Abstract

The substitution of petroleum-based synthetic lubricant with the vegetable oil-based bio-lubricant for an engine fueled with biodiesel is explored in this study. Rapeseed oil was selected as a base oil candidate for the formulation of bio-lubricant as well as biofuel. Further, this study investigated the multi-response optimization of diesel engine for an optimal parametric combination to yield better engine performance such as brake power, brake thermal, and mechanical efficiency with minimum exhaust emissions like carbon monoxide (CO), hydrocarbon (HC), and smoke and oxides of nitrogen (NOx) when the engine is fueled with rapeseed oil biodiesel and lubricated with rapeseed oil-based bio-lubricant using Taguchi-grey relational analysis. Three factors namely, lubricant, compression ratio, and engine load were optimized using L18 orthogonal array. The response table, response graph, and analysis of variance (ANOVA) are used to find the optimal setting and the influence of engine parameters on the multiple performance characteristics. The optimization results have shown that an increase in value of the grey relational grade from 0.6105 to 0.85 confirms the improvement in engine characteristics when using rapeseed oil-based bio-lubricant/biodiesel combination.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The rising world crude oil price, the growing environmental awareness, and the fast depleting crude oil reserves have spurred renewed research interest and advances in alternative lubricant and fuel development from renewable energy sources [1, 2]. The base oil used for the formulation of most lubricants is environmentally hostile mineral oil. But, being a product of distillation of crude oil, the mineral oil is expected to be used only as long as crude oil is available. Additionally, the disposal of mineral oil leads to pollution of ecosystem [3]. Thus the search for environmentally friendly substitutes to mineral oils as base oils in lubricants has become a frontier area of research. Vegetable oils are perceived to be alternatives to mineral oils for lubricant base oils because of certain inherent technical properties and their ability for biodegradability. Compared to mineral oils, vegetable oils in general possess high flash point, high viscosity index, high lubricity, and low evaporative loss.

Nevertheless, the principal weakness of vegetable oils for lubrication has been their tendency to oxidize at higher temperature, giving rise to gum, varnish, and sludge formation at lower temperature [4]. Many literatures revealed that technical solutions such as chemical modification and additivation have been suggested to overcome poor thermo-oxidative stability and low temperature fluidity of vegetable oils. Attempts have been made to improve the oxidative stability and low temperature fluidity by transesterification of trimethylolpropane and rapeseed oil methyl ester [5]. Efforts have been made to improve the low temperature fluidity using an additivation method of blending the vegetable oils with diluents such as poly-a-olefin, oleate, and diisodecyl adipate [6]. Alternatively, the unsaturation present in the fatty acid molecule of the vegetable oil can be used to introduce various functional groups by carrying out chemical modifications. Kim and Sharma discussed the possibilities of utilization of epoxidized products of vegetable oils in PVC formulations and bio-thermoset plastics [7]. Chen-Ching Ting and Chien-Chih Chen investigated the viscosity analysis of a mixture of epoxidized and hydrogenated soybean oils as engine lubricants [8].

Although many valuable polymeric materials and lubricants derived from chemically modified vegetable oil, the use of chemically modified vegetable oil as automotive lubricants was not found as such in India. In this row, green crankcase oil via chemical modifications of rapeseed oil such as epoxidation, hydroxylation, and esterification process was formulated by Arumugam et al. [9]. Furthermore, the issue of friction and wear characteristics of the diesel engine cylinder liner/piston ring combination under chemically modified rapeseed oil bio-lubricant using a high-frequency reciprocating tribometer is addressed in [10]. Twelve percent of higher wear was observed with chemically modified rapeseed bio-lubricant than that of commercial synthetic lubricant (SAE20W40). In order to improve the antiwear behavior of chemically modified rapeseed oil bio-lubricant, nano-copper oxide (CuO) was added [11].

From the alternative fuel point of view, it is proven that biodiesel is a promising fuel for diesel engine up to 20 % blend in connection with emission as well as performance [12]. Agarwal reported that the use of biodiesel contributes to a large reduction in engine wear and although vegetable oil creates various long-term problems in engine components [13]. Hence, the examination of the impact of vegetable oil-based bio-lubricant in a diesel engine fueled with biodiesel is still to be understood. Also, the available synthetic lubricant is dedicated to petroleum fuels. As far as the internal combustion engines are concerned, the thermal efficiency and emission are the important parameters for which the other design and operating parameters have to be optimized. The most common optimization techniques used for multi-objective problems are response surface method [14], grey relational analysis [15], nonlinear regression analysis [16], genetic algorithm [17], and Taguchi method [18].

