Abstract

Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) has outstanding post-cracking behavior which is explained by hardening part due to micro cracking and softening part of crack localization. Most UHPFRC structures are governed by concrete tensile behavior represented as critical crack localization, unlike ordinary reinforced concrete structures are designed to be governed by the yielding of steel reinforced rebar. In this research, crack localization characteristics of UHPFRC were investigated on three point bending test of twenty-four single notched prisms with varied types of location of notch, height of specimens and fiber volume ratio. The tensile fracture properties of UHPFRC were found out based on two parameter fracture model from the three point bending test results of center notched prism and direct tension test results of doubly notched plate. The structural implications of size effect in UHPFRC was examined by the fracture properties in terms of fracture process zone and specimen size. Within the height of 500 mm, size effect on flexural behavior was found only in structural ductility, not in the maximum strength. With respect to the location of notch, crack growth orientation were investigated and analyzed by maximum stress criteria. The results show that in-plane shear behavior of UHPFRC is much higher than ordinary concrete and it implies that the in-plane shear behavior of UHPFRC should be considered for designing structural elements.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) has outstanding post-cracking behavior which is explained by hardening part due to micro cracking and softening part after crack localization. Fracture characteristics of UHPFRC should be analyzed considering its large fracture process zone (FPZ) because the FPZ affects inelastic behavior after initial cracking in a concrete structure. Classical fracture mechanics distinguished three types of fracture modes depending the physical behavior at the crack tip: opening mode or mode I, in-plane shear or mode II, and out-of-plane shear or mode III. For ordinary concrete, mode II (sliding) behavior is usually negligible in comparison with mode I (opening) behavior, on the other hand, UHPFRC has different crack bridging effect of material heterogeneities due to bond strength between fibers and matrix. In this research, three point bending test on off-center notched prism was conducted and flexural shear behavior was analyzed with respect to the mixed mode fracture characteristics for different height and same proportional geometry.

2 Experimental Investigation

RILEM TC89-FMT suggested three types of mixed mode fracture test: three point bending beam with off-center notch, four point shear specimen, and quadratic double-edge-notched specimen. Among the given methods, the first one was conducted in this research to investigate flexural shear behavior with stable crack growth. The fracture properties for UHPFRC as a nonlinear fracture material was found out using two parameter fracture model (Shah and Carpinteri 1991).

The tensile behavior and fracture properties are the most important design parameters in this research. There are two types of mix compositions A and B with different volume ratios. Table 1 shows the details of mix composition. Material A with fiber volume fraction of 1.5% is expected to show tensile hardening behavior and material B with fiber volume fraction of 0.5% is expected to show tensile softening behavior. For each material, the beam size and initial crack location on flexural shear behavior depending on the material type is planned to investigate size effect and the influence of mode II behavior for UHPFRC. It can be regarded as that pure mode I with zero off-set ratio and mixed-mode tests with 1/3, 1/2 and 2/3 off-set ratio can be performed using similar specimens and same testing setup. In addition, to investigate the size effect on the flexural shear behavior of UHPFRC beams, specimens with three different height were prepared for each off-set ratios as shown in Table 2.

3 Characteristics of Uhpfrc Tensile Behavior

Direct Tension Test for Double Edge Notched Plate.

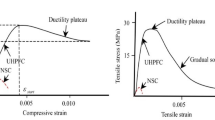

To investigate the tensile strength and opening displacement curve, four dog-bone specimens for each mix composition were fabricated and tested by using a specially designed direct tensile test machine. Figure 1 shows the post cracking behavior of mix composition A with fiber volume fraction of 1.5% and mix composition B with fiber volume fraction of 0.5%. The compressive strength of material A and B is almost same, about 180 MPa. To compare the fracture toughness of the material, fracture energy \( G_{f} \) was compared to each other. The fracture energy of material A is about 50 N/mm and that of material B is about 15 N/mm. For reference, the concrete with compressive strength of 180 MPa is estimated as 0.1–0.2 N/mm following the bilinear softening model given fib MC 2010.

Three Point Bending Test for Single Edge Notched Prism.

Three point bend notched beam tests with notches were performed using two parameter fracture model (Shah 1990). Jenq and Shah (1998) suggested that two fracture mechanics parameters, \( K_{Ic} \) and \( CTOD_{c} \), which is the equivalent linear elastic fracture properties can be determined from test results. Compared with the fracture properties for material A and B, there are big differences in terms of critical stress intensity factor, critical crack tip opening displacement and fracture energy. It was found out that \( K_{Ic} \) and \( CTOD_{c} \) of material A is three times greater than that of material B, whereas the equivalent crack length, the characteristic length for each material, is similar. This results implies that the area of FPZ in terms of the characteristics of energy dissipation is different whereas the length of FPZ in direction of its growth with respect to the brittleness number is similar. Based on this results a schematic shape and dimension for fracture process zone for each material is suggested in Fig. 2 modified by the FPZ of quasi-brittle material adapted from Bazant (1998).

