Abstract

Yttrium is a strategical material for its several usages in a wide range of industrial production. For this reason, improving the recovery of Yttrium has become a crucial focus for international research. In this scientific activity, the utilization of two extractants, 2-ethylhexyl-mono 2-ethylhexyl ester phosphonic acid (P-507) and sec-octylphenoxy acetic acid (CA-12), working in a synergistic extracting system, has been tested. A series of trials have been carried out to optimize the experimental conditions in order to separate yttrium from a mix of heavy rare earths in chloride media. Tests with different relative concentrations of extractants and a phase modifier (TPB, trybutyl phosphate), with different presaponification rate, have been performed to evaluate the behavior of the synergistic system. Results are very promising to recover and separate yttrium with a high purity.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

With the increasing demand for rare earth elements and their compounds, the separation and purification of these elements has gained considerable importance in recent years. Lanthanides have several applications in many areas: life sciences, electronics, catalysis, green technologies and so on.

Yttrium is widely used for fluorescent lamps, phosphors, display and solvent extraction is the common method used for its recovery [1,2,3].

As a branch of solvent extraction , the synergistic extraction has become a common method for the separation of metal ions. It can not only improve the extraction efficiency [4,5,6] and the extraction selectivity, but also enhance the stability of the extracted complexes: the extracted complexes are more soluble in the organic phase, eliminate emulsification and the formation of the third phase, and increase the extraction reaction rate [5,6,7].

Xiaobo Sun et al. [8] investigated a new synergistic extraction system using CA-12) and Cyanex272, resulting that adding Cyanex272 to CA-12, the extractability for Er, Tm, Yb and Lu increases much more than that for Yttrium, and thus, results in the increased separation factors between Y and HRE.

Wang et al. [9] studied solvent extraction and separation of yttrium from other rare earths in chloride medium using the mixture of sec-octylphenoxy acetic acid (CA-12, HA) and three different co-extractants (HB) such as bis(2,4,4-trimethylpentyl) phosphinic acid (Cyanex272), P-204 and P-507 . The results of these tests report that double solvent (HAB) system using CA-12) (HA) as main extractant and Cyanex272 (HB) as co-extractant is quite efficient in separating Y from mixed rare earths. Not only the HAB extraction system keeps advantages of high separation efficiency between Y and LRE, but also it overcomes drawbacks of low separation factor between Y and HRE.

This means that co-extractants promote the extraction of HRE significantly in HAB system. Cyanex272 is selected to constitute the HAB system in this work, considering the stripping acidity of rare earths inCyanex272 system is lower than in P204 and P507 systems [10], and low acid consumptions in the stripping stages are expected.

Wu et al. [11] studied the extraction and separation of trivalent Ho, Y, and Er with the mixtures of Cyanex 302 and another extractant, such as P204, P507, P229, CA-100, Cyanex 925, TBP, P350, or N1923. They concluded that Cyanex 302 individually and combined with others show same extraction efficiency.

By the analysis of the status of art about Y separation it’s possible to note that synergistic separation is a very promising solution to separate yttrium from heavy rare earth, so in this paper the utilization of of two extractants, 2-ethylhexyl-mono 2-ethylhexyl ester phosphonic acid (P-507 ) and sec-octylphenoxy acetic acid (CA-12) ), working in a synergistic extracting system, have been investigated.

Experimental

Apparatus and Reagents

Rare earths , in aqueous media, were analyzed by using an Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) Optima 8300 model by Perkin Elmer. Digital pH meter (Metrohm 780) and an automatic titrator (Metrohm 905 Titrando), equipped by an iSolvotrode probe, were used for pH measurements and to determinate the molar concentration of extractants. Treibacher Industrie kindly provided extractants and rare earths mix in aqueous solution. CA-12) and P507 were titrated by using standard NaOH ([CA-12] = 3.60 M and [P507] = 3.20). These extractants, used without any further purification, were diluted with kerosene. The kerosene was provided by oleotecnica S.p.A. and it’s a selected fraction of linear hydrocarbons compounds (C10–C13, aromatic compounds <2%). Pure Sodium hydroxide ACS-ISO was provided by Carlo Erba and it was dissolved in demineralized water and used for the pre-saponification of the extractants. TBP >99% (provided by Sigma-Aldrich) was used as phase modifier. Stock rare earths solution, used for all tests, was checked by using ICP-OES; the total concentration of all metals, in aqueous solution, is 2 M and their relative abundance is reported in weight percentage in Table 1. All other reagents were of analytical grade.

