Abstract

Heavy metals have been utilized by human beings for thousands of years, and they pervade nearly all aspects in modern economic activities. However, heavy metal ions such as cadmium, lead, zinc, nickel, and copper are detected in waste streams from mining operations, battery manufacturing, electroplating, and smelting industries due to their extensive use. The adverse effects of heavy metals on human health have been studied by international organizations including the WHO. Although the emissions have declined in most developed countries, in some parts of the developing world, human exposure to heavy metals is still a severe problem. Various technologies of heavy metal removal from effluent have been investigated and reported in literature including precipitation, membrane filtration, coagulation, adsorption/ion exchange, and electrochemical treatment. In this chapter, adsorption studies of cadmium, lead, and zinc onto various low-cost adsorbent materials will be reviewed. The equilibrium isotherm, batch kinetic studies, the effect of variables including contact time, initial pH, adsorbate concentrations, dosage, and the application of adsorption models will be discussed.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

5.1 Introduction

Heavy metals presented in source and treated water are a severe problem to public health (Hua et al. 2012). Due to the extensive use of various heavy metals in mining operations, battery manufacturing, electroplating, and other industries, the surrounding underground and surface water are subjected to the risk of metal contamination (Srivastava and Majumder 2008; Wang et al. 2012). Metals associated with these industrial activities such as cadmium, lead, zinc, and nickel are not biodegradable and have the tendency to accumulate in living organisms, leading to diseases and disorders to human health (Khan et al. 2008; Joseph 2009; Li et al. 2015).

During the past decades of development, to treat heavy metal-contaminated wastewater, several technologies have been developed and applied, among which adsorption/ion exchange has been recognized as a promising way to treat industrial waste effluents with the advantage of easy operation (Fu and Wang 2011). Traditional treatment processes such as chemical precipitation (Feng et al. 2000) and electrochemical treatment (Sadrzadeh et al. 2009) are effective when dealing with high metal concentrated wastewater. However, they fail in certain cases when the metal concentration is relatively low (Gautam et al. 2014). Membrane filtration (Blöcher et al. 2003) and adsorption can be applied to low concentration metal-contaminated wastewater, but membrane filtration is extremely expensive when treating large amounts of industrial effluent and thus can hardly be applied on an industrial scale (Fu and Wang 2011).

However, an adsorption process can make full use of certain types of adsorbent materials even when the metal concentration is quite low (Fu and Wang 2011). By choosing from various types of adsorbent materials, heavy metals can be removed together or selectively (Da̧browski et al. 2004). Three types of adsorbent materials have been commercially available in water treatment: activated carbons (Paul Chen and Lin 2001), zeolites (Hui et al. 2005), and synthetic polymeric adsorbents (Kennedy 1973). Most activated carbons have a wide range of pore sizes that can accommodate large organic molecules; zeolite which refers to aluminosilicate materials with varying ratios of Al to Si tends to have very small pores; synthetic polymeric adsorbents usually have only micropores. Activated carbons, zeolite, and synthetic polymeric resins have already been applied successfully in several water treatment applications , among which activated carbon is the most commonly used adsorbent material.

Activated carbon can be manufactured from natural or carbonaceous materials such as coal (Ahmadpour and Do 1996; Chingombe et al. 2005), peat (Ho and McKay 1999a), coconuts (Sekar et al. 2004), and others by high-temperature steam activation or other processes. But the temperature needed in carbonization/activation process is extremely high at around 600–1200 °C which means high energy consumption, whereas the yield of activated carbon from biomass is quite low, usually below 20%, resulting in the relatively high expense to treat large quantities. Thus cost-effective adsorbent materials are needed to replace traditional activated carbons.

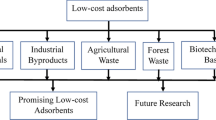

The adsorption capacities vary a lot depending on the nature of the raw material as well as the modification process. Apart from the adsorption capability, cost is also an important parameter in comparing and choosing various adsorbent materials (Bailey et al. 1999; Júnior et al. 2009). The cost of an individual adsorbent material varies depending on several aspects such as local availability and the degree of required activation or modification process. In general, “low-cost” adsorbents should meet the requirements as abundant in nature; need as simple processing as possible are waste materials or by-products from another industrial process (Bailey et al. 1999).

Agricultural wastes are usually available in large quantities with cheap price which meets the requirement as “low-cost” materials (Demirbas 2008). The major constituents of these materials are lignin and cellulose which may also include other functional groups of lignin such as alcohols, ketones, aldehydes, phenolic, carboxylic, and ether groups (Júnior et al. 2009). To some extent, these groups have the ability to donate a lone pair of electrons to bind with heavy metals and form coordination complexes which makes these waste materials potential adsorbents for heavy metal uptake. Commonly used agricultural wastes include rice husks (Ajmal et al. 2003; Krishnani et al. 2008), peanut hull (Periasamy and Namasivayam 1996; Brown et al. 2000; Witek-Krowiak et al. 2011), sawdust (Yu et al. 2000; Argun et al. 2007), pinus bark and different bark samples (Vázquez et al. 1994; Al-Asheh et al. 2000), tea leaves (Ahluwalia and Goyal 2005), banana and orange peels (Annadurai et al. 2003), palm kernel husk (Onundi et al. 2010), coconut husk (Amuda et al. 2007), modified cotton, modified cellulose (O’Connell et al. 2008), modified corncob (Vaughan et al. 2001), wool fibers (Balköse and Baltacioǧlu 1992), and other agricultural by-products.

In addition to agricultural wastes, industrial waste by-products have also been considered and researched for the application of heavy metal adsorption. Nowadays, industrial activities also generate enormous amounts of by-products and solid waste materials, some of which can be reused while the others will be sent for disposal in landfills. Therefore, recycle and reuse of these industrial waste materials to reduce the quantity of waste have become a hot topic. The most attractive aspect of these types of materials is that they are usually provided free or at very low price. During the past decades, many industrial wastes have been investigated with or without treatment processes, and they have been applied to metal adsorption systems such as fly ash from the energy combustion industr y (Cho et al. 2005; Hui et al. 2005), bark and sawdust from the timber industry (Yu et al. 2001; Bulut and Tez 2007), black liquor from the paper industry (Srivastava et al. 1994), red mud from the aluminum industry (Gupta et al. 2001), and others.

Chitin is another kind of material that has been reported to have the ability to adsorb heavy metals (Wu et al. 2000). It is plentiful in nature and can also be produced from shrimp, prawn, and crab meat canning industries. Moreover, chitin’s deacetylated derivative chitosan has a higher adsorption capacity than that of chitin. Chitosan can be produced from chitin using chemical methods or can also be found naturally in some fungal cell walls (Wu et al. 2001).

Finally, naturally abundant clay (Celis et al. 2000) and minerals with the potential to be used as adsorbents have gained attention. Clay has a large surface area which infers it has potential to be an adsorbent material; zeolites are naturally occurring silicate minerals and possess ion-exchange ability (Ok et al. 2007). In particular, zeolite presents a strong affinity toward lead and other heavy metals which makes it an effective adsorbent material.

5.2 Adsorption Process

Adsorption is a surface-based process in which the dissolved species are transported to the porous solid adsorbent by diffusion and are then adhered onto the extensive inner surface of the adsorbent. An adsorbate refers to the constituent that is attracted onto a surface, and adsorbent refers to the solid onto which the constituent is adsorbed. Adsorbent solids bind dissolved molecules by physical forces (physisorption), ion exchange, or chemical binding (chemisorption).

As stated in Chaps. 2 and 3, solid-liquid adsorption systems usually involve two types of experimental investigations: equilibrium isotherm adsorption testes and batch kinetic rate studies. Equilibrium isotherm model equations such as the Langmuir model and the Freundlich model are commonly used to describe experimental adsorption data, while the most widely used kinetic models are the pseudo-first-order model and the pseudo-second-order model. It is important to determine the best-fit isotherm and kinetic model in order to evaluate the material and to further develop suitable industrial adsorption system designs (Gerente et al. 2007).

