Abstract

This chapter lays grounding for principles in a circular economy from the fashion viewpoint. Chapter presents following approaches; design for longevity, design for services, design for reuse in manufacture, design for material recovery and new business models for circular economy. Building a circular economy system and transformative business for fashion requires a new system level and radical innovations. Therefore, also the key stakeholders and their roles for this transformation are discussed. At the end of the text design principles for circular economy are highlighted.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

In the near future, the fashion field will need to overcome new challenges, as sustainable development moves towards more holistic and systemic understanding and further knowledge on circular economy models emerges. A Circular Economy (CE) is regenerative by nature, based on principles of closed loops. The foundation for this closing the loop approach is based on McDonough and Braungart’s (2002) cradle-to-cradle principle. According to this principle a product is designed to have multiple life cycles or it is biodegradable. Accordingly, after the use phase, the product will continue in technical or biological cycles. Composting is not a realistic option for garments and textiles, which include many harmful chemicals, and further composting causes methane, which contributes to greater greenhouse gas emissions and global warming (Niinimäki 2013). Therefore, in the fashion sector, closing the loop must occur in a technical cycle.

A CE approach in fashion aims to develop a more sustainable and closed-loop system where the goal is to extend the use time of garments; furthermore, all materials will be recycled in several rounds. Products are designed to be included in a system where all aspects are considered: the original design and its suitability for several lifecycles, material flows in the system, appreciating waste as a valuable resource and even collecting back all products after their use. Accordingly, moving towards a CE means taking a system perspective on fashion, where all actors are included: designers, producers, manufacturers, suppliers, business people and even consumers. Moreover, building a CE system and transformative business for fashion requires a new system level and radical innovations.

8.2 Design for Longevity, Quality and Design for Long-Term Satisfaction

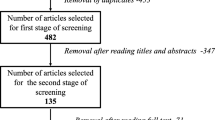

In a CE, system design has a different role compared to that in a linear economy. In the former, design has to contribute strongly to minimising the environmental impact of the garment, through, for example, four different paths, as presented in Fig. 8.1 from the Great Recovery report (RSA 2016). The model starts from a new kind of consumer understanding, and the principle is that a company creates a new kind of relationship with the end user. The company has to know the end user and his/her needs and desires much better if it is to offer a longer use-time of the garment or better and more stable satisfaction with the product.

The first principle of design for CE is to extend the use-time of products (see Fig. 8.1). Therefore, consumer satisfaction has to be the focus of design. How, then, to do this in practice? When considering consumer satisfaction, quality is a critical aspect: the quality of the textile material, all details, dyes and sewing work. Our earlier study (Niinimäki 2014) has shown that product satisfaction correlates strongly with quality issues, but quality is neither a simple aspect nor a one-level approach regarding garments. On the other hand, clothing offers us a certain performance, which can be seen as instrumental or expressive (Swan and Combs 1976; Niinimäki 2011). Instrumental performance is linked to the product’s physical properties while expressive performance is linked to consumers’ psychological response to the garment, the emotional side of the satisfaction. To offer satisfaction to the consumer, the product needs to fulfil expectations at both levels: if first the instrumental performance expectations are met (e.g. durability, fit, quality) and then the expressive performance (e.g. beauty) pleases, the result is deep product satisfaction.

But let us start the investigation from clothing quality. Ophuis and Trijp (1995) argue that in perceived quality, evaluation depends on the consumer’s judgement. Quality in garments from the consumers’ viewpoint can be divided into four sectors (Niinimäki 2011, 2014). The first sector comprises the intrinsic quality cues, of material, manufacturing quality and fit, which all relate strongly to the actual physical product (see Table 8.1). Secondly, extrinsic quality cues, which include price, brand and manufacturing location, are external to the actual product but provide the consumer with important information. These “quality cues” are key elements the consumer evaluates when making the purchase decision. For example, many consumers have reported that when looking for good quality they strongly trust a particular brand and its reputation for high-quality garments. In this case customers rely on their own earlier experiences with the life span of garments from this certain brand (Niinimäki 2011, 2014); therefore, product quality is an important value for a brand and its reputation. Jackson and Shaw (2009, p. 125) argue that price is forgotten not long after purchase, while the quality of the product is remembered long after. Therefore good experienced quality can lead to brand loyalty.

