Abstract

This chapter introduces various construction automation concepts that have been developed over the past few decades and presents examples of construction robots that are in current use (as of 2006) and/or in various stages of research and development. Section 57.1 presents an overview of the construction industry, which includes descriptions of the industry, the types of construction, and the typical construction project. The industry overview also discusses the concept of automation versus robotics in construction and breaks down the concept of robotics in construction into several levels of autonomy as well as other categories. Section 57.2 discusses some of the offsite applications of robotics in construction (such as for prefabrication), while Sect. 57.3 discusses the use of robots that perform a single task at the construction site. Section 57.4 introduces the concept of an integrated robotized construction site in which multiple robots/machines collaborate to build an entire structure. Section 57.5 discusses unsolved technical problems in construction robotics, which include interoperability, connection systems, tolerances, and power and communications. Finally, Sect. 57.6 discusses future directions in construction robotics and Sect. 57.7 gives some conclusions and suggests resources for further reading.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

Construction is a ubiquitous human activity that relates to the creation or realization of physical artifacts or custom-made capital goods. It is distinguished from manufacturing in that the production activity normally occurs in a field setting and is undertaken in the open air, on natural terrain, and often with naturally occurring materials. Typically, building and construction products are large in scale and unique in form. Moreover, the environment or field setting is typically unique and requires a, rather ad hoc, factory to be synthesized on site.

Over the centuries, various forms of machines and mechanical engineering systems have been introduced into the construction engineering domain and into the building and construction industry to increase production efficiency. In common with the fields of agriculture, mining, and forestry, the long-term trend has been for these fields to become increasingly mechanized [57.1].

In the last few decades, with the decrease in the relative cost of machinery to labor and with the globalization of markets, the construction industry has become significantly more capital intensive and large-scale machinery systems and pieces of construction plant – such as tunnel-boring machines and very large tower cranes – have become commonplace. This trend to mechanization is likely to continue with the progressive introduction of computer-controlled construction machinery and flexible manufacturing concepts into the industry.

With the relatively recent development of the microprocessor and the availability of low-cost computer and sensing technology, construction robots have become a technical and economic possibility and this form of technology is now gradually being used in the industry.

1 Overview

The application of robots in construction traditionally falls under construction automation.As the term implies, the field of construction automation is focused on automating construction processes, and the use of robots is but one aspect of automation. Construction processes also fall within several categories best described through a brief introduction to the construction industry.

1.1 Industry Description

The construction industry typically accounts for 5 % of a country’s gross domestic product (GlossaryTerm

GDP

) or gross value added (GlossaryTermGVA

) and employs a significant portion of the country’s workforce. Table 57.1 presents some of these statistics for the USA, the European Union (GlossaryTermEU

), Japan and China [57.2, 57.3, 57.4, 57.5, 57.6, 57.7, 57.8]. Worldwide, construction industry spending was estimated at approximately 11 % of the world’s GDP at the end of the 20th century [57.9].Construction is considered by many to be technologically behind other industries, such as manufacturing. In manufacturing, a product is designed for mass production, whereas construction products (or projects) are usually one-off and unique [57.10]. Thus the efficiencies achieved through mass production are not easily achieved in construction.

Other often attributed reasons for the construction industry’s technological lag are the industry’s fragmentation and aversion to the risks associated with the introduction of new technologies [57.10, 57.11]. For example, in the US in 2010 firms with fewer than twenty employees employed approximately 40 % of all construction workers, and 63 % of all construction workers worked for specialty trade contractors who accounted for 64 % of construction firms [57.10]. Specialty trade contractors are usually subcontractors on a project and are not responsible for the overall outcome of the project.

In addition, unlike their manufacturing counterparts, construction sites are for the most part unstructured, cluttered, and congested, making them difficult environments for robots to operate in. Furthermore, human workers are also present in large numbers on a construction project, making safety a paramount concern.

1.1.1 Types of Construction

Construction projects are usually classified as residential, commercial, industrial, or civil. Residential construction generally involves single-family homes or large apartment buildings; commercial focuses on building structures such as office and retail space, warehouses, and so on; industrial is involved in building factories, power plants, and other similar structures; and civil construction focuses on public infrastructure such as highways, bridges, tunnels, and dams.

1.1.2 The Typical Construction Project

A construction project typically goes through six major phases, as shown in Fig. 57.1. Some projects may go through different variations of the sequence shown, but most projects include planning, design, construction, and operation phases [57.10, 57.4]. Phase 1 begins when a need for a project arises and the requirements are identified. Phase 2 involves developing alternative project plans that could meet the identified needs and evaluating the technological and economic feasibility of each alternative. Phase 3 develops detailed engineering designs and specifications for the plan selected in phase 2. The construction of the facility from ground-breaking through to final inspection takes place in phase 4 of the project. The facility is occupied and commences operation in phase 5 and continues operating until it is time to shut down and dismantle the facility once it becomes obsolete (phase 6).

The actual physical work (building, operating, maintaining, and dismantling) on a construction project takes place in the last three phases. Although these are the only phases in which machines are used, construction automation can also take place during the other phases of a project, as described in Sect. 57.1.2.

During the various phases of a construction project, several stakeholders may be involved at any time. The major stakeholders include the following: the owner and operator, whose needs initiated the project; the architect and engineer, who have the task of translating the owner’s needs into an aesthetically pleasing and structurally sound design; and the general contractor, whose task is to translate the design into a physical structure. In addition several other stakeholders may be involved either independently from the above stakeholders or as part of their organizations; for example, the constructor may employ a project manager, a construction manager, a site superintendent, and others, and he/she will typically subcontract major activities such as excavation and concrete pouring. The subcontractors and sub-stakeholders are often the ones who use a new technology and can either make or break its implementation.

Although the builder is the most likely user of robots on a construction project, the actual work on site is often conducted by subcontractors who often are reluctant or financially unable to use advanced technologies which have not been entirely adopted by industry. A constructor’s goal is often to meet the owner’s requirements by the most efficient and least risky methods possible. Hence, traditional construction methods that have stood the test of time are preferred. Nevertheless, it has often been anecdotally reported that the owner has the power to require the use of certain technologies on a construction project, since that shifts part of the risk and cost associated with the use of the technology to the owner. This phenomenon may be partially responsible for the widespread penetration of laser scanning technology into the construction industry that is currently taking place [57.12].

1.1.3 Typical Construction Processes

From a purely physical-world and practical point of view, construction may be viewed as being comprised of a finite number of elementary processes [57.13, 57.14, 57.15, 57.16], which may be summarized by the following list [57.11]:

-

Attaching

-

Building

-

Coating

-

Concreting

-

Connecting

-

Covering

-

Cutting

-

Digging

-

Finishing

-

Inlaying

-

Inspecting

-

Jointing

-

Measuring

-

Placing

-

Planning

-

Positioning

-

Spraying

-

Spreading.

Most of these processes can also be grouped into three predominant types of functional operators as follows:

-

Materials handling (by bulk and unit load)

-

Materials shaping (cutting, breaking, compacting, and machining)

-

Structural joining.

These functional operators are typically each applied to multiple operands. Common operands in building and civil engineering are steel and other metals, concrete, timber, earth and rock, masonry, plastic and glass, cement, aggregate, epoxy resin, bitumen, and other bulk and formed materials.