5.2.1 Equilibrium Adsorption Isotherm

Establishing the most appropriate correlation for equilibrium curves is very important in the purpose of optimizing the condition of an adsorption system for metal ion uptake. The maximum capacity of the adsorbent can be predicted under a given set of conditions, whereby the adsorption capacity is dependent only on the equilibrium curve established between the adsorbed sites and metal solution concentrations. These equilibrium adsorption capacity curves can be obtained by measuring the adsorption isotherm of the metal ions onto the sorbents with fixed pH, dosage, and temperature. Thus it is necessary to develop isotherm models to fit the experimental data points in order to obtain the correlations of solid-phase concentration to the fluid-phase solute concentration. In this section, we recall some of the most used isotherm models for heavy metal adsorption.

5.2.1.1 The Langmuir Model

The Langmuir model calculates the amount of molecules adsorbed onto a solid surface and is often used to describe the solute adsorption (Langmuir 1918). This model assumes a monolayer adsorption onto a complete homogeneous surface with a negligible interaction between adjacent adsorbed molecules. The equilibrium equation is stated as:

where q e is the solid-phase adsorbate equilibrium concentration (mmol/g), C e is the aqueous-phase adsorbate equilibrium concentration (mmol/L), K L (L/g) and a L (L/mmol) are Langmuir isotherm constants, and the monolayer capacity q max = K L /a L.

The Langmuir equation is apposite to homogeneous adsorption systems where the adsorption of each adsorbate molecule has equal activation adsorption energy. When the concentration is very low, a L C e is far smaller than unity; it implies q e ≈ K L C e which obeys the Henry’s law. Therefore, a linear expression of the Langmuir equation is:

where a plot of C e/q e versus C e gives a straight line where the slope is a L/K L and the intercept is 1/K L. The Langmuir equation gives the theoretical monolayer saturation capacity, q max as K L/a L.

5.2.1.2 The Freundlich Model

The Freundlich equation is an empirical equation proposed by Freundlich. It is commonly used to describe organic components in solution; it assumes that the adsorption sites are not identical. It usually applies to heterogenous surfaces and multilayer adsorption on the adsorbate. The equation is:

where a F is the Freundlich constant, while b F is the heterogeneity factor. When b F equals unity, this model reduces to Henry’s law. The smaller this term is, the more nonlinear the adsorption isotherm becomes. It is notable that when the value of b F gets smaller than 0.1, the shape of the isotherm approaches a rectangular isotherm. But it is often criticized for not reducing to Henry’s law at very dilute concentrations. Also, there is no finite limit for the adsorption uptake when the concentration is sufficiently increased which is contrary to the plateau observed in most real systems. Therefore this model is generally only valid in a narrow range of concentrations. A linear expression of the Freundlich equation can be obtained by taking logarithms of Eq. (5.3):

where a plot of ln q e versus ln C e can determine the constant a F and exponent b F. The Freundlich isotherm is derived by assuming and inserting an exponential decay energy distribution function in to the Langmuir equation. It is commonly used in the description of reversible adsorption having heterogeneous surfaces .

5.2.1.3 The Redlich-Peterson Model

The Redlich-Peterson isotherm (Redlich and Peterson 1959) is also an empirical equation which was proposed by Redlich and Peterson to represent equilibrium data; it combines elements from both Langmuir and Freundlich equations together to incorporate three parameters into the equation. It is applied to both homogeneous and heterogeneous systems.

This equation is widely used as a compromise between the Langmuir and Freundlich systems. The equation is expressed as follows:

where k PR, a PR, and b RP are Redlich-Peterson isotherm constants. b RP is between 0 and 1, and when b RP equals to 1, it reduces to Langmuir. It approximates to Henry’s law at low concentration and to the Freundlich at high concentration.

5.2.1.4 The Sips (Langmuir-Freundlich) Model

The Sips model (Sips 1948) is also known as the Langmuir-Freundlich isotherm. It considers the case of a molecule occupying two sites. The Sips equation takes the following form:

where K LF is the Sips isotherm equilibrium constant (L/g), a LF is Sips isotherm constant \( {\left(\mathrm{L}/\mathrm{mmol}\right)}^{1/{n}_{\mathrm{LF}}} \), and n LF is the Sips isotherm exponent, dimensionless. This equation is a combination of the Langmuir and Freundlich models, it will effectively reduce to a Freundlich isotherm at low adsorbate concentrations, and thus it does not follow Henry’s law, while it predicts a monolayer adsorption capacity of the Langmuir isotherm at high adsorbate concentrations .

5.2.2 Kinetic Studies and Models

Kinetic experiments are carried out to evaluate the potential of the material for commercial applications . An ideal adsorbent shows properties such as high adsorption capacity as well as fast removal rate. Kinetic models are used to evaluate the mechanisms of heavy metal adsorption and its potential rate-controlling steps that include mass transport and chemical reaction processes (Aksu 2001). Another purpose for conducting batch kinetic studies is to optimize the operation conditions for large-scale processes. Various factors such as initial metal concentration, initial pH of the solution, adsorbent dosage, temperature, particle size, and other process parameters will affect the adsorption capacity. Kinetic models only concern the effects of observable parameters on the overall rate of the system. Predicting the overall rate in the given adsorption system is the most important since the system’s kinetics determines adsorbate time and the reactor dimensions.

In order to understand the kinetics and the rate-controlling steps, several adsorption kinetic models have been established: the pseudo-first-order model, the pseudo-second-order model, the Elovich model, the first-order equation of Bhattacharya and Venkobachar, the Weber and Morris adsorption kinetic model, the Weber and Morris adsorption kinetic model, and the Ritchie equation. The two most widely used models are the pseudo-first-order and the pseudo-second-order model which can study the heavy metal adsorption kinetics and quantify the extent of uptake in adsorption kinetics. Some details of the common kinetic models applied in heavy metal adsorption are given below. Note that this discussion complements the information provided in Chaps. 2 and 3.

5.2.2.1 The Pseudo-First-Order Model

The pseudo-first-order rate equation is generally expressed as follows:

where q t and q e are amounts adsorbed onto the adsorbent material (mmol/g) at time t (min) and equilibrium, respectively. k 1 is the pseudo-first-order rate constant (min−1).

The linear expression of this equation can be rearranged as follows:

From this form of this equation, it is clear that q e should be known in order to fit the equation to the experimental data in the linear form. However, in many cases q e is unknown after the batch kinetic experimental contact time unless the equilibrium isotherm has been determined. The amount of adsorbed metal ions is significantly smaller than the equilibrium amount when the adsorption process tends to be very slow. Therefore in most reported literatures, the pseudo-first-order equation does not fit well with the experimental data for the whole range of contact time but is generally applicable for the initial 20–30 min of the adsorption process (Gerente et al. 2007).

Apart from the linear method of fitting, some groups use the sum of squared errors (SSE) method by minimizing the difference of calculated data with the experimental data:

Excel built-in function solver can be used to obtain the unknown q e and k 1 at the same time. However, some literature results show that the calculated q e is still smaller than that from the isotherm experiments; thus this model equation may still underestimate the equilibrium capacity. To sum up, the pseudo-first-order model has been extensively used to describe metal uptake process. However, this model has the problem of predicting the equilibrium capacity; the calculated q e from this model equation frequently does not agree with the experimental data. It only gives a good fit with the experimental data for the first 30 min. After that, the prediction of the model usually goes below the experimental data. It has been suggested that the time lag results in the difference in the q e values. The time to overcome the boundary layer and external resistance controls the process at the beginning, and this time lag is difficult to quantify. This model equation has been applied to metal adsorption systems like cadmium, lead, and zinc, but most of the fits are moderate to poor .

5.2.2.2 The Pseudo-Second-Order Model

The pseudo-second-order model was developed by Ho and McKay (1999b) and is expressed by the following equation:

where q e and q t are the amount of metal ions adsorbed (mmol/g) at equilibrium and at time t, respectively; k 2 is the pseudo-second-order rate constant of adsorption (g mmol−1 min−1).

