Abstract

The continuous miniaturization and increased functionality of modern electronic devices highly demand the development of high-performance dielectric materials. High-k or low-k polymer nanocomposites are receiving a fast-growing interest due to their large tunability of dielectric constant and easy processing. The dielectric properties are usually tuned by properly selecting the identity, shape, property of fillers, and engineering the interfaces between fillers and matrix. In this chapter, we review the recent progress in the fundamentals, processes, and properties of dielectric polymer composites. Particular attention is paid on the current routes toward high-k or low-k nanocomposite materials. Some long-standing problems and topics that warrant further investigations in the near future are also discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The dielectric constant, k, is a physical feature related to the electric polarizability of a material [1]. Physically the greater the polarization developed in the materials, the higher the k. In comparison to the k value of silicon dioxide, which is 3.9, the dielectric materials are classified into high-k dielectrics (k > 3.9) and low-k dielectrics (k < 3.9). Besides polarizability, losses are also an important feature. They arise in dielectrics from the motion of bound charges in response to an applied electrical field. Generally the dielectric constant is treated as a complex function. It includes the contributions of inphase polarizability and losses, respectively, through the real ε ' (ω) and imaginary parts ε ' ' (ω) of the dielectric constant, where ω is the angular frequency. Losses are often quantified through the so-called tan(δ) value which is given for a dielectric material by the ratio of ε ' ' (ω) to ε ' (ω). The k value (also sometimes referred to as relative dielectric constant) is simply given by the ratio ε ' (ω) of to the permittivity of vacuum. When free charges are present, they contribute to increasing the losses via a frequency independent (in the ranges of interest) term, named DC conductivity. Low losses are important for applications and will be discussed throughout the chapter.

Recently, there is a fast-growing interest in both kinds of dielectric materials due to their wide range of applications in electronic and electrical industry. For instance, high-k dielectrics can serve as effective materials for cable insulation [2], charge-storage capacitors [3, 4], electrocaloric cooling [5, 6], and artificial muscles [7, 8]. While low-k materials are the key insulating components for isolating signal-carrying conductors from one another as well as reducing the signal propagation delay and dynamic power dissipation in the high-density and high-speed microelectronic packaging [1, 9].

Traditional dielectric materials are ceramics (e.g., mica, silicon dioxide, and BaTiO3) with excellent dielectric properties, coupled with high stiffness and excellent thermal stability [10–13]. However, their applicability for practical electronic devices is largely impeded by their poor flexibility, high-density, and challenging processing conditions [14, 15]. Considering these limitations, polymeric dielectrics have been broadly explored as alternative dielectrics [16–20]. They can offer tunable dielectric properties, processing advantages including mechanical flexibility, and the capability of being molded into various configurations for electronic devices with reduced volume and weight. To satisfy distinct electronic and electrical applications, it is critical to tune the k values, while maintaining other excellent physical properties of polymers. In the past decade, many efforts have been devoted to tailor dielectric properties of polymers via modifying the polymeric chain architecture [9, 21], blending polymers with different high-k or low-k polymers [16, 20, 22, 23], and forming nanocomposites by dispersing ceramic or conducting nanoparticles into polymer matrices [2, 4, 15].

Polymer nanocomposites consisting of nanoparticles allow for a large tunability of the dielectric constant by varying the identity, shape, and content of nanoadditives, as well as engineering the nanoparticle–polymer interfaces. However, challenges still exist today on rationally designing optimum composite microstructures to realize a target high-k or low-k value. The relationship between the composite morphology and the dielectric properties is far from being fully understood.

To provide a comprehensive understanding to this topic and to clarify the emerging problems, we review the recent progress in the fundamentals, processes, and properties of dielectric polymer composites. Particular attention is paid on the current routes toward high-k or low-k nanocomposite materials. Some long-standing problems and topics that warrant further investigations in the near future are also addressed.

2 Dielectric Polarization in Polymer Composite Materials

To tune the dielectric constant of polymers, it is critical to understand the origin of dielectric constant, i.e., various types of polarization. Generally the polarization in polymer dielectrics includes interfacial, orientational (or dipolar), ionic (migration of ions over a distance beyond 10 nm), and electronic polarization. Each polarization is associated to a dielectric loss (ε ") peak at a specific frequency, as shown in Fig. 1.1. Generally the more types of polarization used, the higher the molar polarization and the k values. Note however that more complex frequency dependencies can be observed depending on the structure of the material. For example, dielectric spectra can exhibit a broad dispersion in so-called near-percolated materials which are of great interest in the field of high-k materials and which are commented further. In such systems the dielectric constant scales with frequency through particular power laws. The absence of singular modes and the broadness of the response reflect in fact the dispersity in characteristic sizes in near-percolated networks. In the following, it is addressed how various polarization is utilized for tailoring the dielectric constant.

Real (ε ') and imaginary part (ε ") of the dielectric constant as a function of frequency in a polymer having interfacial, orientational, ionic, and electronic polarization (Reproduced with permission from Ref. [24]. Copyright 2013 American Chemical Society)

For polymer composites, orientational polarization refers to the reorientation of permanent molecular dipole moments, of nanoparticles, or of dipolar moieties appended to polymers [24]. The dipolar relaxation usually occurs between 0.1 and 107 Hz, depending on the nature of the dipoles (amorphous or crystalline), temperature, and frequency. Actually, by finely controlling the density and structure of dipoles, one can achieve dipolar glass, ferroelectric, and relaxor ferroelectric polymers which exhibit different levels of dielectric constant and dielectric losses [25].

Ionic polarization includes physical transport of incorporated ions in polymer materials. On the basis of this polarization, the polymeric electrolytes can be used to enhance the capacitive performance of gate dielectrics for organic field effect transistors [26]. The fundamental operating mechanism is forming electric double layer at the interface between the polymer electrolyte and electrode. In spite of their excellent energy storage performance, polymer electrolytes are not suitable for film capacitors because of a fundamental weakness, i.e., the high dielectric loss due to the transport of ion species over a long distance. The high dielectric losses are detrimental for the practical applicability of typical polymer dielectrics due to the huge energy waste and large risk of services. Therefore the ionic polarization should be avoided for typical polymeric dielectrics by decreasing the concentration of impurity ions during the polymerization processes.

Electronic polarization is related to the delocalization of electrons in organic polymers in response to an externally applied electric field. It should be noted that the dielectric losses corresponding to the electronic polarization are in the infrared and optical frequencies, not in the lower frequencies, which is a desirable feature for the presently discussed applications. To tailor the dielectric constant from electronic polarization, Si, Ge, and Sn are usually proposed to replace C for new dielectric polymers [25]. Synthesizing such inorganic polymers, however, is very challenging.

Maxwell–Wagner–Sillars (MWS) interfacial polarization related to reorganization of interfacial charges (e.g., electrons and holes accumulated at interfaces) in heterogeneous systems [27]. It exists in all multicomponent dielectric systems, such as semicrystalline polymers (crystal–amorphous interfaces could cause MWS effect), polymer blends, and nanocomposites consisting of high-k ceramic nanoparticles or highly polarizable conducting nanofillers. According to MWS effect [28], when a current flows across the two-material interfaces, charges can be accumulated at the interface between two dielectric materials with different relaxation time (τ = ε/σ, where ε is the dielectric constant and σ is the conductivity). From this point of view, the large contrast in dielectric constant (for ceramic nanoparticles) or conductivity (for conducting nanoparticles) between filler and polymer matrix is highly desirable for interfacial polarization and thus affords a high dielectric constant. However, such large contrast will result in electric field intensification in the polymer matrix near the particle surface [29]. The field intensification is associated with the highly inhomogeneous electric fields and generally either enhances the local probability of dielectric failure or propagation of the discharge cascade [14, 30, 31]. Therefore a big challenge to utilize interfacial polarization consists in finding compromises that allow for high-k, high breakdown strength, and low losses in a single nanocomposite material.