1.2 Automation in Construction

Construction automation describes the field of research and development focused on automating construction processes, and the use of robots is but one aspect of that field. In short, construction automation deals with applying the principles of industrial automation to the construction sector, whether in building construction, civil engineering (roadways, dams, bridges, etc.), or in prefabrication of construction components [57.17]. This can be viewed as an extension to research in field service robots generally designed to replace or assist humans in a specific construction-related task or function.

From a historical perspective, research in construction robotics and automation started in the 1980s with the introduction of single-purpose robots (principally remotely controlled, or teleoperated, machines). The Japanese led this effort, driven primarily out of concern for societal demographics, which showed a significant future shortfall in personnel available for the construction labor pool [57.18]. In the US the principal related work involved developing remote control or teleoperated machinery for hazardous work that required modified construction equipment. Example applications include robots developed for rapid runway repair and unexploded ordinance removal. In the EU, research was focused on the development of large-size masonry (brick laying, assembly) robots for residential and industrial building construction.

During the next decade, as research on task-specific construction robots continued, large Japanese construction firms introduced on-site factories for high-rise construction. These construction systems included just-in-time delivery of components, automated part tracking and material handling, robotic connection and assembly, and centralized control in an enclosed or semi-enclosed environment. It is reported that the systems enable better working conditions (weather invariant) and reduced project completion time [57.19]. Other benefits include improved productivity and quality, though overall construction costs are not necessarily lower [57.20].

Advanced concepts in integrated residential construction automation were developed as part of the EU FutureHome project. In this construction concept, each structure consists of several high-quality, prefabricated three-dimensional (GlossaryTerm

3-D

) modules and two-dimensional (GlossaryTerm2-D

) panels which are assembled production-style on site [57.21]. An analogue of this approach for automated residential construction has been commercialized in Japan [57.22].New methods for collecting, processing, analyzing, and communicating construction information are a significant area of construction automation research [57.23]. This research includes data interoperability and exchange through the design, construction, operations, maintenance, and decommission phases of a capital project [57.24]; advanced sensors for assessing the status of the construction process [57.25, 57.26, 57.27]; visualization systems for planning construction events, verifying constructability, and maintaining site situational awareness [57.28, 57.29, 57.30]; and information models which extend traditional computer-aided design (GlossaryTerm

CAD

) modeling to combine both the physical (geometric) and functional characteristics of building components [57.31].Finally, three notable, large-scale, EU projects attempted to integrate construction automation into the way construction projects are executed: the ManuBuild (open building manufacturing) project dealt with, among other things, the development of mobile field factories, including robots, for on-site modular construction [57.32]; the GlossaryTerm

I3CON

(industrialized, integrated, intelligent, construction) project dealt with the indoor automation and robotization of buildings [57.33]; and the Tunconstruct project dealt with the robotization of inspection and maintenance operations in tunnels [57.34].1.3 Classification of Robotics in Construction

Construction robotics is an advanced form of mechanization (automation) in which an endeavour is made to automate some industrially important operation and thereby reduce the cost of this operation by either removing a human operator from the control loop, or enhance operational efficiency through machine control systems. Due to the nature of construction work, most robots which have been developed for the construction industry are either mobile or relocatable systems. Some platforms, such as floor-finishing robots and machine-controlled earthmovers require mobility as a specific function of the work process to be performed. Others, such as wall and ceiling panel manipulators, require some level of mobility to extend their operating workspace.

Robot terminology can vary depending upon the research discipline. For this chapter two broad classifications of construction robotics are onsite robots and offsite robots. These are distinguished by whether they are applied at the construction site or at a factory or pre-fabrication facility. In addition, a further distinction can be made depending on whether a construction robot is intended to be used for a single task (onsite or offsite) or whether multiple robots are integrated into an automated construction site.

1.3.1 Single Task Construction Robots Versus Integrated Robotized Construction Sites

After the initial experiments in large-scale industrialized, automated and robotized pre-fabrication of system houses were conducted successfully in Japan, and the first products (e. g. Sekisui M1) also proved successful in the market, in 1975 a Japanese construction contractor, Shimizu Corporation in Tokyo, set up a research group for construction robots. The goal was now no longer the mere shifting of complexity into a structured environment as in prefabrication, but the development and deployment of systems that could be used on the construction site to create structures and buildings. The focus initially was set on simple systems in the form of so-called single task construction robots that can execute a single, specific construction task in a repetitive manner.

Single-task construction robots are systems that support workers in executing one specific construction process or task (e. g. digging, concrete levelling, concrete finishing, painting) or completely supplement the physical activity of the human workers necessary to perform this one process or task. Further, the processes and tasks they support or supplement can be allocated to a specific profession or craft. In addition, the processes and tasks for which single task robots were developed had in common that they entailed frequent, repetitive activities. Common characteristics of single-task construction robots are as follows:

-

Highly specialized not only for a profession but even for a task within a profession (e. g., concrete pouring, levelling and finishing.

-

Enhanced productivity compared to conventional labour. E.g., according to [57.17] the conventional labour productivity rate for concrete floor finishing is between and , whereas the productivity using machines is between and .

-

Improved quality through precise control of functions and operations (e. g., uniform distribution of paint) and by allowing real time monitoring (and recording) of the operation.

-

Improved working conditions by removing workers from dangerous environments and reducing the amount of and heavy physical work.

-

Most robots allow various operation modes such as autonomous or sensor guided, pre-programmed, or tele-operated.

-

Reduced material consumption through precise control of material delivery and collection and reuse of unused material.

-

Most robots have simple yet robust sensor technologies, such as gyroscopes, simple laser systems, or touch/pressure sensors.

-

Most robots only require 1 or 2 persons to operate.

The evolution of industrialized and automated building prefabrication during the 1970s along with the development of single tasks robots, envisioned the concept of integrated robotized construction sites. This concept combined prefabrication technology (processing of prefabricated components instead of parts in order to reduce complexity on the site), single task construction robotic systems, and moving or stationary site factories that were able to assemble the building’s main structure (e. g., steel frame or concrete structure) almost automatically. As those site factories not only automated parts of the construction process but also integrated prefabricated component technology and single task automation can thus be called as integrated robotized construction sites.

A major reason for the transition into integrated robotized construction sites was that the construction companies realized that single task construction robots which were not networked or embedded within a greater infrastructure, turned out to be incompatible with the way buildings were designed and built. Single task robots were designed to execute certain tasks meanwhile construction workers were not allowed to interfere significantly with the robots activity. However, it turned out that under these premises, only a very few number of robots could be used efficiently. The constraints for the workers, the necessary safety regulations, coupled with the unforeseen, unpredictable, and dynamic processes at the construction site, led to the implementation of individual robots working in parallel. Although single task construction robots achieved a high throughput, significant time had to be spent on-site for transportation, preparation, programming, configuration, etc. Besides the mentioned frictions single task construction robots caused on (conventional) construction sites, the emergence of concepts for integrated sites was also nurtured by the new technological possibilities. Important for the integration of such systems into larger and coordinated automated systems was the development of systems that allowed controlling and monitoring an uninterrupted flow of information and material on-site, between individual automated entities that are involved in the final assembly of the building.

The transition to integrated sites can also be explained from an evolutionary view. In many industries the evolution from more workshop like production with individual and only loosely coupled production entities or stations, to flow-line like or production line like systems with stable processes and continuous material flow was part of the evolution of other well established and known industries,, i. e., automotive, computer industry.

