel with axis Z. Joint P 23 is a prismatic joint along Z axis. Combinating motion of joint 1(R 01) and 2(R 12) realizes the positioning in XOY plane and motion of joint 3(P 23) realizes movement in Z direction. Revolute joint 4 is used for assembly work like screwing.

From the mechanism diagram, we can obtain that the end-effector position is depend on joint 1, 2 and 3. For simplifying the analysis, take the base coordinate as coordinate system for all components. Denote the origin of base coordinate system O 0 as the intersection point of joint R 01’s axis and the bottom installing plane. And denote k 0 as the direction of joint R 01’s axis, define i 0 as the direction of arm 1 when rotation angle of joint 1 is zero. Shown as Fig. 2. Therefore, the projection of end-effector point Q in XOY plane is shown as Fig. 3. Denote the rotation angle of joint 1 as θ 1 and rotation angle of joint 2 as θ 2. Positive rotation direction is in the anti-clockwise. The position movement of Q in Z direction is the moving parameter of joint 3. Denote P 3 as the moving parameter of joint 3 and h 0 is distance between the bottom installing plane and the extreme position of joint 3, shown as Fig. 4. L1, L2 are the axes distance of joint 1, 2 and joint 2, 4 respectively, which is just the length of arm1 and arm2.

So, the coordinate of Q based on O 0 is:

According to the parameters of the provided YAMAHA YK600XG SCARA robot, it have, L 1 = 300 mm, L 2 = 300 mm, h 0 = 137.6 mm, joint motion scope, P 3: (−200 mm, 0), θ 1: (−130°, 130°), θ 2: (−145°, 145°). Then the coordinate of Q’s projection on XOY plane can be simplified as:

For simplifying the joint clearance model and considering the structure characteristic and main affecting factors, two reasonable assumptions are made. First, assume that the revolute joints of the 3-DOF manipulator only exist circular clearance and a continuity contact between shaft and hole. Second, for the study purpose is to investigate the positioning error of XOY plane and do not consider the orientation error, the parallel axes assumption is made between the shaft and hole of R-joint.

So, the joint clearance of joint 1, 2 can be simplified as a plan vector, whose magnitude is a constant ε = R − r (radius difference between shaft and hole). Uncertain direction θ ε are denoted as the angle between i 0 of base coordinate system O 0 and the clearance error vector (Positive angle is anti-clockwise). Show as Fig. 5. ε i and θ εi present the joint clearance magnitude and direction angle of joint i(i = 1, 2).

Ideal state of Q in XOY plane is shown as Fig. 3. When introducing the joint clearance, the projection of Q in XOY plane is changed to Fig. 6 and the coordinate of Q in XOY plane is:

For the simple mechanism structure of SCARA robot, the positioning error of end-effector Q in XOY plane can be obtained by direct subtraction.

ε 1, ε 2 are constant value, θε 1 and θε 2 are random uncertain quantities. From (2.4), the extreme value of end-effector positioning error can be obtained from analytical way. θε 1 and θε 2 are independent variables. The extreme value of X, Y direction positioning error are:

Define the distance error \(d^{2}=\varepsilon_{\text{x}}^{2}\, + \varepsilon_{\text{y}}^{2}\), then:

So, the extreme value of distance error d is:

The analysis above only consider the extreme value and take θε 1 and θε 2 totally random and have ignored possible influence factors.

3 Combined Idea for Revolute Joint Clearance

The clearance vector direction of revolute joint can be influenced by many factors, and some factors are even uncertain itself. So complete deterministic way is hard to obtain. Meanwhile, total stochastic approach will ignore the main external influence factors, like load force, link gravity, inertia effect etc. A combined way is introduced in this section: first, use the main influence factors to determine a contact point of shaft and hole; then according to this point direction build a deviation distribution for the influence of subtle uncertain factors, such as friction, impact, vibration etc. Specific possible deviation distribution type need be obtained from the experiment.

3.1 Main External Influence Analysis to Clearance

For SCARA robot, the link gravity is along Z-axis. If not consider the orientation error of end-effector, the force along Z axis has no impact in the positioning error of XOY plane. And when robot do certain assembly task, the state of robot motion must be static in order to finish the assembly work. So no centrifugal force exist. Therefore, the mainly external influence factor may be the inertia effect which is related to the rotate direction of each joint. Show as Fig. 7. Then from the arm rotation direction the contact point can be obtained so as to obtain θε i , denoted as θ b . Therefore, when arm rotate from the same side to a position, the joint clearance effect will be the same ideally. While approaching a position from different rotate direction, the effect of joint clearance will be different. Validation of this inference will be shown in the experiment result.