Quality cues are product characteristics that can be observed without actual use experience. In contrast, quality attributes can only be evaluated in use. Quality attributes experienced in garments are fit (experience in long-term use), maintenance quality, tactile feeling, functionality and life span (Niinimäki 2011, 2014). In consumer satisfaction with garments, when the aim is extend the life span of a garment, the use experience is most critical. A critical aspect for consumers’ dissatisfaction, leading to a very short use-time of a garment, is low maintenance quality. Such a garment has lost its fit, size or colour or the material simply looks worn out after laundering, which leads to early disposal of the garment (Niinimäki 2011, 2014).

There are quality attributes that link to a consumer’s own value base, and thus stay at a cognitive level, and these are called credence quality attributes (Ophuis and Trijp 1995). In the clothing sector, such attributes can include ethical production, low environmental impact, safety issues (e.g. no toxic chemicals) and local production, if the consumer’s values are grounded on environmental and ethical interest (Niinimäki 2011, 2014).

But increasing the quality of the product to achieve garment longevity is not enough. Especially in fashion, symbolic values are important. Fashion is linked to our emotional needs, our individuality and the need to express ourselves and gain social acceptance (Kaiser 1990). The emotional aspects of fashion consumption therefore need to be addressed through design when aiming to extend the longevity of a garment. This is quite a challenging task. The aesthetic aspects and emotional experiences are important in clothing, and therefore aiming for better quality alone does not guarantee the longevity of a product. The aesthetic experience with clothing includes multisensorial dimensions: A garment’s beauty is experienced through visual, tactile, olfactory and kinetic experiences, resulting in feelings of beauty, comfort, a pleasant weight or sensual movement of the material against our body (Niinimäki 2010). The experience of beauty with a garment can be above average, making this kind of garment special to us and leading to deep product satisfaction or even to person-product attachment. Therefore this kind of experience helps to extend the use-time of garments (Niinimäki 2011, 2014).

Different garment types and use situations emphasise different satisfaction attributes (Niinimäki and Armstrong 2013). For garments in frequent use, the functional aspects might be much more important than the aesthetic ones. Here, active use defines the satisfaction attributes that need to be at the core of the design. For example, for sport clothing in frequent use, the critical satisfaction attributes are durability, high performance and high functionality, and good quality in maintenance (frequent washing). For festive dresses, for example, on the other hand, aesthetic experiences are more important, which may not be as functional or even pleasurable to use. A festive dress is not in active, frequent use, and we can tolerate much more uncomfortable experiences if we seldom wear the dress. Here, the beauty experience might be the most important aspect for consumer satisfaction. To include a satisfaction offering in design, designers and companies have to know their customers better than currently, and this conclusion is also the basis for the service aspect that will be discussed in the next section (Table 8.2)

8.3 Design for Services: Offering Satisfaction and Change in a Sustainable Way

In Product-Service Systems, the PSS approach, one aim is to move the focus from personal ownership to alternative utilisation options to decrease total material consumption. This can be effected through offerings that mix tangible products and intangible services, and the goal is to offer satisfaction and fulfilment of consumers’ needs and desires in a more sustainable and less materialistic way (Briceno and Stagl 2006; Mont 2002; Tukker and Tischner 2006). Depending on the service offering, product design in PSS can include features such as durability, flexibility, modularity and ease of use (Mont 2002; Pawar et al. 2009; Van Halen et al. 2005). Moreover the service model can aim for less material-intensive consumption as in renting or leasing models (collaborative consumption), in clothing swaps or in using consultancy to update the wardrobe (Armstrong et al. 2015). Change is fundamental to fashion, and services can provide a solution to fulfilling customers’ need for change. In these kinds of service offerings, upgrading and modifications can deliver change experiences for consumers while preventing the desire to buy new clothing.

