Abstract

The conventional biological nitrogen removal process combining the nitrification and denitrification steps is widely implemented worldwide for the treatment of wastewaters with low to moderate nitrogen concentrations. For highly nitrogen-concentrated streams, the conventional process become limited, mainly due to sizing and operation issues. In the 1990s, the paradigm that the only way to biologically convert ammonium into nitrogen gas was the complete oxidation of ammonium to nitrate (nitrification) followed by the reduction of nitrate to nitrogen gas (denitrification) became obsolete. Novel bacteria involved in the nitrogen cycle were identified and isolated from natural and engineered systems, which culminated in the discovery of new metabolic pathways and development of more sustainable processes for nitrogen removal. The idea of this chapter is to illustrate the most relevant innovative nitrogen removal processes and how they evolved over the years from bench-scale research to full-scale implementation.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

5.1 Introduction

The approach toward the biological treatment of wastewaters has changed several times over the years. In the 1960s and 1970s, the main concern revolved around the removal of organic material from wastewaters given its high polluting capacity in the environment. In this context, several aerobic and anaerobic systems were developed aiming at the degradation of organic compounds.

In the 1980s, it was observed that even in the absence of organic material in wastewaters, the polluting effect on the environment remained intense, notably when nitrogen compounds were present. The increase in the global population and the consequent increase in the quantity of human waste as well as the use of synthetic nitrogen fertilizers produced from atmospheric N2 by the Haber-Bosch process, intensified in the past 40 years, are two factors which have contributed significantly to enhance the pollution levels caused by nitrogen compounds.

Nitrogen removal is of crucial importance. When it is available, together with phosphorus, other important nutrient, enhanced primary production occurs, which is exemplified by the excessive growth of phytoplankton species (algal bloom). This phenomenon is referred to as eutrophication. During this process, the microbial population responsible for the degradation of organic matter originating from phytoplankton species grows exponentially, and as a consequence, the oxygen demand is substantially increased. The death of fish and other aquatic organisms by asphyxiation, an increase in the cost of treating eutrophicated waters, and even the inappropriateness of these waters for many uses are some of the consequences of eutrophication.

In this context, it became clear that the application of processes aimed at the removal of nitrogen and phosphorus was essential in order to preserve the quality of the receiving water bodies. Thus, the conventional processes for biological nutrient removal (involving nitrification and denitrification stages) began to be used extensively.

In the following decade (1990s), the increase in the installation costs of traditional technologies for wastewater treatment, the increased strictness of the limits imposed on effluent discharges (the treatment plants requiring significant modifications in order to comply with environmental regulations), the limitations of the conventional processes regarding the treatment of high-strength nitrogen wastewaters, and the appearance of innovative ideas motivated the development of new technologies for biological nitrogen removal.

During this period, novel bacteria involved in the nitrogen cycle were identified and isolated from various environments (natural or engineered bioreactors), which culminated in the development of new nitrogen removal processes. In fact, these new processes still have rather limited application compared with conventional process, particularly for operation in larger scales. However, as will be discussed in Sect. 5.2, most of them have enormous potential for use in wastewater treatment, as they were developed as an attempt to overcome the limitations of the conventional nitrification-denitrification processes encountered under certain conditions.

In comparison with physicochemical processes, such as ammonia stripping and precipitation with magnesium ammonium phosphate, the recently developed biological processes for nitrogen removal offer a considerable economic advantage. The physicochemical processes require significant quantities of chemical products and thus lead to the production of a greater amount of chemical sludge. Despite the argument that physicochemical processes can allow the recovery of ammonium, only a small quantity of the ammonium is recovered in comparison with its general use, for instance, as a fertilizer. Additionally, these techniques, in general, require a greater amount of energy than biological nitrification-denitrification processes. In view of all of these factors, biological nitrogen removal is the option most commonly recommended and used (VAN LOOSDRECHT 2008).

The new nitrogen removal processes are the subject of this chapter. Before they are presented, the new aspects related to the microbial transformation of nitrogen in the context of wastewater treatment are first discussed.

5.2 New Processes for Biological Nitrogen Removal

5.2.1 Introduction and Contextualization

Complex interactions occur between the different nitrogen species (such as ammonium, nitrite, and nitrate) and in the different transformation mechanisms. Organic nitrogen is made up of various compounds including amino acids, urea, uric acid, and nitrogen bases. By means way of hydrolysis and mineralization, organic nitrogen is converted into ammonium nitrogen. Ammonium is one of the most important nitrogen compounds in surface waters and other ecosystems for several reasons: (1) it is the preferred nutrient of various species of plants and autotrophic bacteria; (2) it is chemically reduced and thus can be easily oxidized in natural aquatic environments resulting in the consumption of dissolved oxygen; and (3) non-ionized ammonia (NH3) is toxic to several forms of aquatic life even at low concentrations (<0.2 mg/L) (KADLEC and KNIGHT 1996).

Under aerobic conditions, ammonium is oxidized to nitrite, which is further oxidized to nitrate. This process is called nitrification. Two main groups of bacteria are involved in nitrification: ammonium-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB). Nitrification (Eq. 5.1) is the first step in the conventional nitrogen removal process. The complementary step is denitrification, in which the reduction of nitrate to nitrogen gas occurs (Eq. 5.2). Equation 5.3 represents the combined process involving the two previous steps. The conventional nitrification-denitrification process is the commonly used approach for nitrogen removal in modern wastewater treatment plants. It is very efficient and, when properly operated, is stable and reliable. The operation cost is moderate and the process can be controlled relatively easily (METCALF and EDDY 2003).

Despite its extensive application, the conventional nitrogen removal process occurs very slowly, a characteristic associated with the low microbial activity and the reduced yield of this process. It is used for the treatment of wastewaters containing low concentrations of ammonium, generally less than 100 mgN/L. For the treatment of high-strength nitrogen wastewaters, such as those from anaerobic digesters, pig waste, landfill leachates, and certain industrial effluents, conventional nitrogen removal processes become limited, mainly due to sizing and operation issues. The space limitation and economic restriction are some problems which hinder the achievement of the desired performance in the larger existing treatment plants, particularly when the nitrogen load to be treated is high. Table 5.1 shows some examples of wastewaters containing high concentrations of ammonium.

The water originating from the dewatering of digested sludge is generally returned to the beginning of the treatment and mixed with the influent wastewater. On carrying out a nitrogen mass balance at the Dokhaven sewage treatment plant (Rotterdam, the Netherlands), it was observed that although the reject water contributes very little to the total flow, it corresponded to 15% of the nitrogen load (VAN DONGEN et al. 2001a; MULDER et al. 2001). A separate (sidestream) treatment of this stream rich in ammonium nitrogen, as indicated in Fig. 5.1, could reduce the nitrogen load originating from the sludge digesters and could contribute significantly to reducing the nitrogen concentration of the treatment plant effluent and allow the discharge limits to be reached.

Thus, the application of sidestream processes is particularly important when the treatment plant requires upgrading due to stricter effluent discharge standards or due to an increase in the nitrogen load. With the addition of a relatively small reactor volume, the nitrogen concentration of the effluent can be reduced. An additional advantage is that this allows for the construction of a reactor which is independent from the main treatment process, which is clearly a much simpler approach compared with modifying and expanding the existing treatment plants. Moreover, if the ammonium is not totally converted in the main treatment process, each kg of ammonium removed in the sidestream process will result in 1 kg less in the treatment plant effluent.

Landfill leachates are highly polluting and must be captured and treated. In general, the leachate is returned to the upper layer of the landfill, which leads to a reduction in the concentration of organic material. Conversely, the nitrogen concentration gradually increases, since the landfill acts as an anaerobic bioreactor (CLABAUGH 2001). Similarly, to reject water originating from dewatered sludge, some landfill leachates are characterized by a high concentration of ammonium and a low organic content (ILIES and MAVINIC 2001).

Pig wastes can be separated into two fractions: coarse and fine. The coarse fraction can be used as manure for soils while the fine fraction is treated. The composition of the fine fraction can vary depending on the separation method and the composition of the animal feed. In many cases, besides nitrogen and phosphorus, high concentrations of organic matter can be present, which is not favorable for the application of autotrophic nitrogen removal processes.

Wastewaters coming from industrial processes may contain high concentrations of nitrogen, especially when they are firstly treated in anaerobic digesters. Examples of these are the wastewaters generated in pharmaceutical plants (CARRERA et al. 2003); tanneries (MURAT et al. 2003); slaughterhouses (KELLER et al. 1997); potato, alcohol, and starch processing industries (ABELING and SEYFRIED 1993); and formaldehyde production (CAMPOS et al. 2003).

