Abstract

In this paper, we reviewed the current technology for the hydrogen fuel cells and got the light spots when 1271 papers related to hydrogen fuel cells were analyzed, which were focused on the hydrogen fuel cell technologies, hydrogen fuel cell application and solar hydrogen fuel cell. This paper had outlined these several types of the specific technology and confirmed that hydrogen fuel cells was an inevitable choice when faced to serious environmental pollution and energy structure’s imbalance. And the solar-hydrogen fuel cell system that involved the hydrogen production, hydrogen storage and hydrogen application is of significant importance addressing the problem of the production of renewable energy, power generation and transportation pollution.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

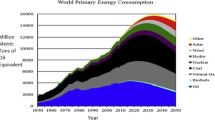

Many environmental issues have been caused by or relate to the production, transformation and use of fossil energies, for example, acid rain, stratospheric ozone depletion and global climate change [5]. Energy is the material basis for the country’s social development and progress of science and technology, but due to the constant use of the three large fossil energies, energy conservation and environmental problem became more and more serious. As a result of the badly exceeds bid of PM2.5, human beings got a warning of continuous haze weather. And the air pollution problem can be settled down when it is mainly closely related to fossil fuel combustion and transport industries. The increasing trend in world’s energy need is expected to continue in the future. As a result, a growth in energy generation capacity will be needed [1]. Cars are important transport means in people’s lives. However, the automobile exhaust is the important cause of increasingly serious environmental pollution. Therefore, we need to find an alternative fuel for the traditional fossil fuels.

Hydrogen has high energy density, and the energy released is enough to make the vehicle’s engine running. Hydrogen energy systems appear to be the one of the most effective solutions and can play a significant role in providing better environment and sustainability [4, 14]. Hydrogen fuel cell vehicle itself works with no noise, no vibration, no loss, and long service life. The electrode is only working as the place of chemical reaction and conductive channel and it does not participate in chemical reactions. The fuel of hydrogen fuel cell is hydrogen and oxygen, and the product is clean water, with the prefect results of no CO and CO\({_2}\), and no sulfur and particulate exhaust. We could have a clear look at the advantages when compared to the thermal power as Table 1 shows. Therefore, hydrogen fuel cell vehicle can run with zero emissions, zero pollution in real sense and hydrogen is regarded as a perfect energy for vehicle. Fuel cell technology with the hydrogen energy is the core technology of the auto industry in the 21st century, and it takes revolutionary significance for the car industry.

In the face of oil price’s rising, increasingly severe atmospheric environment, increasingly strict emission regulations and the pressing needs of light energy, fuel cell is the power generation device which can turn the chemical energy stored in the fuel and oxidant directly into electrical energy. It is considered to be the best choice as clean and efficient power generation technology in the 21st century because of its energy conversion is not limited by Carnot cycle [8], energy conversion efficiency can reach 90%, and the actual service efficiency is 2–3 times of internal combustion engine. And hydrogen fuel cell shows the unique superiority in such aspects as in the comprehensive energy efficiency, environment friendly and high reliability, so the hydrogen fuel cell will have broad market prospects as specific tools for the transition from fossil fuel based era to hydrogen economy-oriented society.

2 Literature Mining

Hydrogen fuel cell is a cutting-edge research problem in current society, but researches about this issue has certain basis and achievements. Based on these researches, literature mining has been shown to be a powerful method for elucidating major trends across time in published scientific literature so that topic maps can be built [2]. Garfield believed that the academic literature citation indexing was crucial when researching similar topic areas [7]. A citation index is a synthesized result based on journal articles, keywords, publication dates and abstracts and is able to separate and highlight the various influences in a specific field, allowing for the research with the greatest impact to be easily identified.

2.1 Data Analysis

Literature mining from published scientific literature allows for the discovery of key areas and trends [2]. CiteSpace is one of the latest development of a generic approaches to detecting and visualizing emerging trends and transient patterns in scientific literature. The work makes substantial theoretical and methodological contributions to progressive knowledge domain visualization. A specialty is conceptualized and visualized as a time-variant duality between two fundamental concepts in information science: research fronts and intellectual bases [3]. 1271 papers had been retrieved as “TI = HFC” been limited, and all the data was imported into the CiteSpace with a data process. Finally, 65 categories were formed after cluster, as Fig. 1 shows.