3 High-k Polymer Composite Materials

The continuous miniaturization and increased functionality in modern electronic devices have spurred the development of easily processed materials, with improved dielectric constant, enhanced breakdown strength, and reduced dielectric losses. Conventional high-k ceramic materials such as BaTiO3 (BTO) can be fabricated into thin films by using chemical solution deposition yielding a high dielectric constant of about 2500 and relatively low losses [10]. However, they require a sintering process at high temperature (900 °C), which is not compatible with most of substrate materials. Though RF magnetron sputtering can be used to make high-k ceramic nanofilms at room temperature [12], the cost is high and fabricating large area defect-free films is still very challenging because of the poor flexibility of ceramics. On the other hand, polymer-based dielectrics have large-scale processability, high electric breakdown field, and light weight, but they suffer from low dielectric constant (usually k < 10).

Recently, a few strategies, including modification of polymer chain structures [21, 32–34] and random composite approaches [15], have been developed to increase the dielectric constant of polymers. Chu et al. [18] obtained a very high energy density with fast discharge speed and low losses in defect modified polyvinylidene fluoride (PVDF) polymers . The resultant ferroelectric terpolymer poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) P(VDF-TrFE-CFE) has a dielectric constant as high as 50, the highest in known unfilled polymers. However, the use of toxic chemicals, needed for the synthesis of the above polymers, is not favorable from environmental and health points of view. Thakur et al. [35], for the first time, successfully realized an environmentally friendly aqueous functionalized PVDF through a refluxing method. The dielectric constant and loss tangent for the dopamine functionalized PVDF have been found to be of 32 (higher than 10 for pristine PVDF) and 0.04, respectively.

Among all the approaches to increase the dielectric constant of polymers, the composite technology is most intensively studied due to its easy processing and a large tunability of dielectric properties by selection of the fillers with various properties (e.g., size, shape, and conductivity, etc.) as well as control of the microstructures of composites (e.g., filler dispersion and distribution, polymer matrix morphology). Approaches include adding high-k inorganic fillers and conductive/semiconductive fillers to polymers.

3.1 High-k Ceramic Nanoparticle–Polymer Composites

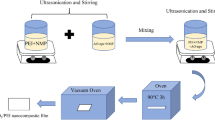

The introduction of ceramic nanoparticles into polymer matrices to form so-called 0-3 dielectric nanocomposites represents one of most promising and exciting avenues in this field [36, 37]. The created nanocomposites combine the advantages of ceramics and polymers and represent a novel type of material that is flexible, easy to process, and of relatively high dielectric permittivity and high breakdown strength. A vast amount of research has in past years succeeded in improving dielectric constant of polymers using ferroelectric metal oxides as filler, such as TiO2 [38, 39], ZrO2 [40], BTO [41], and CaCu3Ti4O12 (CCTO) [42–45]. It was found in the simulation and experimental work that the dielectric constant of composite largely increases only as approaching the percolation threshold of inorganic nanoparticles [46, 47]. For spherical fillers, the percolation threshold is as high as ~30–35 vol% [46, 47]. That’s why a very high filler loading is in general necessary to realize a high enough k value. For instance, Dang et al. [42] developed advanced high-k CCTO/polyimide (PI) functional hybrid films using an in situ polymerization process . A high dielectric constant [48] is obtained at 100 Hz at a concentration of spherical CCTO filler as high as 40 vol%, as shown in Fig. 1.2a. Such high loading of ceramic powders significantly deteriorates the mechanical performance of final composites. Furthermore, it is very difficult to process such composite dielectrics into defect-free and a few micrometers thick films. The porosity caused by high loading even dramatically decreases the dielectric properties of the composites.

(a) Variation of dielectric constant, k, and loss tangent, tanδ, of the CCTO/PI hybrid films as a function of the volume fraction of CCTO filler at 100 Hz and room temperature (The data plotted are taken from Ref. [42]). Inset of (a) shows the SEM image of the fractured cross-surface of the CCTO/PI hybrid film with 40 vol% spherical CCTO fillers (Reproduced with permission from Ref. [42] Copyright 2009 Wiley-VCH). (b) Dependence of k, and tanδ, on the volume fraction of BaTiO3 nanofibers in epoxy-based composites, measured at 1 kHz. Data are taken from the work by Song et al. [48]. Inset of (b) is SEM image of the BaTiO3 nanofibers (Reproduced with permission from Ref. [48]. Copyright 2012 Royal Society of Chemistry). (c) The k, and tanδ of BST nanotube/PVDF composite film loaded with various concentrations of nanotube fillers, measured at 100 Hz (The data plotted are taken from Ref. [52]) Inset of (c) is the TEM image of BST nanotube (Reproduced with permission from Ref. [52]. Copyright 2014 Royal Society of Chemistry)

To circumvent this problem, it is desirable to use rodlike nanoparticles as alternative fillers, such as BTO nanofibers [48–50], Pb(Zr,Ti)O3 (PZT) nanowires [51], and Ba0.6Sr0.4TiO3 (BST) nanotubes [52]. As predicted by a finite element analysis [46], the percolation threshold in a polymer matrix can decrease to 18 vol% as the aspect ratio of particles increases to 3. Recently, electrospun BTO nanofibers with a large aspect ratio were used as dielectric fillers in poly(vinylidene fluoride-trifluoroethylene) (PVDF-TrFE)-based nanocomposites [48]. Because of the reduced percolation threshold, the nanocomposites show a dielectric constant of 30 at a much smaller filler loading (10.8 vol%), as shown in Fig. 1.2b.

Being similar with the nanorods that have 1D morphology, tubular nanostructures also have large aspect ratio yet much smaller density in mass. Such unique features render 1D perovskite BST nanotubes more efficient in enhancing the dielectric constants of composites [52]. It has been demonstrated that the surface hydroxylated BST nanotubes/PVDF nanocomposite flexible films exhibit a high dielectric constant of 58 at 100 Hz at content as low as 10 vol% fillers (see Fig. 1.2c). The key to achieve such high-k nanocomposites is realizing a compact and uniform morphology of the tubular nanostructures by optimizing electrospinning conditions. In addition, if not impossible, exploring 2D high-k nanoplatelets is also very promising for enhancing the dielectric constant of polymers. But to our knowledge, the high-k 2D ceramic platelets/polymer nanocomposites are still in blank up to now.

Although a high dielectric constant can be achieved in polymer composites by loading various high-k ceramic particles, there are still many technological and scientific challenges in realizing high-performance nanocomposites. Typical challenges involve achieving uniform dispersion of inorganic nanoparticles and finely controlling the filler–matrix interfacial morphologies to achieve desirable interfacial polarization. A straightforward way is to use small modifiers (e.g., coupling agents [53] and surfactants [54]) to tailor surface properties of nanoparticle in order to improve their compatibility with host polymers and consequently the apparent dielectric performance of the nanocomposites. The modifiers indeed afford an enhancement in the dispersion of inorganic nanoparticles, but they themselves may not contribute to the enhancement of dielectric properties. In some cases, the modifiers even adversely affect the bulk dielectric properties by inducing discontinuous variations in the local electric field and thereby resulting in a significantly reduced dielectric strength [14, 55].

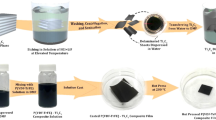

An alternative strategy consists in designing and synthesizing core–shell nanoparticles. The basic idea is introducing one or multi-insulating shells onto individual raw nanoparticles to prevent them from aggregating and forming infinite percolating pathways as well. Consequently core–shell nanoparticles largely enhance the dielectric constant of composites meanwhile well preserving the intrinsic high dielectric strength of polymers by mitigating the propagation of breakdown paths of particles. Recently, Huang et al. [2] reviewed the general methods (Fig. 1.3) developed in the past years for preparing high-k nanocomposites based on the core–shell strategy. The core–shell nanoparticles can be prepared by grafting polymer brushes via “grafting from” or “grafting to” routes as well as by coating inorganic shells.