In recent years, the paradigm that the only way to biologically convert ammonium into nitrogen gas was the complete oxidation of ammonium to nitrate (nitrification) followed by the reduction of nitrate to nitrogen gas (denitrification) became obsolete. With the discovery of new metabolic pathways, more sustainable processes for nitrogen removal were developed and these have undergone continual improvement as research in this area has advanced. Among the most relevant new processes for removal of nitrogen, the following can be mentioned: partial nitrification and denitrification (SHARON, single-reactor high-activity ammonia removal over nitrite), CANON (completely autotrophic nitrogen removal over nitrite), OLAND (oxygen-limited autotrophic nitrification-denitrification), and aerobic/anoxic deammonification (DEMON). The last three are based on partial nitritation and on the relatively recently discovered anammox (anaerobic ammonium oxidation) process. The SHARON technology may also be coupled to anammox, giving rise to the so-called SHARON-anammox process.

In general, the specific application of alternatives available for the removal of nitrogen needs to be evaluated in relation to the aspects involving costs, chemical and energy requirements, operation experience, and the reliability and environmental impact of the process. However, the selection of the best alternative is usually based on the cost criteria. The new processes meet the objective of reducing the operating cost. In most new processes, the aim is to remove nitrogen via nitrite (which is used as electron acceptor) and not via nitrate as in the conventional process.

The nitritation-denitritation process (Eqs. 5.4 and 5.5) is one example of an alternative process for nitrogen removal via nitrite. It consumes less oxygen in the nitrification (partial nitrification up to nitrite) and requires less organic carbon for the denitrification (nitrite and not nitrate should be reduced to nitrogen gas) (SCHMIDT et al. 2003). Another advantage is a lower production of sludge. The application of the combined process of partial nitritation-anammox (described later in this chapter) brings even more advantages. In this combined process, organic matter is not required, since the nitrogen removal is carried out by autotrophic bacteria. This process is especially recommended for the treatment of wastewaters with a low organic carbon-to-nitrogen (C/N) ratio (RUIZ et al. 2003) and which contain high ammonium concentrations (between 100 and 5000 mgN/L) (MULDER 2003). Within this range, the autotrophic removal of nitrogen is more advantageous in relation to the conventional nitrification and denitrification process, requiring a lower amount of energy and chemical products.

In comparison with the traditional nitrogen removal process, the oxygen consumption in the nitritation-denitritation and partial nitritation-anammox processes are 25 and 60% lower, respectively. When the denitritation is applied after the nitritation process, a 40% saving can be obtained in terms of organic carbon. With the application of the anammox process downstream of the nitritation process, the saving is even greater, since this process does not require an organic carbon source (AHN 2006). HAO et al. (2001) and NIELSEN et al. (2005) note that for the treatment of highly concentrated streams, the relatively high installation cost of the combined partial nitritation-anammox processes is compensated for by the lower operating costs and by the good nitrogen removal performance.

The three processes (conventional, nitritation-denitritation, and partial nitritation-anammox), despite being very distinct in terms of oxygen and organic matter requirements, require similar levels of alkalinity, bearing in mind that 1 mol H+ is produced per mol of nitrogen converted. Thus, these processes are not associated with high costs for the pH control when the wastewater to be treated has a good buffering capacity (1 mol HCO3 − per mol of NH4).

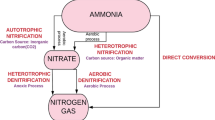

The main disadvantage of the autotrophic removal of nitrogen is the reduced growth rate of ammonium-oxidizing bacteria and anammox microorganisms. The performance of reactors in which slow-growing bacteria predominate can be improved through the application of high cell retention times. One alternative in this regard is the use of support media for the development of biofilms or the creation of conditions for the self-aggregation of the cells in the form of granules (VÁZQUEZ-PADÍN et al. 2009). Figure 5.2a, b show, in an illustrative and simplified manner, two different perspectives of the nitrogen cycle updated with the autotrophic removal of nitrogen. As can be observed, the detection of new microorganisms (such as anammox bacteria) increases substantially the complexity of the nitrogen cycle. The anammox process will be described in the next section. Further details about the new processes developed for nitrogen removal, many of them based on the anammox process, will be addressed further on in this chapter.

Schematic representation of the nitrogen cycle: (a) simplified comparison between the conventional nitrogen removal process and the anammox process; (b) main oxic and anoxic reactions involved in the nitrogen cycle. The different reactions are indicated in different colors: nitrogen fixation (dark gray), ammonification (orange), assimilation (purple), nitrification (black), denitrification (green), dissimilatory reduction of nitrate to ammonium (DNRA) (blue), and anammox (red). The dotted gray line indicates the formation of N2O by ammonium-oxidizing bacteria (adapted from Madigan et al. 2000)

5.2.2 Anammox Process

5.2.2.1 Brief History

In 1977, Engelbert Broda predicted, based on thermodynamic and evolutionary theories, that the oxidation of ammonium under anoxic conditions with nitrate or nitrite as the electron acceptor was possible (BRODA 1977). The oxidation of ammonium using an electron acceptor which is not oxygen had been previously predicted by researchers of marine environments based on mass balance studies (RICHARDS 1965) and later in combination with thermodynamic explanations (CLINE and RICHARDS 1972). These predictions were taken into consideration to some degree, although at the time few researchers were convinced that biological oxidation of ammonium could occur under anoxic conditions.

In 1985, the removal of ammonium was observed for the first time under anoxic conditions in a pilot-scale denitrifying reactor at a yeast powder production plant called Gist-Brocades, now part of the company DSM, in Delft, the Netherlands (HEIJNEN 1988; MULDER 1989; VAN DE GRAAF et al. 1990; MULDER et al. 1995). In this reactor, nitrate was added in order to obtain a combined process of sulfide oxidation and nitrate reduction. As an unexpected result, ammonium (considered not to be reactive under anoxic conditions) was also removed (MULDER et al. 1995). This new biological process was called the anammox process, an abbreviation for anoxic ammonium oxidation (MULDER 1989; VAN DE GRAAF et al. 1990) or anaerobic ammonium oxidation (MULDER 1989; VAN DE GRAAF et al. 1995), the name by which this process is most commonly known. A bench-scale reactor based on the pilot-scale denitrification reactor was run in the laboratory, and the enrichment of the organism responsible for the anammox process was achieved only after nitrite (and not nitrate) had been identified as the actual electron acceptor (VAN DE GRAAF et al. 1996).

Ten years after the first observations of the ammonium oxidation reaction under anoxic conditions in Delft (the Netherlands), in Germany (HIPPEN et al. 1996, 1997), and in Switzerland (BINSWANGER et al. 1997; SIEGRIST et al. 1998), the production of nitrogen gas instead of nitrate (leading to nitrogen loss from the liquid phase) was reported in rotating biological contactors (RBCs) treating ammonium-rich wastewaters originating from landfill leachate. Since the only electron donor present in significant quantities in these wastewaters was ammonium, it was expected that all of the nitrogen in the form of ammonium would be converted to nitrate, instead of being lost to the atmosphere in the form of N2. The conversion of soluble nitrogen compounds into N2 in these reactors was initially related to the denitrification carried out by nitrifying organisms, previously described by POTH and FOCHT (1985). Later on, it was attributed to a combination of nitrifying organisms and the bacteria responsible for the anammox process.

Anammox bacteria have been found not only in wastewater treatment plants but also in natural environments, such as in different marine ecosystems (e.g., the Black Sea) and rivers (KUYPERS et al. 2003), where they substantially influence the nitrogen cycle. Depending on the organic load, up to 70% of the N2 production in marine sediments can be attributed to the anammox process (DALSGAARD and THAMDRUP 2002).

Enriched cultures (purity of 50–90%) obtained by some researchers (SCHMID et al. 2000; EGLI et al. 2001; STROUS et al. 2006; TSUSHIMA et al. 2007a; LÓPEZ et al. 2008) were the only sources of information on the anammox process, since the numerous attempts to isolate the organisms responsible for this process had failed (STROUS et al. 1999a). In order to observe that the enriched organisms were in fact responsible for the anammox process, cells were physically purified up to 99.6% through density gradient centrifugation (Percoll method) (STROUS et al. 1999a). The fact that the purified cells were able to carry out the characteristic anammox conversion (ammonium to nitrite) at a high rate confirmed that the enriched microorganism was indeed responsible for the ammonium oxidation under anoxic conditions. The concentrated cell solution allowed the sequencing of the 16S rRNA gene, which provided evidence that the organism in question belonged to the Planctomycetes phylum (STROUS et al. 1999a) and was named Candidatus Brocadia anammoxidans.