The pseudo-second-order rate constant can be determined by plotting the experimental data t/q versus t, and then q e and k 2 can be calculated from the slope and intercept. In studies on the adsorption of cadmium by chitosan, the pseudo-second-order kinetic model was much more successful than the pseudo-first order. It has been suggested that in chemisorption processes, the pseudo-second-order model is superior to the pseudo-first-order model due to the consideration of adsorbent-adsorbate interaction in the pseudo-second-order model. The pseudo-second-order model has been recognized as the most widely fitted model for the metal adsorption from effluent.

Theoretically, the rate of an adsorption system should remain constant at a certain specified temperature; it only changes with the change of the temperature. However, the literatures show that the rate contact is quite different when the variables such as initial concentration, pH, or dosage are changed. This might be a problem for this useful model, and therefore it is important to develop a correlation between the pseudo-first and the pseudo-second-order rate constant with each variable .

5.3 Low-Cost Adsorbent Materials and Metal Adsorption

In order to reduce the cost of adsorption process, waste materials were taken into consideration to be recycled and reused as well as cheap raw materials. This section is mainly focused on four parts: agricultural wastes, industrial wastes, marine materials, and mineral materials.

5.3.1 Agricultural Waste

Agricultural waste materials are usually abundant and have been proven to be eco-friendly and economic sources of precursors or adsorbent materials. It has been reported that various agricultural wastes can be easily converted to value-added products. Agricultural wastes have been recycled and used in the removal of different types of pollutants from effluent. The basic components of agricultural waste materials include hemicelluloses, lignin, lipids, simple sugars, proteins, hydrocarbons, and starch which contains functional groups that are potential to become adsorbent materials for heavy metal adsorption. Agricultural waste products can be used directly or after modification. The agricultural wastes can be directly used for adsorption tests after recycling, washing, and making into the desired particle size. Another way to reuse the agricultural wastes is to use certain methods to pretreat the material before use. The pretreatment methods have been extensively studied in order to enhance the functional groups and therefore increase the number of active sites for adsorption purposes. The application to remove lead, cadmium, and zinc by agricultural waste with their experimental conditions and adsorption capacities has been listed in Table 5.1.

Sugarcane bagasse is a kind of lignocellulosic material which has a complex configuration with a variety of activated sites; modified sugarcane bagasse has been reported to be effective in terms of heavy metal removal (Orlando et al. 2002; Karnitz et al. 2007). After pretreatment with succinic anhydride, carboxylic functions are introduced to succinic anhydride, and the amide functions are formed by chemical introduction of polyamine. Due to the chelating properties of polyamines toward metals such as zinc, cadmium, lead, and copper, the modified succinic anhydride becomes suitable for the treatment of metal-contaminated wastewater (Bianchi et al. 1991).

Velazquez-Jimenez et al. (2013) tested the raw and modified Agave salmiana bagasse for metal adsorption. HCl, HNO3, NaOH, tartaric, citric, and oxalic acids were used to modify bagasse, respectively, to determine if its concentration of active groups could be improved. These materials were then tested for the removal of Cd(II), Pb(II), and Zn(II) ions from effluent at pH 5, and desorption studies were performed at pH 2 and 4 at 25 °C. The characterization techniques are used mainly to identify carboxyl-, hydroxyl-, sulfur-, and nitrogen-containing groups in bagasse. The carboxylic groups were mainly responsible for metal uptake. The results show that the adsorption capacity of raw bagasse is about 8, 14, and 36 mg/g for zinc, cadmium, and lead, respectively. The adsorption capacity was improved around 27–62% after modification with HNO3 and NaOH. However, citric, oxalic, and tartaric acid did not have significant effects on improving adsorption capacity.

Recently, Demiral and Güngör (2016) used grape bagasse as raw material and phosphoric acid to activate the material to activated carbon. The obtained activated carbon has a highest surface area of 1455 m2/g and total pore volume of 0.88 cm3/g at 500 °C carbonization temperature with an impregnation ratio of 5/1. Then the activated carbon was used to remove copper with maximum capacity of 43.47 mg/g at 45 °C. The Langmuir and Dubinin-Radushkevich isotherm equations showed better fits, while the rate of adsorption was found to conform to the pseudo-second-order kinetic model. Gurgel and Gil (2009) have introduced two different methods to prepare two new chelating materials, MMSCB 3 and MMSCB 5, using succinylated twice-mercerized sugarcane bagasse (MMSCB 1). MMSCB 1 was activated with 1,3-diisopropyl-carbodiimide and acetic anhydride, respectively, and later both intermediate were reacted with triethylenetetramine to obtain MMSCB 3 and MMSCB 5. The capacities of MMSCB 3 and MMSCB 5 for copper, cadmium, and lead uptake from single-component solutions were evaluated at different contact times, pH, and initial metal ion concentrations. The adsorption isotherm results show good fit with the Langmuir model, and the maximum adsorption capacities of MMSCB 3 and MMSCB 5 for copper, cadmium, and lead were found to be 59.5 and 69.4, 86.2 and 106.4, and 158.7 and 222.2 mg/g, respectively. Feng et al. (2011) studied the adsorption of cadmium, lead, and nickel using the grafted copolymerization-modified orange peel (OPAA ). The Langmuir model correlated with the experimental data better than the Freundlich model. From the Langmuir equation , the maximum uptake capacities for lead and cadmium were 476.1 and 293.3 mg/g, respectively. The adsorption capacity of the modified material has increased 4.2- and 4.6-fold for lead and cadmium, respectively, in comparison with the original orange peel. Moreover, the kinetics for lead and cadmium adsorption followed the pseudo-second-order model.

Afroze et al. (2016) recently studied the adsorption of zinc ions from effluent using raw and base-modified Eucalyptus sheathiana bark. Bark is a common by-product from the timber industry; Eucalyptus trees are evergreen and fast-growing trees which are abundantly available worldwide. The equilibrium adsorption studies showed that both the Freundlich and Langmuir models can be capable of describing the systems for zinc uptake using raw or base-modified eucalyptus bark. Also, the pseudo-second-order rate equation is found to well describe the adsorption of zinc for both raw and modified bark. The maximum adsorption capacity of modified eucalyptus bark for zinc removal at 30 °C was 250.0 mg/g which was quite competitive to other adsorbent materials.

Lentil husk was also recognized as a promising low-cost adsorbent with a maximum removal capacity of 81.43 mg/g for lead under the optimized condition of pH (5.0) and temperature (30 °C) with an initial metal ion concentration of 250 mg/L by Basu et al. (2015). The functional groups of lentil husk were modified by treating with different chemicals to investigate their role in adsorption; chemical modification of functional groups revealed both hydroxyl and carboxyl groups played crucial role in the binding process.

Rice husk is another category of agricultural waste; since rice is the most popular food in Asia, large quantities of rice husk were produced every year. Nowadays , rice husk is used as energy source for power plants; however, 18% of the total amount of husk remains as rice husk ash (RHA) . It has been investigated that the major component of RHA is silica, while it also contains some alumina content, both of which are typically used in zeolite synthesis (Gupta et al. 2011). Santasnachok et al. (2015) synthesized zeolite from agriculture waste by-product rice husk ash (RHA). The synthesized material was applied in cadmium-contaminated wastewater in the initial concentration range of 50–500 mg/L. The maximum removal capacity of synthesized zeolite Na-A and Na-X for cadmium was found to be 736.38 and 684.46 mg/g, respectively, at dosage of 0.25 g/L.

5.3.2 Industrial By-Products and Wastes

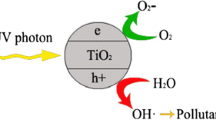

Industrial by-products are usually considered as useless waste materials and cause major disposal problems . Fly ash is a waste material generated from combustion processes. Previously, fly ash is mainly used for road construction or formation of bricks and cement. However, fly ash contains high percentage of silica and alumina which makes it possible to be used as precursor of zeolite-type adsorbent material (Bhatnagar and Sillanpää 2010). The reuse of fly ash to develop low-cost and efficient adsorbents for wastewater treatment follows the concept of using waste to treat waste (Shawabkeh et al. 2004; Belviso et al. 2010). Many studies have been reported on fly ash, raw fly ash, modified fly ash, or on dispersed TiO2-fly ash and have been tested as adsorbents for heavy metals removal from wastewater (Gupta and Ali 2004; Harja et al. 2012; Shyam et al. 2013).