2.2 Results

Keywords are important index terms used to provide access to articles that have been published or presented in journals and conference databases and are essential for clearly identifying arange within a specified boundary. As Fig. 2 illustrates, keywords about hydrogen fuel cells have been shown from 1960 to 2016, which could be divide into three phases as timezone developed. And the first stage could be described as hydrogen fuel cell technologies in Sect. 3, the second could be extracted as hydrogen fuel cell application in Sect. 4, and the latest stage could be know as solar hydrogen fuel cell in Sect. 5, which is on behalf of the most frontier and hot issue on hydrogen fuel cells.

3 Hydrogen Fuel Cell Technologies

Hydrogen production has laid the basis for the development of fuel cells (FC) and the diffusion of associated technologies. The fuel cell technology mechanisms were discovered in 1838 by the German-Swiss chemist Christian Friedrich Schonbein and the British lawyer and natural scientist Sir William Grover [17]. The FC technologies have the potential to be the key technologies that contribute to the transition to a low carbon energy economy. The fuel cell and its application has become the most attractive and promising technology in the hydrogen energy utilization field. Because of its’ promising clean and efficient power generation, as oil and the internal combustion engine displaced coal and the steam engine, FCs will make the transition in a similar way in the future.

3.1 Operational Characteristics

A fuel cell is similar to conventional battery but different, being composed of an anode, cathode and electrolyte. These components generate electricity through an electrochemical reaction in which the external oxygen supply source (usually air) and a hydrogen-rich fuel combine to form water as Eq. (2) show. The difference with a conventional battery is that no combustion occurs in FCs, as the energy to run the FCs is released electro-catalytically. This electrochemical reaction at the two electrodes is shown from Eqs. (1) to (2) respectively.

As the schematic diagram in Fig. 3 shows, the fuel (hydrogen) and oxidizer (oxygen) dissociate to evolve electrons and ions, the ions separating from the pole move towards another under electrolyte conditions while the dissociated electrons are guided to an external electric circuit. The fuel (hydrogen) is supplied for the cathode, and the oxidizer for the anode. The hydrogen dissociates the \({\mathrm{{H}}^ + }\) and \({\mathrm{{e}}^ - }\), and the \({\mathrm{{H}}^ + }\) blends into the electrolyte while the \({\mathrm{{e}}^ - }\), tends towards the positive pole through an external circuit. The \({\mathrm{{H}}^ + }\) and oxygen in the air react at the positive pole to form water when absorbing \({\mathrm{{e}}^ - }\),. As long as the fuel and oxygen are supplied, there is a constant power output in the FCs.

3.2 Outlook for Fuel Cell Technologies

FCs are classified by the kinds of electrolytes they use, which determines the kind of chemical reactions that take place in the cell, the kind of catalysts required, the temperature range in which the cell operates, the fuel required, and other factors. In turn, these chemical reaction condition characteristics affect the applications for which these cells are most suitable. There are six major types of fuel cells presently under development, each with its own advantages, limitations, and potential applications, as shown in Table 2. Respectively, they are proton exchange membrane fuel cells (PEMFC), alkaline fuel cells (AFC), phosphoric acid fuel cells (PAFC), molten carbonate fuel cells (MCFC), solid oxide fuel cells (SOFC) and direct methanol fuel cells (DMFC). The operating characteristics of these systems are highlighted in Table 2.

AFCs use an aqueous solution of potassium hydroxide (KOH) as an electrolyte with a concentration ranging from 35% to 45%, a fuel of pure hydrogen, and typically operate at a low temperature of around 70\(^{\circ }\) C. It is a one of the most developed technologies so far and has been used by NASA spacecraft. Because of the low operating temperature, instead of a platinum catalyst in the system, a variety of non-precious metals such as the most commonly used catalyst of nickel can be employed to speed up the reactions taking place at the anode and cathode in AFC units. Owing to the rate at which the chemical reactions take place, AFCs offer relatively high fuel to electricity conversion efficiencies, as high as 60% in some applications. The major advantage of AFCs is the quick start, but the disadvantage is that they are very sensitive to CO\({_2}\) which causes a slower reaction time and consumes the alkaline in the electrolyte, thereby limiting its commercial applications.

