Abstract

This chapter discusses the applications of gamma irradiation technology for food safety, its nutritional implications, and its involvement in fermentation processes. Gamma irradiation has become an alternative technology for food sterilization due to its nonthermal character, thus replacing the conventional heating processes. Several driving forces are propelling the need of γ-irradiation forward for food applications. Besides food preservation, γ-irradiation is taking place for novel applications, especially involving the enhancement of food fermentation processes, by directly irradiating the medium, or generating performant genetically modified strains.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

7.1 Introduction

The four major types of radiation sterilization described in literature are γ-irradiation, e-beam, natural light, and microwave (Yaman, 2001). Sterilization by γ-irradiation has been widely used to inactivate microorganisms in food and pharmaceutical sectors. There are multiple advantages of γ-irradiation over other competitive techniques which include: its high penetration power, isothermal character, and the absence of residues. Sterilization by γ-irradiation is based on killing microorganisms by breaking their chemical bonds, producing free radicals that attack the nucleic acid of the microorganism, thus preventing its cellular division (Hasanain, Guenther, Mullett, & Craven, 2014). Gamma rays , measured in kiloGrays (kGy), present a radiopasteurization and radiosterilization technique for food preservation (Antonio et al., 2012). In fact, nowadays, food irradiation is increasingly recognized as a method for reducing postharvest food losses, ensuring hygienic quality , and facilitating wider trade in foodstuffs (Sadecka, 2010). Besides the food safety purposes, γ-rays treatment contributes to the preservation of the nutritional value of food products by protecting the thermolabile compounds from degradation due to nonthermal character of the technique (Molins, 2001). Nevertheless, minor changes of food composition by generating free radicals can occur. Moreover, γ-irradiation is recognized to enhance alcohol production through fermentation and reduction of energy consumption. This chapter summarizes the impact of γ-irradiation on food composition, its application to preserve the integrity of food products by their radiosterilization and radiopasteurization along with their role in fermentation processes, which are also discussed.

7.2 Effects of γ-Irradiation

The direct action of γ-rays is mainly by damaging DNA, with its action on sugar base pairs whereas indirect effects are mainly due to the generation of ions, free radicals , and other reactive species. γ-Irradiation involves the chemical breakdown of the major food constituents as a result of either primary ions decomposition or primary ions reaction with neighboring molecules. When γ-irradiation is carried out on dried, frozen, or food containing solid particles, the generated free radicals upon irradiation have longer lifetime, due to their limited mobility, compared to <10−3 s for fluid samples (Stewart, 2001). The generated free radicals may involve nutritional changes of food products by affecting their composition. The major constituents being affected are water , lipids , proteins , carbohydrates , and vitamins. Nevertheless, food irradiation can also degrade certain undesirable compounds (e.g. mycotoxins ) present in the food.

7.2.1 Radiolysis of Water

Radiolysis of water contributes to the indirect effects of γ-irradiation by generating various reactive species. The main species formed during water irradiation by γ-rays are presented in reaction (7.1) (Simic, 1983).

where \( {e}_{\mathrm{aq}}^{-} \), OH, H, H2, H2O2, and H3O+ represent hydrated electron, hydroxyl radical, hydrogen atom (ion), hydrogen, hydrogen peroxide, and hydrated proton, respectively. The numbers between brackets represent the amounts of produced species per 100 eV absorbed, expressed as G-value. These species, especially free radicals , may react with various food components.

7.2.2 Radiation Chemistry of Lipids

Food lipids are composed of fatty acids and their derivatives (mono-, di-, triglycerides and phospholipids), with predominance of triglycerides. γ-Irradiation of these molecules leads to the fragmentation of fatty acids and glycerol backbones, preferentially at –C–C– and –C– O– bonds. The same phenomenon is happening for free fatty acids with generation of species with double bonds for unsaturated fatty acids. The free radicals formed during γ-irradiation may react with each other, forming recombined products (Xuetong, 2012). In general, fatty acids generate higher fragments compared to triglycerides when subjected to γ-irradiation (Nawar, 1977).