5.2.2.2 Conversions Involved in the Anammox Process and Characteristics of the Organisms Responsible for this Process

The main substrates of the anammox process are ammonium, nitrite, and bicarbonate (HCO3 −) (VAN DE GRAAF et al. 1996). The coupling of the nitrogen atom of ammonium (electron donor) and the nitrogen atom of nitrite (electron acceptor) for the formation of nitrogen gas comprises the catabolic reaction (Eq. 5.6).

As an autotrophic biological process, HCO3 − is the carbon source for the production of biomass in the anabolic reactions (Eq. 5.7). The oxidation of nitrite to nitrate generates the electrons required for the HCO3 − reduction process (VAN DE GRAAF et al. 1996). The catabolic reaction is carried out 15 times for the fixation of one molecule of CO2 with nitrite acting as the electron donor, leading to the anaerobic production of nitrate in the anabolism. In autotrophic processes, the anoxic generation of nitrate can serve as a measure of the growth of anammox biomass and is a good indicator of the anammox activity (VAN LOOSDRECHT 2008).

The combination of catabolic (Eq. 5.6) and anabolic (Eq. 5.7) reactions using the biomass yield determined experimentally (0.066 mol C/mol NH4 +, STROUS et al. 1998) results in the following overall reaction (Eq. 5.8):

The stoichiometry of Eq. (5.8) is very close to that obtained experimentally (STROUS et al. 1998), represented in Eq. (5.9). As can be observed, ammonium and nitrite are consumed in almost equimolar proportions (1:1.3). The excess of nitrite (0.3 mol of nitrite per mol of ammonium) is oxidized anaerobically to nitrate. The electrons derived from this oxidation are probably used for the fixation of CO2 (VAN DE GRAAF et al. 1996). The main product of the anammox process is N2, although a small part of the nitrogen fed to the system is converted into nitrate. For the reduction of the nitrate produced through nitrification, organic carbon is needed, which does not present a problem since most real wastewaters contain at least a small quantity of biodegradable organic matter which can be used for this purpose.

The organisms responsible for the anammox process grow very slowly, as evidenced through the stoichiometry. The duplication time is several days under ideal operating conditions (STROUS et al. 1998; TSUSHIMA et al. 2007b). According to SCHMID et al. (2003), the duplication time is 11 days. Other authors, such as VAN DER STAR et al. (2008), have reported duplication times of between 5.5 and 7.5 days, values calculated based on the maximum conversion capacity. The same authors indicated the possibility of obtaining even shorter duplication times of around 3 days. Other researchers have reported the possibility of obtaining a duplication time of only 1.8 days under ideal operating conditions (ISAKA et al. 2006). One possible explanation for these divergent results is the method used for the determination of the growth rate. ISAKA et al. (2006) determined the growth rate based on the direct counting of the anammox bacteria, while in the other studies it was based on the biomass yield and nitrogen removal rate.

Autotrophic growth is a very costly process in terms of energy, and thus it is always associated with low growth rates when compared with heterotrophic growth. Consequently, the start-up period of the anammox process is very long and it takes a considerable time to achieve appreciable reaction rates. The use of reactors with efficient biomass retention is crucial to obtaining the enrichment of the anammox culture (JETTEN et al. 2001). The low growth rate of the anammox bacteria and the difficulty associated with obtaining enriched cultures of these microorganisms may hinder research involving the anammox process (STROUS et al. 1998). However, the low growth rate does not represent a limitation to the nitrogen removal capacity, which can reach values of 5–10 mgN/(m3 day) due to the fact that the anammox microorganisms form compact biofilms or granules, enabling high concentrations of biomass to be reached in the bioreactor.

It should be noted that the extremely slow growth of anammox bacteria cannot be explained simply by autotrophy. The energy obtained from the catabolism (calculated per mol of electrons) is comparable with that of the autotrophic nitrification process, although the growth rate is much lower. Other plausible explanations for the slow growth may be related to the fact that the anammox bacteria have a low intrinsic conversion rate (of ammonium to nitrite) or that the enrichment of the culture is carried out under non-ideal growth conditions.

There are many uncertainties regarding the reaction intermediates in the catabolism of anammox bacteria. However, there is a general consensus that hydrazine (N2H4) is an intermediate. The production of hydrazine from hydroxylamine can be used as a method to detect active anammox biomass. The oxidation of this compound to N2 is an energy-generating stage. Nitrite is not converted directly to hydrazine, but via hydroxylamine and/or nitric oxide (VAN DE GRAAF et al. 1997; STROUS et al. 2006). A schematic representation of the three possible metabolisms is illustrated in Fig. 5.3. Important enzymes involved in the process are hydroxylamine oxidoreductase (HAO), purified by SCHALK et al. (2000); hydrazine oxidase (HZO), purified by SHIMAMURA et al. (2007); and the nitrite reductases ccNir, partially purified by SCHALK (2000), and cd1Nir, found in the genome of Kuenenia (STROUS et al., 2006). Since all of these enzymes are able to carry out several reactions involving the conversion of nitrogen, it is still not clear which enzyme is responsible for a certain reaction.

Catabolic reactions of the anammox process with hydrazine acting as the main intermediate. Other potential intermediates are hydroxylamine (a), nitric oxide (b), or hydroxylamine and nitric oxide (c) (adapted from VAN DER STAR 2008)

According to VAN DONGEN et al. (2001a), the enzyme hydrazinase converts hydroxylamine into hydrazine. The hydrazine formed is oxidized by hydroxylamine oxidoreductase (HAO) to nitrogen gas, a stage in which four protons and four electrons are released. When nitrite is present in the system, the four electrons released allow the conversion of nitrite into hydroxylamine by the enzyme nitrite reductase. When nitrite is not present in the system and the anammox process is operated under limited nitrite conditions, the electrons leave the system in a different way. This process generally occurs through the reaction of hydrazine disproportionation to ammonium and nitrogen gas according to reaction 5.10.

The disintegration of hydrazine occurs more slowly than the formation of hydroxylamine. As a consequence, hydrazine accumulates in the system. Since the disintegration of hydrazine into ammonium and nitrogen gas occurs, ammonium is expected to accumulate in the system.

It should be noted that while N2O is usually the intermediate compound associated with denitrifying bacteria, this compound is not part of the physiology of anammox bacteria. This means that this powerful greenhouse gas is not produced by the anammox organisms.

The main compartment of anammox bacteria is anammoxosome. Anammoxosome is surrounded by riboplasm (where the ribosomes and chromosomes are located), which in turn are surround by the paryphoplasm (LINDSAY et al. 2001; VAN NIFTRIK et al. 2008), as shown in Fig. 5.4. Considering that there is no consensus regarding the characteristics of the membrane between the paryphoplasm and the riboplasm, the classification of the paryphoplasm (whether as a true internal compartment or as a region which is similar to the periplasm in Gram-negative bacteria) is still a matter under debate.

Schematic representation of the different compartments of anammox bacteria (adapted from LINDSAY et al. (2001) and FUERST (2005)). The cytoplasm is divided into the paryphoplasm (external compartment), the riboplasm (where ribosomes and chromosomes are found), and the anammoxosome (where most or all of the cytochrome c is present and catabolism probably occurs)

Microscopic observations suggest that the anammox bacteria, as in the case of other Planctomycetes, do not have peptidoglycans, although they exhibit a protein cell membrane. The lipids of the anammox bacteria contain a combination of fatty acids bound to esters (a typical characteristic of bacteria and eukaryotic cells) and ethers (typically found in Archaea). Lipid membranes are essential for the establishment of gradients of ions and metabolites. The anammox bacteria contain a variety of membrane lipids which are quite special and unique in nature (SINNINGHE DAMSTÉ et al. 2002, 2005; KUYPERS et al. 2003). The anammox cells are spherical shaped (coccus) and have a diameter of less than 1 μm. The anammox biomass presents a reddish brown color (Fig. 5.5), which is probably due to the high content of cytochromes (JETTEN et al. 1999).