PEMFCs are considered to be a promising technology for clean and efficient power generation in the 21st century and are known for their high-power density delivery and short start up time compared with other fuel cells, characteristics which guarantee that the PEMFCs technology is competitive for transportation and commercial applications such as stationary, and portable power generation [13]. PEMFCs use a solid polymer electrolyte (Teflon-like membrane) which is an excellent conductor of protons and an insulator for electrons to exchange ions between two porous electrodes, and operate under a temperature of 100\(^{\circ }\) C. The operating schematics are shown in Fig. 3. Therefore, the membrane is the key point in the PEMFCs technology and current research on PEMFCs also focuses on the development of a proton exchange membrane with high proton conductivity, low electronic conductivity, good thermal stability, and low cost.

Figure 3 shows that the working principles of the PAFCs and PEMFCs are similar even though the structures are different. PAFCs use liquid phosphoric acid as an electrolyte which is contained in a Teflon-bonded silicon carbide matrix, and works at about 150 to 200\(^{\circ }\) C. Different from PEMFCs and AFCs, PAFCs are more tolerant and insensitive to any impurities in the hydrogen fuel. The advantages of PAFCs are that the metal catalysts required are much less than that of the AFCs and the reducing agent purity requirements are significantly lower allowing for up to 5% carbon monoxide. PAFCs are viewed as the “first generation” of modern FCs. According to the state development, these are the first mature cell types to be used commercially. The 100200 and 500 kW size plants are typically available for stationary power generation. A 1.3 MW system has already been tested in Milan and PAFCs have been installed at 70 sites in Europe, USA and Japan [16].

MCFCs are high-temperature (650\(^{\circ }\) C) fuel cells which commonly use a molten carbonate salt, such as lithium carbonate, potassium carbonate or sodium carbonate, suspended in a porous ceramic matrix as the electrolyte. To date, this type has been developed in natural gas and coal based power plants for industrial and military use. The SOFCs’ electrolyte is a hard, non-porous ceramic compound such as yttria stabilized zirconia which has a strong conductivity and operates at a much higher temperature of 800–1000\(^{\circ }\) C [12]. SOFCs are considered to be around 50%–60% efficient at converting fuel to electricity and have rapidly increased in popularity in stationary applications in recent years.

Different from the five types fuel cells which fueled by hydrogen, DMFCs are powered by pure methanol or alcohol which can be generated hydrogen via reforming reaction as presented in Sect. 3. Direct methanol fuel cell technology is relatively new compared with that of fuel cells powered by pure hydrogen, and DMFCs research and development is roughly 3–4 years behind that for other fuel cell types [10]. The working principle and reaction equations are shown in Eqs. (3)–(4).

4 Hydrogen Fuel Cell Application

Generally, today, the application of fuel cell technologies can be categorized in three directions. Respectively, there are portable fuel cells designed to be moved, including auxiliary power units (APU), stationary power fuel cells designed to provide power to a fixed location, and transport fuel cells providing either primary propulsion or range-extending capacity for vehicles as shown in Table 3.

4.1 Portable Technological Direction

Using portable fuel cells can solve the low energy power capability and long charging time problems of current battery technology. Consequently, the global production of portable fuel cells has grown continuously on the basis of FC technology. In the 21st century, commercial portable units are being adopted rapidly in such areas as educational fuel cells and toys, auxiliary power units (APU), and consumer electronics [11]. With the many specific industrial niches that can benefit from fuel cells, the technology’s use in APU has been an area of interest for fuel cell manufacturers and industry players alike. DMFCs are a relatively expensive cell technology and is most cost-effective in small, low-power stack configurations under 100 W. There are a number of products emerging for applications that require a higher APU output. The Danish company Serenergy uses methanol as a fuel, but processes it ahead of a 350 W high-temperature PEMFC (HT PEMFC), which it is marketing fora variety of applications.