In PSS offerings, a critical point is consumers’ readiness to accept and use services to extend the use-time of garments. Therefore, the service has to be designed according to the target customer group’s values and wishes. Armstrong et al. (2015) studied consumers’ attitudes to services in the fashion sector, to define barriers as well as pathways to viability. Findings from this study indicated a moderate level of interest in a variety of clothing-related PSS features, with the highest level of interest in clothing take-back, swaps and consultancy services. PSS concepts including experiential, innovative and social approaches (renting, swapping and fashion result) were evaluated as best suited for younger consumers. Clothing services that emphasised product satisfaction (e.g. redesign, repair/maintenance, customisation and consultancy) were seen to be most suited for older consumers with their more stable value base and less need for appearance change (Armstrong et al. 2015).

In developing a PSS, the service element has to be included in the product design and business model from the beginning. This approach changes the design criteria, for example, the need for high quality in renting services to keep the product in use for an extended time. From the business viewpoint, the PSS will not succeed if the service is a simple add-on and not a fundamental goal in product design and in the business model.

8.4 Design for Reuse in Manufacture

Taking the remanufacturing approach necessitates a completely new model for garment design and construction. Here, the garment construction should be based on modularity and it should be able to be updated or modified. In principle, broken components should be able to be replaced and the product be restored to its original state (Action and Centre 2016). In the fashion sector this is a big challenge. Here, PSS thinking offers the possibility to create services to mend damaged garments, update them or modify them, and these aspects could be included in the business model.

In the ideal case the original garment has to be designed and manufactured in a manner that makes it possible to recycle all parts. One example of modularity is a modular concept design created by Essi Karell for her MA thesis in 2014 in Aalto University (Fig. 8.2). The outcome is a combination of a fashion design concept based on modularity and PSS. The core value is in the service, where a customer can take back the garment to the store so it will be updated or transformed. The idea is to create fashion design that includes a service aspect; this creates a new kind of system that is not linear (i.e. make-use-dispose). The garment is constructed from modules, which enable the garment to be unstitched and reassembled, resulting in different looks. The service can offer sustainable satisfaction for fashion change based on modular design, and moreover the model can provide new profit-making possibilities for the fashion designer (in the reassembling stage) (Karell 2013, 2014).

Essi Karell’s system for modular fashion design (Karell 2013, p. 117)

In CE, products should be able to be disassembled, and thereafter components should be able to be separated into different flows. Components should be separated into consumable or durable elements, which could be used later in remanufacturing processes. Components that cannot be reused could go into a material recovery process. This principle challenges current garment design and manufacturing practices, where most of the materials in garments are blends that are complicated or impossible to separate. Designing garments for disassembly also needs new innovations: for example, thread that can easily be broken apart in the disassembly stage or a durable textile material that can go through a disassembly process.

The remanufacturing principle may be impossible in the garment sector, as scalability is a critical issue. Modular principles might be possible to implement only in a small scale. In the industrial scale, it is quite challenging, and therefore the next principle of design for material recovery might be more relevant for the fashion sector.

8.5 Design for Material Recovery

In a linear system, all products end up as waste. Textile material has long been recycled, but it is mainly down-cycled into lower value products, for example, filling or insulation materials. We need to foster new appreciation of all materials at the end of products’ life and see waste as a valuable raw material for the next round. Here, we need new innovative technologies on how to use waste material. As the textile waste stream is ever increasing, the future of fashion and textiles will need to be based on closed-loop thinking and circularity.

Closing the fashion loop by recycling is quite a new phenomenon. In a closed-loop system, garments are recycled into new fibres and further into yarns. Currently closed-loop examples remain rare (e.g. the Teijin factory that turns post-consumer polyester waste from the company Patagonia into new fibres with the help of virgin polyester), and scalability is by and large missing. In the recycling of textile material, the loss of quality is a clear challenge. Pre-consumer waste is easier to recycle than post-consumer waste. Manufacturing offcuts (pre-consumer waste) can be collected in the factory and re-spun with the help of virgin materials into new yarn, and this practice is more common than using post-consumer waste. But the amount of post-consumer waste is huge and still increasing, so this waste stream should also be used. Here the problem is collecting and separation, where issues include chemicals, unknown fibre content, low quality, and therefore the predicted end quality from this origin is uncertain (Hvass 2016).

