Abstract

As the number of wastewater treatment plants (WWTPs) increases worldwide and the effluent quality requirements become more demanding, the issue of energy efficiency has been attracting increasing attention from an environmental and economic point of view. However, defining and measuring energy efficiency in WWTPs is still a challenge. Energy efficiency is typically approximated by energy intensity, i.e. kWh/m3. However WWTPs can perform different functions (i.e. removing of COD, removing of N and/or P, resource recovery, producing an effluent free of pathogens), or perform the same function with different technologies, making the comparison of WWTPs a challenging task. Thus, common energy intensity indicators have limited value, as they do not provide enough information of the WWTPs operation. Furthermore, changes in energy intensity are just approximate indicators for changes in energy efficiency since they are affected by external (exogenous) factors.

This study describes how linear regression analysis can be used as a means to estimate energy efficiency in WWTPs, by accounting for the impact of external factors and the diversity of treatment functions. Likewise, based on the analysis of a relatively large sample of WWTPs, the effect of some important variables on energy efficiency is discussed, which open possibilities for improving benchmarking comparability of WWTPs.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Modern wastewater treatment plants (WWTPs) count with a number of on- and offline sensors that provide data on the performance of the plant. However, plant management does not always take full advantage of the analysis of process data. One of the potential uses of plant operation data is the evaluation of energy efficiency, which can be carried out by benchmarking. However, defining and measuring energy efficiency in WWTPs is still a challenge. Energy efficiency is typically approximated by energy intensity, despite several shortcomings related to this measure (Longo et al. 2016). Energy intensity is defined as the amount of energy use per unit of activity (e.g. volume of treated wastewater). Changes in energy intensity are just approximate indicators for changes in energy efficiency since they are affected by external (exogenous) factors such as the influent characteristics, climate factors, scale effect of plant size and other construction parameters. Furthermore, considering that WWTPs perform different functions, i.e. removing of COD, removing of N and/or P, resource recovery, producing an effluent free of pathogens, general energy intensity indicators (i.e. kWh/m3 or kWh/PE) have limited value, as they do not provide enough information of the WWTPs operation.

This abstract has two goals. We will describe how linear regression models can be used as a means to determine energy efficiency in WWTPs, while accounting for the impact of external factors. Likewise, based on the analysis of a relatively large sample of WWTPs, we will discuss the effect of some important variables on energy efficiency. Based on these indicators, it is then possible to identify the saving potential that can be reached with improvement in the level of energy efficiency (Chung 2011).

Literature that attempts to analyse the impact of operational variables on the energy efficiency is relatively scarce and sometimes contradictory (Longo et al. 2016). Hence, the analysis undertaken here explicitly takes into account energy consumption, and allows identifying the variables in the process that are drivers for energy consumption and, thus can be used to draw better comparisons among plants.

2 Materials and Methods

2.1 Data Collection

The data about energy consumption and operation of WWTP were gathered (i) by web-search engines with keywords: ‘wastewater’, ‘WWTP’, ‘energy’, ‘energy consumption’, ‘energy performance’, ‘energy efficiency assessment’, ‘energy benchmarking’, ‘life cycle assessment’, and (ii) collecting energy data from regional water agencies (in particular from Germany, Spain and Switzerland) by private communications. A total of 415 WWTPs from different countries were inventoried. The data included and calculated for the analysis are summarized in Table 1.

SecTreat and TertTreat are categorical variables for technology employed for secondary treatment and presence or not of tertiary treatment, respectively. SIZE is plant actual capacity expressed as person equivalent (PE). FLOW is average influent flowrate expressed in m3/day. PLF and DIL are two indices defined as plant load factor and dilution factor, calculated as follow:

CODinf, CODeff, Ninf, Neff, Pinf and Peff are respectively chemical oxygen demand, nitrogen and phosphorus concentration in the influent and effluent of the plant. Temp is outdoor temperature. Finally Y 1 , Y 2 and Y 3 are total energy demand, volumetric and load basis energy intensity.