The review of literature clearly indicated that the researchers have put sincere attempt to find out the suitable alternative to petroleum-based fuel and lubricants without going through any engine modification. Also the information about the use of bio-lubricant on engine performance and emissions is scarce. Therefore, it is of prime importance to investigate the effect of bio-lubricant on diesel engine’s performance and emissions when an engine is fueled with B20 rapeseed oil biodiesel (20 % by vol. rapeseed oil methyl ester and 80 % by vol. diesel). Furthermore to investigate whether the formulated bio-lubricant is in comparable performance with synthetic lubricant or not, the objective of the present study is to determine the optimum compression ratio , lubricant type, and engine load that would result in a better engine performance along with minimum emission characteristics using Taguchi-based grey approach.

2 Materials and Methods

2.1 Formulation of Rapeseed Oil Bio-lubricant

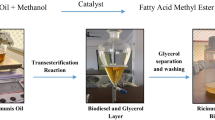

Rapeseed oil is chemically modified via epoxidation, hydroxylation, and esterification process. The detailed procedure for the chemical modification process is adopted from our earlier study [19]. The nano-copper oxide (CuO) ~ 40–70 nm of 0.5 % w/w was dispersed in CMRO as an antiwear additive using ultrasonic sonicator. Commercially available nanoparticles supplied by M/S US Research Nanomaterial Inc., USA were used in this study. Ethylene glycol of 0.1 wt% as dispersant has been added into the mixture to ensure the homogeneity of nanoparticles. The nanoparticles were ultrasonically vibrated using ultrasonic sonicator (Model: PR-1000, 25 kHz; Make: OSCAR®) for 2 h. Figure 1a, b shows the photographic view of chemical modification setup and Table 1 shows the properties of synthetic lubricant and chemically modified rapeseed oil bio-lubricant. The scheme of chemical modification is represented as follows (Scheme 1).

2.2 Experimental Design and Methodology

Three input parameters namely lubricant type (A), compression ratio (B), and engine load (C) were considered to be the main design factors for maximizing the engine performance and minimizing the exhaust emissions of a variable compression ratio (VCR) engine. The control parameters and their levels selected for the present investigation are given in Table 2. Altogether, seven (response) output parameters were analyzed, namely performance characteristics, i.e., Brake power (BP), brake thermal efficiency (BTE), and mechanical efficiency (ME); and exhaust emission characteristics such as CO, HC, NOX, and smoke. Taguchi’s parameter design was adopted to understand the effect of different input parameters on output responses. Since multiple performance characteristics with conflicting goals were present, Taguchi-grey method was adopted to generate a single response from multiple performance characteristics.

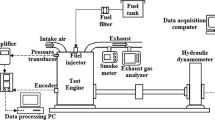

An engine performance and emission test were executed on a computerized four-stroke, single-cylinder, water-cooled, direct injection, VCR diesel engine coupled to an eddy current dynamometer for loading purpose. An online data acquisition system is used to connect the probes through an analog-to-digital converter and the data are fed to the computer. A specialized labview-based engine analysis software “Engine Soft LV” has been employed for online performance analysis. AVL437 smoke meter and AVL444 DI gas analyzer were used for smoke and emission measurements, respectively. The photographic view of VCR engine experimental setup is shown in Fig. 2. The specifications of test engine are summarized in Table 3. A Taguchi L18 orthogonal array was considered to have 18 rows corresponding to the total number of experiments.

An experiment was conducted as per the experimental design to determine performance and emission characteristics with B20 rapeseed oil biodiesel (20 % by vol. rapeseed oil methyl ester +80 % by vol. Diesel) as fuel and chemically modified rapeseed oil bio-lubricant/SAE20W40 as lubricant . The experiments were repeated twice to circumvent the possible experimental errors and an average values are tabulated. In every test, a volumetric fuel consumption and exhaust gas emissions were measured and the results are summarized in Table 4.