The anammoxosome has been considered as the locus of catabolism, with the function of generating energy, in a way analogous to the function of mitochondria in eukaryotic cells (LINDSAY et al. 2001; VAN NIFTRIK et al. 2004). This hypothesis implies that the proton-motive force is created through the anammoxosome membrane for the coupling of energy generation and anabolism. The presence of important enzymes (hydrazine/hydroxylamine oxidoreductase) in the anammoxosome indicates that the anammox catabolism occurs in this compartment.

A biochemical model (Fig. 5.6) has been proposed in which the anaerobic oxidation of ammonium is catalyzed by various c-type cytochromes and proteins (STROUS et al. 2006). In this model, nitrite is firstly reduced to nitric oxide by a c-type cytochrome and d1-type cytochrome containing the enzyme nitrite reductase (NirS). It is assumed that the nitric oxide and ammonium are combined, forming hydrazine through the action of hydrazine hydrolase, and this compound is finally oxidized to nitrogen gas by a c-type cytochrome protein called hydrazine/hydroxylamine oxidoreductase (SCHALK et al. 2000; SHIMAMURA et al. 2007). The four electrons derived from this oxidation are transferred to the cytochrome c electron carriers (CIRPUS et al. 2005; HUSTON et al. 2007), to ubiquinone, to cytochrome bc1 complex, to cytochrome c electron carriers, and finally to nitrite reductase and hydrazine hydrolase.

Biochemical model representing anaerobic oxidation of ammonium coupled with the anammoxosome membrane in anammox bacteria, resulting from the proton-motive force and subsequent synthesis of ATP via ATPases bound to the membrane. bc1 cytochrome bc1 complex, cyt cytochrome, hao hydrazine/hydroxylamine oxidoreductase, Q coenzyme Q, a anammoxosome compartment, r riboplasm compartment (adapted from STROUS et al. 2006)

In this model, the anammox reaction establishes a proton gradient through the translocation of protons from the riboplasm to the anammoxosome, which results in an electrochemical proton gradient directly from the anammoxosome to the riboplasm. This gradient contains chemical potential energy (chemical proton gradient in the form of a difference in the pH in which the riboplasm is more alkaline compared with the anammoxosome) and electrical potential energy (electrical proton gradient in the form of a difference in the charge considering that the riboplasm is negatively charged in relation to the anammoxosome). The differences in both the pH and charge cause a proton displacement from outside to inside the anammoxosome, providing the proton-motive force. This mechanism can be used for the synthesis of ATP catalyzed by adenosine triphosphatases (ATPases) located in the anammoxosome membrane, as shown in Fig. 5.6. The protons passively move back to the riboplasm (due to the electrochemical proton gradient) through the pores formed by the ATPases. The globular and hydrophobic domain of the ATPases where ATP is synthesized will be located in the riboplasm, and its hydrophobic domain where protons are translocated will be located in the anammoxosome membrane. The ATP synthesized will be released into the riboplasm.

The anammox bacteria are dependent on the electrochemical ion gradient through the membrane for ATP synthesis. Since the anammox catabolism is slow, only a few protons are translocated within a certain time, while the dissipation of the electrochemical gradient resulting from the passive diffusion is independent of the growth rate and proceeds at the normal rate. Thus, the passive diffusion of protons through the membrane is relatively important and leads to a greater energy expenditure in the case of anammox bacteria. To give an idea, the expenditure due to the passive diffusion of protons in mitochondria corresponds to 10% (HAINES 2001). Thus, it is clear that the presence of a special, less permeable membrane is essential for the metabolism of anammox cells. Additionally, the intermediates of the anammox reaction, such as hydrazine, easily diffuse through the membrane.

From a bioenergy perspective, the loss of energy associated with the loss of one hydrazine molecule from the anammox cell is equivalent to 15 catabolic cycles. The explanation for this is as follows: when one molecule of hydrazine is lost, the hydrazine reserve needs to be reestablished. Presumably, hydrazine is formed via the reduction of nitrite to nitric oxide and the subsequent combination of nitric oxide with ammonium. The equivalents required (four electrons) must come from the oxidation of the reserve material, such as glycogen, which is derived from CO2. Considering that only one molecule of CO2 is fixed for every 15 mol of ammonium oxidized (15 catabolic cycles), a 10% loss of hydrazine would cause a complete loss of cell viability. Thus, the limitation of the diffusion of both protons and anammox intermediates is extremely important for the metabolism of anammox bacteria. Since anammox catabolism occurs in the anammoxosome, the lipid membrane of this compartment (described previously) needs to have a rigid structure in order to limit the diffusion of intermediates which are important to the process outside the anammoxosome. This is actually a specific adaptation of anammox bacteria for their unusual metabolism.

Due to the dense structure of the anammoxosome membrane, specific transporters are required to regulate the transport of ammonium and nitrite. The genome of Candidatus Kuenenia stuttgartiensis (one of the species of anammox bacteria, as will be described below) encodes four ammonium transporters (Amt), four formate/nitrite transporters (FocA), and two nitrate/nitrite transporters (NarK) of unknown location (STROUS et al. 2006).

While the anammoxosome membrane must be rigid, the cytoplasmic membrane must be flexible and permeable for the maintenance of homeostasis, controlling the intracellular ion concentrations and transport processes. Thus, with a rigid anammoxosome membrane and a flexible cytoplasmic membrane, the cell can overcome a problem associated with the presence of only one membrane, which would have to be impermeable and permeable at the same time. Moreover, the use of an intracytoplasmic compartment (anammoxosome) for the synthesis of ATP through the proton-motive force results in complete control of this force, allowing efficient energy transduction.

Until now, four genera of anammox bacteria have been described. The similarity of the 16S rRNA gene sequences of the species varies between 87 and 99% (SCHMID et al. 2007). Despite this relatively large phylogenetic distance, all of the anammox organisms belong to the same family, called Anammoxaceae (JETTEN et al. 2008), forming a monophyletic group belonging to the phylum Planctomycetes (STROUS et al. 1999a). One characteristic of Planctomycetes is its unusually high level of cellular organization, each cell consisting of one or more internal compartments bound by membranes with variable and unknown functions (LINDSAY et al. 2001; FUERST 2005).

The different anammox bacteria include those which have been enriched from activated sludge reactors, such as Candidatus Kuenenia stuttgartiensis (SCHMID et al. 2000), Candidatus Brocadia anammoxidans (STROUS et al. 1999a), Candidatus Brocadia fulgida (KARTAL et al. 2004), and Candidatus Anammoxoglobus propionicus (KARTAL et al. 2007), as well as those detected in marine environments, particularly in sediments and zones with minimal oxygen content, such as Scalindua brodae, Scalindua wagneri, and Scalindua sorokinii (SCHMID et al. 2003).

Since none of the anammox bacteria have been obtained as a pure culture, all of the species take the name Candidatus. Brocadia and Kuenenia have been generally enriched in laboratory experiments using a synthetic medium similar to that employed by VAN DE GRAAF et al. (1996) regardless of the inoculum used (SCHMID et al. 2000; VAN DONGEN et al. 2001b; CHAMCHOI and NITISORAVUT 2007). The addition of fatty acids was reported to lead to the enrichment of Anammoxoglobus (KARTAL et al. 2007) and Brocadia fulgida (KARTAL et al. 2004, 2008). Despite the considerable diversity in different enrichment systems, Scalindua sorokinii is the dominant species in marine environments.

Some studies have indicated that besides the conversion of ammonium and nitrite, anammox bacteria belonging to the genera Brocadia, Anammoxoglobus, and Kuenenia are also able to metabolize fatty acids such as propionate, acetate, and formate (GÜVEN et al. 2005; KARTAL et al. 2008). The oxidation of these fatty acids to CO2 is coupled with the reduction of nitrate (via nitrite) to ammonium. Thus, the anammox bacteria are able to produce their own substrate (ammonium and nitrite) for their catabolism (Fig. 5.7).

Metabolic versatility of anammox bacteria. Besides the conversion of ammonium and nitrite (solid lines), anammox bacteria can use short-chain fatty acids as electron donors for ammonification (dashed lines) (adapted from VAN DER STAR 2008)

It is still unknown whether the conversion of nitrate to ammonium represents an additional catabolic reaction, which would constitute an energy source. Surprisingly, studies have indicated that the fatty acids are not incorporated into the biomass, being completely converted into CO2 (KARTAL et al. 2008). Bearing in mind that the anammox bacteria also carry out the fixation of CO2 via acetate (the reverse reaction in relation to the previously described acetate oxidation), this characteristic is rather surprising, although already established for anammox bacteria.