Approaches used to prepare core–shell nanoparticles for high-k polymer nanocomposites (Reproduced with permission [2]. Copyright 2015 Wiley-VCH)

The “grafting from” strategy relies on the in situ polymerization of monomers on the initiator-functionalized nanoparticles surfaces. This technology enables the direct formation of high-k nanocomposites by using the shell layer as matrix without mixing any additional polymers. This allows for the preparation of very thin and defect-free nanocomposites bearing high filler loadings. For instance, Xie et al. [56] successfully prepared core–shell BTO/poly(methyl methacrylate) (PMMA) nanocomposites via in situ atom transfer radical polymerization (ATRP) of methyl methacrylate (MMA) from the surface of BTO nanoparticles by using silane monolayers as initiators. The BTO core affords a high-k (~15 at 1 kHz), while the flexible PMMA shell endows the material with good dispersibility and inherent low loss of the host polymer (~0.037 at 1 kHz) by retarding charge carriers movement in composites. Such core–shell structure can lead to suppressed losses compared to the conventional ceramic particle/polymer nanocomposites [36, 53]. Very recently, Paniagua et al. [57] used a phosphonic acid (PA) as surface initiator for the growth of polystyrene (PS) and PMMA from BTO nanoparticles through ATRP with activators regenerated by electron transfer. The process is schematically illustrated in Fig. 1.4a. By covalently attaching the polymer matrix to the nanoparticles, one can create a one-component system with three constituents. The dielectric constant can reach 11.4 at 1 kHz (Fig. 1.4b) for 22 vol% BTO particle, while the loss tangent remains at the same low level (Fig. 1.4c) as polymer matrix.

(a) Schematic illustration for creating core–shell nanoparticles by “grafting from” route. A capacitor dielectric can be prepared without mixing any additional polymer, and without the need for ball milling or ultrasonication. (b) The dielectric constant, k, at 1 kHz as a function of volume fraction of BTO nanoparticles. The nanocomposite films have a similar thickness~3 μm. (c) Frequency dependence of loss tangent, tanδ for the nanocomposites with various BTO loadings (Reproduced with permission from Ref. [57]. Copyright 2014 American Chemical Society)

The “grafting to” strategy deals with grafting polymer chains onto the nanoparticle surfaces via a reaction between the functional groups of polymers and nanoparticles. This approach is more commonly found in the literature given its simplicity and large tunability of the grafted polymer chains according to the desired properties of nanocomposites.

Tchoul et al. [59] used click chemistry to attach PS to TiO2 nanorods and reported a dielectric constant of 6.4 at 1 kHz, while the loss tangent was as low as 0.625 %. State-of-the-art results for polymers attached to ceramic nanoparticles were reported by Jung et al. [58]. They investigated the dielectric properties in a PS nanocomposite comprising core–shell BaTiO3 particles with diblock copolymer shielding layers. The adoption of diblock copolymer resulted in a well-defined layered polymer shell through two-step processes, as illustrated in Fig. 1.5a. A weakly adsorbed layer was first formed by reacting the chloromethyl group of polystyrene-block-poly(styrene-co-vinylbenzylchloride) (PS-b-PSVBC) with the oxy anion on the BaTiO3 surface. The nonpolar chloromethyl functional blocks were subsequently transformed to the polar ammonium blocks and formed a dense layer that interacted strongly with the BaTiO3 particle surfaces. This unique feature not only benefits to good dispersibility in a nonpolar medium but also affords a high dielectric strength at high applied electric field. As shown in Fig. 1.5b, c, the diblock copolymer coated BaTiO3 nanocomposite afforded a high dielectric permittivity (~44 at 10 kHz) and a significantly low leakage current density of 0.76 nA/cm2, even with a fraction of BaTiO3 particle as large as 75 wt%.

(a) Scheme for preparing core–shell nanoparticles by “grafting to” method. A diblock copolymer PS-b-PSVBC was covalently attached on the surfaces of BTO particles. (b) The dielectric constant, k, as a function of volume fraction of BTO nanoparticles. (c) The leakage current density as a function of applied electric fields for BTO@PS-b-PSVBC/PS nanocomposites (Reproduced with permission from Ref. [58]. Copyright 2010 American Chemical Society)

In addition to the polymer shells, a very thin ceramic layer has been also realized on the metal oxide nanoparticles, which provides a route toward decreased permittivity contrast between filler and matrix, and thus addresses the problem of electric field intensification that occurred in conventional ceramic/polymer composites. It was speculated that this ceramic layer formed between the ceramic nanoparticles and polymer phases served as effective electron scatters and trapping centers to reduce the breakdown probability [60]. As illustrated in Fig. 1.6a, Lanagan et al. [61] employed a layer-by-layer methylaluminoxane (MAO) coating process to prepare Al2O3 encapsulated metal oxide core–shell nanoparticles. The Al2O3 shell thickness can be varied depending on the cycles of MAO coating. These core–shell nanoparticles subsequently served as metallocene catalyst support for the following in situ propylene (PP) polymerization. The thickness of the Al2O3 coating actually had little effect on the dielectric constant, only showing a marginal increase upon increasing the shell thickness (Fig. 1.6b). Still, the presence of Al2O3 shell dramatically suppressed the leakage current and high-field dielectric loss in nanocomposites (Fig. 1.6c).

(a) A route to aluminum oxide encapsulated high-k metal oxide core–shell nanoparticles and catalytically synthesized nanocomposites via in situ supported metallocene olefin polymerization process. (b) Dielectric constant versus the volume fraction of the BaTiO3-Al2O3 core–shell nanoparticles with various shell thicknesses. (c) Frequency dependence of the dielectric loss of BaTiO3-Al2O3/PP nanocomposites (Reproduced with permission [61]. Copyright 2010, American Chemical Society)

Most of core–shell nanoparticles currently studied are based on the spherical high-k ceramics. The high aspect ratio 1D or 2D core–shell nanoparticles may have superior dielectric properties at low filler loading because of their large dipole moments and low percolation threshold and therefore deserve more attention in the future.

3.2 High-k Conducting Nanoparticle–Polymer Composites

Conducting materials , like metal particles, have a negative dielectric constant (in the frequency range of interest which is below the so-called plasma frequency). Owing to the particular response of the particles, conducting particle/polymer nanocomposites are expected to possess much higher dielectric constant than their ceramic counterparts. In fact, exceptionally high dielectric constant has been achieved as the particle loading is very close to but does not exceed the percolation threshold [62]. This divergent behavior can be explained by employing the microcapacitor model based on the near-percolated networks (Fig. 1.7) [63].