The discussion above ignored the effect of other subtle uncertain factors. In fact, some disturbance may be generated around the obtained contact point before. A way to consider these uncertain factors is to introduce a deviation distribution above the obtained point. Make average of the deviation distribution θ b and the standard deviation σ to stand for those uncertain disturbances. Specific distribution pattern should be obtained from the experiment.

3.2 Monte Carlo Method to Obtain Positioning Error

Monte Carlo simulation is a random number simulation method supported by basic mathematic theory, i.e. the law of large number and central-limit theory. In Monte Carlo method, suppose function Y = f(X 1, X 2, …, X n), and the probability distribution of variable X 1, X 2, …, X n are already known, a group of value x 1, x 2, …, x n of X 1, X 2, …, X n is generated using a random number generator by sampling. And then obtain the value of Y according to the function relation y i = f(x 1i , x 2i , …, x ni ). Repeat the sampling procedure a number of times (i = 1, 2, …, m), then a large group of sample y 1, y 2, …, y m can be obtained. As long as the sampling time m is large enough, the numerical characteristic of the sample can represent real one of Y accurately.

For certain SCARA robot, the clearance error magnitude ε 1, ε 2 in Eq. (2.4) are constant, which can be assured from the manufacturer or measured by the experiment. Equations (2.4) and (2.6) give the relation function of ε x , ε y , d based on θε 1, θε 2. And the probability distribution of θε 1, θε 2 can be obtained from the way presented in Sect. 3.1. Then we can apply the Monte Carlo method described above to Eqs. (2.4) and (2.6) and obtain the distribution of positioning error as well as some numerical characteristics.

4 Experiment by Ball-Bar

In this experiment, the Ball-Bar is applied to measure the joint clearance effects to positioning error. Ball-Bar is an error measurement instrument and usually applied in CNC machine to measure the positioning error of the machine caused by factors like machine geometry error, wear and control system error etc. shown as Fig. 8. It has three main parts, fixed part B2, center rod P AB and the moving part B1, shown as Fig. 9. Fixed part B2 is connected with the fixed coordinate through a magnetic base. Moving part B1 is connected to the moving component. The joint connection between B1, B2 and P AB are spherical pair. P AB itself is a prismatic pair which include a high accurate sensor. Accord to the value change of the accurate sensor in P AB to reflect the small displacement change between B1 and B2.

Not limited in CNC, Ball-Bar can also be adapted to measure the revolute joint error when referring to the SCARA robot. There are two purposes of using the Ball-Bar, one is to find out whether the combined idea above is adaptable and the other is to study the pattern of the deviation as well as the positioning performance of joint clearance.

Experiment mechanism diagram for joint 1 is shown as Fig. 10. And Fig. 11 is the experiment photo. For fixing the fixed part B2 of the Ball-Bar in the axis of joint 1 accurately, fixture is designed, shown as Fig. 11.

For fixture limitation, only 7 points is measured, P0: −330000 pulses, P1: −270000, P2: −210000, P3: −150000, P4: −90000, P5: 30000, P6: 130000. The unit of the measure position is in pulse for the convenience of the control way in the servo motor in joint 1. Measure point shown as Fig. 12. The experiment process is first regular planned as a cycle P0 → P1 → P2 → P3 → P4 → P5 → P6 → P5 → P4 → … then a random measuring way from point to point is measured.

Experiment mechanism diagram for joint 2 is shown as Fig. 14 and Fig. 15 is the experiment photo. Fixture is shown in Fig. 15.

5 position is measured, P0: 300000 pulses, P1: 150000, P2: 0, P3: −150000, P4: −300000. Measure point shown as Fig. 13. The experiment process is regular planned as a cycle P0 → P1 → P2 → P3 → P4 → P3 → P2 → P1 → P0 → … the measuring times for each point in the same rotate direction is 83 for better obtaining the uncertainty pattern and other features of the joint clearance.

5 Experiment Data and Analysis

When measuring the joint clearance error, which is a random error, the fixed deviation of the fixture and the robot structure error generate no impact to the measurement. Although each point the value of Ball-Bar is different due to fixed error, the disturbance feature of each point is not influenced by the system fixed error for the reason that in the same position the fixed structure error has the same value. Below are the experiment data and some analysis.

For joint 1, considering position P1, P2, P3, P4 and P5 in regular motion when rotating anticlockwise and clockwise, the experiment data shows that when manipulator rotate from the same side to a position, the measuring value is relatively stable with a small disturbance within 0.001. While approaching a position from different rotation direction, the measuring value is different for all measure points. Take P1 and P3 as an example. Figure 16 shows the plot of measuring value of P1 and P3 respectively. Different value of P1 and P3 is caused by the fix error of the fixture and robot structure error, which has no impact for the disturbance measurement for certain position.