4 Size Effect and Fracture Process Zone of Uhpfrc

Fracture Process Zone for UHPFRC.

The FPZ is a nonlinear zone characterized by progressive softening, for which the stress decreases at increasing deformation. This zone is surrounded by a non-softening nonlinear zone characterized by hardening plasticity or perfect plasticity, for which the stress increases at increasing deformation or remains constant. The relative sizes of two zones defines the fracture behavior (Bazant and Planas 1998).

The suggested FPZ of UHPFRC B in Fig. 2 shows typical FPZ of quasi-brittle material including concrete. A major part of the nonlinear zone representative equivalent softening zone undergoes progressive damage with material softening. The nonlinear hardening zone is often negligible. The differences with the ordinary concrete is that the absolute value of tensile strength and crack opening is higher and the shape of softening curve is not bilinear, but almost constant within the fracture process zone. The suggested FPZ of UHPFRC A in Fig. 2 shows an evident hardening behavior with a wide shape. The length of the FPZ along the crack propagation is almost same as that of UHPFRC B, but the overall area of FPZ is greater mainly because of the nonlinear hardening zone. The schematic FPZ suggested in Fig. 2 can explains the size effect and crack propagation characteristics of flexural and flexural shear behavior of UHPFRC A and B.

Size Effect on Flexural Behavior of UHPFRC.

Size effect can be considered with respect to the strength and ductility. In general fracture mechanics, it is the size effect on ductility of a structure with geometrically similar structures of different sizes typically normalized stress and relative deflection curves (ACI 1992). Size effect on ductility for center notched specimens were investigated in Fig. 3. In a plot of \( \sigma_{N} = 1.5Pl/th^{2} \) normalized by the material tensile strength \( f_{t} \) vs. the deflection normalized by the specimen height \( h \), a failure point is characterized by a tangent of a certain constant inverse slope as a measure of structural ductility. While the point of tangential slope as shown is assumed to be the failure point marked by the empty point along the dotted line in Fig. 3 (b), the failure occurs closer to the peak as the size increase. This effect is due to the fact that in a larger structure more strain energy is available to drive the propagation of the failure zone (Bazant and Planas 1998).

The flexural behavior of UHPFRC does not show degradation of the maximum strength with increase of its size. The maximum strength of center notched specimens for UHPFRC A in Fig. 3 (a) shows no tendency and large deviation because of the increase nonlinearity by material heterogeneity. Whereas for B-series specimens in Fig. 3 (b), the ductility with increase of specimen size clearly decreases considering the tangent of inverse slope, but there is no greater peak load. Flexural behavior for material B is dominated by brittle failure but the maximum strength is governed by its material tensile strength within the height of 500 mm.

5 Flexural Shear Behavior Characteristics of Uhpfrc

Mixed Mode Test Results.

There are wide variations in the peak strength of the specimen, especially UHPFRC A with hardening behavior. The test results indicate that the stress redistribution area of UHPFRC A is large enough regardless of initial crack location, and that of UHPFRC B increases proportionally to the distance from the loading point. Therefore the crack propagation should be analyzed considering the size of compressive zone in the cross section and inclination of compressive strut.

The physical mechanics of cracking behavior can be explained by the characteristics of a material FPZ zone in Fig. 2. It can be assumed that micro-cracking behavior arises in the nonlinear hardening zone with wide shape along the crack propagation, and after the peak load, crack localization with softening behavior in the shallow area along the crack path. In other words, a material with larger nonlinear hardening zone tends to have bigger crack growth orientation because the crack localization occurs at the weakest crack among the micro-cracked zone. The test results supports the assumptions.

Crack Growth Orientation.

For mixed mode failure of concrete, the determination of the final failure path and the criteria for crack instability are more complicated than that of pure mode I failure. Where a crack and its tip are subjected to in-plane, normal and shear stress, the crack propagation angle \( \theta \) can be a key parameter to determine the mixed mode fracture criteria. The origin coordinate is taken at the crack tip and \( \theta = 0 \) corresponds to the crack line which represents parallel to the direction of notch, vertical solid line in Fig. 4. Therefore, a crack will propagate along its original plane \( (\theta = 0) \) for pure mode I and will deviate from its own plane \( (\theta \approx 7 3{{^\circ }} ) \) for pure mode II with the assumption of the maximum stress criterion (Jenq and Shah 1988).

