Abstract

The diversity of the criteria and methods of analysis used in Supply Chain Management systems leads to a situation in which the system generates a lot of variants of solutions. However, the user expects the system one final variant. Therefore, the integration of knowledge is necessary. To resolve this problem, the consensus method is proposed in this paper. The aim of this paper is to develop and verify a method for knowledge integration in the SCM module in Cognitive Integrated Management Information System (CIMIS).

The first part characterizes a SCM module in CIMIS. Next, a method for knowledge integration has been described. The last part of paper presents results of verification of developed method.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Supply Chain Management

- Integrated management information systems

- Knowledge integration

- Consensus method

1 Introduction

Nowadays, one can observe an increased interest of organizational units in systems focusing on integrating supply chain management (SCM). The systems enable strict coordination of activities of business partners, which is usually achieved by electronic data interchange (EDI). Systems of the class may function independently, however more and more often such systems function as a module of an integrated management information system. Reference works [8, 12, 13] point out that the SCM module shall include two solutions enabling dynamic reaction to emerging needs, which in turn may result in an increased value of all companies participating in a given supply chain. The SCM module then shall, on the basis of up-to-date and reliable information gathered from the surrounding environment, present users, in real time, with a variant of a solution related to the flow of products. It is however a difficult task due to the turbulent nature of the environment and due to a high computational complexity of algorithms used in the SCM module. Consequently, it leads to the module generating various variants of products flow between particular cooperating partners. Each of such variants may have different values of attributes (features) describing the flow of products (one of such attributes can be for example a delivery time). A user, however, in order to make a decision, needs to get from the system just one, final variant which will bring satisfactory benefits. It should be a variant which ensures a delivery of products in proper quantity and in an adequate time, while keeping costs and risk at the lowest possible level. Thus, knowledge in the SCM module shall be integrated.

In reference papers, as well as in practice, various methods of knowledge integration, have been presented and employed, for example negotiations [2], or deduction and computational methods [1]. However, it needs to be stressed that negotiations enable good integration of knowledge by reaching a compromise, but they require exchanging a large number of communications between elements of a system (e.g. which makes it difficult, or sometimes even impossible for the SCM module to function in real time). The deduction and computational methods, however, (for example ones based on the theory of games, classical mechanics, or the method of choice), enable obtaining a high computational efficiency of a system, but they do not guarantee proper integration of knowledge as it often happens that selecting one variant involves a high level of risk which has been previously discussed [7].

So far, in the practical realization of SCM modules (systems) no attention has been paid to the method which enables integration of knowledge in near to real time [7], and also guarantee reaching a proper compromise [10]. This is the consensus method [5, 10].

The aim of this paper is to develop and verify a method for knowledge integration in the SCM module in Cognitive Integrated Management Information System (CIMIS).

The paper has been divided as follows: the first part characterizes a SCM module in CIMIS. Next, a method for knowledge integration has been described. The last part of paper presents results of verification of developed method.

2 Supply Chain Management Module in CIMIS

The CIMIS has been detailed described in [6]. This is a multi-agent (based on LIDA cognitive agent architecture [4]) system consists of following sub-systems: fixed assets, logistics, manufacturing management, human resources management, financial and accounting, controlling, CRM, business intelligence. The SCM module is placed in logistic sub-system. Agents are grouped depending on an enterprise’s position in a supply chain, for example supplier-serving agents, producer-serving agents, or retailer-serving agents.

However, solutions which have been offered so far [3, 9, 11], despite the fact that agents use various methods of managing the supply chain, it is the system user who has to decide independently which of the decisions generated by agents shall be executed. In the SCM module presented in the article however, the process of selecting final decisions is performed by an integration component.

It is assumed that SCM module components related to suppliers, producers, wholesalers, retailers, and individual customers, on the basis of information from transaction systems (for example Enterprise Resource Planning - ERP), analytical systems (for example Manufacturing Execution Systems - MES, Customer Relationship Management - CRM) and from internet sources, due to different criteria or methods of analyzing the information, generate various variants of solutions to individual elements of a supply chain. These variants are represented by means of information structures.