Dietary intake of both saturated and trans fatty acids has been associated with an increase of coronary heart disease’s risk (Ganguly & Pierce, 2012; Woodside, McKinley, & Young, 2008). To overcome these problems, the health organizations have recommended minimizing the consumption of food products containing these fatty acids. Trans fatty acids are present in minor quantities in vegetable oils , but their presence increases in processed foods as part of hydrogenation or partially hydrogenation process, and their addition as ingredients. Moreover, trans fat are naturally present in some meat products (e.g. beef and lamb), as a result of biohydrogenation (Xuetong, 2012). The formation of trans fat during irradiation of various food products was studied by Luck and Kohn (1963). The formation of trans fatty acids upon irradiation of ground beef was studied by Yılmaz and Geçgel (2007). The authors irradiated ground beef with γ-rays (0, 1, 3, 5, and 7 kGy) from a 60Co source, and evaluated the impact on the formation of trans fatty acids . They demonstrated that irradiated samples had higher concentrations of total trans fatty acids compared to control samples, with highest total of trans fatty acids observed at 7 kGy. The amount of the formed trans fatty acids was proportional to the irradiation dose. Although the formation of trans fatty acids upon irradiation, many authors reported that the amount formed is less noticed than that occurring naturally (Fan & Kays, 2009; Xuetong, 2012). For example, commercial nonirradiated Japanese cattle beef showed a trans fatty acid range from 1.9 to 6.8 % of the total fatty acid content (Matsuzaki et al., 1998). The effect of γ-irradiation might be thus considered as negligible on trans fat formation .

7.2.3 Radiation Chemistry of Proteins

Free radicals generated by water radiolysis may react with proteins and amino acids generating a range of compounds. For example, when \( {e}_{\mathrm{aq}}^{-} \) react with proteins, radiolytic compounds were found in irradiated foods, mainly produced by the deamination and scission of peptide and disulfide bonds (Delincee, 1983). Moreover, ·OH radicals may react with proteins, leading to the oxidation of some compounds following the abstraction of·H atom and its reaction with amino acids, especially sulfur-containing and aromatic residues (Stewart, 2001). Previous works demonstrated that these radiolytic products may decrease in frozen foods due to minor mobility of OH radicals (Nawar, 1977). γ-Irradiation of proteins is very similar to that occurring for amino acids . It results in several processes (e.g. deamination, decarboxylation, disulfide bonds reduction, sulfydryl groups oxidation, peptide-chains cleavage, and protein aggregation) (Delincee, 1983). The reaction mechanisms in the radiolysis of peptides, polypeptides, and proteins were reviewed by Garrison (1987).

The effect of γ-irradiation on the molecular properties of bovine serum albumin (BSA ) was studied by Gaber (2005). The author investigated upon irradiation of BSA the effect of oxygen radicals on its molecular properties. The irradiation of BSA at various doses of γ-rays was followed by the study of the secondary and tertiary structures, molecular weight , and optical anisotropy. The author reported not only the disruption of the ordered structure of BSA (transformation from β-turns into β-sheets), but also its degradation (decrease of the molecular weight ) and aggregation (through ultraviolet absorption spectroscopy measurements) .

The occurring changes in proteins upon irradiation may impact the physical properties of the food product . In fact, the influence of γ-irradiation on physical properties of milk proteins was investigated by Cieśla, Salmieri, Lacroix, and Le Tien (2004). The authors found that γ-irradiation is an effective method to improve both barrier and mechanical properties of edible films and coatings based on calcium and sodium caseinates. They observed that the irradiated and heated samples showed higher content of β-strands, compared to heated control samples. A better-organized β conformation was noticed upon irradiation, compared to thermal treatment alone. These well-ordered β-strands improved the “crystalline” film properties, leading thus to an improved barrier characteristics and mechanical resistance as well as higher rigidity.

7.2.4 Radiation Chemistry of Carbohydrates

Radiolysis of water generating free radicals may affect the carbohydrate structure and composition. The major radiolysis effect is caused by OH radical ; abstracting a·H atom from a carbohydrate’s carbon, thus producing an α-hydroxyl radical. This radical may contribute to other reactions producing at the end stable products (e.g. production of gluconic acid from irradiated glucose ) (Phillips & Moody, 1959). Upon irradiation of carbohydrate solutions, the pH may decrease due to the formation of acidic compounds (Dauphin & Saint-Lebe, 1977; Simic, 1983). Irradiation of sugars may involve gas production (e.g. H2 and CO2) (Dauphin & Saint-Lebe, 1977) as well as the formation of carbonyls (e.g. formaldehyde, acetaldehyde, and malonaldehydes ) (Xuetong, 2012).