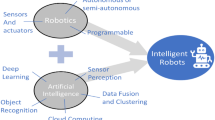

Finally, three general categories of construction robots are introduced. The first class is teleoperated systems, which for simplicity includes remote control systems. The general distinction between the two terms is whether or not the equipment must be operated in line of sight from the human controller [57.35]. The second category, programmable construction machines (GlossaryTerm

PCM

), includes most construction equipment that is outfitted with sensors and mechanisms to augment operation by an onboard human operator. The final category, intelligent systems, relates to unmanned construction robots which operate either in a semi- or fully autonomous mode. In Sect. 57.3 this classification will be expanded to include examples based on various generic activities, materials handled (operand types), levels of onboard intelligence, levels of commercialization, and levels of system integration and computer integration.1.3.2 Teleoperated Systems in Construction

In established engineering terminology, the term teleoperation refers to the remote control of machines and systems. In teleoperation (loosely referred to as telerobotics) the control of the machine is accomplished by the use of remote control means such an umbilical cord or wireless control. Teleoperation ideas and methods are used extensively in the space and nuclear industries (Chaps. 55 and 58, respectively).

In telerobotics, the machine does not operate autonomously but is under the control of a human. Data sensing and interpretation and cognitive activities such as task planning are done by the operator.

Recently, many telerobotic devices have appeared in the construction and mining industries. These machines have evolved in response to industrial situations where there is danger to the operator and where remote-controlled machinery is necessary (e. g., teleoperated small compactors). Situations of this kind occur in the construction, demolition, and mining industries and in other hazardous locations.

The technology for telerobotics in construction is well established, with a number of excellent examples of such activity available, for example, a sophisticated model-based supervisory-control-type distributed teleoperation system for the construction of a trench for a diversion dam in a lava field in Japan using a fleet of heavy earthmoving machines [57.36].

1.3.3 Programmable Construction Machines

A software-programmable construction machine is what most people would consider to be a robot. The operator of this type of machine is able to vary the task to be accomplished within certain constraints either by choosing from a preprogrammed menu of functions or by teaching the machine a new function. Variations in the task to be accomplished could be as simple as slight changes in the driving speed based on the current load for an automated forklift, or as complex as a change from being able to pick and place steel beams and columns using an autonomous crane to being able to deliver concrete autonomously using the same crane.

Generally, software-programmable construction machines are identical to traditional construction machines (such as an excavator), but have been modified to be controllable through a computer (similar to the way in which traditional manufacturing machines – such as mills and lathes – evolved into computer numerically controlled (GlossaryTerm

CNC

) machines).Software-programmable construction machines can make use of an electronic representation of a portion of the construction site where their work is to be conducted in order to control all or part of the machine’s operation. A commercialized example is stakeless grading, where data from a 3-D model is used in combination with global positioning systems (GlossaryTerm

GPS

) and/or laser measurement systems to automate the blade control for bulldozers and motor-graders.1.3.4 Intelligent Systems in Construction

As opposed to a teleoperated or a software-programmable construction machine a fully autonomous construction robot is expected to accomplish its task, within a defined scope, without human intervention. A semiautonomous construction robot would be expected to accomplish its task with some level of planning interaction conducted with a human supervisor [57.35]. In each case the construction robot is expected to adapt to its sensed environment, formulate plans for the execution of its task, and replan as necessary (with possibly some human assistance in the semiautonomous mode). The intelligent construction robot should also be able to determine when its tasking is not executable and request assistance.

Example research in intelligent construction systems includes autonomous excavation [57.37, 57.38] and autonomous crane operations [57.30, 57.39, 57.40, 57.41].

2 Offsite Applications of Robotics in Construction

The infusion of technologies (such as computer aided design (GlossaryTerm

CAD

), computer aided manufacturing (GlossaryTermCAM

)) into the construction industry from other industries (such as the automotive, airplane and shipbuilding industries) are the clearest proof for a shift in building strategy. Fully automated concrete fabrication is currently a reality that are implemented by factories with customized product delivery in order to adapt to the changing requirements of the market. There are two major industrialized production methods for prefabricated concrete: Production methods that (a) use stationary single formwork and (b) that use mobile formwork.2.1 Robotics in Component Production

Production methods using stationary single formwork comprise mobile workflows such as cleaning, pouring/casting and moving the final product to the storage, while the formwork is stationary during the whole process of prefabrication. In production methods using mobile formwork, the work posts are stationary while the formwork is mobile, moving into the various prefabrication posts of the assembly line.

2.1.1 Concrete Production

A plant for combined manufacture of 2-D and 3-D precast concrete elements includes overhead gantry cranes and electric hoists, used to transport consumable materials (such as lattice girders, steel coils, and parts to be inserted/installed) as well as to lift elements from the concreting station into the storage facility or onto transport pallets. Pallets start at the discharging station, from where they proceed via the pallet cleaning station to the first workstation. There, by means of a de-palletizing device attached to a panel-stacking crane, the finished flooring elements are lifted off the pallets and stacked directly within the working range of the discharging vehicle. A cleaning and plotting (magazining, cleaning, plotting (GlossaryTerm

MCP

)) robot is used for a variety of tasks: picking up, insertion of latitudinal anchors, cleaning of pallets, full scale plotting of elements, and installation of latitudinal anchors (Fig. 57.2). Figure 57.3 shows further examples of robotic concrete component manufacturing and handling.(a) Pallet in concreting station; (b) bridge crane; (c) pallets molding systems; (d) demolding-depalletizing device; (e) cleaning, measuring and oiling (after [57.42])

2.1.2 Brickwork Component Production

Since the late 1970s, due to the lack of skilled workers in construction and increasing costs of buildings, rationalization developments were started. They mainly took place in the masonry and the formwork sector, where no ready solutions from other countries were available. In Germany and also in most parts of Europe an often used and still loved building material is brickwork. Most of the building projects are constructed with this material. Due to the lack of brickwork in Japan (not resistant to earthquakes if not reinforced), and missing developments in other countries, main efforts were made in this field.

In the last few decades activities to develop machines that support the laying of bricks and even automated robots have been increasing, especially in Germany. Brick laying is a very labor-intensive activity, which can lead to significant health issues and early retirement [57.43, 57.44]. Consequently a very small number of skilled workers is available nowadays. This in turn is reflected in ultimately high prices and wages, which will make brick building in some time prohibitively expensive. Therefore it should just be a question of time before only houses are put on the market that have not been erected on site by a team of bricklayers, but by a robot in the production shop.

2.1.3 Early Trials of Robotic Assembly of Modular Blocks

One idea for Robot Oriented Design (GlossaryTerm

ROD

) [57.45, 57.46, 57.47], in building construction is to change the conventional construction works adaptable to robotics so that construction system and advanced automation and/or robotics are co-adapted. Thus a structural system for the wall erection named GlossaryTermSMAS

(Solid Material Assembly System) [57.48] was proposed and developed already in the 80s in Japan. SMAS is a of reinforced masonry construction system. A standard building component of this system, in size and 20 kg in weight, is made of pre-cast concrete and includes cross-shaped steel bar inside each component for the reinforced of structural wall. Components are positioned automatically by the robot one by one without arrangements of conventional bonding. Following the positioning of each components, steel bars are connected to those of adjacent components also by the robot. The joint type of steel bar for vertical direction is mechanical, and that for lateral direction is overlapping. Concrete is grouted from the top of the wall which is erected one storey high (about 3 m). The newly developed operating hand is installed to the mother robot (6-articulation-type robot) which was developed for a wide variety of applications in factory use and a series of experiments for wall erection were carried out.The rapid progress being achieved today in the modernization and industrialization of building construction technology has triggered a trend to reduce the complicate works at construction site and increasingly produce building components at factories. It is obviously that the prefabrication has been successful in up-grading the quality of the building and in shortening the construction period. The sizes of those building components such as prefabricated structural members are also becoming larger to simplify assembling work at the construction site.