Microstructure evolution with increasing particle concentration in a polymer matrix. Particles in a composite near percolation can form numerous microcapacitors that would contribute to an abnormally large capacitance of the composite, consequently give rise to a large increase of the dielectric constant

Up to now, very high-k values have been reported in various systems made by randomly mixing polymers with conducting particles , such as metal spheres [64], carbon nanofiber [65], carbon nanotubes (CNTs) [62, 66], and graphene [67, 68]. For instance, Dang et al. [64] first reported a percolative Ni/PVDF composite bearing a k value as high as 400 as approaching the percolation threshold of 17 vol% from below. As compared to the spherical conductive particle, one-dimensional carbon materials with large aspect ratios can lead to a much lower percolation level. Yuan et al. [62] employed CNTs as nanofiber to pursue high-k polymer nanocomposites. The nanocomposites were prepared by melt mixing multi-walled carbon nanotubes (MWNT) within PVDF host polymer. A remarkable interaction at molecular level is achieved by establishing donor–acceptor complexes between the delocalized “π-electron” clouds of MWNTs and strongly electrophilic F groups of PVDF chains (inset of Fig. 1.8d). This strong interfacial interaction is confirmed by the formation of thin PVDF layers on the MWNT surface (Fig. 1.8a). It creates an advanced material with individual nanotube dispersion (Fig. 1.8b). As approaching a critical concentration, the established near-percolated network allows for the formation of microcapacitors with neighboring nanotubes as electrodes and polymer in between as dielectric (Fig. 1.8c). This network morphology has two significant benefits. First it fully takes the advantage of the high specific surface area of nanotubes and results in a huge interfacial area which is considered as the site for additional polarizability. Second, the interfacial polarization, within the microcapacitors, can be significantly reinforced because of the formation of the donor–acceptor complexes. The delocalized “π-electron” clouds of MWNTs provide large domains for nomadic electrons, and the electrophilic F groups strongly attract these electrons. These unique features of individual CNT networks consequently give rise to a very high dielectric constant of 3800 at 1 Hz (Fig. 1.8d). Another promising candidate for creating high-k percolative composites is two-dimensional conductive filler with a disk or plate shape. He et al. [69] employed such design and demonstrated a graphite nanoplatelet/PVDF nanocomposite. A large dielectric constant of 2700 was observed near percolation threshold as low as 1.0 vol%.

(a) TEM image of MWNT with a 20 nm thick PVDF layer. (b) SEM image of fractured surface of MWNT/PVDF nanocomposite with f MWNT=10 vol%. (c) Schematic illustration of a near-percolated network based on individual CNTs. (d) Dependence of the dielectric constant of nanocomposites on the MWNT volume fraction at different frequencies (Reproduced with permission [62]. Copyright 2011 American Chemical Society)

As discussed above, the large k values in conducting particle/polymer composites are afforded by interfacial polarization, also known as the MWS effect [62, 70]. However, the charges stored inside the composite would be possibly delocalized either by tunneling or by ohmic conduction. Both lead to a quite high loss dissipation factor, which is not desirable for the practical applications of high-k materials [15, 70, 71]. Thus, besides largely increasing the dielectric constant, the dielectric losses should be kept as low as possible.

During past years, many efforts have been devoted to address this issue. One potential strategy is to introduce inter-particle barrier layer into percolative polymer composites. As such, the tunneling current between neighboring conductive nanoparticles can be suppressed and hence affords much lower dielectric losses [72–76]. For instance, Liu et al. [76] made an organic polysulfone (PSF) dielectric shell on MWNTs by employing a simple electrospinning method (Fig. 1.9a). The PSF shell served not only as a barrier to prevent MWNTs from direct contact but also as a polymer matrix after fusion by hot pressing. The resultant MWNT/PSF composites showed a high dielectric constant (ca. 58) when the nanotube content reached 25 vol%, while there was only a slight change in loss tangent from 0.02 to 0.05 (Fig. 1.9b).

(a) Schematic image for the formation of MWNT/PSF composites. The inset is the SEM image of cross section of the composites perpendicular to the fiber direction, MWNTs are indicated by arrows. (b) Dependence of the dielectric constant and loss tangent of the composites on the MWNT loading, measured at 1 MHz. The photograph in the inset of (b) shows that the composite can be largely deformed (Reproduced with permission [76]. Copyright 2011 Wiley-VCH)

Realizing heterogeneous spatial distribution of conducting particles can be another promising strategy [65, 77, 78]. Recently, Gu et al. [78] have developed MWNT/cyanate ester (CE) composite with a gradient dielectric constant via the gradient distribution of MWNT along the direction of the thickness. The CE-rich region can break the conducting path along the direction of electric field (thickness direction), which leads to a far lower loss as compared with randomly dispersed MWNT/CE composites. Yuan et al. [79] reported a more general strategy for dielectric constant enhancement by employing vertically aligned CNT arrays as filler. These CNT arrays naturally form effective microcapacitors in series to store charges if polymer matrix can be completely penetrated into them. More importantly, they can avoid the relaxation of charges stored if the hybrids are well isolated to each other. The key to this strategy is uniformly dispersing CNT arrays into polymer matrix without disturbing the given CNT parallel structures. The integrity of the CNT arrays was retained during composite fabrication in the means of attaching them onto a rigid microplatelet. By varying CVD conditions, two different SiC-CNT hybrids were realized [80]: (i) CNT arrays were grown uniformly along a single direction (denoted as “single-direction” hybrid, Fig. 1.10a) and (ii) the growth of CNT arrays was along two opposite directions perpendicular to the flat surfaces of SiC particles (denoted as “two-direction” hybrid, Fig. 1.10b). After blending with PVDF matrix, the unique architecture of hybrids can be retained. A much more effective microcapacitor network with parallel CNTs as electrode can then be formed near percolation, which has a strong effect on the dielectric constant improvement. The produced CNT arrays afford a dielectric constant as high as 1627 at 1 Hz while keeping the loss tangent as low as 0.43 in PVDF composites. More importantly, these improvements were achieved at a very low loading, showing a much higher figure of merit (which describes the relative dielectric constant enhancement with respect to the conducting particle content) than the state-of-the-art nonpercolated polymer composites [79].

(a) SEM images of “single-direction” hybrid and the dielectric properties of their PVDF composites at various CNT contents and frequencies. (b) SEM pictures of “two-direction” hybrid and the dielectric spectra of their PVDF composites (Reproduced with permission [79]. Copyright 2014 American Chemical Society)

In spite of great improvement in enhancing the dielectric constant and lowering the losses, challenges still exist today on finely controlling the network morphology of conducting particles near percolation. In particular, the manufacturing of nanocomposites is often dictated by intuitive expectations or empirical approaches following trials and errors. It is clear that modeling should be further developed to guide more rationally the design of optimal structures. This need becomes even timelier when we consider that formulation and microfabrication technologies are progressing fast. Implementing new technologies such as ink-jet printing and 3D printing, for example, could help in achieving highly controlled structures with enhanced properties. In addition, how to improve the high-field dielectric properties of percolative polymer composites is still not clear. This open question deserves more attention in the future.

4 Low-k Polymer Nanocomposite Materials

The rapid development of electronics and electric technologies is associated to a growing need of high-density, high-speed, and high-frequency microelectronic packing [9]. Developing desirable microelectronic packing materials have received much scientific and technological interest. In the past, silica films with a dielectric constant of 3.9 were used. However, continuous miniaturization of electronic device requires the film with lower dielectric constant to reduce both signal propagation delay and dynamic power consumption [81]. The dielectric constant, k, is a key factor that influences the operational speed of integrated circuit (IC). The propagation delay time T d of IC signal is described as follows:

where l and C are the signal transmission distance and the speed of the light, respectively. Therefore, the lower the dielectric constant of the transmission medium is, the smaller the signal propagation delay time is. The international technology roadmap for semiconductors (ITRS) indicates that future electronics will require an effective k of 2.1–2.5 [82]. Actually realizing such low-k dielectric films is very challenging, in particular combining with other manufacturing requirements, such as high thermal conductivity, low losses, strong mechanical strength, and easy processing. Since water has a high dielectric constant (k~80), minimizing the moisture content or alternatively improving hydrophobicity of materials is also critical.

Among novel materials, polymer-based low-k materials are arousing more and more attention due to their excellent mechanical and physicochemical properties. Typical low-k polymers include fluoropolymers, heteroaromatic polymers, poly(aryl ether)s, polyimides, and hydrocarbon polymers without any polar group [9].

There are two possible ways to lower the dielectric constant of polymers, i.e., decreasing dipole strength or the number of dipoles (Fig. 1.11). In more details, decreasing the molecular polarizability can be realized by designing low polarizability chemical structure of polymers. For example, introducing fluorinated substituent into polymer chains could effectively decrease the k values due to the small dipole and the low polarizability of the C-F bond. Tao et al. [83] synthesized a fluorinated epoxy resin that can bear a dielectric constant lower than 3.3 without affecting the mechanical properties and chemical stability of plain epoxy resin. However, the fluorination process is technologically complicated, time- and energy consuming, and usually of high cost. These features are not desirable for the large-scale production of low-k films.