The long-awaited launch of a number of fuel cell consumer electronics chargers in 2011 and 2012 has marked a turning point in this sector. For many years it proved too difficult to miniaturize fuel cell technology to a level where it could realistically compete with external battery supplies. Continued development is expected to result in units small enough to be integrated inside consumer devices and large multinational companies, such as Apple and Research In Motion, are patenting products in this field.

4.2 Stationary Technological Direction

Stationary units that provide electricity/heat are not designed to be moved. They are used for backup power, in remote locations, as stand-alone power plants for towns and cities, for distributed generation in buildings, and for co-generation [9]. Compared with traditional power stations, stationary fuel cells use is inevitable because of today’s subtle change in energy structures and the breakthroughs in fuel cell technology.

In recent years, both small and large systems in residential, industrial and prime power applications have experienced a fast growth such as in the highly-advanced Japanese Ene-Farm residential micro-CHP plan and the emergence of similar schemes in Europe. Present fuel cell technology allows for a continued cost reduction and optimization of the technology. At the same time, the commercialization of backup power systems for the telecommunications industry has accelerated as the communication field expands with a significant interest emerging in China and elsewhere for both independent and grid-connected systems. The introduction of methanol-fuelled telecommunication backup locations, where delivering hydrogen is difficult, to take advantage of fuel cell technology. Large stationary fuel cell installations have gained increasing interest from multinational companies who are looking for ways to reduce their carbon footprint.

4.3 Transport Technological Direction

The global automotive industry sells in excess of 80 million vehicles per year, and for fuel cells a portion of this market remains the long-term prize in this sector. FCs are capable of replacing ICEs (internal-combustion engines) as they have the potential to achieve higher efficiency and lower GHG emissions. A typical application in vehicles varies from passenger cars, utility vehicles, to buses, with power ranges from 20 kW to 250 kW [15].

The production of regular automobiles increased steadily in the early 2000 s. In the past few years, the fuel cell light-weight vehicle market has been led by Honda, General Motors, and others. Honda has started shipping its FCX Clarity to Southern and Northern California. In 2007 General Motors, through its “Project Driveway” program, delivered over 100 units of its Chevrolet Equinox fuel-cell vehicles to California, Washington DC, and New York. Other fuel cell application technologies are in marine and unmanned aerial vehicles (UAVs), trucks, trains, and bicycles. Siemens has developed a fuel-cell-based air-independent propulsion system intended for use in submarines, such as the U212/214 type hybrid powered submarine manufactured by the German Howaldtswerke Deutsche Werft GmbH (HDW).

5 Solar Hydrogen Fuel Cell

Solar energy is a ubiquitous and rich source, also a kind of renewable energy sources with no environmental pollution. China has abundant solar energy resource, annual total solar radiation area is greater than 1050 kWh/m\(^2\), which is more than 96% of the total land. There are several methods for producing hydrogen from solar energy. Currently, the most widely used solar hydrogen production method is to obtain hydrogen by electrolyzing the water at low temperature. Solar-hydrogen fuel cell power generation system was new-type energy which was based on the solar power for water decomposition, and it could generate electricity by electrochemical reaction using the hydrogen and oxygen produced. Countries are committed to carry on the development and application of solar-hydrogen fuel cell because of rich energy source, high energy conversion efficiency, and no pollution in the whole transformation process. In the future energy system, solar energy will become the main primary energy to replace the current energy such as the coal, oil and gas, and hydrogen fuel cell will become the clean energy to replace petrol, diesel and chemical battery.

As a reversible fuel cell, it gives you the freedom to invent your own clean energy applications using fuel cells and renewable hydrogen formed using sun and water. Figure 4 shows a schematic diagram of hydrogen production system that uses photovoltaic technology. The electrolysis of distilled water using electricity produced by the PV panel takes place in electrolyser unit and produces hydrogen and oxygen as the end product [6]. Through the study of solar-hydrogen fuel cell system’s characteristics, we known that hydrogen fuel cell power generation efficiency could be as high as 36.4%, and solar cell power generation efficiency generally is in 15% to 18% range. Therefore, the hydrogen fuel cells not only greatly improve the efficiency of the power generation, also produce only water in the whole power generation process, which implement the clean, pollution-free and efficient, and will become a leader in the field of new energy in the 21st century.

