Abstract

Negative temperature coefficient (NTC) thermistors are required to have good electrical stability for many domestic and industrial applications. The aging phenomenon of NTC thermistors can be described as the change in electrical resistance due to thermal stress with time. In this study, Ni0.5CoxMn2.5−xO4 (x = 0.5, 0.8 and 1.1) ceramics were fabricated by the conventional solid-state reaction method. The powder mixtures of manganese, cobalt and nickel oxides were ball-milled for 5 h. The powders were calcinated at 900 °C for 2 h. The samples were sintered at 1100 °C for 5 h. To investigate the aging behaviour, the samples were held at 150 °C for 400 h. Aging in the samples were calculated by the following equation; ∆R/R0 = (R − R0)/R0 in which R0 is the resistance at 25 °C before the aging test, and R is the resistance at 25 °C after the aging test.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Nickel manganite based materials are used as negative temperature coefficient (NTC) thermistors. They are widely used in air conditioners, refrigerators, medical equipment etc. as temperature sensors due to their interesting electrical properties [1]. Transport phenomena in these materials are frequently explained by phonon-assisted jump of carriers among localized states, this is known as hopping conductivity. Their electrical resistivity (ρ) varies exponentially with temperature (T) by the well-known Arrhenius equation ρ = ρo exp (B/T), where ρo is the resistivity of the material at infinite temperature and B is the material constant which is a measure of the sensitivity of the material over a given temperature [2]. The material constant (B) can be calculated by Eq. (1).

ρ1 and ρ2 being the electrical resistivity at temperature T1 and T2, respectively. Nickel manganite based thermistors exhibit the spinel-type crystal structure with the general formula AB2O4. In the spinel structure, there are two sites available for the cations; (1) the tetrahedral site is known as A-site and (2) the octahedral site is known as B-site. The distribution of the ions is as follows in nickel manganite: Mn3+ will predominantly occupy the B-site, while Mn2+ can be found on the A-site and the majority Ni2+ can be found on the B-site [3].

The electrical stability of NTC thermistors is very important. However, the drift in resistance (∆R/R) of a thermistor occurs due to thermal stress with time. The long-term stability of the electrical properties depends on many factors such as the chemical composition, crystal structure (cubic or tetragonal) and the heat treatments applied to NTC thermistors. The chemical composition in thermistor alters its microstructural properties such as crystal structure, density, grain size etc. The atomic diffusion in the spinel lattice can be altered by various heat treatments, the intergranular defects could act as barriers against ion mobility thus explaining the better thermal stability of the thermistors [1].

It is generally considered that the aging is connected with ion exchange between tetrahedral and octahedral sites. The ionic diffusion on octahedral sites may give rise to ionic migration between octahedral and tetrahedral sites. The redistribution of cations occurs owing to cation vacancies and a cationic vacancy migration take places from grain boundary to grains during aging [4].

In this study, we aim to investigate the aging behaviour of Ni0.5CoxMn2.5−xO4 (x = 0.5, 0.8 and 1.1) thermistors.

Experimental Procedures

NiO (99% purity, Alfa Aesar), Co3O4 (99.5% purity, Sigma-Aldrich) and Mn2O3 (99% purity, Sigma-Aldrich) powders were weighed according to the compositions of Ni0.5CoxMn2.5−xO4 (where x = 0.5, 0.8 and 1.1). The raw powder mixture was ball-milled using ZrO2 balls as a grinding media with ethyl alcohol in a jar for 5 h. The obtained slurries were dried and powders were calcinated at 900 °C for 2 h. The powders were pressed to form disc shaped specimens and then sintered at 1100 °C for 5 h in air employing a 360 °C/h heating rate then cooled naturally in the furnace.

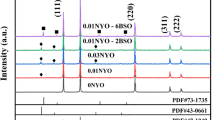

The phases in the sintered samples were determined by X-ray diffraction (XRD, Rigaku D/Max-2200/PC) analysis using CuKα radiation at 60 kV/2 kW. The microstructure of samples was observed using a scanning electron microscope (SEM, JEOL, JSM 5600) on fracture surfaces. The sintered samples were coated with silver paste to form electrodes. The electrical resistance was measured in a temperature programmable furnace between 25 and 85 °C in steps of 0.1 °C. The material constant (B, K), the activation energy (Ea, eV), and the sensitivity coefficient (α, %/K) values were calculated for the NTC thermistors .

The samples were held at 150 °C for 400 h in order to age the samples. The drift in resistance was calculated by equation;

in which “R” is the resistance at 25 °C after aging for 400 h, R0 is the resistance at 25 °C before aging.