However, these movements are not necessarily oriented toward the introduction of robots. The heavy and large components are difficult to be operated by the robots and the complicated assemble techniques are sometimes too skilful for robots. Meanwhile, when one looks at the prefabrication of compact and lightweight structural components as a means of accomplishing construction work more efficiently, robots can be used for assembling these structural members efficiently.

From this point of view SMAS structural system was developed and proposed as a robot-oriented construction system. A masonry structure has not been considered as a major structural system in Japan because of earthquakes; however, it becomes to be recognized as a flexible structural system applied to various building designs when properly reinforced. In addition, it has advantages in the construction cost and in the construction period. The SMAS system itself was designed as a modular system for the purpose that single components could be developed further in the future. All system components including stones are developed as complementary parts according to the guidelines of Robot Oriented Design (ROD) (Fig. 57.4). These robotic approaches were meant to be applied on-site, but technologically they were proven to be not effective. Thus, they became better suited for offsite assembly operations.

2.1.4 Automated Brickwork Plants

The adoption of CAD/CAM systems combined with implementation of Enterprise Resource Planning (GlossaryTerm

ERP

) Solutions has made the implementation of advanced technically refined, fully automatic production plants possible:-

High degree of information and communications technology (GlossaryTerm

ICT

) integrated and automated/interconnected processes -

Integration of as many devices as possible by ICT (interoperability)

-

CAD/CAM Systems

-

Integration of processes by ERP Systems

-

Just in Time and Just in Sequence supporting customization.

2.1.5 Brickwork Robot Plant SüBA

Crucial technical developments preceded the construction of a fully automatic brickwork machine. The prototype of the automatic brickwork plant was developed by the company SüBA in Hockenheim, and the company Windhoff AG in Rheine at the beginning of the 1990s. The production of brickwork panes is appropriate for a capacity of net area of brickwork panes – without windows and door recesses – in a shift of eight hours. The employment of CAD in the architect’s offices made it possible to transfer the large data set for the production of brickwork panes directly without manual input over CAM to the brickwork robots. Considering the large number of data for the automat, which was necessary for the production of a brickwork pane, this was one of the most important problems of the automation of bricking at that time. Figures 57.5 and 57.6 give an overview over the most important SüBA factory modules and automation processes.

2.1.6 Brickwork Robot Plant Winkelmann (Horizontal Brickwork Panel Production)

Today’s fully automated and highly robotized brickwork plants can be distinguished into two basic types: horizontal and vertical brickwork panel production. The brickwork robot plant Winkelmann is a characteristic example for horizontal panel production. All single devices are equipped with Microsystems, interconnected and part of a systemic logistic network. CAD/CAM guarantees efficient data processing between planning section and production. After the delivery standard palettes bricks are brought into processing order by an automated palletizing system with a robot for distribution of bricks (Fig. 57.7a). After that the bricks are taken up by automated de-palletizing system (Fig. 57.7b), which supplies horizontal brickwork layering robot station (Fig. 57.8a). Insertion of reinforcement and house infrastructure as well as plastering are done stationary in the factory (Fig. 57.8b) until a finalized and dried-out brickwork panel is delivered to the construction site.

2.1.7 Brickwork Robot Plant Leonhard Weiss (Vertical Brickwork Panel Production)

The brickwork robot plant Leonhard Weiss is a characteristic example for vertical brickwork panel production. Many processes as for example the palletizing and de-palletizing to bring the bricks into factory order are similar to the horizontal type. Yet the central process of positioning the bricks in given order is done vertically layer by layer. High accuracy robots combined with linear axis are here in charge for the exact positioning. The automated vertical brickwork layering has some advantages in terms of efficient use of the factory area and moreover the firmness of the wall could be improved whereas the exact positioning of reinforcement, cables and other elements of the house infrastructure is done easier with the horizontal type. CAD/CAM combined with variable production and ICT integrated production allows individually fabricated brickwork panels and necessary variations. Figure 57.9 shows the various steps of the automated vertical brickwork panel construction process.

2.1.8 Steel Component Production

Sekisui Heim introduced an automated steel frame production. One of the basic features is the automated assembling and welding station. Ceiling elements, flooring elements and columns are fed into this station, followed by automatic welding into a frame, which is used as chassis and bearing structure during the further completion process on the production line (Fig. 57.10). After the automated welding process, the steel frame chassis is streaming through the factory from work step to work step, until all installations have been completed (Fig. 57.11a). The factories of Sekisui and Toyota have gates on both sides of the assembly lines in order to receive material, parts, components and prefabricated bath or kitchen modules, required for the customized production of individual units. All of them arrive just-in-time and just-in-sequence by cooperating suppliers (Fig. 57.11b).

3 Onsite Applications of Single Task Construction Robots

The construction of larger buildings that use steel as the structural support system can involve a high total amount of welds. If the design of the columns and beams can be adjusted in order to reduce the amount and variety of welds, welding becomes a highly repetitive operation suitable for being automated.

3.1 Steel Welding

Automated welding is able to control and guarantee the quality of the connection between the welded parts to a level similar to (and sometimes better than) that achieved by professional human welders. Manual welding of these and other types of connections requires highly specialized skills that are currently in short supply. Furthermore, conventional welding can have damaging long-term effects on a worker’s vision. Simultaneous automated welding on a beam (e. g., from two or three coordinated positions) is even able to ensure that the steel component is not distorted by the welding operation itself and thus improves the quality of the constructed structures. In Fig. 57.12a the Shimizu steel-welding robot is depicted. The robot can automatically weld a column including the corner portions. The configuration of a joint is detected by a laser sensor, and the welding is performed in an optimized way referring to a database. In Fig. 57.12b, the Obayashi Corporation Steel welding robot operates in a similar principle, using a circular clamp-on type fastener to the column. The welding process is computer-controlled, though workers are still involved in overseeing operations at least for the time being.

3.2 Reinforcement Manufacturing and Positioning

Concrete reinforcement operations involve cutting and bending of rebar (reinforcement bars), precise (relative to each other) arrangement of those rebar, binding of rebar and final positioning of the rebar elements or mesh on a floor or in a mold or formwork system. These tasks are labor intensive and hard on a worker’s body (e. g., back accidents and damage to a worker’s musculoskeletal system occur about ten times more during reinforcement work than during painting work [57.49]). Automated systems mitigate the risks and impacts on the health of workers and enhance the quality of the reinforced concrete structures. Figure 57.13a shows a reinforcement production robot and Fig. 57.13b shows a teleoperated rebar placing robot.