Aluminum industry waste has also been studied under the concept of recycle waste for water treatment. Red mud is a waste material from the aluminum industry and has been widely investigated. It is formed during the production of alumina when bauxite ore is subjected to caustic leaching (Bhatnagar et al. 2011); sodium hydroxide solution is used in the refining process. And thus this material is highly alkaline with a pH as high as 10–13. So it needs to be neutralized before being used as an adsorbent material. Red mud is mainly composed of fine particles containing aluminum, iron, silicon, hydroxides, and titanium oxides. Zhu et al. (2007) evaluated the potential of granular red mud (GRM) to remove cadmium from aqueous solution. The pseudo-second-order model can describe the experimental kinetic data at initial pH 6.0 and 3.0. The maximum adsorption capacities for GRM were 38.2 mg/g at 20 °C, 43.4 mg/g at 30 °C, and 52.1 mg/g at 40 °C. Gupta et al. (2001) converted red mud into an inexpensive and efficient adsorbent and used it for the removal of lead and chromium from aqueous solutions which exhibits good adsorption capacities. The equilibrium data fits well with both the Freundlich and the Langmuir model. Red mud was treated with hydrogen peroxide at room temperature for 24 h in order to oxidize the adhering organic impurities and was then washed repeatedly with distilled water, followed by an activation process in a muffle furnace at 500 °C for 3 h. The adsorption results showed that the maximum uptake for lead took place at pH 4.0.

The steel industry also produces a large quantity of by-products which create serious disposal problems. Basic oxygen furnace (BOF) slag is a kind of by-product from steel-making process which is mainly applied for construction applications including road engineering (Miraoui et al. 2012) and cement production (Han et al. 2015) due to the hydration activity of BOFs. Some authors have investigated the adsorption of cadmium, lead, zinc, and copper from effluent by BOFs (Xue et al. 2009, 2013). The sieve size of BOFs was controlled under 0.6 mm first and then treated by acid (0.1 M HCl) and washed by deionized water. The equilibrium isotherms showed that copper, cadmium, and zinc had similar but relatively higher adsorption capacity compared to lead in single-element system. The adsorption affinity is found to follow the sequence Zn > Cu > Pb > Cd in single-element systems, while the uptake order in the multielement system was Pb > Cu > Zn > Cd.

The paper industry produces a large amount of black liquor, from which lignin can be extracted. The extracted lignin was characterized and used for lead and zinc removal (Srivastava et al. 1994). The uptake amount of lead was more than that of zinc, while the adsorption capacity increases with the increase of pH value.

The waste from the leather-processing industry has also been investigated by researchers in the application of metal adsorption. Fathima et al. (2005) utilized animal skins which are high in protein content to complex with iron and then used it for the removal of chromium(VI ). The effect of pH and the initial concentration of chromium(VI) by iron treated fleshing is studied. The adsorption capacity by iron-treated material is shown to be greatly improved to 51 mg of chromium(VI) per gram of treated fleshing, while it is only flesh 9 mg/g for the untreated fleshing. However, this study has not been applied to other metals to date.

Recently, a newly developed industrial waste material is introduced. The material is recycled from waste printed circuit board recycling industry. With the rapid development of the electronic devices, the lifetime of such devices has become shorter and shorter resulting in the massive waste electronic devices. Printed circuit boards (PCBs ) are the major component of the abandoned electronic devices. Recent commercial recycling of PCBs is based on using a mechanical-physical technique to separate the PCBs into metallic and nonmetallic fractions which is quite environmentally friendly compared to the traditional treatment methods. The metallic fraction is mainly copper which is of high value and can be marketed easily, while the nonmetallic fraction (NMF) which accounts for 70% of the total PCB weight has always been considered as a low-value by-product. Hadi et al. (2013) recycled the nonmetallic part and investigated the activation of this material for the application of heavy metal adsorption. The optimum condition to activate the material is to impregnate the raw material with activating agent KOH at weight ratio of 2 (KOH/NMF = 2) under continuous stirring for 3 h at room temperature. The resulting slurry was heated to 250 °C for 3 h in a muffle furnace under a nitrogen atmosphere. The product was then washed with DI water and subsequently dried at 110 °C. Xu et al. (2014) performed a detailed equilibrium study of this activated nonmetallic fraction for the adsorption of cadmium. The adsorption results show that the maximum uptake capacity of this material for cadmium removal reached to 2.1 mmol/g (initial pH = 4) which shows that this material can effectively remove cadmium ions from effluent and is highly competitive with the commercial resins. The Redlich-Peterson model is the best-fit model. Lead adsorption has also been studied with a maximum capacity of 3.2 mmol/g at initial pH of 4. Lead also shows higher affinity than cadmium in the binary-component system (Xu et al. 2015).

Finally, other adsorbent materials derived from industrial waste and their adsorption capacities for lead, cadmium, and zinc have been listed in Table 5.2.

5.3.3 Marine Materials

Adsorbents have been derived from waste seafood because of the abundant amount of chitin found the in the exoskeletons of crabs and other arthropods (Rinaudo 2006). Seafood processing produces large quantities of by-products. Chitin is second to cellulose in terms of polysaccharide quantities in nature. It is also easily found as waste product from the crab meat canning industry. It has been reported that chitin or modified chitin can remove metal ions from effluent (Benaissa and Benguella 2004; Karthik and Meenakshi 2015). Chitosan is a partially acetylated glucosamine biopolymer that can be found in the cell wall of some fungi such as Mucorales strain. However, it is mainly derived from deacetylation of chitin and has been known as the most important derivative of chitin due to the useful features such as hydrophilicity, biodegradability, and antibacterial property (Rinaudo 2006). Chitosan can be made by treating the chitin in the shells of shrimp and other crustaceans with an alkaline substance such as sodium hydroxide, and it is reported that chitosan chelates six times amounts of metals compared to chitin due to the exposed free amino groups during deacetylation process. Chitosan has potential for commercial biomedical applications and has been applied in the treatment of heavy metal-contaminated wastewaters (Pandey and Tiwari 2015; Chen et al. 2017).

The high adsorption capacity by chitosan and its derivatives for the removal of heavy metal ions from aquatic systems is due to the presence of multifunctional groups; the high hydrophilicity is because a large number of hydroxyl groups on the glucose units with high chemical reactivity as well as flexible structure of the polymer chain (Bhatnagar and Sillanpää 2009).

Compared to chitin, chitosan has superior adsorption ability for heavy metals due to its higher content of amino groups. Chemical modifications of chitosan such as carboxyalkyl substitution, aldehyde cross-linking, ligand cross-linking, and polyamination are accessible to prevent it from dissolution in acidic media (pH < 2) or to enhance adsorption ability. Sargın and Arslan (2015) prepared chitosan microcapsules via cross-linking and evaluated their capability for the removal of copper, cadmium, zinc ions, and other metallic ions. Different pH values, metal concentrations, temperature, amount of adsorbent, and adsorption time have been studied. The adsorption equilibrium followed the Langmuir isotherm model, and the adsorption capacity of the chitosan/sporopollenin microcapsules was found to be 0.15 mmol/g for cadmium and 0.25 mmol/g for zinc.

Seaweed (marine algae) is another kind of abundantly available adsorbent material. Seaweed does not only grow in saltwater but also in freshwater. Usually, seaweed materials, especially brown algae, possess a relatively high surface area and present high binding affinity toward metals due to the functional groups such as amino, hydroxyl, carboxyl, and sulfate as binding sites in the cell wall structure (Özer et al. 2006). Metals can be attracted by an electrostatic force or can form complexes with the material (Hamdy 2000; Jalali et al. 2002).