Recycling of textile material can be done through a mechanical process (e.g. wool, cotton) or through a chemical process (e.g. viscose, polyester). A mechanical process means that fabric is broken down into fibres through a mechanical process, cutting, shredding and carding, and then it is spun into new yarn or used in another way in new product manufacturing. A chemical process means that synthetic fibres can be dissolved and thereafter the fibre is regenerated. Chemical recycling processes have recently been developed to be suitable also for cotton, cellulose materials and blends (cotton-polyester), but it remains quite challenging and needs further development.

In 2013, researchers at the University of Helsinki and Aalto University in Finland were successful in developing a novel cellulose spinning solvent, which revealed excellent spin stability resulting in outstanding fibre properties. This innovation is called Ioncell-F, and it enables the production of man-made cellulosic fibres by dry-jet wet spinning. It offers an alternative to viscose processes, which have high environmental impact. The Ioncell-F process is a green, non-toxic and environmentally friendly technology for dissolving waste cotton utilising an ionic liquid. The waste-cotton solution is then extruded through spinnerets and finally regenerated into cellulose fibres. This innovation opens up new ways to use cotton and cellulose textile waste as a resource for fibre production (Aalto University, 11.2.2016).

Scientific development work to find the best technical solutions to transform waste materials (cotton, cellulose, polyester and blends) into high-quality textile fibres are currently been investigated in “T2C”, the Trash to Cash project (2015–2018). Paper waste or cardboard waste can also be used to produce high-quality textiles in the project (T2C 2015). Recycled paper and cardboard are good raw materials for textiles because of the reuse of material and the low level of processing needed. This method with waste uses less chemicals and energy than pure, virgin birch cellulose (Aalto University, 27.10.2015). The T2C project objectives offer a good example of how, in a CE, all raw waste streams should be considered anew and their capability to be used as material for the next product cycle should be tested.

The closed-loop remanufacturing approach does not only challenge product and material design but also there needs to be consideration of chemical compounds in textiles. The purity and nontoxicity of materials, chemicals and colours are essential if textiles are to be remanufactured from waste materials. We need further research on what kinds of chemicals can be recycled in the system and what cannot. This means that only those chemicals can be used in the original product that can be safely recycled in a closed-loop way. Smirnova et al. (2016), for instance, have been studying the recycling of colours in the Ioncell-F process. The results show that it is possible to recycle some textile colours in a stable way while other colours change or disappear in this fibre regeneration process. The material recovery approach in fashion needs further research and new guidelines for the design and manufacturing of the original product so that it is suitable for recycling in a closed-loop way.

8.6 New Business Models in a Circular Economy

The “take, make and dispose” model of production has long relied on cheap resources to maintain growth and stability. That world no longer exists. By applying the principles of a CE – a system that is regenerative by design – forward looking companies can seize growth opportunities while laying the groundwork for a new industrial era that benefits companies and economies alike (Nguyen et al. 2014, pp. 16–17).

The linear economic system is based on fast material throughput and a mind-set of “take, make, use and dispose” in very fast and unsustainable way. The business thinking in fast fashion emphasises low quality, fast production and a short use-time of garments to maximise sales and profit. The mind-set has to change and slower cycles have to be created, but this needs new business principles. In the buy-and-consume economy, the simple goal is to sell the product. In a CE, the goal must be different; it can propose renting the product to ensure the return of the product’s materials into the material flow, as the responsibility of the product producer (Nguyen et al. 2014). Alternatively, a deposit system or incentives must be included in the business model to guarantee the product’s return. Therefore, rethinking the system has to start from materials, which have to be seen as a valuable source that will be used in multiple cycles through disassembly and reuse – and not as material that quickly flows through the economy only once (Nguyen et al. 2014).