(a) Automated reinforcement production and (b) teleoperated rebar placement (after [57.17])

3.3 Concrete Distribution

Concrete distribution systems are used to distribute mixed concrete with uniform quality over large surfaces or over formwork systems. Concrete distribution covers the continuous supply with concrete (pumps, hoses), a system which slides in a certain pattern over the area where the concrete has to be distributed and a concrete ejection system. Systems can be operated manually, tele-operated and sometimes sensor-guided or fully automatic. Depending on the surface where the concrete needs to be distributed, concrete distribution systems can be truck mounted, stationary or mobile. In Fig. 57.14a, a track mounted automatic concrete distributor robot (DB Robo) can be seen. In Fig. 57.14b a mobile concrete distributor system can be seen, which due to its wheel-based platform, enables an enhanced operating range. Figures 57.15 and 57.16 show other examples of automated concrete distribution systems.

(a) Programmable, articulated-boom machine for the pumped delivery of fresh concrete (after [57.50]) and (b) teleoperated concrete spraying robot (courtesy MEYCO Equipment)

3.4 Robots for Customized Construction On-Site

Several masonry-wall erecting robots have been developed to-date. Examples of these are the SMAS in Japan and the GlossaryTerm

ROCCO

robot at the University of Stuttgart. Many of these systems are still in the prototype stage. The basic concepts that these systems have in common are as follows:-

Autonomous mobility on the construction site

-

Sensor systems determine the robot’s position and orientation in its environment

-

Automatic pick up of the bricks from the pallets

-

Automatic application of mortar

-

Automatic positioning of the bricks.

ROCCO is a Robot Construction System [57.51, 57.52], for Computer Integrated Construction (GlossaryTerm

CIC

). Several companies and institutes participated in this EU funded project in an inter-disciplinary and international approach with experts in the fields of construction technology, mechanical and electrical engineering and information technology from Germany, Spain and Belgium. The goal of the project was the development of a computer integrated robot system, which also contains a continuous solution in the ICT (Information Communication Technology) for all steps from the architectural design to the automated assembly of the components on the construction site.The main emphasis of the project lies on the realization of a mobile robot system for construction site operation as well as on the integration of a computer based system for work preparation and quality control. In the work preparation phase the necessary data is generated for the pre-fabrication and customization of the masonry blocks, for the construction site layout and for the automatic robot program generation.

Based on the CAD-representation of the building, first the walls are divided automatically into the necessary blocks. In the next step the optimal working positions of the mobile robot as well as the positions of the pallets and the arrangement of the blocks on the pallets are automatically calculated. With this information the necessary non-standard and standard blocks can be produced and palletized. Finally the robot programs are generated automatically out of the calculated geometry information. The user interface on the construction site is graphically interactive and enables the user to partially re-program the generated robot programs to deal with the uncertainties of the construction process without the need to learn a specific robot programming language.

To test different approaches based on the construction application (residential buildings vs. industrial) and the sensor integration (autonomous vehicle vs. long reach), two systems were developed within the project. The first one, for residential buildings, has a reach of 4.5 m and it is able to handle up to 400 kg. This robot is placed over an autonomous vehicle that allows the movement on the construction site, Fig. 57.17a. Its main task is the erection of walls in residential buildings. The second one is able to handle up to 1000 kg with a reach of 8.5 m. This robot, Fig. 57.17b, is placed over a towable platform and its main task is the erection of external walls in industrial buildings with typical height of up to 8 m and standardized layout.

3.5 Robotic Interior Finishing

Interior finishing work is work conducted inside a structure (e. g., an office building) to complete construction of the space within the structure (e. g., painting and false ceiling and gypsum board installation). Due to the confined nature of interior finishing work traditional material handling equipment (such as cranes) cannot be used. The following four systems are examples of interior finishing robots:

-

The Shimizu CFR 1 (Fig. 57.18a) could be manually and tele-operated and allowed the installation of suspended ceiling panels to a height of up to 3.5 m. The robot’s compliant gripper mechanism was able to finely adjust the positions of the panels.

-

The Tokyu ceiling panel installation robot (Fig. 57.18b) could position and adjust the panels and also fire nails into the panels to fasten them to the underlying ceiling system.

-

Two variants (Fig. 57.18c,d) of interior finishing modular mobile robot, developed in Technical University of Munich.

-

The Komatsu Mighty Hand LH (Fig. 57.18e) could position and adjust interior wall panels, glass panels, door frames, window casings and the outside walls (up to 350 kg) with high accuracy.

3.5.1 Concrete Finishing

Floor finishing is one of the most critical construction processes in which construction workers carry or guide trowels over an unfinished, wet concrete floor for several hours in a stooped posture. In order to reduce these physical demands on the workers and to ensure a more uniform finish quality, various companies developed and employed concepts for robots that can perform the concrete-leveling task: the Flat-Kun by Shimizu (), the Kote King by Kajima (), the Surfing Robo by Takenaka (), the Obayashi made by Mitsubishi () and the Floor Traveling Robot MHE by Hazama (). Each of these single task construction robots was able to operate on a floor where it was set up into any desired direction (e. g., not only move backwards and forwards and turning but also able to rotate 360 ° in place).

The finishing mechanism consisted, in most cases, of automatically controlled and operated rotating trowels. The degree of autonomy ranged from systems with human-machine interfaces for tele-operation to systems that could generate motions themselves and to pre-programming of paths for the robot to follow. In many cases gyroscopes and rotating laser levels assisted navigation and motion planning at a low level. After an intensive research and development phase that lasted until 1985, the first concrete finishing robots where deployed commercially to finish concrete floors in office buildings, factories, warehouses and shopping centers. The use of the robot systems became efficient once a floor plan allowed for a working area that could be processed without interruption of more than 500 to . Examples of commercial systems are depicted below in Fig. 57.19.

3.5.2 Tile Placement

The exterior of many buildings are sometimes finished with weather-resistant tiles. In Japan single-family buildings, factories, offices and high-rise buildings are often finished with tiles. Tiles are relatively small building elements compared to the total surface area of a building and thus a very large number of tiles have to be installed using the same, repetitive process, which involves applying mortar and positioning the tiles on top of the mortar. This and the fact that building facades are generally difficult to access make the use of automated systems feasible. Hazama’s tile-setting robot (Fig. 57.20) also showed that accuracy could be enhanced and that the laying of patterns could be accomplished without dramatically increasing construction time.

3.5.3 Fireproof Coating

In many countries building regulations require that steel structures be coated with fire proof materials and/or a fire-retarding paint. The application of the fire-roof coating and paint can only be done after the steel structure has been erected and joined on site (e. g., by welding) in order not to interfere with the joining process and in order to avoid any damage to the fire-proof coating. Therefore, it is not possible to shift the coating operations to upstream production steps that can be performed in structured factory environments where high efficiency can be achieved. Due to seismic considerations, most high-rise construction involves the use of steel structures and thus, the development and employment of automated and robotic systems that are able to apply the fire-proof coatings after the structure is erected took place in Japan. Robots developed by Shimizu (Fig. 57.21) and others were mostly autonomous.

3.6 Robotic Facade Operation

Facade operations involve the installation of windows, complete facade elements or building exterior walls. Facade elements are, in modern architecture and especially in high-rise construction, decoupled from the main load-bearing concrete or steel structure and can thus be considered as a type of add-ons. Facade installation operations are complex operations that involve the accurate positioning of heavy parts or elements at locations that are difficult to access (e. g., high elevations without scaffolding). This involves risk of injury (and thus extensive safety measures must be taken) and of damaging the building or the elements themselves. Furthermore, the positioning and alignment of prefabricated facade elements requires precision and low tolerances. A widespread trend (since the 1980s) of designing large buildings as monolithic structures that repeat the same or similar facade elements, has been a major motivation for investment in automated or robotic systems. Figure 57.22 shows an example of a tele-operated façade installation robot.

