Abstract

Globalisation has activated a new industrial revolution, leading to a worldwide distribution of production and markets. The increasing demands for sustainability, however, have created new challenges and emerging opportunities for society and for business. In line with increasing international trade, the need to transport raw materials, energy, components, intermediate products and goods increases. The traditional transnational ways of manufacturing products and delivering services cannot be sustained in the emerging eco-sensitive business environments, where growing trade volumes and commercial operational patterns impose significant environmental challenges. This is for example evident in the greenhouse gas emission footprint related to production, logistics, transportations and other internationally operating network-related activities. Therefore, the society has to find answers how to design products and services in a more sustainable way.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Social Sustainability

- Sustainable Solution

- Product Service System

- Sustainable Manufacturing

- Traditional Business Model

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Globalisation has activated a new industrial revolution, leading to a worldwide distribution of production and markets. The increasing demands for sustainability, however, have created new challenges and emerging opportunities for society and for business. In line with increasing international trade, the need to transport raw materials, energy, components, intermediate products and goods increases. The traditional transnational ways of manufacturing products and delivering services cannot be sustained in the emerging eco-sensitive business environments, where growing trade volumes and commercial operational patterns impose significant environmental challenges. This is for example evident in the greenhouse gas emission footprint related to production, logistics, transportations and other internationally operating network-related activities. Therefore, the society has to find answers how to design products and services in a more sustainable way.

In this chapter, the trend in manufacturing and service industry towards sustainability is introduced and its challenges are shown. In a next step, a new trend—the combination of products and services (PSS), also called solutions—is introduced. After introducing the idea of product service systems, the necessity for an integrated development framework to develop them in a sustainable way is demonstrated.

2 Concept of Sustainability

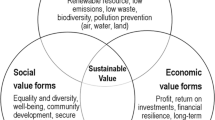

The concept of sustainability first appeared in the context of the Green Movement during the 1960s resulting in the formation of influential non-governmental organisations like Greenpeace. Whereas in the beginning the idea of sustainability included primarily ecological aspects, it has evolved into a broad concept with high relevance for today’s management across all industries (Bhamra and Lofthouse 2007). Today and within the EU-funded Sustain Value project, the definition of sustainability is a state that requires that humans carry out their activities in a way that protects the functions of the earth’s ecosystem as a whole. It affects three fundamental dimensions (economic, environmental and social). The following Fig. 1 shows the different aspects of each dimension.

The three aspects of sustain value (adopted from Elkington 1997)

These three dimensions provide an important area for requirements concerning the advised solution development process. Direct requirements and characteristics can be deduced from these fields. It has to be noted that three factors can work contrary as well as complementary to each other depending on the individual case. Today, sustainability is a core element of any entrepreneurial activity. For example, sustainability can be reached by accompanying products during the whole life cycle.

3 New Developments in the Manufacturing Branch

To be successful and resilient in this ever changing business environment, manufacturers must be proactive. Industrial practitioners need to be creative in recognising the opportunities that the sustainable economy will present for development of new products, identification of changes in markets and optimising their internationally operating network according to the new sustainability criteria. A concrete way for exploiting these opportunities is the development and implementation of new sustainability-based industrial models and concepts.

Key challenges related to sustainable manufacturing networks (adopted from Jovane et al. 2008)

-

Sustainable manufacturing must respond to

-

economic challenges, by producing wealth and new services ensuring development and competitiveness through time;

-

environmental challenges, by promoting minimal use of natural resources (in particular non-renewable energy) and managing them in the best possible way while reducing environmental impact;

-

societal challenges, by promoting social development and improved quality of life through renewed quality of wealth and jobs.

-

-

At the enterprise level, products and services must be

-

safe and ecologically sound throughout their life cycle;

-

appropriate, designed to be durable, repairable, readily recycled, compostable or easily biodegradable;

-

produced and packaged using minimal amounts of most environmentally benign materials and energy;

-

transported, stored, delivered and commissioned for use in an eco-efficient, economic and socially responsible manner.

-

Enterprises must take into consideration not just the economic goals but also the need to now simultaneously meet environmental and social goals in carrying out business; recognising that economic, environmental and social impacts occur at all stages in the value network, including during customer use. This implies not only being able to manage internal activities and operations of the producing organisation, but also getting all the value-network partners to follow the same principles and performance standards that have implicit or explicit influence on the sustainable product and service delivery performance. Sustainable value creation is the key contribution of enterprises to sustainability, i.e. to create long-term value on an economically, socially and environmentally sustainable basis.

4 Product Service Systems as an Enabler for Sustainability

In order to succeed in a globalised economy, companies are required to move beyond the traditional business model of “make and sell” physical products. They have to sell new offerings that additionally include services as the key factor for competitive advantage (Bullinger and Scheer 2006). In particular, large industrial corporations of the manufacturing industry need integrated solutions, so called product service systems (PSS), to sell their original products profitably and drive revenue growth.