An alternative approach to prepare low-k polymers is to decrease the dipole density. The density of a material can be decreased by increasing the free volume through rearranging the material structure (constitutive porosity) or removing part of the material (subtractive porosity) [84]. By taking the advantage of the low dielectric constant of air (k = 1, so-called air gaps ) in the pores, a mesoporous organic polymer can exhibit an ultralow dielectric constant. The nano/mesopores are generally produced by methods including reprecipitation, sol–gel, thermolysis, supercritical foaming, and electrochemical etching [85]. The pore size and size distribution are critical to the mechanical and dielectric properties of bulk materials and thus need to be finely controlled during pore processing. Jiang et al. [86] prepared a low-k nanoporous PI films by first preparing silica/PI nanocomposites via sol–gel process and subsequently treating the nanocomposites with hydrofluoric acid to remove the dispersed silica particles, leaving pores with diameters between 20 and 120 nm. The dielectric constant decreased from 3.4 to 1.8 as the pore content reached up to 20 %, the film kept a tensile strength about 95 MPa.

Despite the achievement of very low dielectric constant (k ~ 2) in porous polymers, the aforementioned approaches commonly result in a broad pore size distribution and open pore structures, which detrimentally affect the mechanical properties of polymers and thus limit their use. Furthermore, polymer sole actually cannot meet the multirequirements expected for low-k materials in advanced microelectronic packing because of their low thermal conductivity (0.2 Wm−1K−1). The manufacturable solutions may rely on the nanocomposite approaches consisting of dispersing hollow particles or high thermal conductivity core–shell nanoparticles into polymer matrix to find compromises of dielectric, mechanical, and thermal properties.

4.1 Low-k Hollow Particle /Polymer Nanocomposite Materials

Comparing with introducing subtractive porosity, dispersing ordered mesoporous particles allows for much easier control over the size and distribution of pores in polymers. Decreased dielectric constant and improved mechanical properties can be simultaneously achieved in nanocomposites filled with mesoporous silica materials such as MCM-41 [87, 88] and SBA-15 [89, 90]. This new family of mesoporous materials has attracted considerable interests due to their highly ordered and uniform mesoporosity (Fig. 1.12a, b). The typical pore size ranges from 2 to 10 nm and the surface areas are as high as ~1000 m2 g−1. These unique features can largely decrease the dipole density of polymers as they are used as fillers in nanocomposites. Dang’s group [87] reported a low dielectric constant (k = 2.6) in nanohybrid PI films filled with 3.0 wt% MCM-41. Similarly, Min et al. synthesized a series of PI composite thin films composed of SBA-15 modified with functional groups of octyltrimethoxysilane (OTMS) or 3-aminopropyl trimethoxy silane (ATS). They systematically investigated the modification effect on the mechanical and dielectric properties as well as the thermal stability of thin films. It was found that the tensile strength and elongation of the composite films containing SBA-15 modified with ATS were much higher than those of composite without modification while the dielectric constant was significantly reduced to 2.7.

Schematic diagram of (a) MCM-41, (b) SBA-15 with micropores in walls and mesoporous channels, and (c) molecular structure of POSS. R may be a hydrogen atom or an organic functional group, e.g., alkyl, alkylene, acrylate, hydroxyl, or epoxide unit (Reproduced with permission [91]. Copyright 2014 Royal Society of Chemistry)

Although mesoporous silica has been successfully used to lower k values, two tricky problems still exist to restrict their application in fabricating advanced low-k polymeric hybrids [89]. First, the size of the inner channels of mesoporous silica is generally so large that the resin molecule can enter into the channels and decrease the porosity density. Second, the existence of rich polar and hydrophilic silanol groups in the inner channels renders mesoporous silica capable of adsorbing moisture. As water has a high k~80, mesoporous silica particles usually show a high dielectric constant. Therefore further lowering the dielectric constant of the resultant hybrid nanocomposites is limited. Using smart molecular caps to block the entrance of channels in mesoporous silica particles is a promising method to address this issue. Suzuki et al. [88] first modified the entrance of the mesopores by polyhedral oligomeric silsesquioxane (POSS) molecules. Trimethylsilyl (TMS) agents are grafted onto silanol groups at the inner mesopores to reduce the polarity. The process is schematically illustrated in Fig. 1.13. Subsequently they added the capped particles into epoxy resin and found that the dielectric constant of the hybrid with 20 wt% particles is as low as 2.5.

Schematic illustration of preparation of POSS-capped mesoporous silica particles. Epoxy polymer cannot enter into the inner channels due to the steric hindrance of isobutyl groups (Reproduced with permission [88]. Copyright 2011 Elsevier)

Being similar with mesoporous silica , POSS is also referred to as a silica nanoparticle consisting of a silica cage core, as well as organic functional groups attached to the corners of the cage (Fig. 1.12c) [92]. Nanoporous POSS has received extensive research attention as a filler to reduce the dielectric constant of hybrid nanocomposites [93–96] because its unique nanometersized cage provides POSS composites with a very low dielectric constant. In addition, owing to the variable reactive external groups, the POSS moieties can be chemically bond to the organic matrix and uniformly distributed within the polymeric system at molecular level and thus enhance the thermal and mechanical properties of the resultant hybrid materials. Therefore, formation of polymer/POSS nanocomposites could simultaneously lower the dielectric constants and enhance the mechanical properties of polymers [92, 97]. For example, Yang et al. prepared three-dimensional organic–inorganic network hybrids via hydrosilylative addition reaction of octahydridosilsesquioxanes with dienes to form chemical bonds between two monomers. As such, POSS molecules were uniformly dispersed into the polymeric system at the nanoscale. The resultant hybrid films exhibited enhanced mechanical properties (elastic modulus of 8.9 GPa) and a reduced dielectric constant (k ~2.43). This strategy offers the advantage of tunability of dielectric and mechanical properties by adjusting the length and the structure of the linking chain between POSS cages.

4.2 Low-k Hybrid Particle /Polymer Nanocomposite Materials

As discussed above, in addition to the high mechanical strengths and extremely low dielectric constant, the advanced microelectronic packing materials should also have high thermal conductivity to dissipate the generated heat. Recent studies have shown that ceramic nanoparticles with high thermal conductivity (e.g., boron nitride nanosheets [98] and aluminum oxide spheres [99]) can afford an efficient thermal conduction in polymer composites. However, most of the ceramic particles with high thermal conductivity usually lead to a high dielectric constant of polymer composites because of the lack of porosity. Therefore it is urgent to seek solutions to simultaneously improve thermal conductivity and decrease the dielectric constant of polymers.

Designing and synthesizing novel hybrid nanoparticles can meet this end by combining high thermal conductivity particles with low-k particles. Recently, Huang and Zhi [100] achieved an ideal dielectric thermally conductive epoxy nanocomposite using POSS-functionalized boron nitride nanotubes as fillers (Fig. 1.14a). The unique hybrid structure afforded a decreased dielectric constant (Fig. 1.14b) due to the intrinsic low-k in boron nitride nanotubes and POSS molecules, while the thermal conductivity was dramatically improved by 1360 % as compared with the pristine epoxy resin (Fig. 1.14c). However, to further lower the dielectric constant of such composites, the key relies on well preserving the porosity of boron nitride nanotubes.