7.3 Application of γ-Irradiation

7.3.1 Food Fermentation

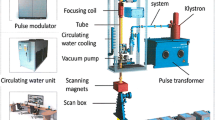

Food irradiation represents a promising technique among few others addressing both food safety and quality due to its ability to control spoilage and foodborne pathogens, without significantly affecting the organoleptic properties of the food product (Sadecka, 2010; Verde et al., 2013). Figure 7.1 shows an example of schematic equipment for γ-irradiation of food products at industrial scale. Studies have demonstrated the effect of γ-rays in preserving the food products. γ-Irradiation of Kimchi, a Korean salted and fermented vegetables, and its impact in extending the shelf-life was evaluated (Song et al., 2004). The authors found a lower lactate dehydrogenase (LDH ) activity and delaying acidification when applying up to 10 kGy γ-irradiation at the early stage of Kimchi fermentation with a dose-dependent effect on the inactivation of fermentative microorganisms. When applying γ-irradiation on the mid-fermentation stage of Kimchi, the authors observed effective inactivation of microorganisms, LDH exhibited high activity and the acidification continued. It has been reported through this study that the samples treated at 10 kGy were less appreciated than those treated at either 2.5 or 5 kGy, concluding thus that γ-irradiation at up to 5 kGy on the early fermentation stage can preserve the organoleptic quality of Kimchi.

The shelf-life of minimally processed cabbage and cucumber through γ-irradiation was studied by Khattak et al. (2005). Microbial safety , texture, and sensory quality were investigated for minimally processed, polyethylene-packed, and irradiated cabbage and cucumber . The samples were stored at 5 °C for 2 weeks, with firmness values ranging from 3.23 to 2.82 kg, for the control and the irradiated cucumbers at 3 kGy. Gradual decrease in firmness was observed when increasing the radiation dose (up to 3 kGy). Either after applying 3 kGy irradiation dose or after 14 days storage, cucumbers softened, whereas acceptable texture was obtained when samples were treated with up to 2.5 kGy dose, and no effect on the appearance scores of cabbage was observed. The authors reported a better overall acceptability of cucumbers at 2.5 and 3 kGy irradiation doses, contrary to the appearance and flavor , which decreased for the higher irradiation doses.

The effects of γ-irradiation on sensory qualities , microbial population, and chemical properties of salted and fermented squid (Todarodes pacificus) were investigated (Byun et al., 2000). After salting with 5, 10, and 20 % (w/w) sodium chloride, squid slices were γ-irradiated with 2.5, 5, and 10 kGy doses then fermented at 15 °C for 50 days, and compared to nonirradiated samples. The authors concluded that the sensorial properties, bacterial populations, and pH values were depending to salt concentration and irradiation doses. When combining low salt concentration (10 %) with γ-irradiation, effective squid fermentation and shelf-life extension were observed compared to control without food additives.

In another study performed by Byun, Son, Yook, Jo, and Kim (2002), the physiological activity of Korean soybean fermented foods under γ-rays was studied. The authors compared the γ-irradiation of Chungkookjang and Doenjang; the whole cooked soybean product and the soybean paste, respectively. They applied the γ-irradiations at doses of 5, 10, and 20 kGy and evaluated the physiological activity by analyzing the inhibition of the angiotensin-converting enzyme , xanthine oxidase, and tyrosinase, as well as by testing the free radical scavenging ability. The authors demonstrated that up to 10 kGy, no significant changes on physiological activities were noticed. The irradiation effects on biogenic amines in Korean fermented soybean paste during fermentation was studied by Kim et al. (2003). The authors prepared and irradiated soybean paste at 5, 10, and 15 kGy, followed by fermentation for 12 weeks at 25 °C. Results showed a decrease in Bacillus spp. and lactic-acid bacteria after irradiation but their increase during fermentation. Biogenic amine contents between control and irradiated samples were not significant before fermentation. However, some of them were showing significant decrease during fermentation, for irradiated samples. The potential applications of γ-irradiation and fermentation are summarized in Table 7.1.