The adsorption capacity for metal ions was significantly improved after modification. Typical modification methods include acid and acid-base treatment (Suzuki et al. 2005). The surface chemistry was changed dramatically after the treatment resulting in different adsorption preferences. Suzuki et al. (2005) used 0.1 M HCl and 0.1 M NaOH to treat Ulva seaweed, respectively. The adsorption isotherm of the acid-pretreated material was similar to that of the non-treated one, while the adsorption capacity of the alkali-pretreated material increased a lot. The isotherm model was well fitted by the Langmuir model with an adsorption capacity of 90 mg/g for the alkali-pretreated material. The uptake capacities of typical marine material-derived adsorbents for heavy metal removal have been listed in Table 5.3.

5.3.4 Zeolite and Clay

Zeolites, clays, sediment, and soil are readily available, inexpensive materials, and thus are good candidates as low-cost adsorbent materials or precursors. Sediment and soil are mostly used for the removal of organic pollutants such as glyphosate (Morillo et al. 2000) and herbicides (Kibe et al. 2000) from water, while zeolite and clay present good adsorption capabilities for metal removal. The removal capacities for cadmium, lead, and zinc using zeolite and clay as adsorbent materials are listed in Table 5.4.

Zeolites are naturally occurring, highly porous aluminosilicate minerals with different cavity structures, which can also be produced commercially. The porous structure of zeolite can accommodate various cations including sodium, potassium, calcium, magnesium ions, and others. These positive-charged ions are loosely held in the structure and can be easily exchanged with other metal ions in solution and therefore possess ion-exchange abilities. Zeolites consist of more than 40 natural species, among which clinoptilolite is the most abundant and frequently studied one. Sprynskyy et al. (2006) studied the adsorption behavior on raw and pretreated clinoptilolite for lead and cadmium removal. The maximum adsorption capacity is 4.22 mg/g and 27.7 mg/g for Cd2+ and Pb2+, respectively, at an initial concentration of 80 mg/L. The experimental data is well fitted with both the Langmuir and the Freundlich models; the Freundlich model exhibits better fitting at high metal concentrations. Wingenfelder et al. (2005) investigated the removal of lead, cadmium, and zinc from synthetic mine waters by a natural zeolite. Lead can be efficiently removed from neutral as well as from acidic solutions, whereas the uptake of zinc and cadmium decreased when the pH is low and the iron concentrations are high.

Clay usually possesses large surface area and negative charge on the structure of fine-grain silicate minerals. The negative charge can be neutralized by the adsorption of positive-charged cations which might be the reason that it presents good adsorption capacities for metal removal (Ali et al. 2012). Various types of clay have been investigated and modified to enhance their efficiency for heavy metal removal. Kaolinite and montmorillonite are two of the most important and commonly used clay minerals that have been reported in heavy metal removal applications.

Gupta and Bhattacharyya (2008) used kaolinite and montmorillonite for cadmium and lead removal from water. The uptake capacities increase with the increase of pH values until the formation of insoluble metal hydroxides. The adsorption reaction is rapid with maximum uptake amount being observed within 180 min for lead and 240 min for cadmium. Both kaolinite and montmorillonite follow the Langmuir monolayer model with respect to lead and cadmium; the removal capacity values are in the range of 6.8–11.5 mg/g (kaolinite) and 21.1–31.1 mg/g (montmorillonite). Different modification methods have also been developed in order to improve the quality and characteristics of the clay. Two commonly used techniques are intercalation/pillaring and acid activation . Intercalation is the insertion of a guest species in the interlayer region of a clay mineral with preservation of the layered structure (Liu and Wu 2001), while acid treatments of clay minerals control mineral weathering and genesis (Panda et al. 2010). These treatments can replace exchangeable cations with H+ ions, Al3+, and other cations. The attached ions can escape out from both tetrahedral and octahedral sites leaving SiO4 groups largely intact (Theocharis et al. 1988). Gupta and Bhattacharyya (2006) use kaolinite, montmorillonite, and their poly(oxo zirconium) and tetrabutylammonium derivatives to remove cadmium from aqueous solution. The uptake of cadmium was very fast at the beginning of contact and slowed down gradually indicating diffusion into the inner surface of the adsorbent. The pseudo-second order can describe the experimental data better than the pseudo-first order. And the equilibrium isotherm data was fitted well by both the Langmuir model and the Freundlich model. The adsorption behavior was poor in strongly acidic solution but improved in an alkaline medium, and the uptake amount continuously increased with the increase of pH values.

5.4 Conclusion

Adsorption plays an important role in removing heavy metals from effluent. Activated carbon is the most popular adsorbent material and has been used widely in wastewater treatment for decades. However, commercial activated carbons have drawbacks in terms of heavy metal removal efficiency and cost problems. So the overall idea is to find suitable cost-effective alternatives to replace traditional activated carbon. Under these circumstances, new adsorbent materials, especially cost-effective adsorbent materials, need to be developed. The low-cost adsorbent materials usually have the problem of low adsorption capacity; thus cheap and effective modification methods should be introduced to improve the adsorption capacity while controlling the cost of activation at the same time.

In this chapter, a wide range of low-cost adsorbent materials have been reviewed and discussed. Low-cost materials have been divided into four categories based on the nature of the materials. The common characteristics of these materials are abundance either naturally occurring or low-value by-products. By analyzing the composition and developing low-cost treatment methods, they become value-added materials with good adsorbent properties.

References

Afroze S, Sen TK, Ang HM (2016) Adsorption removal of zinc (II) from aqueous phase by raw and base modified Eucalyptus sheathiana bark: kinetics, mechanism and equilibrium study. Process Saf Environ Prot 102:336–352

Ahluwalia SS, Goyal D (2005) Removal of heavy metals by waste tea leaves from aqueous solution. Eng Life Sci 5:158–162

Ahmadpour A, Do DD (1996) The preparation of active carbons from coal by chemical and physical activation. Carbon 34:471–479

Ahmady-Asbchin S, Andres Y, Gerente C, Le Cloirec P (2009) Natural seaweed waste as sorbent for heavy metal removal from solution. Environ Technol 30:755–762

Ajmal M, Ali Khan Rao R, Anwar S, Ahmad J, Ahmad R (2003) Adsorption studies on rice husk: removal and recovery of Cd(II) from wastewater. Bioresour Technol 86:147–149

Aksu Z (2001) Equilibrium and kinetic modelling of cadmium(II) biosorption by C. vulgaris in a batch system: effect of temperature. Sep Purif Technol 21:285–294

Al-Asheh S, Banat F, Al-Omari R, Duvnjak Z (2000) Predictions of binary sorption isotherms for the sorption of heavy metals by pine bark using single isotherm data. Chemosphere 41:659–665

Ali I, Asim M, Khan TA (2012) Low cost adsorbents for the removal of organic pollutants from wastewater. J Environ Manag 113:170–183

Amuda OS, Giwa AA, Bello IA (2007) Removal of heavy metal from industrial wastewater using modified activated coconut shell carbon. Biochem Eng J 36:174–181

Annadurai G, Juang RS, Lee DJ (2003) Adsorption of heavy metals from water using banana and orange peels. Water Sci Technol 47:185–190

Anwar J, Shafique U, Waheed-uz-Zaman SM, Dar A, Anwar S (2010) Removal of Pb(II) and Cd(II) from water by adsorption on peels of banana. Bioresour Technol 101:1752–1755

Argun ME, Dursun S, Ozdemir C, Karatas M (2007) Heavy metal adsorption by modified oak sawdust: thermodynamics and kinetics. J Hazard Mater 141:77–85

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) A review of potentially low-cost sorbents for heavy metals. Water Res 33:2469–2479

Balköse D, Baltacioǧlu H (1992) Adsorption of heavy metal cations from aqueous solutions by wool fibers. J Chem Technol Biotechnol 54:393–397

Basu M, Guha AK, Ray L (2015) Biosorptive removal of lead by lentil husk. J Environ Chem Eng 3:1088–1095

Belviso C, Cavalcante F, Fiore S (2010) Synthesis of zeolite from Italian coal fly ash: differences in crystallization temperature using seawater instead of distilled water. Waste Manag 30:839–847

Benaissa H, Benguella B (2004) Effect of anions and cations on cadmium sorption kinetics from aqueous solutions by chitin: experimental studies and modeling. Environ Pollut 130:157–163