(a) Schematic diagram of preparation of POSS-functionalized boron nitride nanotubes. (b) Frequency dependence of the dielectric constant of the epoxy composites filled with POSS-functionalized boron nitride nanotubes. (c) The composites’ thermal conductivity varies as a function of the filler loading (Reproduced with permission [100]. Copyright 2013 Wiley-VCH)

5 Conclusions

Polymer nanocomposites allow for a large tunability of dielectric constant by properly selecting the identity, size, shape, property of filler and by controlling the morphology of polymer matrices, and engineering the interfaces between filler and matrix. To make high-k nanocomposites, ceramic or conducting particles with high dielectric constant are usually used as filler to improve the dielectric constant of composites, but attention should be paid in avoiding the formation of conducting path of particles so as to suppress the high loss tangent and preserve the intrinsic high dielectric strength of polymers. On the other hand, decrease of the dielectric constant of polymer to fabricate low-k nanocomposite materials relies on introducing uniformly sized pores. Simultaneously achieving a low dielectric constant, improved mechanical strength, and high thermal conductivity is the big challenge in the field. Potential solution to this problem is designing and synthesizing novel and multifunctional hybrid fillers. From a more general point of view, it can be noted that manufacturing of nanocomposites is often guided by intuitive expectations and empirical approaches. Advanced modeling should be further developed in order to provide a more rational guidance of experimental efforts. In addition, it is expected that the development of new formulation and microfabrication technologies will help in the optimization and control of nanocomposite structures to achieve enhanced properties in the years to come.

References

Nalwa H (1999) Handbook of Low and High Dielectric Constant Materials and Their Applications. Academic, London

Huang X, Jiang P (2015) Core-shell structured high-k polymer nanocomposites for energy storage and dielectric applications. Adv Mater 27(3):546–554

Rao Y, Wong CP (2004) Material characterization of a high-dielectric-constant polymer-ceramic composite for embedded capacitor for RF applications. J Appl Polym Sci 92(4):2228–2231

Dang ZM, Yuan JK, Yao SH et al (2013) Flexible nanodielectric materials with high permittivity for power energy storage. Adv Mater 25(44):6334–6365

Neese B, Chu B, Lu SG, Wang Y, Furman E, Zhang QM (2008) Large electrocaloric effect in ferroelectric polymers near room temperature. Science 321(5890):821–823

Zhang G, Li Q, Gu H, Jiang S, Han K, Gadinski MR et al (2015) Ferroelectric polymer nanocomposites for room-temperature electrocaloric refrigeration. Adv Mater 27(8):1450–1454

Zhang QM, Li HF, Poh M, Xia F, Cheng ZY, Xu HS et al (2002) An all-organic composite actuator material with a high dielectric constant. Nature 419(6904):284–287

Brochu P, Pei Q (2010) Advances in dielectric elastomers for actuators and artificial muscles. Macromol Rapid Comm 31(1):10–36

Maier G (2001) Low dielectric constant polymers for microelectronics. Prog Polym Sci 26(1):3–65

Ihlefeld J, Laughlin B, Hunt-Lowery A, Borland W, Kingon A, Maria JP (2005) Copper compatible barium titanate thin films for embedded passives. J Electroceram 14(2):95–102

Barber P, Balasubramanian S, Anguchamy Y, Gong S, Wibowo A, Gao H et al (2009) Polymer composite and nanocomposite dielectric materials for pulse power energy storage. Materials 2(4):1697–1733

Yao SH, Yuan JK, Gonon P, Bai J, Pairis S, Sylvestre A (2012) Effect of oxygen vacancy on the dielectric relaxation of BaTiO3 thin films in a quenched state. J Appl Phys 111(10):104109

Wu JB, Nan CW, Lin YH, Deng Y (2002) Giant dielectric permittivity observed in Li and Ti doped NiO. Phys Rev Lett 89:217601

Li JY, Zhang L, Ducharme S (2007) Electric energy density of dielectric nanocomposites. Appl Phys Lett 90:132901

Dang Z-M, Yuan J-K, Zha J-W, Zhou T, Li S-T, Hu G-H (2012) Fundamentals, processes and applications of high-permittivity polymer matrix composites. Prog Mater Sci 57(4):660–723

Wang Y, Zhou X, Chen Q, Chu B, Zhang Q (2010) Recent development of high energy density polymers for dielectric capacitors. IEEE Trans Dielectr Electr Insul 17(4):1036–1042

Job AE, Alves N, Zanin M, Ueki MM (2003) Increasing the dielectric breakdown strength of poly(ethylene terephthalate) films using a coated polyaniline layer. J Phys D-Appl Phys 36(12):1414–1417

Chu B, Zhou X, Ren K, Neese B, Lin M, Wang Q et al (2006) A dielectric polymer with high electric energy density and fast discharge speed. Science 313(5785):334–336

Tuncer E, Sauers I, Randy James D, Ellis AR, Parans Paranthaman M, Goyal A et al (2007) Enhancement of dielectric strength in nanocomposites. Nanotechnology 18:325704

Rahimabady M, Chen S, Yao K, Tay FEH, Lu L (2011) High electric breakdown strength and energy density in vinylidene fluoride oligomer/poly(vinylidene fluoride) blend thin films. Appl Phys Lett 99:142901

Wu S, Li W, Lin M, Burlingame Q, Chen Q, Payzant A et al (2013) Aromatic polythiourea dielectrics with ultrahigh breakdown field strength, low dielectric loss, and high electric energy density. Adv Mater 25(12):1734–1738

Islam MS, Qiao Y, Tang C, Ploehn HJ (2015) Terthiophene-containing copolymers and homopolymer blends as high-performance dielectric materials. ACS Appl Mater Interfaces 7(3):1967–1977

Tan L, Liu S, Zeng F, Zhang S, Zhao J, Yu Y (2011) A low dielectric constant polyimide/polyoxometalate composite. Polym Adv Technol 22(2):209–214

Fredin LA, Li Z, Lanagan MT, Ratner MA, Marks TJ (2013) Sustainable high capacitance at high frequencies: metallic aluminum – polypropylene nanocomposites. ACS Nano 7(1):396–407

Zhu L (2014) Exploring strategies for high dielectric constant and low loss polymer dielectrics. J Phys Chem Lett 5(21):3677–3687

Kim SH, Hong K, Xie W, Lee KH, Zhang S, Lodge TP et al (2013) Electrolyte-gated transistors for organic and printed electronics. Adv Mater 25(13):1822–1846

Kremer F, Schönhals A (2003) Broadband dielectric spectroscopy. Springer, New York

Tamura R, Lim E, Manaka T, Iwamoto M (2006) Analysis of pentacene field effect transistor as a Maxwell-Wagner effect element. J Appl Phys 100(11):114515

Ducharme S (2009) An inside-out approach to storing electrostatic energy. ACS Nano 3(9):2447–2450

Li JY, Huang C, Zhang QM (2004) Enhanced electromechanical properties in all-polymer percolative composites. Appl Phys Lett 84:3124

Cheng Y, Chen X, Wu K, Wu S, Chen Y, Meng Y (2008) Modeling and simulation for effective permittivity of two-phase disordered composites. J Appl Phys 103:034111

Chu B, Zhou X, Neese B, Zhang QM, Bauer F (2006) Relaxor ferroelectric poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) terpolymer for high energy density storage capacitors. IEEE Trans Dielectrics Electrical Insulation 13(5):1162–1169

Qiao Y, Islam MS, Han K, Leonhardt E, Zhang J, Wang Q et al (2013) Polymers containing highly polarizable conjugated side chains as high-performance all-organic nanodielectric materials. Adv Funct Mater 23(45):5638–5646

Burlingame Q, Wu S, Lin M, Zhang QM (2013) Conduction mechanisms and structure-property relationships in high energy density aromatic polythiourea dielectric films. Adv Energy Mater 3(8):1051–1505

Thakur VK, Lin M-F, Tan EJ, Lee PS (2012) Green aqueous modification of fluoropolymers for energy storage applications. J Mater Chem 22(13):5951–5959