The approaches of design for longevity, for services, for reuse or for material recovery do not only challenge the current industrial design and manufacturing principles but also business models in the current linear fashion system. The whole business thinking has to change, and profit making has to be based on totally different grounds. Antikainen and Valkokari (2016) have argued that CE needs radical and systemic innovation, and therefore the whole value chain has to be redesigned through new business thinking. Circularity can be seen as a threat or an opportunity for a fashion business. New business opportunities can be created, for example, with a PSS approach or in take-back schemes. If aiming for a PSS, the service aspect has to be included in the business model from the beginning. The service has to increase the customer satisfaction or extend the use-time of the garment, but it can also be a clear strategy to make profit. For example, if the product is meant to be rented, it has to be durable and long lasting, and the profit comes from rent, not from selling the product. The business model in CE thereby has to change from ownership of the product to performance-based payment models (EMF 2012).

Reverse-logistic providers (collectors, sorters, remanufacturers) will have an ever more important role in the CE if the future norm is material return into remanufacturing and material recovery. All these new business approaches need new networks and totally new thinking in the global context. In Sustainable Business Model Innovation (SBMI), the aim is not only to create economic value but also environmental value, for example, through creating value from waste or societal value and through re-purposing the business existence (Antikainen and Valkokari 2016). Therefore, considering SBMI might provide a good starting point for building new understanding for a CE business model.

8.7 Who Is Needed and How to Make the Transformation

This chapter began by presenting the model for a CE (Fig. 8.1). It is good to notice that the diagram also presents stakeholders and different knowledge holders who need to be included in this system. Starting from the centre, Design for longevity, the critical stakeholders are the consumers and their willingness to participate in using garments longer with their own actions and consumption habits. The second level is Design for service, and here companies are the stakeholders who carry the responsibility to develop the product-service offering so that it extends the use-time of garments and offers consumers a more sustainable way to fulfil their needs in the fashion arena. The third level is Design for reuse, and here the main stakeholders are manufacturers. With the help of new design understanding, the product should be designed and manufactured in a manner where reuse of components is possible. The fourth level is Design for material recovery, where material experts’ and resource management experts’ knowledge is needed.

Policymakers have a critical role in speeding up the change process. Policymakers could push business to move towards transformative, creative and circular business models. Extended Producer Responsibility (EPR) could be used to push business towards closed-loop thinking where products have to be collected back after their life span. If virgin materials were more expensive than today because of green taxation, this would have a positive effect on the price of recycled materials. This development could be accelerated with the help of taxation on the use of virgin materials or with regulations.

Textile waste legislation and EPR principles can speed up the transformation. For example, in Finland a new regulation for recycling all waste and preventing organic waste from ending up in landfills came into force in 2016. EPR is a policy that requires the original manufacturer or producer to take back the product after its use. It can be a mandatory system, as exists in, for example, France. There, producers, distributors and importers of clothes, linens and footwear have had to take back old products since 2008. A company has to have a take-back system itself or it can join a scheme, which is accredited by the French government, and pay to participate in it (Tojo et al. 2012; cited in Niinimäki 2013). Voluntary EPR is driven by industry, and we have seen examples of this lately in the fashion business. Companies pro-actively take back old clothes and mainly donate them to charity. The companies see these actions as improving brand value more than emphasising closed-loop systems. Some positive examples do exist, mainly in the Research & Development sector. In Finland, the Relooping Fashion project collected back old cotton clothes with the help of the Recycling Centre and a fashion company. Waste was thereafter sorted, processed into new fibres and manufactured as new garments (Relooping Fashion 2016). The project is a good example of the experimental collaboration among academy, industry, a fashion company and stakeholders we need to build new knowledge for CE (Fig. 8.3)

Relooping Fashion project (Relooping Fashion 2016, used with permission)

EPR does not yet cover the fashion and textile field, but it soon might, as EU policy increasingly aims at waste prevention and closing landfills. This would change fashion companies’ actions and business logic, as old garments mean extra cost through waste treatment. Therefore an effective material recycling system needs to be established (Niinimäki 2013).