Benguella B, Benaissa H (2002) Cadmium removal from aqueous solutions by chitin: kinetic and equilibrium studies. Water Res 36:2463–2474

Bhatnagar A, Sillanpää M (2009) Applications of chitin- and chitosan-derivatives for the detoxification of water and wastewater—a short review. Adv Colloid Interface Sci 152:26–38

Bhatnagar A, Sillanpää M (2010) Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment—a review. Chem Eng J 157:277–296

Bhatnagar A, Vilar VJP, Botelho CMS, Boaventura RAR (2011) A review of the use of red mud as adsorbent for the removal of toxic pollutants from water and wastewater. Environ Technol 32:231–249

Bianchi A, Micheloni M, Paoletti P (1991) Thermodynamic aspects of the polyazacycloalkane complexes with cations and anions. Coor Chem Rev 110:17–113

Blöcher C, Dorda J, Mavrov V, Chmiel H, Lazaridis NK, Matis KA (2003) Hybrid flotation—membrane filtration process for the removal of heavy metal ions from wastewater. Water Res 37:4018–4026

Brown P, Atly Jefcoat I, Parrish D, Gill S, Graham E (2000) Evaluation of the adsorptive capacity of peanut hull pellets for heavy metals in solution. Adv Environ Res 4:19–29

Bulut Y, Tez Z (2007) Removal of heavy metals from aqueous solution by sawdust adsorption. J Environ Sci 19:160–166

Celis R, HermosÍn MC, Cornejo J (2000) Heavy metal adsorption by functionalized clays. Environ Sci Technol 34:4593–4599

Chen A-H, Liu S-C, Chen C-Y, Chen C-Y (2008) Comparative adsorption of Cu(II), Zn(II), and Pb(II) ions in aqueous solution on the crosslinked chitosan with epichlorohydrin. J Hazard Mater 154:184–191

Chen A, Shang C, Shao J, Lin Y, Luo S, Zhang J, Huang H, Lei M, Zeng Q (2017) Carbon disulfide-modified magnetic ion-imprinted chitosan-Fe(III): a novel adsorbent for simultaneous removal of tetracycline and cadmium. Carbohydr Polym 155:19–27

Chingombe P, Saha B, Wakeman RJ (2005) Surface modification and characterisation of a coal-based activated carbon. Carbon 43:3132–3143

Cho H, Oh D, Kim K (2005) A study on removal characteristics of heavy metals from aqueous solution by fly ash. J Hazard Mater 127:187–195

Da̧browski A, Hubicki Z, Podkościelny P, Robens E (2004) Selective removal of the heavy metal ions from waters and industrial wastewaters by ion-exchange method. Chemosphere 56:91–106

Demiral H, Güngör C (2016) Adsorption of copper(II) from aqueous solutions on activated carbon prepared from grape bagasse. J Clean Prod 124:103–113

Demirbas A (2008) Heavy metal adsorption onto agro-based waste materials: a review. J Hazard Mater 157:220–229

Ding Y, Jing D, Gong H, Zhou L, Yang X (2012) Biosorption of aquatic cadmium(II) by unmodified rice straw. Bioresour Technol 114:20–25

Echeverría JC, Churio E, Garrido JJ (2002) Retention mechanisms of Cd on illite. Clay Clay Miner 50:614–623

El-Said AG, Badawy NA, Abdel-Aal AY, Garamon SE (2011) Optimization parameters for adsorption and desorption of Zn(II) and Se(IV) using rice husk ash: kinetics and equilibrium. Ionics (Kiel) 17:263–270

Fathima NN, Aravindhan R, Rao JR, Nair BU (2005) Solid waste removes toxic liquid waste: adsorption of chromium(VI) by iron complexed protein waste. Environ Sci Technol 39:2804–2810

Feng D, Aldrich C, Tan H (2000) Treatment of acid mine water by use of heavy metal precipitation and ion exchange. Miner Eng 13:623–642

Feng N, Guo X, Liang S, Zhu Y, Liu J (2011) Biosorption of heavy metals from aqueous solutions by chemically modified orange peel. J Hazard Mater 185:49–54

Freitas OMM, Martins RJE, Delerue-Matos CM, Boaventura RAR (2008) Removal of Cd(II), Zn(II) and Pb(II) from aqueous solutions by brown marine macro algae: kinetic modelling. J Hazard Mater 153:493–501

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manag 92:407–418

Garg U, Kaur MP, Jawa GK, Sud D, Garg VK (2008) Removal of cadmium (II) from aqueous solutions by adsorption on agricultural waste biomass. J Hazard Mater 154:1149–1157

Gautam RK, Mudhoo A, Lofrano G, Chattopadhyaya MC (2014) Biomass-derived biosorbents for metal ions sequestration: adsorbent modification and activation methods and adsorbent regeneration. J Environ Chem Eng 2:239–259

Gerente C, Lee VKC, Le Cloirec P, McKay G (2007) Application of chitosan for the removal of metals from wastewaters by adsorption—mechanisms and models review. Crit Rev Env Sci Technol 37:41–127

Günay A, Arslankaya E, Tosun İ (2007) Lead removal from aqueous solution by natural and pretreated clinoptilolite: adsorption equilibrium and kinetics. J Hazard Mater 146:362–371

Guo XY, Liang S, Tian QH (2011) Removal of heavy metal ions from aqueous solutions by adsorption using modified orange peel as adsorbent. Adv Mater Res 236:237–240

Gupta VK, Ali I (2004) Removal of lead and chromium from wastewater using bagasse fly ash—a sugar industry waste. J Colloid Interface Sci 271:321–328

Gupta SS, Bhattacharyya KG (2006) Removal of Cd(II) from aqueous solution by kaolinite, montmorillonite and their poly(oxo zirconium) and tetrabutylammonium derivatives. J Hazard Mater 128:247–257

Gupta SS, Bhattacharyya KG (2008) Immobilization of Pb(II), Cd(II) and Ni(II) ions on kaolinite and montmorillonite surfaces from aqueous medium. J Environ Manag 87:46–58

Gupta VK, Rastogi A, Dwivedi MK, Mohan D (1997) Process development for the removal of zinc and cadmium from wastewater using slag—a blast furnace waste material. Sep Sci Technol 32:2883–2912

Gupta VK, Gupta M, Sharma S (2001) Process development for the removal of lead and chromium from aqueous solutions using red mud—an aluminium industry waste. Water Res 35:1125–1134

Gupta VK, Jain CK, Ali I, Sharma M, Saini VK (2003) Removal of cadmium and nickel from wastewater using bagasse fly ash—a sugar industry waste. Water Res 37:4038–4044

Gupta VK, Agarwal S, Saleh TA (2011) Synthesis and characterization of alumina-coated carbon nanotubes and their application for lead removal. J Hazard Mater 185:17–23

Gurgel LVA, Gil LF (2009) Adsorption of Cu(II), Cd(II) and Pb(II) from aqueous single metal solutions by succinylated twice-mercerized sugarcane bagasse functionalized with triethylenetetramine. Water Res 43:4479–4488

Hadi P, Barford J, McKay G (2013) Toxic heavy metal capture using a novel electronic waste-based material—mechanism, modeling and comparison. Environ Sci Technol 47:8248–8255

Hadi P, Barford J, McKay G (2014) Selective toxic metal uptake using an e-waste-based novel sorbent—single, binary and ternary systems. J Environ Chem Eng 2:332–339

Hamdy AA (2000) Biosorption of heavy metals by marine algae. Curr Microbiol 41:232–238

Han F, Zhang Z, Wang D, Yan P (2015) Hydration heat evolution and kinetics of blended cement containing steel slag at different temperatures. Thermochim Acta 605:43–51

Harja M, Buema G, Sutiman D-M, Munteanu C, Bucur D (2012) Low cost adsorbents obtained from ash for copper removal. Korean J Chem Eng 29:1735–1744

Hegazi HA (2013) Removal of heavy metals from wastewater using agricultural and industrial wastes as adsorbents. HBRC J 9:276–282