Dang ZM, Xu HP, Wang HY (2007) Significantly enhanced low-frequency dielectric permittivity in the BaTiO3/poly(vinylidene fluoride) nanocomposite. Appl Phys Lett 90(1):012901

Arbatti M, Shan XB, Cheng ZY (2007) Ceramic-polymer composites with high dielectric constant. Adv Mater 19(10):1369–1372

Balasubramanian B, Kraemer KL, Reding NA, Skomski R, Ducharme S, Sellmyer DJ (2010) Synthesis of monodisperse TiO2-paraffin core-shell nanoparticles for improved dielectric properties. ACS Nano 4(4):1893–1900

Dang Z-M, Xia Y-J, Zha J-W, Yuan J-K, Bai J (2011) Preparation and dielectric properties of surface modified TiO2/silicone rubber nanocomposites. Mater Lett 65(23-24):3430–3432

Zou C, Kushner D, Zhang S (2011) Wide temperature polyimide/ZrO2 nanodielectric capacitor film with excellent electrical performance. Appl Phys Lett 98(8):082905

Tuncer E, Sauers I, James DR, Ellis AR, Duckworth RC (2008) Nanodielectric system for cryogenic applications: barium titanate filled polyvinyl alcohol. IEEE Trans Dielectr Electr Insul 15(1):236–242

Dang Z-M, Zhou T, Yao S-H, Yuan J-K, Zha J-W, Song H-T et al (2009) Advanced calcium copper titanate/polyimide functional hybrid films with high dielectric permittivity. Adv Mater 21(20):2077–2082

Yang W, Yu S, Sun R, Du R (2011) Nano- and microsize effect of CCTO fillers on the dielectric behavior of CCTO/PVDF composites. Acta Mater 59(14):5593–5602

Prakash BS, Varma KBR (2007) Dielectric behavior of CCTO/epoxy and Al-CCTO/epoxy composites. Compos Sci Technol 67(11-12):2363–2368

Amaral F, Rubinger CPL, Henry F, Costa LC, Valente MA, Barros-Timmons A (2008) Dielectric properties of polystyrene-CCTO composite. J Non-Cryst Solids 354(47-51):5321–5322

An AL, Boggs SA, Calame J, IEEE (2006) Energy storage in polymer films with high dielectric constant fillers. Conference Record of the IEEE International Symposium on Electrical Insulation, Toronto, Ont

Calame JP (2006) Finite difference simulations of permittivity and electric field statistics in ceramic-polymer composites for capacitor applications. J Appl Phys 99(8):084108

Song Y, Shen Y, Liu H, Lin Y, Li M, Nan C-W (2012) Enhanced dielectric and ferroelectric properties induced by dopamine-modified BaTiO3 nanofibers in flexible poly(vinylidene fluoride-trifluoroethylene) nanocomposites. J Mater Chem 22(16):8063–8068

Song Y, Shen Y, Liu H, Lin Y, Li M, Nan C-W (2012) Improving the dielectric constants and breakdown strength of polymer composites: effects of the shape of the BaTiO3 nanoinclusions, surface modification and polymer matrix. J Mater Chem 22(32):16491–16498

Avila HA, Ramajo LA, Goes MS, Reboredo MM, Castro MS, Parra R (2013) Dielectric behavior of epoxy/BaTiO3 composites using nanostructured ceramic fibers obtained by electrospinning. ACS Appl Mater Interfaces 5(3):505–510

Tang H, Lin Y, Andrews C, Sodano HA (2011) Nanocomposites with increased energy density through high aspect ratio PZT nanowires. Nanotechnology 22(1):015702

Liu S, Xue S, Zhang W, Zhai J, Chen G (2014) Significantly enhanced dielectric property in PVDF nanocomposites flexible films through a small loading of surface-hydroxylated Ba0.6Sr0.4TiO3 nanotubes. J Mater Chem A 2(42):18040–18046

Dang Z-M, Wang H-Y, Xu H-P (2006) Influence of silane coupling agent on morphology and dielectric property in BaTiO3/polyvinylidene fluoride composites. Appl Phys Lett 89(11):112902

Ramesh S, Shutzberg BA, Huang C, Gao J, Giannelis EP (2003) Dielectric nanocomposites for integral thin film capacitors: Materials design, fabrication, and integration issues. IEEE Trans Adv Pack 26(1):17–24

Li J, Khanchaitit P, Han K, Wang Q (2010) New route toward high-energy-density nanocomposites based on chain-end functionalized ferroelectric polymers. Chem Mater 22(18):5350–5357

Xie L, Huang X, Wu C, Jiang P (2011) Core-shell structured poly(methyl methacrylate)/BaTiO3 nanocomposites prepared by in situ atom transfer radical polymerization: a route to high dielectric constant materials with the inherent low loss of the base polymer. J Mater Chem 21(16):5897–5906

Paniagua SA, Kim Y, Henry K, Kumar R, Perry JW, Marder SR (2014) Surface-initiated polymerization from barium titanate nanoparticles for hybrid dielectric capacitors. ACS Appl Mater Interfaces 6(5):3477–3482

Jung HM, Kang J-H, Yang SY, Won JC, Kim YS (2010) Barium titanate nanoparticles with diblock copolymer shielding layers for high-energy density nanocomposites. Chem Mater 22(2):450–456

Tchoul MN, Fillery SP, Koerner H, Drummy LF, Oyerokun FT, Mirau PA et al (2010) Assemblies of titanium dioxide-polystyrene hybrid nanoparticles for dielectric applications. Chem Mater 22(5):1749–1759

Guo N, DiBenedetto SA, Kwon D-K, Wang L, Russell MT, Lanagan MT et al (2007) Supported metallocene catalysis for in situ synthesis of high energy density metal oxide nanocomposites. J Am Chem Soc 129(4):766–767

Li Z, Fredin LA, Tewari P, DiBenedetto SA, Lanagan MT, Ratner MA (2010) In situ catalytic encapsulation of core-shell nanoparticles having variable shell thickness: dielectric and energy storage properties of high-permittivity metal oxide nanocomposites. Chem Mater 22(18):5154–5164

Yuan J-K, Yao S-H, Dang Z-M, Sylvestre A, Genestoux M, Bai J (2011) Giant dielectric permittivity nanocomposites: realizing true potential of pristine carbon nanotubes in polyvinylidene fluoride matrix through an enhanced interfacial interaction. J Phys Chem C 115(13):5515–5521

Nan CW, Shen Y, Ma J (2010) Physical properties of composites near percolation. Annu Rev Mater Res 40:131–151

Dang ZM, Lin YH, Nan CW (2003) Novel ferroelectric polymer composites with high dielectric constants. Adv Mater 15(19):1625–1629

Sun LL, Li B, Zhao Y, Mitchell G, Zhong WH (2010) Structure-induced high dielectric constant and low loss of CNF/PVDF composites with heterogeneous CNF distribution. Nanotechnology 21:305702

Yuan J-K, Yao S-H, Sylvestre A, Bai J (2012) Biphasic polymer blends containing carbon nanotubes: heterogeneous nanotube distribution and its influence on the dielectric properties. J Phys Chem C 116(2):2051–2058

Fan P, Wang L, Yang J, Chen F, Zhong M (2012) Graphene/poly(vinylidene fluoride) composites with high dielectric constant and low percolation threshold. Nanotechnology 23:365702

Yu J, Huang X, Wu C, Jiang P (2011) Permittivity, thermal conductivity and thermal stability of poly(vinylidene fluoride)/graphene nanocomposites. IEEE Trans Dielectr Electr Insul 18(2):478–484

He F, Lau S, Chan HL, Fan JT (2009) High dielectric permittivity and low percolation threshold in nanocomposites based on poly(vinylidene fluoride) and exfoliated graphite nanoplates. Adv Mater 21(6):710–715