Methods

The experiments were carried out shaking equal volumes of aqueous solution (feed) and extractants mix diluted with kerosene for 40 min with the support of a mechanical shaker at room temperature (298 ± 1 K) to ensure complete equilibration. NaOH was used for the pre-saponification of the extractants in order to reach the required pH at the end of reaction test.

The extractant mixture was prepared by mixing CA-12) , P507 and TBP in order to reach the desired value of XCA-12 defined as:

The amount of TBP used is the 15 vol% respect to CA-12. The resulting extractant mixture is diluted with kerosene 1/1 in volume. The ingredients in the aqueous phase were analyzed by ICP-OES and the concentration of rare earths in organic phase was determined by mass balance. Distribution factor was obtained as D = [RE]o/[RE]a, where ‘a’ and ‘o’ denote aqueous and organic phase.

Results and Discussion

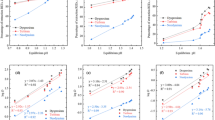

Several tests at [feed] = 0.5 M were performed. At this feed concentration the extraction system has a poor selectivity due to its high loading capacity. Figure 1 shows that, with higher values of pH, the extractant is able to extract all rare earths contained in the feed.

For this reason, in this work [feed] = 1 M was used.

In Fig. 2 the amount of rare earths extracted versus pH at different XCA-12 is reported. The results show that the extraction of rare earths increase enhancing the pH of aqueous phase. At XCA-12 ≥ 0.7, reachable values of pH are between 0.5 and 4; pH over than 4.2–4.4 can be considered the upper limit in order to avoid the degradation of extractants. For the highest values of pH, reported in Fig. 2, we observe an amount of rare earths extracted equals to 50–60%. At XCA-12 = 0.5 reachable values of pH are between 0 and 1 without degradation of organic phase.

Extraction efficiency is defined as \( E = (C_{0} - C_{f} )/C_{0} \) 100: where C0 represents the concentration of single rare earth in the feed and Cf represents the concentration of single rare earth in aqueous phase after extraction reaction.

The optimal pH working range is between 2 and 4 (Fig. 3) and in this pH range the system permit the separation of yttrium from the other metals. Yttrium efficiency values are lower than all other rare earths and it is preferentially leaved in aqueous phase.

Increasing XCA-12 from 0.7 to 0.95 we observe a decrease in efficiency values for heavier rare earths such as Lu, Yb, Tm and Er while for lighter rare earth the extraction efficiency variation is not so relevant.

In 3.7–3.9 pH range we observe an higher difference in efficency extraction between yttrium and lighter rare earths than in 2.1–2.3 pH range; for heavier rare earths the behaviour is the opposite. In a feed with a large amount of lighter rare earths, as the used one, in which the amount of Sm, Gd, Tb, Dy and Ho is about three times more than Er, Tm, Yb and Lu, we can say that the higher pH range is the best choice for a separation process.

When the pH of aqueous phase falls below the value of 2, with XCA-12 ≥ 0.7, the separation of yttrium and lighter rare earths became more difficult; this aspect is highlighted in Fig. 4 in which we can observe a drastic decrease in extraction efficiency for Y, Sm, Eu, Gd, Tb, Dy, and Ho.

At XCA-12 ≤ 0.5 the extraction efficiencies are higher than 30% only for heavier rare earth, such as Lu, Yb, Tm and Er, so the CA-12) + P507 system don’t allow an easy separation of lighter rare earth from yttrium (Fig. 5 and Table 2). At these conditions, for the high presence of P507, is impossible to reach pH values greater than 1 without the degradation of organic phase.

In Table 2 are reported the separation factors (β) of rare earth elements versus yttrium, calculated as: distribution factor of single element divided by distribution factor of yttrium. Data shows that for lighter rare earths (Sm, Eu, Gd, Tb and Dy) the system CA-12 + P507 presents the better selectivity with the increase of CA-12) concentration; the best values of separation factor are obtained for XCA-12 = 1 (CA-12 alone).

However for 0.7 ≤ XCA-12 ≤ 0.9 the separation factor values of Sm, Eu, Gd, Tb and Dy are very good (2 ≤ β ≤ 4.4).

Holmium β factor is quite costant changing XCA-12 from 1 to 0.7.

With XCA-12 ≤ 0.5 the β values are too low to permit a suitable separation of Sm, Eu, Gd, Tb, Dy and Ho from yttrium. For heavier rare earths (Lu, Yb and Tm) the extraction system shows the best selectivity with XCA-12 equals to 0.1 and 0.3. In the range of 0.7 ≤ XCA-12 ≤ 0.9 Lu, Yb and Tm presents values of separation factors between 2 and 3 (making separation possible).