Ho YS, McKay G (1999a) Batch lead(II) removal from aqueous solution by peat. Process Saf Environ Prot 77:165–173

Ho YS, McKay G (1999b) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Hua M, Zhang S, Pan B, Zhang W, Lv L, Zhang Q (2012) Heavy metal removal from water/wastewater by nanosized metal oxides: a review. J Hazard Mater 211:317–331

Huang K, Zhu H (2013) Removal of Pb2+ from aqueous solution by adsorption on chemically modified muskmelon peel. Environ Sci Pollut Res Int 20:4424–4434

Hui KS, Chao CYH, Kot SC (2005) Removal of mixed heavy metal ions in wastewater by zeolite 4A and residual products from recycled coal fly ash. J Hazard Mater 127:89–101

Iqbal M, Saeed A, Kalim I (2009) Characterization of adsorptive capacity and investigation of mechanism of Cu2+, Ni2+ and Zn2+ adsorption on mango peel waste from constituted metal solution and genuine electroplating effluent. Sep Sci Technol 44:3770–3791

Jalali R, Ghafourian H, Asef Y, Davarpanah SJ, Sepehr S (2002) Removal and recovery of lead using nonliving biomass of marine algae. J Hazard Mater 92:253–262

Joseph P (2009) Mechanisms of cadmium carcinogenesis. Toxicol Appl Pharmacol 238:272–279

Júnior OK, Gurgel LVA, de Freitas RP, Gil LF (2009) Adsorption of Cu(II), Cd(II), and Pb(II) from aqueous single metal solutions by mercerized cellulose and mercerized sugarcane bagasse chemically modified with EDTA dianhydride (EDTAD). Carbohydr Polym 77:643–650

Karnitz O Jr, Gurgel LVA, de Melo JCP, Botaro VR, Melo TMS, de Freitas Gil RP, Gil LF (2007) Adsorption of heavy metal ion from aqueous single metal solution by chemically modified sugarcane bagasse. Bioresour Technol 98:1291–1297

Karthik R, Meenakshi S (2015) Chemical modification of chitin with polypyrrole for the uptake of Pb(II) and Cd(II) ions. Int J Biol Macromol 78:157–164

Kennedy DC (1973) Treatment of effluent from manufacture of chlorinated pesticides with a synthetic, polymeric adsorbent, Amberlite XAD-4. Environ Sci Technol 7:138–141

Khan S, Cao Q, Zheng YM, Huang YZ, Zhu YG (2008) Health risks of heavy metals in contaminated soils and food crops irrigated with wastewater in Beijing, China. Environ Pollut 152:686–692

Kibe K, Takahashi M, Kameya T, Urano K (2000) Adsorption equilibriums of principal herbicides on paddy soils in Japan. Sci Total Environ 263:115–125

Krishnani KK, Meng X, Christodoulatos C, Boddu VM (2008) Biosorption mechanism of nine different heavy metals onto biomatrix from rice husk. J Hazard Mater 153:1222–1234

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Li X, Tang Y, Xuan Z, Liu Y, Luo F (2007) Study on the preparation of orange peel cellulose adsorbents and biosorption of Cd2+ from aqueous solution. Sep Purif Technol 55:69–75

Li P, Lin C, Cheng H, Duan X, Lei K (2015) Contamination and health risks of soil heavy metals around a lead/zinc smelter in southwestern China. Ecotoxicol Environ Safe 113:391–399

Liang S, Guo X, Feng N, Tian Q (2010) Effective removal of heavy metals from aqueous solutions by orange peel xanthate. Trans Nonferrous Met Soc China 20:s187–s191

Liang S, Guo X, Tian Q (2011) Adsorption of Pb2+ and Zn2+ from aqueous solutions by sulfured orange peel. Desalination 275:212–216

Liu X, Wu Q (2001) PP/clay nanocomposites prepared by grafting-melt intercalation. Polymer 42:10013–10019

Liu Y, Cao Q, Luo F, Chen J (2009) Biosorption of Cd2+, Cu2+, Ni2+ and Zn2+ ions from aqueous solutions by pretreated biomass of brown algae. J Hazard Mater 163:931–938

Liu W, Liu Y, Tao Y, Yu Y, Jiang H, Lian H (2014) Comparative study of adsorption of Pb(II) on native garlic peel and mercerized garlic peel. Environ Sci Pollut Res Int 21:2054–2063

López E, Soto B, Arias M, Núñez A, Rubinos D, Barral MT (1998) Adsorbent properties of red mud and its use for wastewater treatment. Water Res 32:1314–1322

López-Delgado A, Pérez C, López FA (1998) Sorption of heavy metals on blast furnace sludge. Water Res 32:989–996

Maheshwari U, Mathesan B, Gupta S (2015) Efficient adsorbent for simultaneous removal of Cu(II), Zn(II) and Cr(VI): kinetic, thermodynamics and mass transfer mechanism. Process Saf Environ 98:198–210

Miraoui M, Zentar R, Abriak N-E (2012) Road material basis in dredged sediment and basic oxygen furnace steel slag. Constr Build Mater 30:309–319

Morillo E, Undabeytia T, Maqueda C, Ramos A (2000) Glyphosate adsorption on soils of different characteristics: influence of copper addition. Chemosphere 40:103–107

Naiya TK, Chowdhury P, Bhattacharya AK, Das SK (2009) Saw dust and neem bark as low-cost natural biosorbent for adsorptive removal of Zn(II) and Cd(II) ions from aqueous solutions. Chem Eng J 148:68–79

O’Connell DW, Birkinshaw C, O’Dwyer TF (2008) Heavy metal adsorbents prepared from the modification of cellulose: a review. Bioresour Technol 99:6709–6724

Ok YS, Yang JE, Zhang Y-S, Kim S-J, Chung D-Y (2007) Heavy metal adsorption by a formulated zeolite-Portland cement mixture. J Hazard Mater 147:91–96

Onundi YB, Mamun AA, Al Khatib MF, Ahmed YM (2010) Adsorption of copper, nickel and lead ions from synthetic semiconductor industrial wastewater by palm shell activated carbon. Int J Environ Sci Technol 7:751–758

Orlando US, Baes AU, Nishijima W, Okada M (2002) Preparation of chelating agents from sugarcane bagasse by microwave radiation as an alternative ecologically benign procedure. Green Chem 4:555–557

Özer A, Akkaya G, Turabik M (2006) The removal of Acid Red 274 from wastewater: combined biosorption and biocoagulation with Spirogyra rhizopus. Dyes Pigments 71:83–89

Pagnanelli F, Mainelli S, Vegliò F, Toro L (2003) Heavy metal removal by olive pomace: biosorbent characterisation and equilibrium modelling. Chem Eng Sci 58:4709–4717

Panda AK, Mishra BG, Mishra DK, Singh RK (2010) Effect of sulphuric acid treatment on the physico-chemical characteristics of kaolin clay. Colloid Surf A 363:98–104

Pandey S, Tiwari S (2015) Facile approach to synthesize chitosan based composite—characterization and cadmium(II) ion adsorption studies. Carbohydr Polym 134:646–656

Pandey RLP, Ruchi Pandey RCM, Ansari NG (2014) Removal of Cd(II) ions from simulated wastewater by HCl modified cucumis sativus peel: equilibrium and kinetic study. Air Soil Water Res 7:93–101

Paul Chen J, Lin M (2001) Equilibrium and kinetics of metal ion adsorption onto a commercial H-type granular activated carbon: experimental and modeling studies. Water Res 35:2385–2394

Pavan FA, Mazzocato AC, Jacques RA, Dias SLP (2008) Ponkan peel: a potential biosorbent for removal of Pb(II) ions from aqueous solution. Biochem Eng J 40:357–362

Pei YY, Liu JY (2012) Adsorption of Pb2+ in wastewater using adsorbent derived from grapefruit peel. Adv Mater Res 391:968–972

Periasamy K, Namasivayam C (1996) Removal of copper(II) by adsorption onto peanut hull carbon from water and copper plating industry wastewater. Chemosphere 32:769–789