7.3.2 Alcohol Fermentation

Radiopasteurization method was applied to molasses fermentation media and its effect on fermentation and ethanol production was studied by Iizuka, Shibabe, and Ito (1969). The authors reported a decrease of viability of yeast in molasses to 70 % by heating at 80 °C for 30 min, to 10 % and 1 % by irradiation with 3.0 × 105 rad and 6.0 × 105 rad, respectively. The growth rate and performance of Saccharomyces cerevisiae in irradiated mash were similar to those observed by heat-pasteurized mash. In the absence of nitrogen in the molasses mash, 14 % difference in fermentation yield was observed between heating at 80 °C and irradiation with 3 × 105 rad. Furthermore, when nitrogen was supplemented to the molasses mash, the fermentation rate and ethanol production were higher upon irradiation compared to heating . The effect of γ-irradiation on alcohol production from corn was also studied (Han, Cho, & Ciegler, 1983). Different doses of γ-rays (0–100 Mrad) were applied to cracked corn in order to evaluate their effects on sugar yield, enzymatic hydrolysis of starch , growth of yeast, and production of alcohol. The authors found that beyond 50 Mrad, the amount of reducing sugars increased significantly; however, small amount of glucose was observed. It was found that when γ-irradiation was applied at lower doses, the susceptibility of corn starch to enzymatic hydrolysis increased significantly, giving about 12.5 % reducing sugar after amylase treatment without cooking. This amount was higher than that produced from cooked (gelatinized) corn by the same enzyme treatment. The authors found similar level of alcohol produced on uncooked/irradiated, and cooked corns . They concluded that the conventional cooking process prior to saccharification could be replaced by irradiation which provides additional benefit of sterilization of the medium.

The influence of γ-irradiation on ethanol production from yeast was studied later by Del-Mastro, Gimenes, and Villavicencio (1988). γ-irradiation was applied at up to 6 kGy to investigate the fermentative capacity of two yeast strains. The authors reported unchanged ethanol production using irradiated cells at 3 kGy; however, reduced yield by 43 % was observed for one strain treated at 6 kGy. They suggested the radio-resistant process of yeast to convert sugar to alcohol , and the most important conclusion is that these cells are not affected by γ-rays when treating the fermentation medium. Similarly, the fermentation of irradiated “sugarcane must” was studied by Alcarde, Walder, and Horii (2003). The authors investigated the influence of γ-irradiation in reducing the bacterial population (Bacillus and Lactobacillus ) usually contaminating the ethanolic fermentation by yeasts. Lethal radiation dose benefits on some parameters of fermentation were also verified. Contaminated sugarcane must with Bacillus and Lactobacillus bacteria was irradiated with 2, 4, 6, 8, and 10 kGy γ-rays. Total acidity produced during ethanolic fermentation by Saccharomyces cerevisiae was evaluated, as well as yeast viability and ethanol yield. The authors reported reduced bacterial population upon irradiation and decreased acidity as the dose rate of radiation increased.

7.4 New Perspectives

Apart from the food preservation , γ-irradiation can be used in several processes related to fermentation. Some of the most important applications are summarized in Fig. 7.2. For instance, the ability of γ-irradiation to reduce the cost of producing fermentation-based drugs has been recently described. Moreover, γ-irradiation can be used to improve alcohol fermentation, thus eliminating steps in the process (i.e. elimination of heat gelatinization) (Han, 1983). In addition, γ-irradiation has been widely applied for the generation of genetically modified fermentative strains to enhance the production of ethanol through fermentation, among many other applications. In fact, although medium irradiation by γ-rays leads to its sterilization , by killing bacterial contaminants, the impact on yeast remains lower than that noticed for bacteria. γ-Irradiation of yeast was primarily used to generate highly resistant strains to temperature and ethanol concentration, which are more suitable for industrial applications . For instance, Saccharomyces cerevisiae strains were screened after γ-irradiation for their tolerance to temperature and ethanol during fermentation (Mehdikhani, Rezazadeh Bari, & Hovsepyan, 2011). The authors irradiated with γ-rays at different doses (0.1, 1, 2, 3, 4, 5, and 10 kGy/h) three yeast strains and screened them to grow and ferment molasses in a range of 35–45 °C. Two strains were able to grow at 42 °C, and their efficiency for ethanol tolerance was significantly higher compared to control.

In a similar study, 25 strains of Saccharomyces cerevisiae highly tolerant for sugar and ethanol as well as resistant to inhibitors were screened (Jang, Lim, & Kim, 2014). The authors reported that the strain S. cerevisiae KL5-G2 was selected after γ-irradiation and was showing improved features for inhibitor (mixture of 75 mM formic acid, 75 mM acetic acid, 30 mM furfural, 30 mM hydroxymethyl furfural, and 2.7 mM vanillin), and high concentration of ethanol resistances . The authors selected this strain after sequential transfer of survival strains on increasing inhibitor cocktail concentrations, showing growth in YNB medium with up to 80 % inhibitor cocktail, whereas the parental KL5 strain could not grow at all. After γ-irradiation and sequential adaptation, one strain; KL5-G2-A9 was selected to produce the highest ethanol yield in a complex YP medium containing 60 % inhibitor cocktail and 5 % glucose , with 0.304 g/L/h, compared to only 0.072 g/L/h for the non-irradiated strain KL5.