3 Grey Relational Analysis

Grey relational analysis was employed to convert a multiple-response process optimization problem into a single-response problem with the objective function of overall grey relational grade . The corresponding level of parametric combination with a highest grey relational grade was considered as the optimum process parameter [20].

Signal-to-noise ratio (S/N) is a measure used in science and engineering for comparing the level of a desired signal to the level of background noise. Since the present study aimed at optimizing seven output response parameters, it might so happen that the higher S/N ratio for one characteristic (performance characteristics) may exhibit a lower S/N ratio for other characteristics (emission characteristics). Therefore, the overall evaluation of the S/N ratio was required for the optimization of multiple performance characteristics. The criteria for optimization of the emission characteristics were based on the smaller-the-better S/N ratio and it is expressed as

The S/N ratio with a higher-the-better for the engine performance characteristic can be expressed as

where y i represents the measured value of the response variable i; r is the total number of tests. The calculated S/N ratio using Eqs. (1) and (2) is illustrated in Table 5.

Therefore, when the target value of the original sequence was “the larger-the-better,” the original sequence was normalized as follows:

When the purpose was “the smaller-the-better,” the original sequence was normalized as follows:

where y i (k) = original reference sequence, x i (k) = sequence for comparison. i = 1, 2, …, m; k = 1, 2, 3, …, n; m, n being total no of experiments and responses. min y i (k) = smallest value of y i (k), max y i (k) = highest value of y i (k). Here, x i (k) was the value after the grey relational generation. An ideal sequence was x 0(k). The grey relational grade revealed the relational degree between the experimental run sequences (x 0(k) and x i (k), i = 1, 2, …, m). The normalized S/N ratio using Eqs. (3) and (4) is illustrated in Table 6. The grey relational coefficient was calculated as

where Δoi(k) = ‖X 0(k) − X i (k)‖ was the difference of the absolute value between X 0(k) and X i (k). Δmin, Δmax were the minimum and maximum values of the absolute differences (Δoi) of all comparing sequences. The purpose of distinguishing coefficient ψ (0 ≤ ψ ≤ 1) was to weaken the effect of Δmax when it became too large. In the present analysis, the value of ψ was taken as 0.5. After averaging the grey relational coefficient, the grey relational grade γ o was being calculated.

The higher value of the grey relational grade was considered to be the stronger relational degree between the ideal sequence x 0(k) and the given sequence x i (k). The ideal sequence x 0(k) was supposed to be the best process response in the experimental layout. Thus the higher relational grade implied that the corresponding parameter combination was closer to the optimal. The calculated grey relational coefficient using Eq. (5) is illustrated in Table 7.

In case of engine performance, the maximum amount of brake power, brake thermal efficiency, and mechanical efficiency is observed at 100 % load (full load), Bio-lubricant, and compression ratio of 17.5. In case of emission study, the minimum amount of HC is emitted at no load, bio-lubricant, and compression ratio of 17.5; the minimum amount of CO is emitted at full load, bio-lubricant, and compression ratio of 17.5; the minimum amount of NOx is emitted at no load, bio-lubricant, and compression ratio of 15; and the minimum smoke emission is at no load, synthetic lubricant (SAE20W40), and compression ratio of 17.5 under this combination of study. Grey relational analysis is to be performed because of multi-response data. Some of them are higher-the-better, and some of them are lower-the-better. Taguchi method cannot optimize them. The performance characteristics like brake thermal efficiency, brake power, and mechanical efficiency should be as high as possible, so the higher-the-better (HB) formula (Eq. 3) is used to normalize it; HC, CO, NOx, and smoke emission should preferably be as low as possible, and hence the lower-the-better (LB) formula (Eq. 4) is used to normalize it.

3.1 Grey Relational Grade

All the grey relation grades are needed to be converted into “ONE” grey relation grade to perform the optimization process. The optimum combinations of engine parameters also depend on the output responses. The engine performance and exhaust emission parameters owe different weighting factors toward them as they have different impacts upon the study. The weighting factors are to be decided as per requirement. Our main goal is to substitute rapeseed oil-based bio-lubricant, yet maintaining, more or less, the same performance as synthetic lubricant. Since reduction of engine emission could be achieved by other means of emission control techniques, in general, while converting multiple grey relation grades, the value of weighting factor in engine performance was taken higher than that of emission characteristics.

