Abstract

In this paper, a closed-loop supply chain (CLSC) model with part and module inventory centers is proposed and optimized. Part supplier, module assembler, manufacturer, distribution center and retailer in forward logistics (FL) and customer, collection center, recovery center, secondary market and waste disposal center in reverse logistics (RL) are taken into consideration for constructing the proposed CLSC model. Especially, for the reuses of recovered part and module, part and module inventory centers are also considered. The proposed CLSC model is represented by a mathematical formulation, which is to minimize the sum of various costs resulting from each stage of FL and RL under satisfying various constraints. The mathematical formulation is implemented by an adaptive hybrid genetic algorithm (a-HGA) approach. In numerical experiment, various scales of the proposed CLSC model are presented and the performance of the a-HGA approach are compared with those of several conventional approaches. In conclusion, the efficiency of the proposed CLSC model and the a-HGA approach are proved.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

- Closed-loop supply chain

- Part and module inventory centers

- Forward and reverse logistics

- Adaptive hybrid genetic algorithm

1 Introduction

Closed-loop supply chain (CLSC) model is generally consisted of forward logistics (FL) and reverse logistics (RL). For FL, part supplier, manufacturer, distribution center and retailer are considered. For RL, customer, collection center, recovery (remanufacturing or refurbishing) center, secondary (used) market and waste disposal center are taken into consideration. In general, the objective for implementing the CLSC model can be divided into two aspects as follows:

-

Constructing various facilities which can be used in FL and RL stages and considered in real-world situation.

-

Optimizing the CLSC model.

There are many conventional studies considering the above two aspects in the CLSC model [1,2,3,4, 7, 10, 12].

For constructing various facilities, Fleischmann et al. [4] proposed the CLSC model with three activities of product production, resale and waste disposal in customer, reused market and disposer market, respectively. Amin and Zhang [1] proposed the CLSC model with reuse activity. For the reuse activity, they considered the new part from supplier as well as the reusable part from refurbishing center so that all parts are used for producing product at manufacturer in FL. Wang and Hsu [12] suggested the CLSC model with reuse activity, that is, recycler in RL classifies the returned product into reusable and unusable materials, respectively. The reusable materials are then reused at manufacturer in FL and unusable materials are disposed in landfill area. Similar to Wang and Hsu [12], Chen et al. [3] also suggested the CLSC model with various reuse activities. In this CLSC model, recycling center collects the returned product from customer and then classifies them into reusable and unusable products. The reusable product is reused at retailer in FL and the unusable product is disassembled into reusable and unusable materials. The reusable material is reused at manufacturer and the unusable material is treated at waste disposal plant in RL.

For optimizing the CLSC model, Amin and Zhang [1] and Wang and Hsu [12] minimized the total costs resulting from each stage of FL and RL. However, Chen et al. [3] maximized the total profit consisting of total revenue and total cost.

Although, the conventional studies mentioned above considered various activities of each facilities in FL and RL, they do not explained exactly how to use the reusable part (or material) for the facilities in FL. Therefore, in this paper, we propose a new CLSC model with two inventory centers (part and module inventory centers) so that the reusable part (or material) is exactly and effectively used for the facilities in FL. In Sects. 2 and 3, the proposed CLSC model is represented by a mathematical formulation, which is to minimize the sum of various costs resulting from each stage of FL and RL under satisfying various constraints. The mathematical formulation is implemented by an adaptive hybrid genetic algorithm (a-HGA) approach in Sect. 4. In Sect. 5 for numerical experiment, various scales of the proposed CLSC model are presented and the performance of the a-HGA approach are compared with those of several conventional approaches. Finally, in Sect. 6, as a conclusion, the efficiencies of the proposed CLSC model and the a-HGA approach are proved.

2 Proposed CLSC Model with Two Inventory Centers

The proposed CLSC model is consisted of part suppliers in areas 1, 2, 3 and 4, module assembler, product manufacturer, distribution center and retailer for FL and customer, collection center, recovery center, secondary market and waste disposal center in RL and two inventory centers (part and module inventory centers). Its conceptual structure is shown in Fig. 1.