Perić J, Trgo M, Vukojević Medvidović N (2004) Removal of zinc, copper and lead by natural zeolite—a comparison of adsorption isotherms. Water Res 38:1893–1899

Prasanna Kumar Y, King P, Prasad VSRK (2007) Adsorption of zinc from aqueous solution using marine green algae—Ulva fasciata sp. Chem Eng J 129:161–166

Purna Chandra Rao G, Satyaveni S, Ramesh A, Seshaiah K, Murthy KSN, Choudary NV (2006) Sorption of cadmium and zinc from aqueous solutions by zeolite 4A, zeolite 13X and bentonite. J Environ Manag 81:265–272

Qiu W, Zheng Y (2009) Removal of lead, copper, nickel, cobalt, and zinc from water by a cancrinite-type zeolite synthesized from fly ash. Chem Eng J 145:483–488

Rangel-Mendez JR, Monroy-Zepeda R, Leyva-Ramos E, Diaz-Flores PE, Shirai K (2009) Chitosan selectivity for removing cadmium (II), copper (II), and lead (II) from aqueous phase: pH and organic matter effect. J Hazard Mater 162:503–511

Redlich O, Peterson DL (1959) A useful adsorption isotherm. J Phys Chem 63:1024

Rinaudo M (2006) Chitin and chitosan: properties and applications. Prog Polym Sci 31:603–632

Sadrzadeh M, Mohammadi T, Ivakpour J, Kasiri N (2009) Neural network modeling of Pb2+ removal from wastewater using electrodialysis. Chem Eng Process 48:1371–1381

Sankararamakrishnan N, Sharma AK, Sanghi R (2007) Novel chitosan derivative for the removal of cadmium in the presence of cyanide from electroplating wastewater. J Hazard Mater 148:353–359

Santasnachok C, Kurniawan W, Hinode H (2015) The use of synthesized zeolites from power plant rice husk ash obtained from Thailand as adsorbent for cadmium contamination removal from zinc mining. J Environ Chem Eng 3:2115–2126

Sargın İ, Arslan G (2015) Chitosan/sporopollenin microcapsules: preparation, characterisation and application in heavy metal removal. Int J Biol Macromol 75:230–238

Sarı A, Tuzen M (2008) Biosorption of cadmium(II) from aqueous solution by red algae (Ceramium virgatum): equilibrium, kinetic and thermodynamic studies. J Hazard Mater 157:448–454

Sekar M, Sakthi V, Rengaraj S (2004) Kinetics and equilibrium adsorption study of lead(II) onto activated carbon prepared from coconut shell. J Colloid Interface Sci 279:307–313

Shawabkeh R, Al-Harahsheh A, Hami M, Khlaifat A (2004) Conversion of oil shale ash into zeolite for cadmium and lead removal from wastewater. Fuel 83:981–985

Sheng PX, Ting Y-P, Chen JP (2007) Biosorption of heavy metal ions (Pb, Cu, and Cd) from aqueous solutions by the marine alga sargassum sp. in single- and multiple-metal systems. Ind Eng Chem Res 46:2438–2444

Shyam R, Puri JK, Kaur H, Amutha R, Kapila A (2013) Single and binary adsorption of heavy metals on fly ash samples from aqueous solution. J Mol Liq 178:31–36

Sips R (1948) On the structure of a catalyst surface. J Chem Phys 16:490

Sprynskyy M, Buszewski B, Terzyk AP, Namieśnik J (2006) Study of the selection mechanism of heavy metal (Pb2+, Cu2+, Ni2+, and Cd2+) adsorption on clinoptilolite. J Colloid Interface Sci 304:21–28

Srivastava NK, Majumder CB (2008) Novel biofiltration methods for the treatment of heavy metals from industrial wastewater. J Hazard Mater 151:1–8

Srivastava SK, Singh AK, Sharma A (1994) Studies on the uptake of lead and zinc by lignin obtained from black liquor—a paper industry waste material. Environ Technol 15:353–361

Suzuki Y, Kametani T, Maruyama T (2005) Removal of heavy metals from aqueous solution by nonliving Ulva seaweed as biosorbent. Water Res 39:1803–1808

Tan G, Xiao D (2009) Adsorption of cadmium ion from aqueous solution by ground wheat stems. J Hazard Mater 164:1359–1363

Theocharis CR, Jacob KJ, Gray AC (1988) Enhancement of Lewis acidity in layer aluminosilicates. Treatment with acetic acid. J Chem Soc Faraday Trans 84:1509

Torab-Mostaedi M, Asadollahzadeh M, Hemmati A, Khosravi A (2013) Equilibrium, kinetic, and thermodynamic studies for biosorption of cadmium and nickel on grapefruit peel. J Taiwan Inst Chem Eng 44:295–302

Vaughan T, Seo CW, Marshall WE (2001) Removal of selected metal ions from aqueous solution using modified corncobs. Bioresour Technol 78:133–139

Vázquez G, Antorrena G, González J, Doval MD (1994) Adsorption of heavy metal ions by chemically modified Pinus pinaster bark. Bioresour Technol 48:251–255

Velazquez-Jimenez LH, Pavlick A, Rangel-Mendez JR (2013) Chemical characterization of raw and treated agave bagasse and its potential as adsorbent of metal cations from water. Ind Crop Prod 43:200–206

Wang Y, Qiao M, Liu Y, Zhu Y (2012) Health risk assessment of heavy metals in soils and vegetables from wastewater irrigated area, Beijing-Tianjin city cluster, China. J Environ Sci 24:690–698

Wingenfelder U, Hansen C, Furrer G, Schulin R (2005) Removal of heavy metals from mine waters by natural zeolites. Environ Sci Technol 39:4606–4613

Witek-Krowiak A, Szafran RG, Modelski S (2011) Biosorption of heavy metals from aqueous solutions onto peanut shell as a low-cost biosorbent. Desalination 265:126–134

Wu F-C, Tseng R-L, Juang R-S (2000) Comparative adsorption of metal and dye on flake- and bead-types of chitosans prepared from fishery wastes. J Hazard Mater 73:63–75

Wu F-C, Tseng R-L, Juang R-S (2001) Kinetic modeling of liquid-phase adsorption of reactive dyes and metal ions on chitosan. Water Res 35:613–618

Xu M, Hadi P, Chen G, McKay G (2014) Removal of cadmium ions from wastewater using innovative electronic waste-derived material. J Hazard Mater 273:118–123

Xu M, Hadi P, Ning C, Barford J, An KJ, McKay G (2015) Aluminosilicate-based adsorbent in equimolar and non-equimolar binary-component heavy metal removal systems. Water Sci Technol 72:2166–2178

Xue Y, Hou H, Zhu S (2009) Competitive adsorption of copper(II), cadmium(II), lead(II) and zinc(II) onto basic oxygen furnace slag. J Hazard Mater 162:391–401

Xue Y, Wu S, Zhou M (2013) Adsorption characterization of Cu(II) from aqueous solution onto basic oxygen furnace slag. Chem Eng J 231:355–364

Yu B, Zhang Y, Shukla A, Shukla SS, Dorris KL (2000) The removal of heavy metal from aqueous solutions by sawdust adsorption—removal of copper. J Hazard Mater 80:33–42

Yu B, Zhang Y, Shukla A, Shukla SS, Dorris KL (2001) The removal of heavy metals from aqueous solutions by sawdust adsorption—removal of lead and comparison of its adsorption with copper. J Hazard Mater 84:83–94

Zhu C, Luan Z, Wang Y, Shan X (2007) Removal of cadmium from aqueous solutions by adsorption on granular red mud (GRM). Sep Purif Technol 57:161–169

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Xu, M., McKay, G. (2017). Removal of Heavy Metals, Lead, Cadmium, and Zinc, Using Adsorption Processes by Cost-Effective Adsorbents. In: Bonilla-Petriciolet, A., Mendoza-Castillo, D., Reynel-Ávila, H. (eds) Adsorption Processes for Water Treatment and Purification . Springer, Cham. https://doi.org/10.1007/978-3-319-58136-1_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-58136-1_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-58135-4

Online ISBN: 978-3-319-58136-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)