3 Methodology

In this study, a linear regression approach is used to control for aspects that systematically influence the energy use at WWTPs. Regression models describe the relationship between a depended variable, Y, and independent variables, X. The dependent variable is also called the response variable. Independent variables are also called explanatory or predictor variables. Preliminary data analysis has shown that energy efficiency has a nonlinear dependency of operational variables (Longo et al. 2016). Therefore, using a log-log functional form it is possible to determine a linear model describing the energy use in function of the explanatory variables. The log-log estimated equation is given by:

After estimating the log-log model, the β coefficients can be used to determine the impact of independent variables (X) on dependent variable (Y). In fact the coefficients in a log-log model represent the elasticity of Y variable with respect to X variable. In other words, the coefficient is the estimated percent change in your dependent variable for a percent change in the independent variables. The sign of the coefficient gives the direction of the effect. Moreover, \( \varepsilon \), which represents the difference between actual and predicted average energy use, defines the relative energy inefficiency versus an equivalent plant with average performance.

Three different response variables, Y, were modelled here (as reported in Table 1) in order to study impact of external factors on total energy consumption (Y 1 ) and on two common energy intensity indicators (Y 2 and Y 3 ), which are commonly used as proxy of energy efficiency when comparing WWTPs performance. The models obtained were refined and checked for outliers, variegate multicollinearity, leverage and whether improper functional forms were used.

4 Results and Discussion

4.1 Estimated Energy Use Models

Following the previously described procedures three regression models were tested in order to describe the relationship between energy consumption and operational parameters in the following way:

where \( Y_{i} \) is one of the three dependent variables modelled as reported in Table 1.

The estimation results of the WWTPs energy demand model using different dependent variables are given in Table 2. The estimated coefficients are statistically significant in all models and show that the effect of the covariates on the dependent variable has the expected sign. For easier interpretation, the plots of estimated effects of predictors in the fitted models are presented in Fig. 1.

Plot effect of estimated models M1 (left), M2 (centre) and M3 (right). This plot shows the estimated effect on the response variable from changing each predictor vales from one value to another. The two values are chosen to produce a relatively large effect on the response. The circles show the magnitude of the effect and the lines show the upper and the lower confidence limits for the main effect

4.2 Impact of Operational Conditions on Energy Consumption

Plant size.

It has been reported that the size of WWTPs influences its energy efficiency (Longo et al. 2016), which is confirmed by this study. Plant size has the largest effect in M1, and its elasticity found was 0.91 (Table 2), thus it results that on average 1 percent increase in plant size is associated with 0.91 percent increase in total energy consumption. Moreover, considering the used econometric specification (log-log), a positive coefficient included in the range \( 0 < \beta_{i } < 1 \) indicates that the impact of the independent variable becomes smaller as it increases, which is consistent with previous studies reporting that larger plants are normally more energy efficient. Likewise, Fig. 1 shows how, as size increases energy efficiency decreases, leading to an improvement of energy efficiency as measured by these indicators.

Type of treatment.

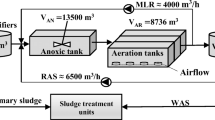

Different technologies, which tend to have different costs and operational characteristics, are used worldwide. Designers choose specific treatment type based on environmental standards and socio-economic factors in order to maximize the effectiveness of WWTPs. As WWTPs usually operate in different conditions, comparing the performance of WWTPs using different technologies is not trivial. Our analysis confirms that the type of treatment plays an important role in determining energy performance and the results are reported in Fig. 2. MBR are characterized by the higher energy consumption for the three models, due to their intensive membrane aeration rate. In contrast, the less energy intensive technology was found to be tricking filtration. The rest of technologies, correlated with higher energy consumption than tricking filter but lower than MBR, do not present significant differences when compared among themselves (results not shown). On the contrary plant carrying out additional tertiary treatment were found on average to have a 13% higher energy consumption with comparison to plant carrying out only secondary treatment (Table 2, M1).

Adjusted plot of energy use (M1) for type of secondary treatment. This plot shows the fitted response as function of variable secondary treatment type, with other predictors averaged out by averaging the fitted values over the data used in the fit. Adjusted points are computed by adding the residual to the adjusted fitted values for each observation.