The difference between the proposed CLSC model and the conventional CLSC models [1, 3, 12] is that the former considers two inventory centers and the latter does not taken into account them. The detailed logistics are as follows. Each part supplier at areas 1, 2, 3, and 4 respectively produces new part types 1, 2, 3, and 4 and then send them to part inventory center. Also, each module assembler assembles new module types 1 and 2 and then send them to module inventory center. Recovery center checks the returned product from collection center and then classifies them into recovered modules (recovered module types 1 and 2) and recovered parts (recovered part types 1, 2, 3, and 4). Each recovered part and module are sent to part and module inventory centers, respectively. Each inventory center has a function that new part and module in FL and recovered part and module in RL can be used for respectively assembling and producing module and product in module assembler and product manufacturer in FL. The recovered product and unrecovered module at recovery center are sent to secondary market and waste disposal center so that they are resold and land filled, respectively.

3 Mathematical Formulation

First, some assumptions are presented.

-

Only single product is produced.

-

The numbers of facility at each stage are already known.

-

Among all facilities at each stage, only one facility should be opened.

-

Fixed cost for operating each facility are different and already known.

-

Unit handling cost considered at same stage is the same and already known.

-

Unit transportation cost considered between each facility are different and already known.

-

All products from customer are returned to collection center.

-

The qualities of recovered part and module at recovery center are identical with those of new part and module.

Under considering the above assumption, the mathematical formulation for the CLSC model is proposed. Some indexes, parameters and decision variables are defined.

Index Set:

a : index of part supplier; \(a\in A\);

p : index of area of part supplier; \(p\in P\);

b : index of module assembler; \(b \in B\);

m : index of area of module assembler; \(m \in M\);

v : index of part inventory center; \(v \in V\);

g : index of module inventory center; \(g \in G\);

d : index of product manufacturer ; \(d \in D\);

e : index of distribution center; \(e \in E\);

y : index of retailer/customer; \(y \in Y\);

j : index of collection center; \(j \in J\);

z : index of recovery center; \(z \in Z\);

i : index of secondary market; \(i \in I\);

k : index of waste disposal center; \(s \in S\).

Parameters:

\(B{S_{ap}}\) : fixed cost at part supplier a of area p;

\(B{I_{v}}\) : fixed cost at part inventory center v;

\(B{M_{bm}}\) : fixed cost at module assembler b of area m;

\(B{V_{g}}\) : fixed cost at module inventory center g;

\(B{P_d}\) : fixed cost at product manufacturer d;

\(B{D_e}\) : fixed cost at distribution center e;

\(B{C_j}\) : fixed cost at collection center j;

\(B{R_z}\) : fixed cost at recovery center z;

\(L{S_{ap}}\) : unit handling cost at part supplier a of area p;

\(L{I_v}\) : unit handling cost at part inventory center v;

\(L{M_{bm}}\) : unit handling cost at module assembler b of area m;

\(L{V_g}\) : unit handling cost at module inventory center g;

\(L{P_d}\) : unit handling cost at product manufacturer d;

\(L{D_e}\) : unit handling cost at distribution center e;

\(L{C_j}\) : unit handling cost at collection center j;

\(L{R_z}\) : unit handling cost at recovery center z;

\(\text {TSI}_{apv}\) : unit transportation cost from part supplier a of area p to part inventory center v;

\(\text {TIM}_{vbm}\) : unit transportation cost from part inventory center v to module assembler b of area m;

\(\text {TMV}_{bm}\) : unit transportation cost from module assembler b of area m to module inventory center g;

\(\text {TVP}_{gd}\) : unit transportation cost from module inventory center g to product manufacturer d;

\(\text {TPD}_{de}\) : unit transportation cost from product manufacturer d to distribution center e;