In addition to the conversion of fatty acids, Kuenenia stuttgartiensis has been shown to be able to oxidize Fe2+ to Fe3+ using nitrate as the electron acceptor, as well as to reduce Fe3+ to Fe2+ and Mn4+ to Mn2+ using formate as an electron donor (STROUS et al. 2006). As in the case of the fatty acids conversion, the metabolism and the growth on these substrates are unknown.

5.2.2.3 Factors Influencing Anammox Bacteria Activity

5.2.2.3.1 Substrates and Products

The concentration of nitrite is an important parameter that needs to be controlled in the anammox process. However, a certain concentration of nitrite is required during the start-up of the anammox system. If the concentration of nitrite is very low, substrate limitation may lead to a low growth rate. On the other hand, a very high concentration can lead to inhibition. Several ranges of nitrite concentration which can cause inhibition have been reported in the literature, and thus there is no consensus observed in the previous studies.

STROUS et al. (1999b) observed that the anammox process (using Candidatus Brocadia anammoxidans) was completely inhibited when the nitrite concentration was higher than 100 mgN/L. DAPENA-MORA et al. (2007) observed that 350 mgNO2-N/L caused 50% inhibition of the anammox process. FUX (2003) maintained the nitrite concentration at around 40 mgN/L for several days and observed an irreversible inactivation of anammox bacteria. To restore the anammox activity due to inhibition by nitrite, trace amounts of intermediates of the anammox process, such as hydroxylamine and hydrazine, were added, even after long periods of exposure to high nitrite concentrations (STROUS et al. 1999b).

In this regard, studies have shown that the nitrite tolerance differs according to the genera of the anammox bacteria. EGLI et al. (2001) carried out experiments with Candidatus Kuenenia stuttgartiensis and observed that the anammox process was only inhibited when submitted to nitrite concentrations higher than 182 mgN/L. The experiments carried out by STROUS et al. (1999b) showed that with an increase in the nitrite concentration, the stoichiometry of the process changed. The stoichiometry of the ammonium and nitrite consumption increased from 1.3 g of nitrite per gram of ammonium (when the nitrite concentration was 0.14 gN/L) to almost 4 g of nitrite per gram of ammonium (when the nitrite concentration was 0.7 gN/L).

The significant change in the stoichiometry at high nitrite concentrations suggests that the microorganisms, when submitted to these conditions, do not use only ammonium as the electron donor, but they must also generate an internal electron donor to reduce the nitrite. A change in the stoichiometry has also been observed at high temperatures. DOSTA et al. (2008) reported nitrite-to-ammonium consumption ratios of 1.38:1 at 30 °C and 1.05:1 at 18 °C.

STROUS et al. (1999b) reported that the anammox process is not inhibited by ammonium or by nitrate at concentrations below 1 gN/L. However, DAPENA-MORA et al. (2007) observed a 50% drop in activity at high concentrations of ammonium and nitrate (770 and 630 mgN/L, respectively). Considering that chemolithoautotrophic organisms essentially use inorganic carbon as a carbon source, the influent concentration of bicarbonate is an important factor which can affect the enrichment of the anammox culture.

DEXIANG et al. (2007) observed low anammox activity at low bicarbonate-to-ammonium ratios (2.3:1). The reduction in the activity under these conditions may be due to the limitation of CO2. On the other hand, a high bicarbonate concentration (bicarbonate-to-ammonium ratio of 4.7:1) can also lead to inhibition. In this case, the inhibition is related to the formation of significant quantities of free ammonia due to the increase in the pH to values above 8.

5.2.2.3.2 Oxygen

Anammox bacteria are strictly anaerobic and are inhibited by the presence of dissolved oxygen in the medium. The inhibition caused by low oxygen concentrations has been described in several reports in the literature as being reversible. Based on experiments in which oxygen was provided intermittently, STROUS et al. (1997) concluded that the anammox process was reversibly inhibited by oxygen, which would make it possible to obtain partial nitritation and anammox in a single reactor. EGLI et al. (2001) affirmed that the anammox metabolism is reversibly inhibited at low oxygen levels (0.25–2% of air saturation) although it is probably irreversible at high levels (>18% of air saturation).

5.2.2.3.3 Organic Carbon

The treatment of landfill leachates and effluents from sludge digesters, which contain a high concentration of nitrogen, can be carried out through the new nitrogen removal processes, such as the combined partial nitritation-anammox. However, besides the substantial amount of nitrogen, these wastewaters may also contain a high concentration of organic matter. Nevertheless, they are considered to be potentially treated in an anammox system. During anaerobic digestion, organic matter is easily biodegraded and converted into biogas. Thus, only the portion with low biodegradability remains in the digester effluent.

RUSCALLEDA et al. (2008) observed that anammox bacteria and denitrifying organisms can coexist and are important for the treatment of wastewaters with high concentrations of slowly biodegradable organic matter, such as digester effluent and leachates. In these wastewaters, in particular, the growth of denitrifying heterotrophic organisms is limited by the low availability of easily biodegraded organic carbon. As a consequence, these microorganisms cannot become dominant and do not hamper the growth of anammox organisms.

However, in several studies reported in the literature, a negative effect of the presence of organic matter on the growth of anammox bacteria was observed (JETTEN et al. 1999; MOLINUEVO et al. 2009; TANG et al. 2010). In the presence of certain quantities of organic matter, the slow-growing anammox bacteria are no longer able to compete with the denitrifying organisms for nitrite, given the higher growth rate of the latter. Furthermore, the denitrification reaction is thermodynamically more favorable than the anaerobic oxidation of ammonia, since the Gibbs free energy of anammox and denitrification reactions are of the order of −355 kJ/mol (JETTEN et al. 1999) and −427 kJ/mol (RITTMANN and MCCARTY 2001), respectively. Thus, the denitrifying heterotrophs will grow more rapidly when organic carbon is present in combination with ammonium and nitrite, hindering the development of anammox microorganisms.

As in the case of nitrite, there is no consensus in the literature regarding the concentration of organic matter at which denitrifying microorganisms hamper the growth of anammox bacteria. CHAMCHOI et al. (2008) reported that concentrations of organic matter above 300 mg/L (in terms of COD) or COD/N ratios greater than 2 caused the inactivation of anammox organisms in a UASB reactor fed with milk with a high fat content as a source of organic carbon. TANG et al. (2010) reported that the denitrifying microorganisms began to dominate the system when a high COD/NO2-N ratio (2.9:1) was applied. MOLINUEVO et al. (2009) observed complete inhibition of the anammox process when the COD was 292 mg/L.

Since the anammox process removes only 90% of the nitrogen present in the form of ammonium/nitrite and 10% of the nitrogen remains in the effluent in the form of nitrate, the coexistence of anammox and denitrifying organisms is favorable. Under anoxic conditions, nitrate can be reduced to nitrite by denitrifiers, and nitrite can then be used by anammox bacteria for the anaerobic oxidation of ammonium (KUMAR and LIN 2010).

It should be noted that not all types of organic matter can be used in processes in which anammox and denitrifying bacteria coexist. As reported by GÜVEN et al. (2005), the anammox activity is completely and irreversibly inhibited by methanol and ethanol. This aspect needs to be taken into consideration, given that methanol is commonly used to remove nitrate in post-denitrification systems. Inhibition by methanol may be caused by the formation of formaldehyde by the enzyme hydroxylamine oxidoreductase (PAREDES et al. 2007).

On the other hand, some carbon sources do not have an inhibitory effect on the anammox activity. Therefore, they can be used by anammox bacteria. As mentioned in Sect. 5.2.2.2, where the different types of anammox metabolisms were described, some genera of anammox bacteria are able to oxidize acetate and propionate.

Studies regarding the adaptation of anammox bacteria to wastewaters containing toxic components have also been described in the literature. TOH and ASHBOLT (2002) and TOH et al. (2002) observed the acclimation of anammox organisms to a synthetic medium simulating a coke oven effluent, which contained not only a high concentration of organic compounds (COD of 2000–2500 mg/L) but also some chemical compounds such as phenol (300–800 mg/L), cyanides (10–90 mg/L), and thiocyanates (300–500 mg/L). The initial attempt to enrich the anammox bacteria failed, although the gradual addition of 50–500 mg/L of phenol allowed the adaptation of these organisms.