However, the present investigation is aimed at running the engine with rapeseed oil biodiesel/bio-lubricant combination without any engine modification; hence, an equal weighting factor (β = 0.5) was used for both performance as well as emission characteristics [18]. When appropriate, weighting factor (β) was used with the sequence values, the general form of grey relational grade became

Then the grey relation grade with weighting factor should be put in the response column and analyze it by the S/N ratio curve, and the S/N ratio is selected as larger-the-better as the higher value of the grey relational grade is considered as the stronger the relational degree between the ideal sequence and the given sequence. After giving this weighting factor to the individual grey relation grade, the mean grey relation grade and its rank was calculated and is given in Table 8.

4 Results and Discussion

4.1 Analysis of Grey Relational Grade

The signal-to-noise ratio for overall grey relation grade is calculated using the higher-the-better (HB) criteria. The results expressed in terms of S/N ratio and the mean of grey relational grades. The response to the mean of the grey relational grade is given in Table 9. The corresponding main effect plots are shown in Fig. 3. In the main effect plot, if the line for a particular parameter is nearly horizontal, the parameter has a less significant effect. On the other hand, a parameter for which the line has the highest inclination will have the most significant effect.

From the main effect plot, the parameter C (load) has the most significant effect among these three parameters followed by compression ratio (B). The optimum process parameter combination of minimum emission and better engine performance is the one which has the maximum value of signal-to-noise ratio and grey relational grade. Thus, the optimum process parameter combination is found to be A 2 B 1 C 3, i.e., bio-lubricant (A), compression ratio (B) at 12, engine load (C) at 100 %, i.e., full load condition.

4.1.1 Effect of Engine Load on Grey Grade

The effect of load on grey grade is presented in Fig. 4a. It is observed that BP, BTE, and ME are found to increase significantly with increase in load as lesser losses are encountered at higher load. The same trend is reported by Labeckas and Slavinskas with the use of biofuel /synthetic lubricant combination [21]. The main reason for this is that relatively less portion of power is lost at higher load. But it is observed that with increase in load, the smoke and NOx emissions increase, and however CO and HC emissions decrease. With increase in load, smoke and NOx emissions increase because a richer air–fuel ratio mixture is burnt in the cylinder which leads to an increase in combustion chamber temperature. However, at higher loads, higher temperature in the combustion chamber results in better combustion of fuel leading to very low CO and HC emissions. This result agrees with the findings of Mohanraj and Murugu Mohankumar [12]. Thus the overall engine performance is better and reflects in higher value of weighted grey relational grade at higher load.

4.1.2 Effect of Compression Ratio on Grey Grade

The effect of compression ratio (CR) on grey grade is presented in Fig. 4b. It is observed that with increase in CR, the brake power, brake thermal efficiency, and mechanical efficiency increase. This trend is observed because, at higher CR, of higher the combustion chamber temperature which results in better combustion of fuel. Moreover, the conversion of chemical energy of biodiesel fuel into mechanical energy is higher. Similarly, at higher compression ratios, HC, CO, and smoke emissions are low, because of increased combustion temperature and pressure at higher CR, and better combustion can be ensured. Also at higher CR, higher combustion chamber temperature due to better combustion leads to an increase in NOx emissions compared with lower CR. However, NOx emissions are lower with lower CR. Therefore, the overall engine performance is better and reflects in higher value of weighted grey relational grade at lower CR.

4.1.3 Effect of Lubricant on Grey Grade

The effect of lubricant on grey grade is presented in Fig. 4c. There is not much of a variation with two different lubricants used in this study. However, the experimental results indicate a marginal improvement in BP, BTE, and ME with the use of bio-lubricant as compared with SAE20W40. This improvement in engine performance can be attributed to higher lubricity of biodiesel/bio-lubricant combination in comparison with biodiesel/SAE20W40 which reduces the frictional losses that ultimately leads to an improvement in brake power and consequently increases the brake thermal efficiency [19]. Thus, the overall performance of the engine is marginally improved when bio-lubricant is used which can be seen in the grey relational grade plot.