\(\text {TDT}_{ey}\) : unit transportation cost from distribution center e to retailer/customer y;

\(\text {TTC}_{yj}\) : unit transportation cost from retailer/customer y to collection center j;

\(\text {TCV}_{jz}\) : unit transportation cost from collection center j to recovery center z;

\(\text {TVU}_{zk}\) : unit transportation cost from recovery center z to secondary market k;

\(\text {TVI}_{zv}\) : unit transportation cost from recovery center z to part inventory center v;

\(\text {TVV}_{zg}\) : unit transportation cost from recovery center z to module inventory center g;

\(\text {TUW}_{zk}\) : unit transportation cost from recovery center z to waste disposal center k;

Decision Variables:

\(i{i_v}\) : handling capacity at part inventory center v;

\(i{m_{bm}}\) : handling capacity at module assembler o of area e;

\(i{v_g}\) : handling capacity at module inventory center g;

\(i{p_d}\) : handling capacity at product manufacturer d;

\(i{d_e}\) : handling capacity at distribution center e;

\(i{r_y}\) : handling capacity at retailer/customer y;

\(i{c_j}\) : handling capacity at collection center j;

\(i{v_z}\) : handling capacity at recover center z;

\(i{u_i}\) : handling capacity at secondary market i;

\(i{w_k}\) : handling capacity at waste disposal center k

Objective function and constraints are as follows:

Minimize Total Cost (TC)

The objective function of Eq. (1) is to minimize the total sum of fixed costs, handling costs and transportation costs. Equations (2)–(9) means that only one facility is opened at each stage. Equation (10) implies that the sum of the handling capacity at each supplier in areas 1, 2, 3 and 4 is the same or greater than that of the module inventory center. The same meaning is considered in Eqs. (11)–(17). Equation (18) implies that the sum of the recovered products at each recovery center is the same or greater than that of the recoverable products with \({a_1}\)% at each collection center. Equation (19) restricts that the sum of the handling capacity at all part inventory center is the same or greater than that of the recoverable product with \({a_2}\)% at all recovery centers. Equations (20)–(21) indicate the same meanings of the Eqs. (18) and (19). Equations (22)–(29) restrict the variables to integers 0 and 1. Equation (30) means non-negativity.

4 A-HGA Approach

The mathematical formulation is implemented using the a-HGA approach. The a-HGA approach is a hybrid approach with adaptive scheme. For the hybrid approach, conventional GA and Cuckoo search (CS) are used and for the adaptive scheme, Srinivas and Patnaik’s approach [11] is used. Using the hybrid approach can achieve a better improvement of solution rather than using a single approach does. By using the adaptive scheme, the rates of crossover and mutation operators used in GA are automatically regulated. The detailed implementation procedure [5, 6, 8] is as follows.

- Step 1. :

-

GA approach

- Step 1.1. :

-

Representation 0–1 bit representation scheme is used for effectively representing opening/closing decision of all facilities at each stage.

- Step 1.2. :

-

Selection Elitist selection strategy in enlarged sampling space is used

- Step 1.3. :

-

Crossover Two-point crossover operator (2X) is used.

- Step 1.4. :

-

Mutation Random mutation operator is used.

- Step 1.5. :

-

Reproduce offspring

- Step 2. :

-

CS approach Apply Levy flight scheme [8] to the offspring of GA and produce new solution.

- Step 3. :

-

Adaptive scheme Apply the adaptive scheme used in Srinivas and Patnaik [11] to regulate crossover and mutation rates.

- Step 4. :

-

Termination condition If pre-determined stop condition is satisfied, then stop all Steps, otherwise go to Step. 1.2.