The transformation towards CE requires systemic and multilevel thinking, as well as radical innovations. Innovations are needed at the macro level (trends and drivers), the meso level (ecosystem and value co-creation) and the micro level (company, customer, consumer) (Valkokari et al. 2014). As Hvass (2016) has pointed out, all stakeholders and members of the value chain have to be included in this CE system, which necessitates global thinking. Currently “…[c]hain members, such as garment producers, brands, collectors, sorters, fabric spinners and recyclers are diffused over different countries and continents, which challenge global closed loop supply chain management and its integration” (p. 134). There are political obstacles in, for example, legislation in different countries, which prevents the import of used textiles. This is the reality in, for example, Turkey, which is a significant textile producer. Local legislation thereby prevents the global transformation towards CE. Hvass (2016) further argues that a critical mass of closed-loop material is needed to create a functional system; this also needs global thinking. Moreover much coordination, collaboration and transparency is needed across the total value chain with the support of textile waste legislation to make this happen (Krikke et al. 2004, cited by Hvass 2016, p. 134).

How this can all happen at the product, manufacturing, use, material recovery and system levels should be the target of new research, with the support of design examples. To initiate the change with fashion designers, some design approaches for a CE are therefore highlighted in Table 8.3.

References

Aalto University. (27.10.2015). Luxury fibre from recycled cardboard, retrieved from http://chem.aalto.fi/en/current/news/2015-10-27-005/ [accessed on: 01/06/2016].

Aalto University. (11.2.2016). A process revolutionising cotton recycling wins the H&M Global Change Award, retrieved from http://www.aalto.fi/en/current/news/2016-02-11/ [accessed on: 01/06/2016].

Antikainen, M., & Valkokari, K. 2016. Framework for sustainable circular business model innovation. ISPIM Innovation Forum, 13–16 March 2016, Boston, USA, retrieved from http://search.proquest.com/openview/bbdc162809e5430c6a3d151bb65e657d/1?pq-origsite=gscholar&cbl=2040562 [accessed on: 01/05/2016].

Armstrong, C., Niinimäki, K., Kujala, S., Karell, E., & Lang, C. (2015). Sustainable product-service systems for clothing: Exploring consumer perceptions of consumption alternatives in Finland. Journal of Cleaner Production, 97: 30–39. DOI: 10.1016/j.jclepro.2014.01.046.

Briceno, T., & Stagl, S. (2006). The role of social processes for sustainable consumption. Journal of Cleaner Production, 14(17): 1541–1551.

EMF. (2012). Towards the circular economy: Economic and business rationale for accelerated transition. Ellen MacArthur Foundation, UK, retrieved from https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf [accessed on: 05/03/2016]

Hvass, K. K. (2016). Weaving the Path from Waste to Value: Exploring Fashion Industry Business Models and the Circular Economy. Doctoral dissertation, CBS, Copenhagen, Denmark.

Jackson, T., & Shaw, D. (2009). Mastering Fashion Marketing. Palgrave Macmillan: New York.

Kaiser, S. (1990). The Social Psychology of Clothing: Symbolic Appearances in Context, 2nd ed. Macmillan Publishers: New York.

Karell, E. (2013). Planned continuity; multi-life garments through modular structures & supplemental services, in K. Niinimäki (Ed.) Sustainable Fashion: New Approaches, 110–123, Aalto ARTS Books: Helsinki, Finland.

Karell, E. (2014). Planned Continuity: Design of Sustainable Clothing Service Concept. MA thesis, Aalto University. https://aaltodoc.aalto.fi/handle/123456789/13401. [accessed on: 01/06/2016]

Krikke, H., le Blank, I., & van de Velde, S. (2004). Product modularity and the design of closed loop supply chains. California Management Review, 46(2): 23–39.

McDonough, W., & Braungart, M. (2002). Cradle to Cradle: Remaking the Way We Do Things. North Point Press: New York.

Mont, O. K. (2002). Clarifying the concept of product-service system. Journal of Cleaner Production, 10(3): 237–245.

Nguyen, M., Stuchtey, M., & Zils, M. (2014). Remaking the industrial economy. McKinsey Quarterly, February, retrieved from http://vuggetilvugge.dk/wp-content/uploads/2015/12/Circular_economyEMF-Newsletter-februar-2014.pdf [accessed on: 01/05/2016].