7.5 Conclusions

Several studies have demonstrated the potential of γ-irradiation to preserve fermented products, thus maintaining nutritional and physicochemical properties. Minor changes are occurring during treatment with γ-irradiation, mainly produced by the generation of free radicals , but remain lower than that occurring naturally. γ-Irradiation technology has been extended for a wide range of applications, including the enhancement of fermentation features by either treating the medium or genetically modifying strains to ameliorate the fermentative characteristics. Although the potential use of γ-irradiation for food product preservation and the economical benefits drawn, its application remains limited, and more consumer awareness should be deployed.

References

Alcarde, A. R., Walder, J. M. M., & Horii, J. (2003). Fermentation of irradiated sugarcane must. Scientia Agricola, 60(4), 677–681.

Antonio, A. L., Carocho, M., Bento, A., Quintana, B., Luisa Botelho, M., & Ferreira, I. C. F. R. (2012). Effects of gamma radiation on the biological, physico-chemical, nutritional and antioxidant parameters of chestnuts—A review. Food and Chemical Toxicology, 50(9), 3234–3242.

Byun, M. W., Lee, K. H., Kim, D. H., Kim, J. H., Yook, H. S., & Ahn, H. J. (2000). Effects of gamma radiation on sensory qualities, microbiological and chemical properties of salted and fermented squid. Journal of Food Protection, 63(7), 934–939.

Byun, M.-W., Son, J.-H., Yook, H.-S., Jo, C., & Kim, D.-H. (2002). Effect of gamma irradiation on the physiological activity of Korean soybean fermented foods, Chungkookjang and Doenjang. Radiation Physics and Chemistry, 64(3), 245–248.

Cieśla, K., Salmieri, S., Lacroix, M., & Le Tien, C. (2004). Gamma irradiation influence on physical properties of milk proteins. Radiation Physics and Chemistry, 71(1–2), 95–99.

Dauphin, J. F., & Saint-Lebe, L. R. (1977). Radiation chemistry of carbohydrates. In P. S. Elias & A. J. Cohen (Eds.), Radiation chemistry of major food components (pp. 131–187). Amsterdam, Netherlands: Elsevier.

Delincee, H. (1983). Recent advances in radiation chemistry of proteins. In P. S. Elias & A. J. Cohen (Eds.), Recent advances in food irradiation (pp. 129–147). Amsterdam, Netherlands: Elsevier Biomedical Press.

Del-Mastro, N. L., Gimenes, J. J., & Villavicencio, A. L. (1988). Influence of gamma radiation on ethanol production from yeast. Brazilian Journal of Medical and Biological Research, 21(2), 375–377.

Fan, X., & Kays, S. E. (2009). Formation of trans fatty acids in ground beef and frankfurters due to irradiation. Journal of Food Science, 74(2), C79–C84.

Gaber, M. H. (2005). Effect of gamma-irradiation on the molecular properties of bovine serum albumin. Journal of Bioscience and Bioengineering, 100(2), 203–206.

Ganguly, R., & Pierce, G. N. (2012). Trans fat involvement in cardiovascular disease. Molecular Nutrition & Food Research, 56(7), 1090–1096.

Garrison, W. M. (1987). Reaction mechanisms in the radiolysis of peptides, polypeptides, and proteins. Chemical Reviews, 87(2), 381–398.

Han, Y. W. (1983). Irradiation alcohol fermentation process. Patent: US4631258 A

Han, Y. W., Cho, Y. K., & Ciegler, A. (1983). Effect of gamma-ray irradiation on alcohol production from corn. Biotechnology and Bioengineering, 25(11), 2631–2640.

Hasanain, F., Guenther, K., Mullett, W. M., & Craven, E. (2014). Gamma sterilization of pharmaceuticals--a review of the irradiation of excipients, active pharmaceutical ingredients, and final drug product formulations. PDA Journal of Pharmaceutical Science and Technology, 68(2), 113–137.

Iizuka, H., Shibabe, S., & Ito, H. (1969). Gamma irradiation on fermentation mashes consisting mainly of cane molasses. Agricultural and Biological Chemistry, 33(4), 473–479.