3.6.1 Painting

Facade-painting robots were developed to simplify the painting or re-painting of high-rise buildings during construction and operation. Facade painting robots have a particular advantage in that they can keep the paint finish quality constant. They usually have multiple spray nozzles and the spray area is either encapsulated or hermetically sealed in order to avoid streaking. A further advantage of facade painting robots is the fact that workers are not exposed to harmful paint fumes and vapours. Single task, facade-painting robots use one of the following three different strategies to move along the facade:

-

Cable-suspended cage/gondola systems

-

Rail guided systems

-

Vacuum or other adhesion technology.

The use of façade-painting robots was not considered efficient for facades with an area . Facade-painting robots were thus used primarily to paint large facades of warehouses and skyscrapers. Facades to be processed were required to have a low curvature and wherever possible no corners or lugs which can hinder the operation of the robot. Further, the design of window frames as well as the number of windows and the area they cover impact the feasibility and efficiency of facade-painting robots. Between 1984 and 1988 various companies introduced facade-painting robots. Shimizu and Kajima Corporations of Japan both applied the principle of the suspended cage or gondola (Fig. 57.23a,b, respectively). The Taisei Corporation of Japan used a rail-guided system and combined it with the gondola approach for their robot (Fig. 57.23c). The fastest of the systems (Kajima’s robot) worked with a speed of during the application of the primer paint, for the base coat and for the top coat.

3.6.2 Robotized Inspection and Maintenance

Facades of high-rise buildings are in many cases equipped with tiles or other surface panels that have to be inspected regularly during the building’s life-cycle in order to detect structural damage and in order to replace tiles or panels that might fall from the facade. Typically, workers access those tiles or panels via cages or gondolas suspended from the roof of the buildings. This work process was considered by Japanese construction firms as monotonous, inefficient and dangerous. Further, since the method for identifying damaged tiles or panels involves listening to the sound a tile or panel makes when gently impacted by a handheld tool, the sounds were difficult to classify at high elevations due to wind noise. Therefore, with substantial financial commitment, autonomous facade-inspection and maintenance robots were developed. Between 1985 and 1988, six different facade-inspection robots were developed in Japan by the Kajima, Takenaka, Obayashi, Taisei, Tamagawa and Seki Corporations. For the inspection of the facade of a 40 m high building ( facade) an inspection robot needed in average 8 h including ≈1 h for task as preparation, configuration, conversions, dismantling and cleaning of the robot (Fig. 57.24a,b).

Today robotic systems are not only developed for the construction of buildings but also for the operation, maintenance and decommissioning of buildings and other construction products. These types of service robots were developed for the construction sector for inspection of nuclear power plants, exterior walls of high-rise buildings and cleaning of high-rise facades or glass roofs (Fig. 57.24c).

3.7 Earthmoving

Earthmoving is a construction process for preparing project sites for construction by digging, grading, trenching, scraping and other similar tasks. There have been significant developments in many earthmoving areas and certain tasks (such as grading) can now be completely automated. Figure 57.25 shows several examples of automated earthmoving equipment some of which were still in the research and development phase while other are already commercial products.

Earthmoving: (a) Teleoperated excavation system (courtesy Fujita Research); (b) computer assisted road compacting system (after [57.53]); (c) automated grading system (courtesy Caterpillar, Inc.); (d) automated drag line control system (after [57.54]); (e) autonomous excavator robot (after [57.55]); (f) autonomous off-road dump truck (after [57.56])

3.8 Road Maintenance

Figure 57.26 shows three examples of machines that perform pothole repairs and crack sealing on road with various degrees of automation. Figure 57.26a is a commercial product while the other two machines were research projects undertaken by departments of transportation in the US.

3.9 Material Handling

The transport and handling of materials is a critical activity at most construction sites. Figure 57.27 shows examples of material handling robots developed under different research efforts.

Material handling: (a) six degree of freedom robotic crane (after [57.59]); (b) large scale pipe manipulator; (c) large manipulator system (courtesy of Shimizu Corp.)

4 Integrated Robotized Construction Sites

The first prototypes for mainly automated high-rise construction sites were put into operation in 1990 and 1991 by Shimizu (Fig. 57.28) after five years in development and a financial outlay of almost sixteen million Euros. Since then, twenty automated high-rise sites have been implemented by different companies (Taisei, Takenaka, Kajima, Maeda, and Kumagai) [57.60, 57.61].

4.1 Robotic Roof Field Factory Approach

An integrated robotized construction site involves the use of semi- and fully-automated storage, transport and assembly equipment and/or robots that are used to erect a building almost completely automatically. It is an attempt to improve the sequencing of construction processes and construction site management by using real-time control. This includes an unbroken flow of information from the planning and design phase through programming the on-site robots and controlling and monitoring the construction operations.

The robotic roof field factory approach is typically implemented once the building foundations have been laid. The production equipment, on which the steel construction has been installed with assembly and transport robots, is then covered completely with a roof made of plastic film. Depending on the roof system used, this process takes from three to six weeks after which the robots go into production. Due to the lack of space around building sites in Japan, steel and concrete plants are also often installed to supply parts in 10 min cycles on a just-in-time basis.

Prefabricated parts are checked and then placed in specific depots at the foot of the building or in the building itself where they are readily accessible by the robots. This is where the automated construction process actually starts. As many as 22 robots equipped with automatic crane winches deliver the columns, supports, floors, ceilings, walls and other elements to the floor of the steel skeleton under construction. These components are then positioned and fixed into place almost completely automatically. The steel columns and supports are joined together by welding robots after they have been positioned. The position and quality of the welding seams are monitored with lasers.

In the Obayashi GlossaryTerm

ACBS

(Automatic Constructions Building System) (Fig. 57.29 and in ), once a storey has been finished, the whole support structure, which rests on four columns, is pushed upwards by hydraulic presses to the next storey over a 1.5 h period. Fully extended, the support structure is 25 m high; retracted it measures 4.5 m. Once everything has been moved up, work starts on the next storey. By constructing the topmost storey of the high-rise building as the roof at the beginning of the building process, the site is closed off in all directions, considerably reducing the effect of the weather and any damage it might cause.

), once a storey has been finished, the whole support structure, which rests on four columns, is pushed upwards by hydraulic presses to the next storey over a 1.5 h period. Fully extended, the support structure is 25 m high; retracted it measures 4.5 m. Once everything has been moved up, work starts on the next storey. By constructing the topmost storey of the high-rise building as the roof at the beginning of the building process, the site is closed off in all directions, considerably reducing the effect of the weather and any damage it might cause.4.2 Robotic Field Factory on-Ground Approach

The Amurad-system (Fig. 57.30), developed by the Kajima Corporation, is a way of construction based on the idea of after the first floor is built (which is the top floor), it is pushed up one floor at a time with the aid of large hydraulic cylinders. The plumbing, electrical and mechanical equipment and the interior fittings and cladding of the facade then begin. This process is repeated until the building is completed, where the last floor to be built becomes the ground floor. In order to realize the AMURAD System three automated systems were developed for pushing up the whole building, for transporting and assembling and for material handling.