Results

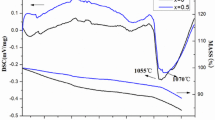

Figure 1a shows the variation of electrical resistance with Co content at 25 °C before and after the aging process. The resistance of samples decreased with the increasing Co content. For the Ni0.5Co0.5Mn2O4 (A05) sample, the resistance was found as 298 Ω, it decreased to 136 Ω for the Ni0.5Co0.8Mn1.7O4 (A08) sample. A further decrease in resistance to 88 Ω was observed for the Ni0.5Co0.8Mn1.7O4 (A11) sample. In our previous work, the resistivity, B25/85 constant and activation energy of samples decreased when Co content increased from 0.5 to 1.1 [5]. This can be explained by the increase in Co2+ and Co3+ ions, which are responsible for the hopping mechanism on octahedral sites, due to increased Co content.

Muralidharan et al. [6] reported that the resistivity, B constant, the activation energy and temperature coefficient of resistance decreased with the increasing Co content for Ni0.7Mn2.3−xCoxO4 (0 ≤ x ≤ 0.7) NTC thermistors . This observation was explained by the Co2+ and Co3+ ions also occupying the octahedral sites and contribute to the electrical conductivity along with Mn3+/Mn4+ ion pairs in the octahedral sites.

Park et al. [7] reported that the resistivity of samples increased with the addition of Cr2O3 in Mn1.1Ni1.4Co0.5−xCrxO4 (0 ≤ x ≤ 0.35) NTC thermistors. They reported the resistivity of the thermistors increased as the Cr content increased. There are two possible reasons for the increase in the resistivity with increasing Cr content. (1) Both the grain size and density of the as-sintered samples decreased with an increase in Cr content, decreasing the time between electron scattering events of charge carriers and thus increasing the resistivity. (2) The amount of Co3O4 for the thermistors decreases with increasing Cr content, decreasing Co2+/Co3+ ions on octahedral sites. As a result, the number of Mn3+/Mn4+ ions on octahedral sites decreases to preserve the overall electrical neutrality of the system.

Figure 1b shows the variation of ∆R/R0 as a function of Co content for Ni0.5CoxMn2.5−xO4 (where x = 0.5, 0.8 and 1.1) ceramic system. The A05 sample aged negatively, but A08 and A11 samples behaved unlike A05 sample. The drift in resistance of A05 sample was calculated as ≈−6%. For A08 sample, the aging value was a positive change in resistance of ≈5%. Then, it decreased sharply to +0.4% with increasing Co content from 0.8 to 1.1.

Conclusion

Aging phenomenon of nickel manganite based NTC thermistors thermally stressed at 150 °C for 400 h was investigated. The drift in resistance (∆R/R) of Ni0.5CoxMn2.5−xO4 (where x = 0.5, 0.8 and 1.1) thermistors varied in the range from −5.7% to +0.4%. The drift in resistance decreased with increasing Co content from 0.8 to 1.1. In this study, the best electrical stability was observed for the Ni0.5Co1.1Mn1.4O4 thermistor with a positive change in resistance of 0.4%.

References

Battault T, Legros R, Brieu M, Couderc J-J, Bernard L, Rousset A (1997) Correlation between microstructure and ageing of iron manganite thermistors. J de Physique 3(7):979–992

Wang J, Zhang J (2012) Effects of Mg substitution on microstructure and electrical properties of NiMn2-xMgxO4 NTC ceramics. J Mater Res 27:928–931

Park K (2005) Fabrication and electrical properties of Mn–Ni–Co–Cu–Si oxides negative temperature coefficient thermistors. J Am Ceram Soc 88:862–866

Li DF, Zhao SX, Xiong K, Bao HQ, Nan CW (2014) Aging improvement in Cu-containing NTC ceramics prepared by co-precipitation method. J Alloy Compd 582:283–288

Hardal G, Price BY Influence of nano-sized cobalt oxide addition on the structural and electrical properties of nickel manganite based NTC thermistors. In: Paper presented at the 23rd international conference on materials and technology, Portorož, Slovenia, 28–30 Sept 2015, p 256

Muralidharan MN, Rohini PR, Sunny EK, Dayas KR, Seema A (2012) Effect of Cu and Fe addition on electrical properties of Ni–Mn–Co–O NTC thermistor compositions. Ceram Int 38:6481–6486

Park K, Han IH (2006) Effect of Cr2O3 addition on the microstructure and electrical properties of Mn-Ni-Co oxides NTC thermistors. J Electroceram 17:1069–1073

Acknowledgements

This study is supported by TÜBİTAK (The Scientific and Technical Research Council of Turkey), Project number 3001-114M860. We would like to thank TÜBİTAK for its financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Hardal, G., Price, B.Y. (2017). Aging Behaviour in Ni0.5CoxMn2.5−xO4 (x = 0.5, 0.8 and 1.1) Thermistors. In: Ikhmayies, S., et al. Characterization of Minerals, Metals, and Materials 2017. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-51382-9_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-51382-9_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51381-2

Online ISBN: 978-3-319-51382-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)