Across academia, there exist multiple definitions of product service systems within the context of sustainability. Brezet for example (Brezet et al. 2001) states that “Eco-efficient services are systems of products and services that are developed to cause a minimum environmental impact with a maximum added value”. According to Belz et al. (1997), integrated product service systems combine physical products and services as defined in ISO 26000:2010 (Guidance on social responsibility) to address new market demands and meet requirements holistically and more economically. On the other hand, individual customer offerings are often simply consist of a “comprehensive bundle of products and/or services, which fully satisfy the needs of a customer related to a specific event or problem” (Stremersch et al. 2001). A solution should not be understood as a simple combination of both product and service, but as a hybrid product that cannot be precisely deconstructed again. A hybrid product is defined as a bundle of products and services that consists of an individually adjusted combination of product and service components tailored to customer requirements (Burianek et al. 2007). The drivers for transition to a service-orientated model are generally strategic moves to create a new value proposition for competitive advantage, often when differentiation on product features or cost is growing increasingly difficult to maintain. The service-based model, largely labour and knowledge based, offers an opportunity to create a competitive advantage that is less easily emulated by competitors as the experience and skills earned by the employees in the process. Service provision cannot be easily copied in a way a technical feature can. Additionally, the service approach automatically builds a closer relationship with the customer, providing opportunities for customised services and enhanced customer value, creating customer loyalty, better chances of repeat business and greater barriers to entry of competitors. Furthermore, in a world of specialisation and outsourcing, many customers are specifically looking for total solution providers; hence, being able to offer a service is a strong marketing tool.

In the following, some examples of successful PSS are explained.

PPG Industries (Rothenberg 2012 )

PPG Industries Inc. is a coatings manufacturer. In the 1990s, PPG was faced with Chrysler’s demand for reductions in product use as a result of two main drivers. Chrysler wanted to cut costs on the one hand, and on the other hand, they had to fulfil new environmental regulations. The strategic response for PPG was to help its customer reduce paint use.

PPG on-site representatives started to take over new management tasks at the plant. They participated in tasks such as material ordering, inventory tracking, inventory maintenance and regulatory-response duties. Through this increased service role, the company has helped Chrysler reduce material use.

Aerospace Industry (Baines et al. 2009 )

Engine manufactures in the aerospace sector such as Rolls-Royce, General Electric and Pratt & Whitney developed a new business model. Instead of selling turbines to airlines, they now offer performance-based contracts. They provide the service for their engines like maintenance. By that they do not sell engines but product availability. Such contracts provide the airline operator with fixed engine maintenance costs, over an extended period of time (e.g. ten years) and enlarge efficiency of the engines.

4.1 Advantages of PSS

Sustainable solutions are more complex than traditional product service systems. While economic sustainability can easily be measured through key indicators such as revenue, profit or market share and the growth thereof, social and environmental aspects are more complex. Generally, PSS offer potential environmental benefits. Zaring et al. (2001), who studied product service systems in a business-to-business context, discuss two main factors driving environmental benefits: first, the creation of intangible value by dematerialisation through more productive utilisation of assets, and secondly, a change in user and producer behaviour encouraged by the PSS. Wong (2001) notes a list of potential benefits. Environmental benefits can include the following:

-

Development of better end-of-life disposal processes, as there will be clear pressure to design for this stage of the product life cycle from the start of the concept generation phase onwards. Manufacturers incentivised to develop innovative uses for end-of-life products

-

Easier upgrading to more eco-efficient technologies.

-

Manufacturers, which are also the main operators of the PSS, will have no incentive to sell excess material, will also be in a better position to optimise the products for their true function, will have far better knowledge regarding the true requirements and characteristics of the equipment.

Social sustainability requirements of a PSS are even less understood, especially in a non-macroeconomic context. Tukker and Tischner (2006) note multiple social benefits while noting potential negative social impacts such as degeneration of employee or customer skills and outsourcing of labour to low wage countries. Potential benefits include the following:

-

PSS can strengthen the role of the local economy because services are created at the same time and often at the same place when and where they are consumed. This may also contribute to enhancing social coherence in the region.

-

Use- and result-oriented PSS have a revenue model that does not require payment for the full value of the product upfront—a relatively small payment is asked for every use or every time a result is delivered.

-

PSS may integrate customers directly in the generation of the PSS and address special customer groups or needs that otherwise would be neglected, thus empowering consumers.

4.2 Necessity for an Integrated Development Framework

However, the challenges in transitioning to a PSS-based business model are significant. For an OEM used to selling discrete products, it can be difficult to develop somewhat ‘fuzzy’ intangible service solutions, some industries, especially those selling components in the B2B market such as steel mills, will find it difficult to even identify value adding services. The new business environment may be more complicated and different, with unexpected competitors outside their usual sphere of business pushing into the market. Entering new markets that before were served primarily through product exports alone requires competent local staff, that in many cases has to be trained and educated first. Furthermore, PSS places a major financing burden/cash flow issue on the PSS provider because rather than buying the product up front the user might only pay fees over an extended period of use. There are associated financial and business risks associated with contractual default/bankruptcy of users. Significant barriers to adoption may exist, including consumers’ lack of enthusiasm for ‘ownerless consumption’ or shared communal assets, and the challenges of building distribution/service networks at scale. This is especially true when comparing different markets. Whereas urban residents in developed nations are moving away from private car ownership towards car sharing schemes, the prestige associated with private car ownership is driving car sales in emerging markets.