5.2.2.3.4 Temperature and pH

A pH range of 6.7–8.3 is considered to be ideal for anammox bacteria, with an optimum value of 8.0 (STROUS et al. 1999b). The ideal temperature is between 30 and 40 °C (STROUS et al. 1999b; EGLI et al. 2001). Experiments carried out by DOSTA et al. (2008) to evaluate the short-term effect of temperature on the anammox activity showed that the maximum non-adapted anammox biomass activity was obtained at between 35 and 40 °C, while a temperature of 45 °C caused an irreversible decrease in the anammox activity due to cell lysis. Small differences in the optimum temperature were found for K. stuttgartiensis (40 °C) and B. anammoxidans (37 °C) (STROUS et al. 1999b; EGLI et al. 2001).

Although the optimum temperatures for the anammox process are relatively high, CEMA et al. (2007) and ISAKA et al. (2006) managed to operate the anammox process in a rotating biological contactor (RBC) and an anaerobic biofilter, respectively, at a temperature of 20 °C. The gradual adaptation of the biomass appears to be a key factor in successfully operating the anammox process at temperatures lower than those considered ideal for the process (SZATKOWSKA and PLAZA 2006).

In order to start up the anammox system at low temperatures, one strategy is to produce the desired quantity of biomass in a separate reactor, which should be operated at temperatures close to those considered ideal. Later, the biomass can be gradually adapted to lower temperatures in the same reactor, and finally the adapted biomass can be inoculated into the reactor maintained under low temperature conditions (DOSTA et al. 2008).

Some researchers who have carried out studies on samples of anammox bacteria originating from sediments have reported anammox activity at low temperatures, suggesting that local environmental factors influence the characteristics of these bacteria. RYSGAARD et al. (2004) observed anammox activity in artic sediments at a temperature ranging from −1.3 to 30 °C. The optimum temperature was found to be 12 °C. Similar results were obtained by DALSGAARD and THAMDRUP (2002), who observed an optimum temperature of 15 °C for marine sediments from the Baltic Sea.

It should be noted that, in contrast to anammox bacteria in wastewater treatment systems, anammox bacteria in marine environments are dependent on another process to obtain the nitrite required in the process. In marine environments, nitrate is much more abundant than nitrite, and thus the anammox process requires an additional step for the reduction of nitrate to nitrite. Since the dissolved oxygen concentration decreases progressively through the sediment, in the deeper layers, nitrate reducers can cause the accumulation of nitrite, allowing the occurrence of the anammox process (DALSGAARD et al. 2005).

Although the physical properties of sludge and the bacterial populations can remain constant during the reactor operation at lower temperatures, the nitrogen conversion rate is substantially reduced. This drawback can be minimized by applying a strategy described by ISAKA et al. (2006), who achieved a high nitrogen conversion (8.1 kgN/(m3 day)) through reducing the hydraulic retention time (HRT) and adding appropriate and non-inhibiting concentrations of nitrite to the influent.

5.2.2.3.5 Biomass Concentration

The anammox activity is highly influenced by the biomass concentration. According to STROUS et al. (1999b), anammox bacteria are only active when the cell concentrations are greater than 1010–1011 cells/mL, even in highly enriched cultures. It is possible that the presence of contaminant cells, 1 in 200–500, is required to sustain the growth, since these cells could ensure vitamin supplementation and the removal of toxic components (KUENEN and JETTEN 2001).

PYNAERT et al. (2004) described a hypothesis in which the presence of ammonium-oxidizing bacteria is required for the reactivation of anammox organisms after the biological system has undergone some disturbances. Through the production or accumulation of hydroxylamine or hydrazine by the bacteria responsible for the oxidation of ammonium, anammox bacteria can reactive their metabolism. Once the process is reestablished, the tendency is that the ammonium-oxidizing bacteria do not participate in the anammox process. This supposition has also been described by STROUS (2000) based on the fact that the addition of the intermediates hydroxylamide and hydrazine was needed in order to restart the anammox process after its inhibition.

5.2.2.3.6 Suspended Solids

Flocculating agents are generally used to remove organic and inorganic colloidal substances from wastewaters prior to the anammox process. The effect of these flocculants on the anammox process was the focus of a study carried out by DAPENA-MORA et al. (2007). Concentrations of up to 1 g/L of a positively charged polymeric compound used as a flocculant did not have a negative effect on the anammox activity.

In a study carried out by YAMAMOTO et al. (2008), a large amount of influent suspended solids present in partially nitrified digested liquid adhered to the material covering the anammox biomass, which was growing on a support material. Consequently, the anammox activity decreased and the performance was significantly adversely affected. The use of a flocculant improved the settleability of the influent suspended solids and reduced its accumulation in the reactor. However, the flocculant was also retained on the surface of the support media, leading to a reduction in the anammox activity.

The precipitation of salts can also lead to the unstable operation of anammox reactors. TRIGO et al. (2006) operated an anammox reactor with membranes, which functioned as a barrier to retain inorganic salts which precipitated and accumulated in the biomass. The precipitation of these salts on the biomass surface led to a reduction in the nitrogen removal from 100 to 10 mg/(L day).

5.2.2.3.7 Light and Reactor Mixing Velocity

A study carried out by VAN DE GRAAF et al. (1996) indicated that anammox bacteria are sensitive to visible light. These authors observed a decrease in the anammox activity from 30 to 50%. The results influenced the operating conditions and thus the reactors were covered to avoid the negative effect of light. The effect of shear stress on the anammox process was evaluated by ARROJO et al. (2006), who observed that stirring velocity of up to 180 rpm did not have a negative effect on the performance of the anammox process. However, when the stirring speed was increase to 250 rpm, the anammox activity and the average diameter of the flocs were reduced by 40% and 45%, respectively. In addition, an accumulation of nitrite was observed under these conditions.

5.2.2.4 Application of Anammox Process

The anammox process offers several advantages for the removal of ammonium from wastewaters. In conventional systems, ammonium is removed through nitrification (oxidation of ammonium to nitrate) followed by denitrification (reduction of nitrate to nitrogen gas). The anammox process should always be combined with a partial nitritation process, in which half of the ammonium is oxidized to nitrite (and not to nitrate). The nitrite produced reacts with the remaining ammonium to form nitrogen gas. The main advantages of the combined autotrophic process of partial nitritation + anammox are:

-

Lower energy requirement considering the lower aeration costs.

-

An organic carbon source (external oxidant) is not required, which leads to a lower production of sludge with a consequent reduction in the sludge disposal costs.

-

Absence of CO2 emissions due to the autotrophic nature of the nitritation and anammox processes (CO2 is consumed and not produced).

The anammox process is especially appropriate for the treatment of wastewaters containing high concentrations of ammonium but with low organic content. Given that the anammox bacteria are characterized by their interaction with other bacteria, since they require nitrite generated by another microbial group, two main reactor configurations are possible for the removal of ammonium through the anammox process:

-

1.

A system comprised of two reactors (Fig. 5.8a) in which part of the ammonium is firstly oxidized to nitrite (partial nitritation) in the reactor maintained under aeration. Subsequently, the ammonium/nitrite mixture is sent to the second reactor, maintained under anoxic conditions, where it is subjected to the anammox process (VAN DONGEN et al. 2001b). The partial nitritation process can be carried out in a SHARON (single-reactor high-activity ammonia removal over nitrite) system, which will be described in detail below.

Fig. 5.8 Removal of ammonium through the anammox process carried out with two-reactor configurations: (a) two-reactor configuration, nitritation occurs in the first reactor (aerated) and the anammox process in the second reactor (anoxic); (b) both processes occur in the same aerated reactor (adapted from VAN DONGEN et al. 2001b)

-

2.

A configuration comprising only one reactor (Fig. 5.8b), in which partial nitritation and the anammox process occur in the same reactor, maintained under aeration. In this configuration the nitrification occurs in the aerobic region of the floc or granule, while the anammox reaction occurs in the deepest zone of the biofilm, maintained under anoxic conditions (HIPPEN et al. 1997; KUAI and VERSTRAETE 1998). The alternation of aerobic (aeration on) and anoxic (aeration off) periods is another approach to achieving nitritation and anammox reactions in a single reactor.