4.3 Robotic Deconstruction and Robotic Recycling

Controlled deconstruction supported by robotic systems can be combined with component reuse systems since some elements such as structural steel have long life spans, and total recycling (i. e., scrapping, melting and recasting) consumes large amounts of energy. In a component reuse system all structural building components are accepted as trade-ins. Therefore, the deconstruction process comprises a reversed version of the construction process, which if it is based on industrialized fabrication, all deconstructed parts and elements could be directly reintroduced into the fabrication systems. The DARUMA system by Kajima Corporation (Fig. 57.31) enables such a controlled deconstruction process. Deconstructed structural steel elements are transported to special dismantling factories just-in-time and just-in-sequence, where the old joints and finishes can be dismantled under factory conditions and fed into advanced reuse cycles. Modularized and standardized structural units can be inspected and renewed and then equipped with new finishes according to each customer’s needs. Component Reuse systems could be connected to Advanced Construction ERP Systems and companies could match customers who want to sell their modular building for reuse and customers willing to buy reused building modules for further customization. Renewed building components are reorganized and customized in the factory and transported to other building sites. A combined system of controlled deconstruction and component reuse saves large amounts of materials and energy.

By adopting integrated industrialization processes the construction industry would have the chance to address all parameters relevant for sustainable economic, environmental and social development. Innovative industrialization-oriented architectural design structures, appropriate modularization and standardization of building structures, logistics, equipment and processes, could serve as a fundamental integration framework. Customized prefabrication could further be able to supply construction sites with individualized elements. Hyper-flexible robotic systems could support a limited amount of trained workers to perform positioning, joining and finishing operations. Construction ERP systems could support organization as well as a lean and demand oriented construction based on just-in-time and just-in-sequence resource supply meanwhile locally based factories grant identity and reduced logistic effort. Moreover integrated industrialization would not only be limited to the fabrication but also link systems of controlled deconstruction and component reuse to a network for continuous resource circulation.

In addition to fully automated deconstruction systems, a number of teleoperated demolition robots have been widely adopted in the construction industry. Two examples of these are shown in Fig. 57.32.

5 Currently Unsolved Technical Problems

A recent study found that the US construction industry does not realize approximately 15 billion US dollars per year in potential savings due to inadequate interoperability related to information exchange and management practices [57.62].

5.1 Interoperability

Although the lack of interoperability between the various information systems used in construction is a significant source of inefficiency for the industry, it is also a roadblock to the use of automated systems in construction. Automated systems need electronic information on past, current, and/or projected future states of a construction project to function efficiently.

For example, in order for a robotic crane to pick a steel beam from the site and deliver it to its target location, the robot must be able to know that the steel beam has been delivered to the site, as well as its current position and orientation. While information on the current inventory of parts on a site may be available on paper, it is rarely available electronically unless someone enters it manually into some computer system, which in turn may not be compatible with other systems used in that project. In many of the examples of automated construction technologies presented in this chapter, custom electronic databases and/or data formats have to be devised to demonstrate the robot’s operation. In some cases, the electronic information had to be entered manually from paper into a computer for the robot to work correctly.

In addition to information exchange and management, many of the measurement instruments and sensors used in construction are not interoperable. This problem is not limited to the construction sector but is a relatively large problem in many robotic applications where different types of sensors are used. Several efforts are underway to make sensors interoperable [57.63] and construction equipment in general [57.64], but the issues have yet to be resolved.

5.2 Structural Connection Systems

Traditionally, structural member connections in construction have been designed for human installation. Whether using bolted, welded, or other types of connections, manual labor is usually involved in guiding the mating parts together and in establishing the connection.

For example, in structural steel erection, workers perched on the structure typically guide a crane operator through visual or auditory cues in order to maneuver a steel beam (or column) into place. The workers must then physically manipulate the beam in order to align corresponding surfaces for bolting or welding. Once the correct beam pose has been achieved, it must be maintained while the workers temporarily fasten the beam to the structure. The workers then release the beam from the crane and permanently fasten the beam to the structure at a later stage.

For automated (or robotic) construction to work, new connections that are more amenable to automation must be designed. These connections need not mimic traditional, human-installed connections, but should be optimized for use with robots instead. For example, the Lehigh University Advanced Technology for Large Structural Systems (GlossaryTerm

ATLSS

) Center designed a gravity-load-only shear steel connector [57.65] back in the early 1990s that is more suitable for automated construction (Fig. 57.33). This type of male–female connector for automatic assembly of building modules allows, together with an adequate control strategy, small tolerances, which permit assembly by automatic cranes [57.66].An example of a nonstructural connector that is more amenable to automation is the piping and electrical connector developed for the FutureHome project, shown in Fig. 57.34 [57.21, 57.67].

Although automated welding has been applied in some limited form in construction, it is generally used to replace manual welding without changing the design of the parts being welded. In other words, no significant change in the way in which construction components are designed has occurred as a result of automated welding. Moreover, apart from a few examples of automated welding applied at the construction site, most of the other limited applications are done at the component fabrication facility.

5.3 Tolerances

Specifications for tolerances in the construction sector exist for most types of construction, however, they are not always achieved in practice [57.68]. For example, it has been stated that one of the biggest sources of problems in structural steel erection in the US is that fabricated pieces are often out of tolerance, and that this is only discovered during installation at the construction site [57.69]. However, since the finished facility must meet the design tolerances before it is accepted, this shifts the burden to workers and supervisors during construction. The workers are expected to handle problems as they come up rather than expect all fabricated construction components to be within tolerance. Since most construction projects are under tight schedules, it is often preferable to fix these kinds of problems on site rather than wait for replacement components to be fabricated and delivered.

However, tolerance problems are not all due to fabrication errors. Installation problems are also responsible for out-of-tolerance problems, for example, anchor rod installation has been an area of concern for structural steel erection. (Anchor rods (or bolts) are the connection interface between the concrete foundation and the structural steel columns. The rods are usually installed by the concrete foundation crew before the concrete is dry.) The situation of anchor rod patterns that do not match the hole patterns in a mating column is an identified problem in construction [57.26, 57.70].

Given the relatively loose achievable tolerances in construction, the application of robotics in construction faces an uphill battle. This, in addition to the unstructured nature of the construction site environment, requires that robots either be highly intelligent in order to correctly interpret and react to their surroundings or to be human assisted. However, site structure and tolerances are expected to improve as pressures to reduce costs and improve productivity continue to rise. Improvements in site organization and construction tolerances have already been proved to be achievable in a few cases, as has been demonstrated in Japan [57.71]. However, the economic case for these demonstration projects has yet to be made.

5.4 Power and Communications in the Field

Unlike manufacturing environments, in which specially designed factories are outfitted with the necessary power and communications installations, a construction project often begins before such resources have been installed at the site. Therefore, robots with large power requirements that need to communicate with supervisory systems located off site would be challenging to implement without significant added cost.

Although communications technologies have advanced significantly in the last few decades, it is still considered difficult to maintain a reliable local-area network at a construction site and to connect that network to the Internet. The use of cellular telephones with a press-to-talk (the digital version of the traditional two-way radio communication method) feature has largely replaced the traditional two-way radios that also revolutionized on-site construction communications. However, in order for construction sites to become more automated, reliable interference-free high-bandwidth networks must be able to carry data transmission between sensors, machines, and supervisory systems.