More and more enterprises are taking partial steps towards the goal of sustainable solutions, but they are not using a comprehensive approach to manage sustainability at the value-network level and inevitably deliver sub-optimisation at best. Individual businesses cannot deliver the system changes required at the value-network level. Collaboration among partners with respect to economic, ecological and social sustainability can and must be enabled by developing attractive and common approaches for sustainable production and services.

4.3 Process of PSS Development

The Chap. “Development Methodology for Sustainable Solutions” in this book deals with the development of sustainable solutions that ensure maximum value of products and processes through the complete life cycle. The development of a framework for sustainable development solutions was part of the Sustain Value project which is described in the chapter below. In the Sect. 4 in Chap. “Development Methodology for Sustainable Solutions”, a development methodology is elaborated, which allows a step-by-step development in order to create goal-orientated solutions. For a complete and successful application of the development methodology, the developers need applicable tools and methods to develop sustainable solutions.

In Sect. 3 in Chap. “Methods and Tools for Sustainable Development of Products and Services”, a tool and method box for a structured and efficient development process is presented. The tools and methods presented in there will provide companies with the necessary equipment for the analysis and optimisation of their processes in order to improve sustainability. The tools are selected according to the constraints given by the industrial context and life cycle phases considered in the industrial partner premises. Otherwise, the tool and method box consider the applicability of the tools in co-development context in value networks.

In addition, Sect. 4 in Chap. “Methods and Tools for Sustainable Development of Products and Services” shows a possible development path and the suitable tools for application, which can be used as a guideline for companies and value networks to evaluate and optimise their current business processes. Together with the methodologies described, the presented toolbox helps a developer in a company or value network to develop sustainable solutions. It assures a structured and systematic approach by giving tools that are needed for a complete and successful sustainable solution.

References

Baines T, Lightfoot H, Peppard J, Johnson M, Tiwari A, Shehab E, Swink M (2009) Towards an operations strategy for product-centric servitization. Int J Oper Prod Manag 29(5):494–519

Belz C, Schuh G, Groos SA, Reinecke S (1997) Erfolgreiche Leistungssysteme in der Industrie. Erster Teil. In: Christian Belz, Torsten Tomczak und Heinz Weinhold-Stünzi (Hg.) Industrie als Dienstleister. St. Gallen: Thexis, S. 14–109

Bhamra T, Lofthouse V (2007) Design for sustainability. A practical approach. Aldershot, Gower

Brezet JC, Bijma AS, Ehrenfeld J, Silvester S (2001) The design of eco-efficient services

Bullinger H-J, Scheer A-W (2006) Service Engineering. Entwicklungen und Gestaltung innovativer Dienstleistungen. In: Hans-Jörg Bullinger und August-Wilhelm Scheer (Hg.): Service-Engineering. Entwicklung und Gestaltung innovativer Dienstleistungen. Berlin: Springer, S. 3–18

Burianek F, Ihl C, Bonnemeier S, Reichwald R (2007) Typologisierung hybrider Produkte. Ein Ansatz basierend auf der Komplexität der Leistungserbringung. Arbeitsberichte des Lehrstuhls für Betriebswirtschaftslehre - Information, Organisation und Management. Technische Universität München, München

Elkington J (1997) Cannibals with forks. The Triple Bottom Line of 21st Century Business. Oxford: Capstone Publishing Limited

Jovane F, Yoshikawa H, Alting L, Boër CR, Westkamper E, Williams D et al (2008) The incoming global technological and industrial revolution towards competitive sustainable manufacturing. CIRP Annals Manufact Technol 57(2):641–659. doi:10.1016/j.cirp.2008.09.010

Rothenberg S (2012) Sustainability through servicizing. In: MIT Sloan Manage Rev 48(2)

Stremersch S, Wuyts S, Frambach RT (2001) The purchasing of full-service contracts. Ind Mark Manage 30(1):1–12. doi:10.1016/S0019-8501(99)00090-5

Tukker A, Tischner U (eds) (2006) New business for old Europe. Product-service development, competitiveness and sustainability. Greenleaf, Sheffield

Wong M (2001) Industrial sustainability os and product service systems (pss).: A Strategy Decision Support Tool for Consumer Goods Firms. Cambridge

Zaring O, Bartolomeo M, Eder P, Hopkinson P, Groenewegen P, James P et al (2001) Creating eco-efficient producer services. Gothenburg, Gothenburg Res Inst 503

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Grefrath, C., Wagner, D., Stermann, S. (2017). Products and Services in a Sustainable World. In: Liyanage, J., Uusitalo, T. (eds) Value Networks in Manufacturing. Springer Series in Advanced Manufacturing. Springer, Cham. https://doi.org/10.1007/978-3-319-27799-8_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-27799-8_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-27797-4

Online ISBN: 978-3-319-27799-8

eBook Packages: EngineeringEngineering (R0)