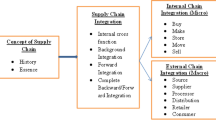

For the need of the paper, taking into account first of all its size, the producers-related SCM module has been used. The module consists of following elements (Fig. 1):

-

data servers,

-

agents,

-

integration component,

-

users.

Data servers consist of data from Internet sources and transactional and analytical databases systems.

The agents are intelligent programs that are based on the data read from the servers carry out the process of calculation and reasoning. The result of these processes is decision related to supply management. Each agent uses a different method for supply chain management. In the present prototype used only a few commonly used methods in practice (described in details in [14]), which include:

-

Fixed Order Quantity,

-

Fixed Order Period,

-

Optional Replenishment,

-

Combined Replenishment

-

Two Bin,

-

Material Requirements Planning,

-

Distribution Requirements Planning.

Agents’ decisions are stored in database as following structure of variant:

Definition 1

Let set of products \( P = \{ p_{1} ,p_{2} , \ldots ,p_{n} \} \) and set of places \( M = \{ m_{1} ,m_{2} , \ldots ,m_{g} \} \) are given.

The collective member’s knowledge representation of product flow is called the following structure:

where:

\( (s1,s2, \ldots ,sn) \in [1..\,g], \) where g denotes number of places (cardinality of set M), \( (r1,r2, \ldots ,rn) \in [1..\,g], \)

\( dt_{s1} ,dt_{s2} , \ldots ,dt_{sn} \)- date and time of sending of product \( p_{1} ,p_{2} , \ldots ,p_{n} \) from the places \( m_{s1} ,m_{s2} , \ldots ,m_{sn} \),

\( dt_{r1} ,dt_{r2} , \ldots ,dt_{rn} \)- date and time of receiving of product \( p_{1} ,p_{2} , \ldots ,p_{n} \) at the places \( m_{r1} ,m_{r2} , \ldots ,m_{rn} \),

\( i_{1} ,i_{2} , \ldots ,i_{n} \)- the amount of transported products \( p_{1} ,p_{2} , \ldots ,p_{n} \) (the size of the batch),

\( c_{1} ,c_{2} , \ldots ,c_{n} \)- the cost of transport \( p_{1} ,p_{2} , \ldots ,p_{n} \).

Integration component (characterized in details in the next section of this paper), in turn, allows for agreeing to a variant (which is to be presented to the user) on the basis of different variants generated by individual agents. This component performs on the basis of consensus algorithm.

Users are persons managing the supply chain that using computers connected to the Internet read variants determined by the module consensus.

The next part of paper presents the method for agents’ knowledge integration performing by integration component.

3 Method for Knowledge Integration

Knowledge integration is performed by consensus algorithm. The structures of variants constitute a profile on the basis of which a consensus is calculated, and within a given module they should have the same attributes.

Definition 2.

The profile \( {\text{w = \{ w}}^{(1)} ,\,{\text{w}}^{(2)} , \ldots ,\,{\text{w}}^{{({\text{K}})}} \} \) is called set of K structures of variants, such that:

The algorithm of consensus determining running in such a way that an ascending order of dt xy value is set from all variants, and the same is done with values i y and k y . Then, calculations are done to determine between which values in the orders a value which is the consensus has been placed. The next step is to determine values of consensus of products, sending and receiving place by selecting from a profile values of attributes from a variant in which the distance between the cost of such a variant and the cost of a variant selected in the consensus is minimal. The algorithm finishes once all elements of a variant have been verified and a consensus has been found. Formal definition of the algorithm is as follows:

Implementation of this algorithm in the SCM module allows for omitting mentioned earlier, the analysis by human of the various variants of product flow.

4 Research Experiment

In order to verify of the developed method for knowledge integration in SCM module, the research experiment has been carried out. The aim of the experiment was to compare the variants generated by the integration component with variants generated by agents performed on the basis of the various another methods for supply chain management supporting (mentioned in Sect. 2). The following conditions have been assumed:

-

1.