5 Numerical Experiments

In numerical experiment, three scales of the proposed CLSC model are presented. Each scale has various sizes of part suppliers in areas 1, 2, 3 and 4, par inventory center, module assembler in area 1 and 2, module inventory center, product manufacturer, distribution center and retailer in FL and customer, collection center, recovery center, secondary market, and waste disposal center in RL. The detailed sizes of each scale are showed in Table 1. For each scale, 1,500 products are produced in FL and handled in RL. The rates at recovery center for handling the returned products from collection center are as follows: \({\alpha _1}=60\%\), \({\alpha _2}=20\%\), \({\alpha _3}=15\%\) and \({\alpha _4}=5\%\), for recoverable products, parts, modules and unrecoverable modules, respectively.

To prove the efficiency of the a-HGA approach, two conventional approaches (GA, HGA) and Lingo [9] as a benchmark are used and they are summarized in Table 2. The performances of each approach are compared using various measures of performance as shown in Table 3.

All approaches ran on a same computation environment (IBM compatible PC 1.3 Ghz processor-Intel core \(I5-1600\) CPU, 4 GB RAM, OS-X EI) and programmed by MATLAB version R2014a. The parameter settings for GA, HGA and a-HGA are as follows: For each scale, total number of generations is 1,000, the population size is 20, the crossover and mutation rates are 0.5 and 0.3 respectively. Total 30 trials were independently done for eliminating the randomness in the search processes of the GA, HGA and a-HGA. Table 4 shows the computation results by GA, HGA, a-HGA and Lingo.

In the scale 1 of Table 4, the a-HGA including the GA and HGA has the same re-sult and their performances are greater than that of Lingo in terms of the best solution and percentage difference. In terms of the average solution, the a-HGA shows the best performance compared with the GA and HGA. However, in terms of the average time, the a-HGA shows the worst performance and the GA is the best performer. In scale 2, the performance of the a-HGA is more efficient than the GA and HGA in terms of the best solution and average solution. The difference in terms of the percentage difference means that the a-HGA is 0.05% and 0.06% advantageous compared with the HGA and GA. However, in terms of the average time, the a-HGA is the slowest and the GA is the quickest.

Similar results are also shown in the scale 3, that is, the a-HGA shows the best performances in terms of the best solution, average solution and percentage difference when compared with the GA, HGA and Lingo. However, the search speed of the a-HGA is about thirty times slower than those of the GA and HGA.

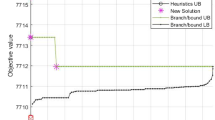

Figure 2 shows the convergence behaviors of GA, HGA and a-HGA until the generation number is reached to 200.

In Fig. 2, all approaches show rapid and various convergence behaviors during initial generations. However, after about 50 generations, each approach does not show any more convergence behaviors and the a-HGA shows to be more efficient behaviors than the GA and HGA.

The result of the detailed material flows in the a-HGA for the scale 3 is shown in Fig. 3. The opened facilities at each stage are displayed as white-coloured boxes. The 975 new parts in each area are produced and then sent to part inventory center. The recovery center recovers the quality of the returned products and then sent 225 recovered parts to part inventory center. Part inventory center stores 975 new parts and 225 recovered parts. Total 1,200 parts \((=975 + 225)\) are shipped to module assembler. Module assembler assembles 1,200 parts and produces 1,200 new modules. Recovery center recovers the quality of the returned products and then sent 300 recovered modules to module inventory center. Module inventory center stores 1,200 new modules and 300 recovered modules. Total 1,500 modules are sent to product manufacturer for producing 1,500 products. 1500 products are sent to each retailer via distribution center. In RL, 1,500 products from all customers are returned to recovery center through collection center. 900 recovered products \((= 60\% \times 1,500)\) of all returned products are resold at secondary markets. 75 unrecovered parts \((=5\% \times 1,500)\) of all returned products are sent to waste disposal center.

Based on the results of Table 4, Figs. 2 and 3, we can reach the following conclusions.

-

The proposed CLSC model can represent the detailed material flows at each stage and effectively handle the recovered part and module by using two inventory centers, when compared with the conventional models of Amin and Zhang [1], Wang and Hsu [12], and Chen et al. [3].