The crack propagation of test specimens are shown in Fig. 4. The specimens with a height of 100 mm showed a large difference in crack growth orientation with respect to the fiber volume fraction. The initiation angle of UHPFRC A is 45° and the propagation angle varied depending on the crack location. The initiation angle of UHPFRC B is 20° but the propagation is linear and brittle. The major cracks of specimens with a height of 250 mm were relatively scattered and the characteristics of crack propagation is opposite to the specimens with a height of 100 mm. The cracking behavior of UHPFRC A is more brittle than that of UHPFRC B for the specimens with a height of 250 mm. As shown in Fig. 4 (b), the overall cracks propagated in a linear way and it was observed that the angle of crack path is dependent the initial crack location for the specimens with a height of 500 mm.

Maximum Stress Criterion and Mode II Behavior of UHPFRC.

The existing mixed mode failure criteria is the use of stresses expressed in terms of \( K_{I} \) and \( K_{II} \) based on crack propagation angle \( \theta \). Maximum stress criterion was proposed by Erdogan and Sih (1963) depicted in Fig. 5. The criterion is suggested on the assumption that the crack initiates from its tip in a direction normal to the circumferential stress when the circumferential stress \( \sigma_{\theta } \) becomes the maximum and a principal stress and \( \tau_{\theta } \) is zero (Shah and Carpinteri 1991). Based on the maximum stress criterion, test results in this research including the test results for ordinary concrete (Jenq and Shah 1988) were denoted in Fig. 5. Assuming that crack initiate and propagate in a straight line, the final crack angle of off-center notches is 20°–55°. The range of crack growth inclination for ordinary concrete was 0°–20° with the similar test setup (Jenq and Shah 1988). The ratios of \( K_{II} /K_{I} \) measured from test results are much higher, so mode II behavior of UHPFRC should be quantified and considered for structural design, whereas the mode II behavior of ordinary concrete is usually neglected.

Maximum stress criterion (Erdogan and Sih 1963) and mode II behavior of UHPFRC

6 Conclusion

Fracture properties of UHPFRC were investigated on three point bending test of twenty-four single notched prisms with varied types of location of notch, height of specimens and fiber volume ratio. Flexural shear strength on material A with tensile hardening behavior shows nonlinearity with a large deviation and the maximum strength on material B with tensile softening behavior is governed by its tensile strength. It can be concluded that size effect on flexural strength of UHPFRC within the depth of 500 mm can be negligible, but size effect on flexural shear strength has to be analyzed with respect to the size of compressive zone in the cross section and the inclination of compressive strut. The crack propagation angle for flexural shear behavior was investigated and analyzed with respect to the maximum stress criterion. As a result, the ratios of \( K_{II} /K_{I} \) values for UHPFRC A and B are much higher than ordinary concrete, so the tractions generated through the frictional force and the contribution of the tractions should be considered.

References

ACI committee 446: Fracture mechanics of concrete: concepts, models and determination of material properties. In: Bazant, Z.P. (ed.) Fracture Mechanics of Concrete Structures, Elsevier Applied Science, London, pp. 1–140 (1992)

Bazant, Z.P., Planas, J.: Frature and Size Effect in Concrete and Other Quasibrittle Materials. CRC Press LLC, Boca Raton (1998)

Erdogan, F., Sih, G.C.: On the crack extension in plates under plane loading and transverse shear. J. Basic Eng. 85(4), 519–525 (1963)

Jenq, Y.S., Shah, S.P.: Mixed-mode fracture of concrete. Inter. J. Fract. 38(2), 123–142 (1988)

Shah, S.P.: Determination of fracture properties of plain concrete using three-point bend tests. RILEM draft recommendations. Mater. Struct. 23(6), 457–460 (1990)

Shah S.P., Carpinteri A. (eds.): Fracture Mechanics Test Methods for Concrete. RILEM Report of TC 89-FMT, Chapman & Hall, London (1991)

Shah, S.P., Swartz, S.E., Ouyang, C.: Fracture Mechanics of Concrete: Applications of Fracture Mechanics to Concrete, Rock and Other Quasi-Brittle Materials. Wiley, New York (1995)

Acknowledgments

This research was supported by a Grant (13SCIPA02) from Smart Civil Infrastructure Research Program funded by Ministry of Land, Infrastructure and Transport (MOLIT) of Korean Government and Korea Agency for Infrastructure Technology Advancement (KAIA).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Lee, Jh., Hong, SG., Joh, C. (2018). Effect of Specimen Size and Initial Crack Location on Flexural Shear Behavior of UHPFRC. In: Hordijk, D., Luković, M. (eds) High Tech Concrete: Where Technology and Engineering Meet. Springer, Cham. https://doi.org/10.1007/978-3-319-59471-2_59

Download citation

DOI: https://doi.org/10.1007/978-3-319-59471-2_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59470-5

Online ISBN: 978-3-319-59471-2

eBook Packages: EngineeringEngineering (R0)