Dang ZM, Wang L, Yin Y, Zhang Q, Lei QQ (2007) Giant dielectric permittivities in functionalized carbon-nanotube/electroactive-polymer nanocomposites. Adv Mater 19(6):852–857

Yao S-H, Yuan J-K, Zhou T, Dang Z-M, Bai J (2011) Stretch-modulated carbon nanotube alignment in ferroelectric polymer composites: characterization of the orientation state and its influence on the dielectric properties. J Phys Chem C 115(40):20011–20017

Zhou T, Zha J-W, Hou Y, Wang D, Zhao J, Dang Z-M (2011) Surface-functionalized MWNTs with emeraldine base: preparation and improving dielectric properties of polymer nanocomposites. ACS Appl Mater Interfaces 3(12):4557–4560

Wu C, Huang X, Wu X, Yu J, Xie L, Jiang P (2012) TiO2-nanorod decorated carbon nanotubes for high-permittivity and low-dielectric-loss polystyrene composites. Comp Sci Technol 72(4):521–527

Wu C, Huang X, Xie L, Yu J, Jiang P (2011) Morphology-controllable graphene-TiO2 nanorod hybrid nanostructures for polymer composites with high dielectric performance. J Mater Chem 21(44):17729–17736

Zhang S, Wang H, Wang G, Jiang Z (2012) Material with high dielectric constant, low dielectric loss, and good mechanical and thermal properties produced using multi-wall carbon nanotubes wrapped with poly(ether sulphone) in a poly(ether ether ketone) matrix. Appl Phys Lett 101:012904

Liu H, Shen Y, Song Y, Nan C-W, Lin Y, Yang X (2011) Carbon nanotube array/polymer core/shell structured composites with high dielectric permittivity, low dielectric loss, and large energy density. Adv Mater 23(43):5104–5108

Wang B, Liang G, Jiao Y, Gu A, Liu L, Yuan L et al (2013) Two-layer materials of polyethylene and a carbon nanotube/cyanate ester composite with high dielectric constant and extremely low dielectric loss. Carbon 54:224–233

Wu H, Gu A, Liang G, Yuan L (2011) Novel permittivity gradient carbon nanotubes/cyanate ester composites with high permittivity and extremely low dielectric loss. J Mater Chem 21(38):14838–14848

Yuan J, Yao S, Li W, Sylvestre A, Bai J (2014) Vertically aligned carbon nanotube arrays on SiC microplatelets: a high figure-of-merit strategy for achieving large dielectric constant and low loss in polymer composites. J Phys Chem C 118(40):22975–22983

Li W, Yuan J, Lin Y, Yao S, Ren Z, Wang H et al (2013) The controlled formation of hybrid structures of multi-walled carbon nanotubes on SiC plate-like particles and their synergetic effect as a filler in poly(vinylidene fluoride) based composites. Carbon 51:355–364

Zhou Y, Wang L, Zhang H, Bai Y, Niu Y, Wang H (2012) Enhanced high thermal conductivity and low permittivity of polyimide based composites by core-shell Ag@SiO2 nanoparticle fillers. Appl Phys Lett 101:012903

International Technology Roadmap of Semiconductors (2013) http://www.itrs.net.

Taa Z, Yang S, Ge Z, Chen J, Fan L (2007) Synthesis and properties of novel fluorinated epoxy resins based on 1,1-bis(4-glycidylesterphenyl)1-(3'-trifluoromethylphenyl)-2,2,2-trifluo roethane. Eur Polym J 43(2):550–560

Shamiryan D, Abell T, Iacopi F, Maex K (2004) Low-k dielectric materials. Mater Today 7(1):34–39

Ma S, Wang Y, Min Z, Zhong L (2013) Nano/mesoporous polymers based low-k dielectric materials: a review on methods and advances. Adv Polym Technol 32:21358

Jiang LZ, Liu JG, Wu DZ, Li HQ, Jin RG (2006) A methodology for the preparation of nanoporous polyimide films with low dielectric constants. Thin Solid Films 510(1-2):241–246

Dang Z-M, Ma L-J, Zha J-W, Yao S-H, Xie D, Chen Q et al (2009) Origin of ultralow permittivity in polyimide/mesoporous silicate nanohybrid films with high resistivity and high breakdown strength. J Appl Phys 105:044104

Suzuki N, Kiba S, Yamauchi Y (2011) Low dielectric property of novel mesoporous silica/polymer composites using smart molecular caps: theoretical calculation of air space encapsulated inside mesopores. Micropor Mesopor Mater 138(1-3):123–131

Shan W, Chen L, Chu Y, Zhao F, Liang G, Gu A et al (2013) Synthesis of a fully capped mesoporous silica and its hybrids with extremely low dielectric constant and loss. Micropor Mesopor Mater 176:199–208

Min C-K, Wu T-B, Yang W-T, Chen C-L (2008) Functionalized mesoporous silica/polyimide nanocomposite thin films with improved mechanical properties and low dielectric constant. Compos Sci Technol 68(6):1570–1578

Gibson LT (2014) Mesosilica materials and organic pollutant adsorption: part a removal from air. Chem Soc Rev 43(15):5163–5172

Kuo S-W, Chang F-C (2011) POSS related polymer nanocomposites. Prog Polym Sci 36(12):1649–1696

Ye Y-S, Chen W-Y, Wang Y-Z (2006) Synthesis and properties of low-dielectric-constant polyimides with introduced reactive fluorine polyhedral oligomeric silsesquioxanes. J Polym Sci Part a-Polym Chem 44(18):5391–5402

Wang Y-Z, Chen W-Y, Yang C-C, Lin C-L, Chang F-C (2007) Novel epoxy nanocomposite of low Dk introduced fluorine-containing POSS structure. J Polym Sci Part B-Polym Phys 45(4):502–510

Wahab MA, Mya KY, He C (2008) Synthesis, morphology, and properties of hydroxyl terminated-POSS/polyimide low-k nanocomposite films. J Polym Sci Part a-Polym Chem 46(17):5887–5896

Tseng M-C, Liu Y-L (2010) Preparation, morphology, and ultra-low dielectric constants of benzoxazine-based polymers/polyhedral oligomeric silsesquioxane (POSS) nanocomposites. Polymer 51(23):5567–5575

Geng Z, Huo M, Mu J, Zhang S, Lu Y, Luan J et al (2014) Ultra low dielectric constant soluble polyhedral oligomeric silsesquioxane (POSS)-poly(aryl ether ketone) nanocomposites with excellent thermal and mechanical properties. J Mater Chem C 2(6):1094–1103

Kuang Z, Chen Y, Lu Y, Liu L, Hu S, Wen S et al (2015) Fabrication of highly oriented hexagonal boron nitride nanosheet/elastomer nanocomposites with high thermal conductivity. Small 11(14):1655–1659

Li Y, Huang X, Hu Z, Jiang P, Li S, Tanaka T (2011) Large dielectric constant and high thermal conductivity in poly(vinylidene fluoride)/barium titanate/silicon carbide three-phase nanocomposites. ACS Appl Mater Interfaces 3(11):4396–4403

Huang X, Zhi C, Jiang P, Golberg D, Bando Y, Tanaka T (2013) Polyhedral oligosilsesquioxane-modified boron nitride nanotube based epoxy nanocomposites: an ideal dielectric material with high thermal conductivity. Adv Funct Mater 23(14):1824–1831

Acknowledgments

This work was financially supported by France ANR and Solvay through the Project ELENA.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Yuan, J., Yao, S., Poulin, P. (2016). Dielectric Constant of Polymer Composites and the Routes to High-k or Low-k Nanocomposite Materials. In: Huang, X., Zhi, C. (eds) Polymer Nanocomposites. Springer, Cham. https://doi.org/10.1007/978-3-319-28238-1_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-28238-1_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-28236-7

Online ISBN: 978-3-319-28238-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)