Niinimäki, K. (2010). Forming sustainable attachments to clothes, in The Proceedings of the 7th International Conference on Design & Emotion, 4–7 October 2010, Chicago, USA.

Niinimäki, K. (2011). From Disposable to Sustainable. The Complex Interplay between Design and Consumption of Textiles and Clothing, Doctoral dissertation, Aalto University: Helsinki, Finland.

Niinimäki, K. (Ed.) (2013). Sustainable Fashion: New Approaches, Aalto ARTS Books: Helsinki, Finland. retrieved from https://aaltodoc.aalto.fi/handle/123456789/13769 [accessed on: 01/03/2016].

Niinimäki, K. (2014). Sustainable consumer satisfaction in the context of clothing, in C. Vezzoli, C. Kohtala, A. Srinivasan, J. C. Diehl, S. M. Fusakul, L. Xin, & D. Sateesh (Eds) Product-Service System Design for Sustainability, 218–237. Greenleaf: Sheffield, UK.

Niinimäki, K., & Armstrong, C. (2013). From pleasure in use to preservation of meaningful memories: A closer look at the sustainability of clothing via longevity and attachment. International Journal of Fashion Design, Technology and Education, 6(3): 190–199.

Ophuis, P., & Trijp, H. (1995). Perceived quality: A market driven and consumer oriented approach. Food Quality and Preference, 6: 177–183.

Pawar, K. S., Beltagui, A., & Riedel, J. C. K. H. (2009). The PSO triangle: Designing product, service and organization to create value. International Journal of Operation and Production Management, 29(5): 468–493.

RSA Action and Research Centre. (2016). Designing for a Circular Economy: Lessons from the Great Recovery 2012–2016, RSA Action and Research Centre: London, UK.

Relooping Fashion. (2016). What is the relooping fashion initiative? retrieved from http://reloopingfashion.org/ [accessed on: 08/07/2016]

Smirnova, E., Elina Ilén, E., Sixta, H., Hummel, M., & Niinimäki, K. (2016). Colours in a Circular Economy. Circular Transitions – Mistra Future Fashion Conference on Textile Design and the Circular Economy. 23–24 November 2016. Chelsea College of Arts & Tate Britain. London UK.

Swan, E., & Combs, L. (1976). Product performance and consumer satisfaction: A new concept. Journal of Marketing, 40 (2, April): 25–33.

T2C. (2015). Trash2Cash: Utilising zero-value waste textiles and fibres with design-driven technologies to create high quality products, retrieved from http://trash2cashproject.eu/ [accessed on: 05/06/2016].

Tojo, N., Kogg, B., Kiørboe, N., Kjær, B., & Aalto, K. (2012). Prevention of Textile Waste: Material Flows of Textile in Three Nordic Countries and Suggestions on Policy Instruments. Nordic Council of Ministers: Copenhagen, Denmark.

Tukker, A., & Tischner, U. (2006). Product-services as a research field: Past, present and future. Reflections from a decade of research. Journal of Cleaner Production, 14(17): 1552–1556.

Valkokari, K., Valkokari, P., Palomäki, K., Uusitalo, T., Reunanen, M., Macchi, M., Rana, P., & Liyanage, J. P. (2014). Road-mapping the business potential of sustainability within European manufacturing industry. Foresight, 16(4): 360–384.

Van Halen, C., Vezzoli, C., & Wimmer, R. (2005). Methodology for Product Service System Innovation. Koninklijke Van Gorcum: The Netherlands.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Author(s)

About this chapter

Cite this chapter

Niinimäki, K. (2017). Fashion in a Circular Economy. In: Henninger, C., Alevizou, P., Goworek, H., Ryding, D. (eds) Sustainability in Fashion. Palgrave Macmillan, Cham. https://doi.org/10.1007/978-3-319-51253-2_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-51253-2_8

Published:

Publisher Name: Palgrave Macmillan, Cham

Print ISBN: 978-3-319-51252-5

Online ISBN: 978-3-319-51253-2

eBook Packages: Business and ManagementBusiness and Management (R0)