Currently, the anammox process is employed in both configurations for the removal of ammonium from sludge digester effluents, leachates, and different industrial wastewaters. Besides the application of the anammox process for the removal of ammonium, the combined removal of ammonium and nitrate has also been employed in laboratory scale (KALYUZHNYI et al. 2006; PATHAK et al. 2007). In this process, partial denitrification (reduction of nitrate to nitrite) is coupled with the anammox process. In cases where the electron donors for the denitrification consist of fatty acids, the anammox bacteria are able to carry out the reduction of nitrate (GÜVEN et al. 2005). In the next section, the two systems (two reactors and single reactor) aimed at partial nitritation and anammox will be described, with emphasis on the different types of reactors used and the practical implementation of these systems.

5.2.2.4.1 Partial Nitritation and Anammox in Two Separate Reactors (Two Stages)

The combined process of partial nitritation and anammox in two separate reactors makes use of the advantages of the first process to carry out the conversion of half of the ammonium only up to nitrite (and not up to nitrate), providing the substrates required for the anammox process (ammonium and nitrite) in proportions suitable for the generation of nitrogen gas.

One of the challenges during the operation of the first reactor is obtaining an effluent with an ammonium-to-nitrite ratio similar to the stoichiometric ratio of 1:1.32, proposed by STROUS et al. (1998) to represent the anammox reaction. In practice, however, this ratio should be close to 1:1 in order to prevent inhibition by nitrite and provide an excess of ammonium. Given that there is no need for organic compounds or anoxic periods, a partial nitritation reactor can provide the desired ammonium/nitrite mixture, without the need to control the refeeding. One factor which makes this conversion possible is that after 50% of the ammonium has been oxidized the decrease in the pH hinders the oxidation of the residual ammonium.

By limiting the supply of oxygen in a nitrifying reactor with sludge retention, the same results can be obtained, although control of the refeeding may be required (STROUS et al. 1997). It is important that the composition of the anammox reactor influent remains constant, considering the toxicity of nitrite, regardless of the strategy used to obtain adequate proportions of ammonium and nitrite in the first reactor (partial nitritation).

The application of the two-reactor configuration is particularly appropriate when biodegradable organic compounds and toxic compounds are present, since these are degraded in the step prior to partial nitritation and do not reach the anammox reactor (VÁZQUEZ-PADÍN et al. 2009; LACKNER et al. 2008).

As previously mentioned, nitrogen removal based on partial nitritation with the anammox process offers many advantages. Besides the fact that the external addition of carbon is not required, it generates a low quantity of sludge and requires 40% less oxygen than the conventional process, which leads to energy savings (AHN 2006). Furthermore, the operation of a system comprised of two separate reactors (one for partial nitritation and one for the anammox process) is more flexible in comparison with the configuration in which both processes occur in a single reactor. Additionally, since the two processes occur in different units, the process performance is more stable (WYFFELS et al. 2004). Detailed description of the operating conditions required to achieve partial nitritation and anammox conversions is provided below.

5.2.2.4.1.1 Partial Nitritation

In this section, firstly the factors which affect the nitrification process will be presented, some of which, or their combination, represent the basis of the development of partial nitritation technologies. Several studies on this subject will then be described.

In practice, all of the factors involved in achieving partial nitritation are related to the inhibition or limitation of the second stage of nitrification (nitratation or the formation of nitrate). The crucial point in the control of partial nitrification is to obtain a nitrifying reactor with the stable accumulation of nitrite. In order to force biological processes to follow the nitrite route, different strategies have been used (BERNET et al. 2005), which include controlling the temperature, hydraulic retention time, pH, dissolved oxygen, and presence of free ammonia. Table 5.2 details how these factors influence the growth and activity of the microorganisms responsible for nitrification.

One approach to achieving partial nitrification is based on the difference in the activation energies of ammonium (68 kJ/mol) and nitrite (44 kJ/mol) oxidation. The high activation energy of the ammonium oxidation reaction leads to the velocity of this process having a greater degree of dependence on the temperature in comparison with the nitrite oxidation reaction. Only at temperatures above 25 °C is it possible for ammonium-oxidizing bacteria to become dominant to the detriment of nitrite-oxidizing bacteria (VAN DONGEN et al. 2001a; BROUWER et al. 1996). If this condition is combined with a low hydraulic retention time and low cell retention time, the bacteria which oxidize nitrite can be selectively washed out of the system (HELLINGA et al. 1998).

The pH has a strong influence on the system due to the fact that at low values of this parameter the nitrite-oxidizing bacteria grow more rapidly than the ammonium-oxidizing bacteria. Thus, the hydraulic retention times (or dilution rate) required to maintain the ammonium oxidizers and wash out the nitrite oxidizers are more flexible at higher pH values (HELLINGA et al. 1998).

In relation to the pH ranges considered ideal for nitrification, some main effects of this parameter on nitrifying bacteria have been identified: activation/deactivation of nitrifying bacteria, nutritional effects associated with the alkalinity and inorganic carbon species, and inhibition by ammonium and nitrous acid (VILLAVERDE et al. 1997). The activation/deactivation of nitrifying bacteria is related to the binding of H+ or OH− ions to enzyme groups, blocking the active sites in a reversible manner (QUINLAN 1984). Nutritional effects are mainly associated with the availability of inorganic carbon, which is essential for autotrophic nitrifying microorganisms. At low pH values, the CO2 species predominate which can be easily removed from water by way of stripping. On the other hand, at high pH values, inorganic carbon is present mainly in the form of carbonate, which is rarely assimilated.

The presence of free ammonia and nitrous acid is strongly associated with the pH value of the medium. The pH affects the substrate concentration in both stages of nitrification, modifying the acid-base equilibrium. With an increase in the pH, for instance, greater concentrations of free ammonia are present in the medium, which can inhibit both the ammonium-oxidizing bacteria and the nitrite-oxidizing bacteria. A reduction in the pH, however, favors the presence of nitrous acid. Both the free ammonia and the nitrous acid can inhibit ammonium-oxidizing and nitrite-oxidizing microorganisms, although the latter are more sensitive than the former, especially in the presence of free ammonia.

Another strategy aimed at avoiding the development of nitrite-oxidizing bacteria and promoting the accumulation of nitrite is to reduce the concentration of dissolved oxygen in the medium. This approach is based on the fact that nitrite-oxidizing bacteria are more sensitive to low dissolved oxygen concentrations in the medium than ammonium-oxidizing bacteria, which have less affinity for oxygen. The oxygen saturation coefficients (Monod kinetics) for the oxidation of ammonium and nitrite are 0.3 and 1.1 mg/L, respectively (WEISMANN 1994).

A possible mechanism for the inhibition of nitrite oxidation caused by low oxygen concentrations is based on the accumulation of hydroxylamine, an intermediate product in ammonium oxidation. In general, ammonium-oxidizing bacteria obtain energy by way of ammonium oxidation to nitrite in a two-step reaction, with hydroxylamine (NH2OH) as an intermediate. The first step is the oxidation of ammonium, catalyzed by the enzyme ammonia monooxygenase, while the second step involves the oxidation of hydroxylamine, catalyzed by the enzyme hydroxylamine oxidoreductase. At low oxygen concentrations and high ammonium concentrations, the accumulation of hydroxylamine can occur, which can inhibit the nitrite-oxidizing microorganisms starting from concentrations of 250 μM. Concentrations above 2000 μM can also lead to the inhibition of ammonium-oxidizing bacteria. Equations 5.11–5.13 represent the accumulation of hydroxylamine under oxygen-limiting conditions (YANG 1990).

From these equations it can be observed that the four electrons generated from the oxidation of hydroxylamine can be transferred to the oxidation of ammonium when the reduction of the terminal oxygen is interrupted, due to the oxygen deficiency aimed at balancing the number of electrons of this redox reaction (YANG 1990). In a study carried out by HU (1990), the hydroxylamine caused a severe inhibition of Nitrobacter, suggesting that nitrite may be accumulated in nitrifying systems. However, hydroxylamine has been practically ignored in terms of nitrification processes, since its concentration is considered to be insignificant.

YANG and ALLEMAN (1992) studied the possibility of hydroxylamine accumulation and its relation to the accumulation of nitrite in a batch system containing a nitrifier-enriched culture. The results obtained by these authors indicated that the quantity of nitrite accumulated increased with an increase in pH, and this was directly related to an increase in the non-ionized hydroxylamine. Hydroxylamine was considered to be the main cause of nitrite accumulation in a nitrifying system maintained under conditions of low dissolved oxygen concentrations and high pH.