Jang, Y., Lim, Y., & Kim, K. (2014). Saccharomyces cerevisiae strain improvement using selection, mutation, and adaptation for the resistance to lignocellulose-derived fermentation inhibitor for ethanol production. Journal of Microbiology and Biotechnology, 24(5), 667–674.

Khattak, A. B., Bibi, N., Chaudry, M. A., Khan, M., Khan, M., & Qureshi, M. J. (2005). Shelf life extension of minimally processed cabbage and cucumber through gamma irradiation. Journal of Food Protection, 68(1), 105–110.

Kim, J.-H., Ahn, H.-J., Kim, D.-H., Jo, C., Yook, H.-S., Park, H.-J., et al. (2003). Irradiation effects on biogenic amines in Korean fermented soybean paste during fermentation. Journal of Food Science, 68(1), 80–84.

Luck, H., & Kohn, R. (1963). The effect of ionizing radiation on fats. IV. Cis-trans isomerization and shifting of double bonds. Nahrung/Food, 7, 199–211.

Matsuzaki, H., Baba, A., Maruyama, T., Niiya, I., Yanagita, T., & Sugano, M. (1998). Study of trans fatty acid content in commercial foods in Japan. III. Meats and meat products. Journal of Japan Oil Chemists' Society, 47(3), 495–499.

Mehdikhani, P., Rezazadeh Bari, M., & Hovsepyan, H. (2011). Screening of Saccharomyces cerevisia for high tolerance of ethanol concentration and temperature. African Journal of Microbiology Research, 5(18), 2654–2660.

Molins, R. A. (2001). Food irradiation principles and applications. New York: Wiley.

Nawar, W. W. (1977). Radiation chemistry of lipids. In P. S. Elias & A. J. Cohen (Eds.), Radiation chemistry of major food components (pp. 21–62). Amsterdam, Netherlands: Elsevier.

Phillips, G. O., & Moody, G. J. (1959). The chemical action of gamma radiation on aqueous solutions of carbohydrates. The International Journal of Applied Radiation and Isotopes, 6, 78–85.

Sadecka, J. (2010). Influence of two sterilisation ways, gamma-irradiation and heat treatment, on the volatiles of black pepper (Piper nigrum L.). Czech Journal of Food Sciences, 28(1), 44–52.

Simic, M. G. (Ed.). (1983). Radiation chemistry of water-soluble food components. In Preservation of food by ionizing radiation: Vol. 2 (pp. 1–73). Boca Raton, FL: CRC Press.

Song, H.-P., Kim, D.-H., Yook, H.-S., Kim, D.-H., Kwon, J.-H., & Byun, M.-W. (2004). Application of gamma irradiation for aging control and improvement of shelf-life of kimchi, Korean salted and fermented vegetables. Radiation Physics and Chemistry, 71(1–2), 57–60.

Stewart, E. M. (Ed.). (2001). Food irradiation chemistry. In Food irradiation: Principle and application (pp. 37–76). New York: Wiley.

Verde, S. C., Trigo, M. J., Sousa, M. B., Ferreira, A., Ramos, A. C., Nunes, I., et al. (2013). Effects of gamma radiation on raspberries: Safety and quality issues. Journal of Toxicology and Environmental Health. Part A, 76(4-5), 291–303.

Woodside, J. V., McKinley, M. C., & Young, I. S. (2008). Saturated and trans fatty acids and coronary heart disease. Current Atherosclerosis Reports, 10(6), 460–466.

Xuetong, F. (2012). Radiation chemistry of food components. In X. Fan & C. H. Sommers (Eds.), Food irradiation research and technology (pp. 75–97). West Sussex: Wiley.

Yaman, A. (2001). Alternative methods of terminal sterilization for biologically active macromolecules. Current Opinion in Drug Discovery & Development, 4(6), 760–763.

Yılmaz, I., & Geçgel, U. (2007). Effects of gamma irradiation on trans fatty acid composition in ground beef. Food Control, 18(6), 635–638.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Koubaa, M., Barba-Orellana, S., Roselló-Soto, E., Barba, F.J. (2016). Gamma Irradiation and Fermentation. In: Ojha, K., Tiwari, B. (eds) Novel Food Fermentation Technologies. Food Engineering Series. Springer, Cham. https://doi.org/10.1007/978-3-319-42457-6_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-42457-6_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-42455-2

Online ISBN: 978-3-319-42457-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)