The initial stock value is 100, the demand for the next day is determined at random.

-

2.

As chronon one day has been assumed. The test was performed over a period of 100 days (each agent generated 100 knowledge structures on the basis of the structures of all the agents on any given day a consensus is determined).

-

3.

In order to knowledge evaluation the following measures have been assumed: storage cost, delivery cost, delivery time and average coefficient of variation (risk level measure).

-

4.

The storage cost was calculated based on the number of products stored in the storehouse (proportional relationship), and the holding time (proportional relationship).

-

5.

The delivery cost is calculated based on the quantity of transported products (proportional relationship) and the delivery time (inverse proportion). Delivery time is determined by the deadlines specified in the planning of the demand by individual agents.

-

6.

As a measure of risk the average coefficient of variation is used, because it is a relative measure, calculated as follows:

where:

V – average coefficient of variation,

s – average deviation of measured value,

E(r) – arithmetic average of measured value.

The knowledge structures generated by individual agents on each day have been saved in a database. Next, the consensus has been determined on the basis of these structures. Table 1 presents achieved results.

Analyzing the results of verification one can notice that the lowest average storage costs and the shortest delivery times in the studied period have been obtained by variants generated by agents a6 and a7 (229 and 227 respectively). The result obtained by integration module (I), i.e. 239, ranks as the third in terms of the amount of average costs of storing and delivery times in the analyzed period. So two agents have generated better results than results generated using the consensus algorithm. However five agents have generated even worse results. Thanks to the use of the consensus algorithm it was possible to obtain lower average storage cost and shorter delivery times in comparison to average storage costs and delivery times of all agents which in the studied period amounted to 260 and 1,56 respectively.

It needs to be noticed, however, that even though decisions of agents a6 and a7 enabled obtaining low average storage cost and short average delivery times, they also generated high average delivery costs. The lowest average delivery costs could be obtained as a result of decisions generated by agent a5 (101), however they also generated high average storage costs (279) and long delivery times (2,71). The result obtained using the consensus algorithm, i.e. 190, also ranks as the third, in terms of average delivery costs, in the analyzed period. Application of the consensus algorithm has also enabled obtaining lower average delivery costs compared to average deliveries costs calculated on the basis of variants of all agents, which in the analyzed period amounted to 194.

While analyzing the risk connected with managing a supply chain, it has been observed that the use of the consensus algorithm enables executing the process with the lowest level of risk (average ratio of change was, in case of storage costs –1,9 %, 2,2 % in case of delivery costs, and 27,9 % in case of delivery times) among analyzed methods of supply chain management (for the remaining methods of supply chain management in the studied period the value of an average ratio of change in case of costs of storing ranged between 5,1 % and 9,1 %, between 3,0 % and 97 % in case of delivery costs, and between 31 % and 150 % in case of delivery times).

It can be said then that variants generated by the integration component are characterized by a low level of fluctuation of storage costs, delivery costs, and delivery times. The phenomenon may positively affect the stability of a company’s financial liquidity (if costs do not fluctuate so much it is easier to plan them), and it help maintain continuity of production (low fluctuation of delivery times lowers the risk of downtime).

To sum up, it needs to be stressed that variants generated by the integration component enable, to obtain lower costs of storing and deliveries, and shorter delivery times in a given period of supply chain management while keeping the risk lower compared to the situation when we each time use a single method of supply chain management. The possibility of generating target variants in real time as opposed to a situation where a decision maker has to independently select from variants generated by individual methods is of great importance too. Consequently, the level of usefulness of a selected variant increases, which results in satisfactory benefits such as: timeliness, adequate volumes of a given batch, or decreased costs of deliveries, which may in turn lead to a company obtaining good financial results.