Several studies aimed at obtaining nitrification through controlling the dissolved oxygen have been carried out, both in suspended biomass and biofilm systems (Table 5.3). In the case of systems with suspended biomass operated under oxygen-limiting conditions, the complete and stable conversion of ammonium into nitrite was obtained, regardless of the sludge age. However, the sludge age became a critical parameter for obtaining partial nitrification when the operation was not carried out under oxygen-limiting conditions. YANG and ALLEMANN (1992) concluded that a combination of parameters, such as the concentrations of free ammonia, dissolved oxygen, and hydroxylamine, comprise the main factors involved in the accumulation of nitrite in a batch system containing a nitrifier-enriched culture.

As indicated in Table 5.3, the results obtained in biofilm systems are similar to those obtained in reactors with suspended biomass. In general, low oxygen concentrations lead to an accumulation of nitrite. However, in biofilm systems, the nitrite-oxidizing bacteria can be further adversely affected by the actual stratification of the biofilm. In most cases, ammonium-oxidizing bacteria are located in the most external regions of the biofilm, while the nitrite oxidizers are found in a deeper layer (KIM et al. 2003). This spatial distribution means that the nitrite-oxidizing bacteria are more exposed to oxygen-limiting conditions compared with the ammonium oxidizers.

The main reactors used to date to obtain partial nitritation are the continuous stirred-tank reactor (CSTR), membrane bioreactors (MBRs), and sequencing batch reactors (SBRs). In the MBR and SBR, high cell retention times (50–75 days) can be obtained (STROUS et al. 1997). In MBR systems and in other biofilm systems, the cell retention time is difficult to control, in contrast with reactors in which the biomass grows in suspension. Thus, it is difficult to force the washout of nitrite-oxidizing bacteria even under oxygen-limiting conditions (XUE et al. 2009) and the production of nitrite without the accumulation of nitrate may not be achieved (FUX et al. 2004).

In some cases, even applying criteria which favor the selection of ammonium-oxidizing bacteria over nitrite-oxidizing bacteria, such as a high concentration of free ammonia, low oxygen concentration, and a high ammonium load, the suppression of nitrite oxidizers is difficult. Thus, the use of reactor configurations such as CSTR and SBR with suspended biomass is recommended, particularly for operation in real scale. In reactors operated in continuous mode (e.g., CSTR), the criterion for the selection of ammonium-oxidizing bacteria is the hydraulic retention time. In batch reactors (e.g., SBR), the sludge age is the controlling factor regarding the nature of the dominant microbial populations.

The possibility of obtaining an effluent from the partial nitritation process which is ideal for subsequent treatment in an anammox reactor was initially tested by VAN DONGEN et al. (2001a), in a process known as SHARON (single-reactor high-activity ammonia removal over nitrite).

Although this process is not adequate for the treatment of all types of wastewaters, due to its strong dependence on temperature, it is ideal for the removal of nitrogen from high-strength nitrogen wastewater (effluent from sludge digesters, landfill leachates, wastewater from composting processes, and liquid from the sludge drying process), which would consume enormous quantities of dissolved oxygen in the conventional nitrification process (AHN 2006).

In many cases the SHARON process can function as a pretreatment, applied to substantially reduce the ammonium concentration, thus allowing the application of a subsequent conventional system for the final polishing of the wastewater (HELLINGA et al. 1998; MULDER and KEMPEN 1997). In this case, the application of the SHARON system as a sidestream process can be evaluated in terms of load removed and not in terms of effluent quality, since the effluent of the SHARON reactor will later be discharged to the main treatment plant (VAN LOOSDRECHT 2008).

The SHARON process makes use of the different growth rates of ammonium-oxidizing and nitrite-oxidizing bacteria at sufficiently high temperatures (above 26 °C). Thus, it is associated with the selection of ammonium-oxidizing bacteria (from an inoculum originating from a system in which nitrification occurs) in a continuous reactor operating with high specific feed flows. The process conditions are unfavorable for the bacteria responsible for nitrite oxidation and can promote their washout (SCHMIDT et al. 2003; MULDER and VAN KEMPEN 1997).

In the original proposal, operation of a single-stage system using intermittent aeration was envisioned. During the periods in which the reactor is aerated, reduction in the pH with the generation of nitrite (nitritation) is observed. On the other hand, in the periods without aeration, anoxic conditions are established, an external organic carbon source is supplied, and nitrite can be converted to nitrogen gas (denitritation). The latter step would cause an increase in the pH and the production of alkalinity, compensating for the acidifying effect of nitrification. Moreover, the denitritation step is responsible to prevent accumulation of nitrite, which is inhibitory to ammonium oxidizers. Thus, the sequential aerated and anoxic periods were defined as a function of the pH limit values stipulated a priori. Alternatively to the single-stage configuration, partial nitrification and denitritation may be carried out in two separate tanks (two-stage configuration) to decrease the aeration capacity. The nitritation-denitritation (SHARON) process is represented in Eqs. 5.4 and 5.5.

The SHARON process can also be followed by the anammox process, a combination referred to as SHARON-anammox process. In this case, only partial nitritation should be achieved in the SHARON reactor in order to obtain an effluent with NH4 +/NO2 − ratio close to 1, which is suitable for the anammox process. In this case, no organic carbon is required while sludge production is low. To reach the desired NH4 +/NO2 − ratio of 1, the alkalinity of the wastewater is an important factor to be controlled. Depending on this parameter, the SHARON reaction can convert a fraction or the entire ammonium load to nitrite. Considering that the oxidation of 1 mol of ammonium to nitrite consumes 2 mol of bicarbonate and given that this process is practically interrupted at pH values below 6.5, with an ammonium-to-bicarbonate molar ratio of 1:1, approximately 50% of the ammonium is converted to nitrite, the rest remaining in the form of ammonium.

Conversely, the accurate control of alkalinity does not have great importance in cases where a SHARON system achieves complete ammonium oxidation to nitrite to be followed by heterotrophic denitrification via nitrite (denitritation) (VAN DONGEN et al. 2001a; HELLINGA et al. 1998).

The SHARON process is operated with hydraulic retention times which are higher than the growth rate of the nitrite oxidizers, although not as long as that of the ammonium oxidizers. In general, nitritation is carried out without sludge retention, with a hydraulic retention time (HRT) of 1 day, within a temperature range of 30–40 °C and with pH values of 6.6–7. Under these conditions the nitrification process is stable, with nitrite being the final product (AHN 2006).

Since this process is conducted mainly in continuous systems and consequently without sludge retention (hydraulic retention time = cell retention time), the dilution rate (specific feed flow) must be determined in such a way that the ammonium-oxidizing organisms are able to grow sufficiently to remain in the reactor, while the nitrite oxidizers are washed out.

The SHARON process can also be operated with sludge retention. In this case the aeration time will be the limiting factor for the reactor design due to the greater quantity of oxygen required. The economic balance, taking into consideration the reactor volume and the sludge retention equipment, determines the appropriate choice for the application of the SHARON system with sludge retention. In practice, when the nitrogen concentration is above 0.4–0.5 gN/L, a system without biomass retention is cheaper. Also, a system operated without sludge retention requires less maintenance. The sludge produced in the SHARON reactor will leave with the effluent, which does not represent a problem since the effluent of this process will be sent to the influent of the main treatment plant.

As briefly noted, the SHARON process is not suitable for all types of wastewater since it is dependent on high temperatures. However, for the treatment of sludge digester effluents, the SHARON process is ideal, since the temperature of these effluents varies between 20 and 35 °C, permitting reactor operation at reduced sludge retention times. The absence of sludge retention and the fixed hydraulic residence time, common characteristics of the SHARON process, mean that the volumetric nitrogen load applied is dependent on the ammonium concentration of the influent. Therefore, the process cost is also dependent on the ammonium influent concentration, with the increase in the operation cost being directly proportional to the decrease in this concentration. The composition of the effluent of the SHARON process is also dependent on the rate of bacterial growth involved, which, in turn, varies according to the ammonium concentration of the influent (VAN DONGEN et al. 2001a).

Aeration is required not only to provide oxygen but also for the stripping of CO2 in the reactor and to control the pH. Nitrite can be reduced to nitrogen gas through denitritation using organic compounds (e.g., methanol) as electron donors, added periodically while the aeration is deactivated (SCHMIDT et al. 2003), or by applying the anammox process.

VAN HULLE et al. ( 2005 ) described the start-up of a laboratory-scale SHARON reactor operated at 35 °C without pH control. The effluent of the SHARON reactor was found to be suitable for feeding to the anammox process when the influent of the process consisted of synthetic wastewater containing an ammonium load of 1.5 kgN/m3 day.