6 Conclusion

Through the researches on the existing hydrogen fuel cell technologies and the application technologies, we learned that the real value of the hydrogen fuel cells is does not poor. Especially this particular and reversible solar-hydrogen fuel cell system is bright star prior to other styles with a steady stream of resources and the cycle of zero pollution. The direct hydrogen fuel cell vehicle is preferred, since it would be less complex, have better fuel economy, lower greenhouse gas emissions, greater oil import reductions and would lead to a sustainable transportation system once renewable energy was used to produce hydrogen. All countries need to increase comprehensive and multi-functional analysis and research on hydrogen fuel cell’s characteristics if we want to keep in active status in the field of energy development in the 21st century.

References

Acar C, Dincer I (2014) Comparative assessment of hydrogen production methods from renewable and non-renewable sourcesn. Int J Hydrogen Energy 39(1):1–12

Bruijn BD, Martin J (2002) Getting to the (c) ore of knowledge: mining biomedical literature. Int J Med Inform 67(1):7–18

Chen C (2006) CiteSpace II: detecting and visualizing emerging trends and transient patterns in scientific literature. J Am Soc Inform Sci Technol 57(3):359–377

Dincer I (2007) Environmental and sustainability aspects ofhydrogen and fuel cell systems. Int J Hydrogen Energy 31(1):29–55

Dincer I (2012) Green methods for hydrogen production. Int J Hydrogen Energy 37(2):1954–1971

Joshi AS, Dincer I, Reddy BV (2010) Exergetic assessment of solar hydrogen production methods. Int J Hydrogen Energy 35(10):4901–4908

Leydesdorff L (2015) Bibliometrics/citation networks. arXiv preprint arXiv 1502.06378

Li J, Chen L et al (2015) Finite time optimizations of a newton’s law carnot cycle. Int J Energy Environ 5(6):517

Miller EL, Randolph K et al (2016) Innovative approaches to addressing the fundamental materials challenges in hydrogen and fuel cell technologies. MRS Advances 1:1–13

Murray EP, Tsai T, Barnett SA (1999) A direct-methane fuel cell with a ceria-based anode. Nature 400(6745):649–651

Narayanan S, Valdez T (2002) Portable direct methanol fuel cell systems. Handbook of fuel cells

Park SD, Vohs JM, Gorte RJ (2000) Direct oxidation of hydrocarbons in a solid-oxide fuel cell. Nature 404(6775):265–267

Stumper J, Stone C (2008) Recent advances in fuel cell technology at ballard. J Power Sources 176(2):468–476

Turner J, Sverdrup G et al (2008) Renewable hydrogen production. Int J Energy Res 32(5):379–407

Wilberforce T, Alaswad A et al (2016) Advances in stationary and portable fuel cell applications. Int J Hydrogen Energy 41(37):16,509–16,522

Winter CJ (2009) Hydrogen energy-abundant, efficient, clean: a debate over the energy-system-of- change. Int J Hydrogen Energy 34(14):1–52

Young S (2001) Tomorrow’s energy: hydrogen, fuel cells and the prospects for a cleaner planet. Nature 414(6863):487–488

Acknowledgements

This research is supported by the Liaoning economic and social development project (No. 2017slktjd-063); The authors are also grateful to the Liaoning doctoral research start-up funding (No. 201501131).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Li, L., Zhang, Y., Li, Q. (2018). Literature Mining Based Hydrogen Fuel Cell Research. In: Xu, J., Gen, M., Hajiyev, A., Cooke, F. (eds) Proceedings of the Eleventh International Conference on Management Science and Engineering Management. ICMSEM 2017. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-59280-0_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-59280-0_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59279-4

Online ISBN: 978-3-319-59280-0

eBook Packages: EngineeringEngineering (R0)