Erbium don’t show a great difference in separation factors changing XCA-12.3.

By the analysis of reported data yttrium separation can be better performed working at a pH ≈ 3.8 with a XCA-12 equal to 0.7–0.8.

Conclusions

Data showed that synergistic effect made possible to tune this extraction system to optimize separation of each rare earths . In the studied case, the separation one-throw of yttrium is achievable and the best conditions are reached with a XCA-12 = 0.7–0.8 at a pH ≈ 3.8. At these conditions the efficiency of extraction for yttrium is around 50% with a β factor value about 4 for europium and samarium and not lower than 1.7 for the other rare earths.

References

L. Xu, Y. Xiao, D.Q. Li, An expert system for solvent extraction of rare earths. J. Chem. Inf. Comput. Sci. 32, 437–442 (1992)

C. Sposato, A. Blasi, G. Devincenzis, P. Garzone, M. Morgana, Comparison among different extractants, As (2-ethylhexyl)-mono (2-ethylhexyl) ester phosphonic acid (P507), secondary-octyl phenoxy acetic acid (CA-12) and BIS(2, 4, 4-trimethylpentyl)phosphinic acid (CYANEX272), in the separation of heavy rare earths via hydrometallurgical processes. Rare Metal Technol. 2014, 201–206 (2014)

A. Blasi, C. Sposato, G. Devincenzis, P. Garzone, M. Morgana, Definition of the process to separate light rare earths by working with (2-Ethylexyl)-Mono(2-Ethylexyl)ester phosphonic acid (P507) in a mixer settler battery. Rare Metal Technol. 2014, 197–200 (2014)

Y. Masuda, Y.W. Zhang, C.H. Yan, B.G. Li, Studies on the extraction and separation of lanthanide ions with a synergistic extraction system combined with 1,4,10,13-tetrathia-7,16-diazacyclooctadecane and lauric acid. Talanta 46(1), 203–213 (1998)

K. Ishimori, H. Imura, K. Ohashi, Effect of 1,10-phenanthroline on the extraction and separation of lithium(I), sodium(I) and potassium(I) with thenoyltrifluoroacetone. Anal. Chim. Acta 454, 241 (2002)

J. Ydberg, T. Sekine, Principles and pratices of solvent extraction, in Principles and Practices of Solvent Extraction, ed. by J. Rydberg, C. Musikas, G.R. Choppin (Marcel Dekker, New York, 1992), p. 101

Q. Jia, W.P. Liao, D.Q. Li, C.J. Niu, Synergistic extraction of lanthanum (III) from chloride medium by mixtures of 1-phenyl-3-methyl-4-benzoyl-pyrazalone-5 and triisobutylphosphine sulphide. Anal. Chim. Acta 477, 251–256 (2003)

X. Sun, J. Zhao, S. Meng, D. Li, Synergistic extraction and separation of yttrium from heavy rare earths using mixture of sec-octylphenoxy acetic acid andbis(2,4,4-trimethylpentyl)phosphinic acid. Anal. Chim. Acta 533, 83–88 (2005)

Y. Wang, W. Liao, D. Li, A solvent extraction process with mixture of CA-12 and Cyanex272 for the preparation of high purity yttrium oxide from rare earth ores. Sep. Purif. Technol. 82, 197–201 (2011)

J.D. Wang, J.Y. Chen, Handbook of Solvent Extraction (Chemical Industry Press, Beijing, 2001), pp. 538–553

D.B. Wu, W. Li, D.Q. Li, The extraction and separation of Ho, Y, and Er(III) with the mixtures of Cyanex 302 and another organic extractant. Sep. Sci. Technol. 42(4), 847–864 (2009)

Acknowledgements

The authors wish to thank R&D division of Treibacher Industrie, in particular Dr. Stephan Pirker, Dr Christiane Kartusch and Gunther Bierbaumer for support and help during this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Blasi, A., Sposato, C., Romanelli, A., Braccio, G., Morgana, M. (2017). Study of a Synergistic Solvent Extracting System to Separate Yttrium and Heavy Rare Earths: A Deep Investigation on System Behavior. In: Kim, H., Alam, S., Neelameggham, N., Oosterhof, H., Ouchi, T., Guan, X. (eds) Rare Metal Technology 2017. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-51085-9_29

Download citation

DOI: https://doi.org/10.1007/978-3-319-51085-9_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51084-2

Online ISBN: 978-3-319-51085-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)