5 Conclusions

The SCM module enables integration and coordination of the flow of products, information and money between individual organizations within a supply chain, which of course affects their capacity to properly adapt to market demands. The use of the consensus algorithm in order to integrate knowledge, and to select one variant presented then to a user, based on variants suggested by a system, may lead to shortening time required to select such a variant, and to lowering the risk of choosing the worst variant. Consensus method cannot guarantees that a given decision will be optimal, however it does ensure an adequate level of satisfaction. Results of verification of the method of knowledge integration presented in the paper help to draw a conclusion that application of the consensus method enable to generate, in near to real time, variants which bring satisfactory benefits.

Further research may focus, among other things, on developing the function of assessment of knowledge of agents functioning within the SCM module, and on developing consensus algorithms enabling improvement of the agents’ knowledge.

References

Barthlemy, J.P.: Dictatorial consensus function on n-trees. Math. Soc. Sci. 25, 59–64 (1992)

Dyk, P., Lenar, M.: Applying negotiation methods to resolve conflicts in multi-agent environments. In: Zgrzywa A. (red.) Multimedia and Network Information systems, MISSI 2006. Oficyna Wydawnicza PWr, Wrocław (2006)

Farrell, B., Loffredo, D.: A Simple Agent for Supply Chain Management. Department of Computer Science, The University of Texas at Austin (2006)

Franklin, S., Patterson, F.G.: The LIDA architecture: adding new modes of learning to an intelligent, autonomous, software agent. In: Proceedings of the International Conference on Integrated Design and Process Technology. Society for Design and Process Science, San Diego (2006)

Hernes, M., Nguyen, N.T.: Deriving consensus for hierarchical incomplete ordered partitions and coverings. J. Universal Computer Science 13(2), 317–328 (2007)

Hernes, M.: A cognitive integrated management support system for enterprises. In: Hwang, D., Jung, J.J., Nguyen, N.-T. (eds.) ICCCI 2014. LNCS, vol. 8733, pp. 252–261. Springer, Heidelberg (2014)

Hernes, M., Sobieska-Karpińska, J.: Application of the consensus method in a multi-agent financial decision support system. IseB 14(1), 167−185 (2016). Springer, Heidelberg

Lu, D.: Fundamentals of Supply Chain Management. Dr. Dawei Lu & Ventus Publishing ApS, bookboon.com (2011)

Moyaux, T., Chaib-draa, B., D’Amours, S.: Supply chain management and multiagent systems: an overview. In: B. Chaib-draa, J.P. Müller (eds.), Multiagent-Based Supply Chain Management. SCI, vol. 28, pp. 1−27. Springer, Heidelberg (2006)

Maleszka, M., Mianowska, B., Nguyen, N.T.: A method for collaborative recommendation using knowledge integration tools and hierarchical structure of user profiles. Knowl. Based Syst. 47, 1–13 (2013)

Podobnik, V., Petric, A., Jezic, G.: An agent-based solution for dynamic supply chain management. J. Univers. Comput. Sci 14(7), 1080–1104 (2008)

Rutkowski, K.: Best practices in logistics and supply chain management. the case of central and eastern europe. In: Waters, D. (ed.) Global Logistics and Distribution Planning. Kogan Page, London (2010)

Sitek, P., Wikarek, J.: Cost optimization of supply chain with multimodal transport. In: Proceedings of the Federated Conference on Computer Science and Information Systems (2012). http://fedcsis.org/proceedings/fedcsis2012/pliks/182.pdf

Siurdyban, A., Møller, C.: Towards intelligent supply chains: a unified framework for business process design. Int. J. Inform. Syst. Supply Chain Manag. 5(1), 1−19 (2012). IGI Global, New York

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this paper

Cite this paper

Hernes, M. (2016). Knowledge Integration Method for Supply Chain Management Module in a Cognitive Integrated Management Information System. In: Nguyen, NT., Iliadis, L., Manolopoulos, Y., Trawiński, B. (eds) Computational Collective Intelligence. ICCCI 2016. Lecture Notes in Computer Science(), vol 9875. Springer, Cham. https://doi.org/10.1007/978-3-319-45243-2_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-45243-2_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-45242-5

Online ISBN: 978-3-319-45243-2

eBook Packages: Computer ScienceComputer Science (R0)