The result verifies the inference made in Sect. 3.1 and shows that the seemingly random joint clearance vector indeed rough decided by some factors. And some deviation also exist whose pattern will be roughly show in the measurement of joint 2 when repeat the measurement a lot of times. The rough decided law can also be verified in the experimental data of joint 2.

For joint 2, consider position P1, P2, P3 in Fig. 14 which has two direction approaches. P0 and P4 only have one approach direction. For verification, Fig. 17 shows the plot of measuring value of P1 and P3 from different approaching direction respectively. The result once again verifies that the seemingly random joint clearance vector indeed rough decided by some factors.

For the same approaching direction, the experiment shows that uncertainty deviation indeed exist and the uncertainty pattern of different positions in same rotation direction has similar features. Shown as Fig. 18. The figure is the probability density function of the measuring value of position Pi from the data, having smoothed by kernel estimation method. The approach direction is clockwise.

From Fig. 18, we can found the disturbance pattern are almost similar, one peak density in the distribution and then plummet as the value away from the center value. The pattern is close to a normal distribution but a little different from ideal normal distribution. Possible reason is that so many small uncertain factors affect the joint clearance, like friction, compact, vibration, elasticity, etc. and according to the central-limit theory, the distribution of the disturbance tend to a normal distribution. And from the data, it shows that the standard deviation of P1, P2, P3 and P4 are 0.0013 mm, 0.0016 mm, 0.0016 mm and 0.0011 mm respectively, which shows that for a certain motion condition and environment the deviation degree is almost the same. For ascertaining the specific disturbance distribution pattern and the accurate decided model of joint clearance vector rather than a reasonable explain model, further study and experiment should be carried out.

6 Conclusion

This paper first simplified the revolute joint clearance and set up the positioning error model of SCARA robot. According to the error model, some simple analysis to obtain the extreme error value is made, which take clearance direction θε 1 and θε 2 totally random and have ignored possible influence factors for joint clearance. Then a combined idea is presented for considering main external influence factors and uncertain factors separately. Finally, experiments scheme and result is shown to verify whether joint clearance vector is totally random or roughly decided by some factors. The result show that the joint clearance is indeed exist and it is not totally random which means compensation is possible. And the experiment also show similar pattern for the uncertainty of joint clearance, from these patterns, a norm distribution may be adaptable for the deviation distribution of clearance vector direction.

Above combined idea is just giving a method to illustrate the feasibility of separating the rough deciding factors and uncertain factors. For further study, the rough decided model of the joint clearance should be investigated accurately and if the rough decided model can be obtained, the compensation is possible for this seemingly random joint clearance error.

References

Innocenti, C.: Kinematic clearance sensitivity analysis of spatial structures with revolute joints. In: ASME, Design Engineering Technical Conference, Paper DETC98/DAC-8679 (1999)

Lai, M.-C., Chan, K.-Y.: Minimal deviation paths for manipulators with joint clearances. In: ASME, Mechanisms and Robotics Conference, p. V05BT08A058 (2014)

Nicolas, B., Philippe, C., Stéphane, C.: The kinematic sensitivity of robotic manipulators to joint clearances. In: Computers and Information in Engineering Conference (2010)

Erkaya, S.: Trajectory optimization of a walking mechanism having revolute joints with clearance using ANFIS approach. Nonlinear Dyn. 71(1–2), 75–91 (2013)

Stefano, V., Vincenzo, P.C.: A new technique for clearance influence analysis in spatial mechanisms. ASME J. Mech. Rob. 127(3), 446–455 (2002). Montreal, Quebec, Canada

Ting, K.L., Zhu, J.M., Watkins, D.: The effects of joint clearance on position and orientation deviation of linkages and manipulators. Mech. Mach. Theory 35(3), 391–401 (2000)

Tsai, M.J., Lai, T.H.: Kinematic sensitivity analysis of linkage with joint clearance based on transmission quality. Mech. Mach. Theory 39(11), 1189–1206 (2004)

Acknowledgement

This work was financially supported by the National Natural Science Foundation of China (No. 51375065), Liaoning Province STI major projects (No. 2015106007), and the National Science and Technology Major Project (No. 2013ZX04003041-6).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Xu, C., Dong, H., Xu, S., Wu, Y., Wang, C. (2017). Study and Experiment on Positioning Error of SCARA Robot Caused by Joint Clearance. In: Huang, Y., Wu, H., Liu, H., Yin, Z. (eds) Intelligent Robotics and Applications. ICIRA 2017. Lecture Notes in Computer Science(), vol 10463. Springer, Cham. https://doi.org/10.1007/978-3-319-65292-4_14

Download citation

DOI: https://doi.org/10.1007/978-3-319-65292-4_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-65291-7

Online ISBN: 978-3-319-65292-4

eBook Packages: Computer ScienceComputer Science (R0)