-

The a-HGA approach shows to be more efficient in many measures of performance than the GA, HGA and Lingo, which implies that the former can explore whole search space rather than the latter do.

-

The search speed of the a-HGA is significantly slower than those of the GA and HGA, since the former has an adaptive scheme to regulate crossover and mutation operators and the search structure requires many times.

6 Conclusion

In this paper, we have proposed a new type of the CLSC model. The proposed CLC model has part suppliers at areas 1, 2, 3, and 4, module assembler, product manufacturer, distribution center and retailer for FL and customer, collection center, recovery center, secondary market and waste disposal center for RL. Especially, for effectively handling recovered part and module, two inventory centers (part and module inventory centers) have been used.

The proposed CLSC model has been represented by a mathematical formulation, which is to minimize the sum of handling cost, fixed cost and transportation cost resulting from each stage of FL and RL under satisfying various constraints. The mathematical formulation has been implemented by the a-HGA approach. The a-HGA approach is a hybrid algorithm with GA and CS approach. Also, using an adaptive scheme, the rates of crossover and mutation operators are automatically regulated in a-HGA approach. The a-HGA approach has been implemented in various scales of the proposed CLSC model to compare its performance with those of GA, HGA and Lingo. The experimental results have shown that the a-HGA approach is more efficient in terms of various measures of performance than the GA, HGA and Lingo. However, since the search speed of the a-HGA approach is significantly slower than those of the others, a room for improvement is still left in the a-HGA approach.

References

Amin SH, Zhang G (2012) An integrated model for closed-loop supply chain configuration and supplier selection: multi-objective approach. Expert Syst Appl 39(8):6782–6791

Amin SH, Zhang G (2013) A multi-objective facility location model for closed-loop supply chain network under uncertain demand and return. Appl Math Model 37(6):4165–4176

Chen YT, Chan FTS, Chung SH (2014) An integrated closed-loop supply chain model with location allocation problem and product recycling decisions. Int J Prod Res 53(10):3120–3140

Fleischmann M, Krikke HR et al (2000) A characterisation of logistics networks for product recovery. Omega 28(6):653–666

Gen M, Cheng R (1997) Genetic algorithms and engineering design. Wiley, New York

Gen M, Cheng R (2000) Genetic algorithms and engineering optimization. Wiley, New York

Georgiadis P, Besiou M (2008) Sustainability in electrical and electronic equipment closed-loop supply chains: a system dynamics approach. J Cleaner Prod 16(15):1665–1678

Kanagaraj G, Ponnambalam SG, Jawahar N (2013) A hybrid cuckoo search and genetic algorithm for reliability–redundancy allocation problems. Comput Ind Eng 66(4):1115–1124

Lingo (2015) Lindo Systems. www.lindo.com

Savaskan RC, Bhattacharya S, Van Wassenhove LN (2004) Closed-loop supply chain models with product remanufacturing. Manage Sci 50(2):239–252

Srinivas M, Patnaik LM (1994) Adaptive probabilities of crossover and mutation in genetic algorithms. IEEE Trans Syst Man Cybern 24(4):656–667

Wang HF, Hsu HW (2010) A closed-loop logistic model with a spanning-tree based genetic algorithm. Comput Oper Res 37(2):376–389

Acknowledgements

This work is partly supported by the Grant-in-Aid for Scientific Research (C) of Japan Society of Promotion of Science (JSPS): No. 15K00357.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Yun, Y., Chuluunsukh, A., Chen, X., Gen, M. (2018). Optimization of Closed-Loop Supply Chain Model with Part and Module Inventory Centers. In: Xu, J., Gen, M., Hajiyev, A., Cooke, F. (eds) Proceedings of the Eleventh International Conference on Management Science and Engineering Management. ICMSEM 2017. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-59280-0_85

Download citation

DOI: https://doi.org/10.1007/978-3-319-59280-0_85

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59279-4

Online ISBN: 978-3-319-59280-0

eBook Packages: EngineeringEngineering (R0)