5.5 Sensing

Field measurements are an integral part of the construction process. The tape measure and the transit have been used in construction for decades for measuring distances and angles, respectively. However, construction measurements are not limited to distances and angles, but can also include measurements of installed quantities, percentages of completion of activities, and so on. All of these measurements are necessary to be able to lay out the site where a facility is to be built, to measure the conformance of the as-built facility to the intended design, and to monitor safety, productivity, and progress.

In the past few decades, more advanced means of making measurements on construction sites have come into play. These include (but are not limited to) total stations, GPS, indoor GPS, ultra-wide band, laser scanners, ground-penetrating radar, equipment and structural health monitoring sensors, concrete maturity meters and radio frequency identification [57.72, 57.73, 57.74, 57.75, 57.76, 57.77, 57.78, 57.79, 57.80, 57.81, 57.82, 57.83, 57.84]. These technologies, as well as others that have not yet been adopted in the construction industry, are crucial for enabling more automation and robotics in construction. Nevertheless, despite all of these advances in technology, one of the biggest challenges for implementing robotics at the construction site is to be able to provide accurate and up-to-date information to the robots about where everything is and what other equipment are doing. This challenge will eventually be solved by the introduction of more sophisticated sensing and perception systems.

6 Future Directions

As previously discussed, developing new methods for collecting, processing, analyzing, and communicating construction information is a significant area of construction automation research, and will dominate near-term efforts. As this construction information becomes more readily accessible, automation of processes can be enabled directly from the combination of design information and current site status that is accurately captured and shared. Resource tracking will become ubiquitous and just-in-time delivery of needed materials and equipment will happen throughout the site.

Advances in mobility (humanoid robotics, smart cars, legged locomotion, etc.) will enable ever more automated material handling on the job site. These advances will require better control systems for the construction robots that can provide high payload and good positioning accuracy. The increased use of robots at the construction site will also drive research into safety systems for construction robots working around human workers and other machines.

Perhaps most important, more extensive automatic design systems will enable more prefabrication of building components and new methods of assembling those components on site, which in turn will provide the promise of faster, better, and cheaper construction robotics first envisioned in the 1980s.

7 Conclusions and Further Reading

The application of robotics to construction has yet to catch up with other industries such as automobile manufacturing. Construction presents a unique challenge for robotic applications. The construction environment is cluttered, unstructured, and teaming with human workers. In addition, construction processes are usually labor intensive and have to accommodate wide margins of error in the constructed facility. The application of robotics in construction to date has been limited to commercial teleoperated and programmable machines. Autonomous or semiautonomous machines are currently mostly limited to research projects within various nonconstruction organizations. With the increase in competition throughout the global construction market, construction companies are on the lookout for ways to improve productivity, quality, and safety. The use of automation and robotics is one answer that the industry is slowly turning toward. However, before these potential solutions can be successfully applied, much work is needed to improve construction tolerances, develop standards, and achieve real-time site status monitoring.

The International Association for Automation and Robotics in Construction holds an annual conference (the International Symposium on Automation and Robotics in Construction) at which researchers can present the latest developments in the field. The proceedings from this conference hold a wealth of information on the state of the art of the field and are accessible to the general public through IAARC’s website (www.iaarc.org).

There are several journals that publish articles on various aspects of automation in construction. Most notable of these are Automation in Construction, Computer-Aided Civil and Infrastructure Engineering, the Journal of Computing in Civil Engineering, and the Journal of Construction Engineering and Management. In addition, some journals publish special editions on robotics in construction. Some examples are Autonomous Robots and the Journal of Advanced Robotic Systems.

Abbreviations

- 2-D:

-

two-dimensional

- 3-D:

-

three-dimensional

- ACBS:

-

automatic constructions building system

- ATLSS:

-

advanced technology for large structural systems

- CAD:

-

computer-aided design

- CAM:

-

computer-aided manufacturing

- CIC:

-

computer integrated construction

- CNC:

-

computer numerical control

- ERP:

-

enterprise resource planning

- EU:

-

European Union

- GDP:

-

gross domestic product

- GPS:

-

global positioning system

- GVA:

-

gross value added

- I3CON:

-

industrialized, integrated, intelligent, construction

- ICT:

-

information and communication technology

- MCP:

-

magazining, cleaning, plotting

- PCM:

-

programmable construction machine

- ROCCO:

-

robot construction system for computer integrated construction

- ROD:

-

robot oriented design

- SMAS:

-

solid material assembly system

References

E. Ginzberg: The mechanization of work, Sci. Am. 247(3), 66–75 (1982)

US Census Bureau: Value of Construction Put in Place – Seasonally Adjusted Annual Rate (U.S. Census Bureau, Washington DC 2012), http://www.census.gov/

Bureau of Labor Statistics: Industries at a Glance: Construction: NAICS 23 (US Department of Labor, Washington DC 2012), http://www.bls. gov/iag/tgs/iag23.htm

US Census Bureau: Statistics of U.S. Businesses (U.S. Census Bureau, Washington DC 2012), http://www.census.gov/csd/susb/

European Commission: Eurostat Regional Yearbook 2012 (Publications Office of the European Union, Luxembourg 2012), http://ec.europa.eu/eurostat/web/products-statistical-books/-/KS-HA-12-001

Statistics Bureau, Ministry of Internal Affairs and Communications: Statistical Handbook of Japan (Statistics Bureau, Tokyo 2012), http://www.stat.go.jp/english/data/handbook/index.htm

National Bureau of Statistics of China: The Results of Preliminary Verified GDP for the First Three Quarters in 2012 (National Bureau of Statistics of China, Beijing 2012) http://www.stats.gov.cn/english/pressrelease/201211/t20121102_72217.html

National Bureau of Statistics of China: China Statistical Yearbook (China Statistics Press, Beijing 2012), http://www.stats.gov.cn/tjsj/ndsj/2012/indexeh.htm

D. Crosthwaite: The global construction market: A cross-sectional analysis, Constr. Manag. Econ. 18(5), 619–627 (2000)

D.W. Halpin, R.W. Woodhead: Construction Management, 2nd edn. (Wiley, New York 1998)

K.S. Saidi: Possible Applications of Handheld Computers to Quantity Surveying, Dissertation (Univ. Texas, Austin 2002)

T. Greaves, B. Jenkins: Capturing Existing Conditions with Terrestrial Laser Scanning: A Report on Opportunities, Challenges and Best Practices for Owners, Operators, Engineering/Construction Contractors and Surveyors of Built Assets and Civil Infrastructure (Spar Point Research, Danvers 2004)

J.G. Everett, A.H. Slocum: Automation and robotics opportunities – Construction versus manufacturing, J. Constr. Eng. Manag. ASCE 120(2), 443–451 (1994)

L.A. Demsetz: Task identification for construction automation, 6th Int. Symp. Autom. Robotics Constr. (1989) pp. 95–102

R. Kangari, D.W. Halpin: Potential robotics utilization in construction, J. Constr. Eng. Manag. 115(1), 126–143 (1989)

R.L. Tucker: High payoff areas for automation applications, 6th Int. Symp. Autom. Robotics Constr. (1988) pp. 9–16

L. Cousineau, N. Miura: Construction Robots: The Search for New Building Technology in Japan (ASCE, Reston 1998)