Abstract

Ultrasonic thickness meters are generally used in corrosion evaluations of pipes. On the other hand, there are pipes with gusset plates. Then the meters using a simple reflection cannot be used, because the ultrasonic is attenuated by an air gap between pipes and gusset plates. For the pipes with the dual structure, new method with multiple reflections is being studied. When the method is used, it is important to know number and positions of thinning spots.

This work is motivated by the desire to evaluate positions of thinning spots in a Dual Structure of steel nondestructively. Our approach is based on the Eddy Current Testing with DC magnetization. The ECT with DC magnetization has been studied. Recent studies have revealed that the Hall coefficient is sensitive to the presence of elastic strain. However, there are not still studies which applied the ECT to the structures. In this paper, the ECT is applied to an evaluation of thinning spots in the dual structure.

This paper attempts a first step toward visualizing magnetized states of specimens with an electromagnet using the 2D nonlinear electromagnetic field analysis. Here, needed magnetic force is obtained to detect the thinning spots on the back surface. Then, the measurement principle is explained. In the next section, the ECT with DC magnetization is applied to a specimen with a thinning spot. From the results, the usability of this method is evaluated.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ultrasonic thickness meters are generally used in corrosion evaluations of pipes. On the other hand, there are pipes with gusset plates. Then the meters using a simple reflection cannot be used, because the ultrasonic is attenuated by an air gap between pipes and gusset plates. For the pipes with the dual structure, new method with multiple reflections is being studied [1]. When the method is used, it is important to know number and positions of thinning spots.

This work is motivated by the desire to evaluate positions of thinning spots in a dual Structure of steel nondestructively. Our approach is based on the Eddy Current Testing with DC magnetization. The ECT with DC magnetization has been studied [2]. Recent studies have revealed that the usability of ECT is evaluated. However, there are not still studies which applied the ECT to the structures as far as I know. In this paper, the ECT is applied to an evaluation of thinning spots in the dual structure.

This paper attempts a first step toward visualizing magnetized states of specimens with an electromagnet using the 2D nonlinear electromagnetic field analysis. Here, needed magnetic force is obtained to detect the thinning spots on the back surface. Then, the measurement principle is explained. In the next section, the ECT with DC magnetization is applied to specimens with 25 or 75 % thinning spot. From the results, the usability of this method is evaluated.

2 Simulations of Magnetized States of Specimens with DC Magnetization

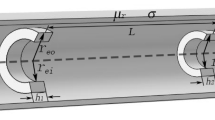

In this work, the 2D FEM with vector potential A was used in order to calculate magnetic statuses of specimens. Distributions of magnetic flux density and permeability in the specimens were obtained from this. Figure 1 illustrates a model and conditions of the simulation. There is an electromagnet on the dual structure. The width and height of the electromagnet are 300 and 190 mm. There is 1 mm air gap between plates of the dual structure. The bottom plate has a thinning spot on the back surface.

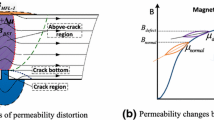

Figure 2 shows distributions of the magnetic flux density and permeability which are obtained from the simulations. When the specimen was magnetized by the electromagnet, distributions of the statuses were changed. The magnetic permeability on the surface of the top plate responds to changes in the thinning shape. This result suggests that measurements of the permeability on the surface are useful in order to detect positions of the thinning on the back surface from the surface of the top plate. Figure 3(a) shows distributions of the permeability on the surface of the top plate. When the specimen had no thinning, the line that showed the permeability was flat. However, the permeability of the thinning area was lower than the permeability of other areas. Figure 3(b) shows a correlation between the permeability changing and the thinning depth. The simulations were also performed in order to evaluate an effect of the thinning depth. The simulation results show that the changing became larger as the depth was larger.

3 Experimental Results

As illustrated in Fig. 4, this technique uses an electromagnet, two ECT coils, and a lock-in amplifier. The material of the magnetizer is electromagnetic soft iron which is set on a couple of plate specimens of ferromagnetic material. The electromagnet coil has 640 turns coil. Used specimens were made from a couple of plates. Figure 5 shows two plates with a 25 or 75 % thinning spot. The plates were used as the bottom plate of a specimen. A plate without thinning was used as the top plate of the specimen. There was 1 mm gap between the plates. The surface of the top plate was scanned by the ECT coil. Another ECT coil was used as the reference coil. Then, 100 kHz was used in order to detect status of magnetic permeability on near surface of the top plate.

First of all, I performed experiments in order to evaluate an effect of the magnet force. Figure 6 shows measurement results of the specimens with 25 % thinning spot at 100 kHz. The color bar at each figure shows detection signals of the ECT. In Fig. 6(a), you can seem like that the signal captured the status of surface of the top plate when the magnet force was low. A part at a center of Fig. 6(c) has high value. There was a 25 % thinning spot under the part. From the simulation results, the permeability of the part on the thinning spot becomes lower than the permeability of other parts as the magnet force is higher. It is known that magnetic permeability has an impact on the signal of the ECT. Therefore, the part with high value means that there is a thinning spot under the part. As shown Fig. 6(a), (b) and (c), the contrast between the part with high value and other parts became higher as the magnet force was higher. On the other hand, Fig. 7 shows measurement results of the specimens with 75 % thinning spot. These results also show that the contrast became higher as the magnet force was higher. However, you can detect the 75 % thinning spot using lower magnet force than magnet force of the 25 % thinning spot. In other words, these results show that the contrast between the thinning spot part and other parts became higher as the thinning depth was deeper.

In the next place, I performed experiments in order to evaluate an effect of frequency of the ECT. Figure 8 shows measurement results of the specimens with 25 % thinning spot at 5120A magnet force. In Fig. 8(a), you can seem like that the contrast of the thinning spot became higher as the frequency was higher. It is possible that one of the origins of a difference between the results at each frequency is the skin effect. However, the impedance of coils changes depending on the frequency. It is also possible that one of the origins is the impedance matching between the coils and the input impedance of the LIA. The effect of the frequency invites closer analysis.

4 Conclusion

I tried to detect a spot thinning on the back surface of the dual structure by using the ECT with DC magnetization. The contrast of magnetic permeability on the surface of the top plate has been studied in the simulations. The depth of the thinning had an impact on the contrast. This trend of the simulation results was applicable to those of measurement results. Therefore, this method can detect thinning spots on the back surface of the dual structure with an air gap.

It is expected that the width of the thinning spot, magnetic characteristic of specimens and the gap length also would have an impact on this method. My future research will be focused on experiments and evaluation of the effects.

References

Shiroshita, S., et al.: Study of a thickness measurement under gusset plates. In: Proceedings of 9th Annual Conference, Japan Society of Maintenology (2012). (In Japanese)

Bönisch, A.: Magnetic flux and SLOFEC inspection of thick walled components. The e-Journal of Nondestructive Testing (2000). http://www.ndt.net/article/wcndt00/papers/idn352/idn352.htm

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this paper

Cite this paper

Kosaka, D. (2016). Evaluation of Positions of Thinning Spots in a Dual Structure Using ECT with DC Magnetization. In: Kubota, N., Kiguchi, K., Liu, H., Obo, T. (eds) Intelligent Robotics and Applications. ICIRA 2016. Lecture Notes in Computer Science(), vol 9834. Springer, Cham. https://doi.org/10.1007/978-3-319-43506-0_68

Download citation

DOI: https://doi.org/10.1007/978-3-319-43506-0_68

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-43505-3

Online ISBN: 978-3-319-43506-0

eBook Packages: Computer ScienceComputer Science (R0)