Under-over capacity.

The estimated PLF elasticity is positive and highly significant in all three models. Plants receiving lower loads compared to design values present a significantly worse energy performance, since energy consumption decreases when approaching values of 100% and keeps decreasing for overloaded plants. The results suggest that plant oversize should be as much as possible reduced the design phase and/or by revamping operation with division in two or more treatment lines in order to adapt process operation to seasonal variation of pollution load.

Influent characteristics.

Another factor that impact negatively energy use at WWTPs is influent dilution. Influent characteristics are critical factors of WWTP performance greatly impacting several key parameters for operation (such as C/N ratio, aeration requirement, sludge production etc.…). From the analysis of our dataset energy consumption increases when increasing the DIL. Thus, keeping the rest of variables constant, (i.e. size, load factor and nitrogen concentration in the effluent) a plant receiving a more diluted wastewater has higher energy consumption. This effect it is clearer in M3 (Fig. 1) where energy consumption is normalized on the load entering the plant (Y 3 (kWh/PE)). In this case increasing DIL has a strong negative effect on energy efficiency due to additional energy consumption for influent pumping. Moreover, the coefficient for DIL is found to be negative and very high in M2, confirming that kWh/m3 is a poor proxy for the energy efficiency as it is highly influenced by the degree of dilution of the wastewater.

Nitrogen removal treatment intensity.

Nitrogen effluent concentration is expected to be positively correlated with energy consumption. In fact when controlling for influent dilution, lower nitrogen concentration in the effluent is supposed to cause higher energy consumption for aeration. As expected, Nout is positively and significantly associated with higher energy consumption at WWTPs in all three models.

Temperature.

Temperature has a complex effect on a WWTP operation. On the one hand increasing the temperature increases the biological activity, both the substrate uptake rate as the endogenous respiration. On the other hand, oxygen solubility decreases sharply when increasing temperature, leading to a higher energy demand for aeration. It is difficult to conclude which of these effects prevail. Table 2 shows that an increase of outdoor temperature (taken as a proxy of water temperature) is related to an increase of energy consumption suggesting that, in the analysed range, the higher aeration energy demand may be more significant.

5 Conclusion

This study describes how linear regression analysis can be used as a means to determine energy efficiency in WWTPs, by accounting for the impact of external factors. Likewise, based on the analysis of a relatively large sample of WWTPs, the effect of some important variables on energy efficiency is discussed, which open possibilities for improving benchmarking comparability for WWTPs. This analysis confirms that energy intensity indicator (i.e. kWh/m3) is not an accurate proxy for energy efficiency given that changes in energy intensity are a function of changes in several factors. Based on these findings, it is then possible to identify the saving potential that can be reached with improvement in the level of energy efficiency. Finally, due to its relative simplicity, the analysis here discussed can be easily reproduced by engineers, auditors or water utilities, helping them with the decision-making process when investing on energy efficiency measures.

References

Chung W (2011) Review of building energy-use performance benchmarking methodologies. Appl Energy 88(5):1470–1479

Longo S, d’Antoni BM, Bongards M, Chaparro A, Cronrath A, Fatone F, Hospido A (2016) Monitoring and diagnosis of energy consumption in wastewater treatment plants. A state of the art and proposals for improvement. Appl Energy 179:1251–1268

Acknowledgements

This project is carried out with financial support from the H2020 Coordinated Support Action ENERWATER (grant agreement number 649819): www.enerwater.eu.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Longo, S., Lema, J.M., Mauricio-Iglesias, M., Hospido, A. (2017). Measuring Energy Demand and Efficiency at WWTPs: An Econometric Approach. In: Mannina, G. (eds) Frontiers in Wastewater Treatment and Modelling. FICWTM 2017. Lecture Notes in Civil Engineering , vol 4. Springer, Cham. https://doi.org/10.1007/978-3-319-58421-8_64

Download citation

DOI: https://doi.org/10.1007/978-3-319-58421-8_64

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-58420-1

Online ISBN: 978-3-319-58421-8

eBook Packages: EngineeringEngineering (R0)