5 Analysis of Variance for Grey Grade

The grey relational grade obtained using Eq. 6 is analyzed using analysis of variance (ANOVA) and the analysis of means (ANOM). ANOVA is used to reveal the level of significance of influence of factors on a particular response. This is accomplished by separating the total variability of the grey relational grades, which is measured by the sum of squared deviations from the total mean of the grey relational grade into contributions by each engine parameters and the error. The response table of Taguchi method was employed here to calculate the average grey relational grade for each factor level. In this, the grouping of grey relational grades was done initially by the factor level for each column in the orthogonal array and then by averaging them. Results of ANOVA (Table 10) indicate that engine load is the highly influential parameter (percentage contribution is 80.5 %) followed by compression ratio (13.37 %). This is evident from Fig. 5a–c. It is confirmed that the improvement of mean grey relational grade is observed at full load condition as shown in Fig. 5c in comparison with no load or part load condition as shown in Fig. 4a, b, respectively.

6 Confirmatory Test

Since the optimal level of engine parameters is selected, the confirmation experiment is processed to verify the improvement of total performance characteristics. The results of the confirmation experiments are expressed by the estimated grey relational grade ή o. The estimated grey grade ή o for the optimal levels of engine parameters can be calculated using Eq. (7)

where ή o is the mean of grey relational grade at optimal level. The initial design engine parameters are A 1 B1 C 1 , which is experiment No. 1 in Table 4.

The results of confirmation experiment as given in Table 11 indicate that the brake power is increased from 0.04 to 3.4 kW, the brake thermal efficiency is improved from 0.3 to 25.7 %, the mechanical efficiency is improved from 5.3 to 57 %, HC emission is decreased from 190 to 101 ppm, CO emission is decreased from 0.55 to 0.16 % by vol., smoke emission is increased from 9 HSU to 22 HSU, and NOx emission is increased from 50 to 130 ppm. The estimated grey grade increases from 0.6105 to 0.85, which is the largest value obtained in all experimental results as given in Table 8. It is found that there is an improvement of 5 % observed in the weighted grey relational grade. This ensures the usefulness of grey relational approach to the process optimization, where multiple quality criteria have to be fulfilled simultaneously.

7 Conclusions

The outcome of the present investigation is as follows:

-

The VCR engine can safely be operated at various compression ratios with the formulated rapeseed oil bio-lubricant without any engine modifications and significant changes in engine power and fuel economy.

-

Even the marginal improvement in BP, BTE, and ME with the use of rapeseed oil bio-lubricant as compared to SAE20W40. This can be attributed to the higher lubricity of rapeseed oil-based bio-lubricant.

-

Among the tested parameters, the engine load has the strongest correlation to the engine performance and emission characteristics. The recommended levels of engine parameters for maximizing the engine performance and minimizing the engine exhaust emissions simultaneously are lubricant at level 2 (bio-lubricant) , compression ratio at level 1 (CR-12), and engine load at level 3 (100 % load-full load), which shows that the use of rapeseed oil-based bio-lubricant improves the performance in VCR engine fueled with rapeseed oil biodiesel.

-

An increase in the value of predicted weighted grey relational grade from 0.6105 to 0.88 confirms the improvement in the engine performance of VCR engine using optimal values of engine parameters .

From this detailed study, it can be concluded that vegetable oil-based bio-lubricant is a strong renewable candidate for the replacement of petroleum-based lubricant in the near future, especially the developing country like India, as India is an agricultural-based country.

References

Demirbas A (2009) Biodegradability of biodiesel and petrodiesel fuels. Energy Sour—Part A 31:169–174

Arumugam S, Sriram G (2012) Effect of bio-lubricant and bio-diesel contaminated lubricant on tribological behavior of cylinder liner-piston ring combination. Tribol Trans 55:438–445

Ssempebwa JC, Carpenter DO (2009) The generation, use and disposal of waste crankcase oil in developing countries: a case for Kampala district of Uganda. J Hazard Mater 161:835–841

Mercurio P, Burns KA, Negri A (2004) Testing the eco toxicology of vegetable versus mineral based lubricating oils: degradation rates using tropical marine microbes. Environ Pollut 129:165–173

Uosukainen E, Linko YY, Lamasa M, Tervakangas T, Linko P (1998) Transesterification of trimethylol propane and rapeseed oil methyl ester to environmentally acceptable lubricants. J Am Oil Chem Soc 75:1557–1563

Asadauskas S, Erhan SZ (1999) Depression of pour points of vegetable oils by blending with diluents used for biodegradable lubricants. J Am Oil Chem Soc 76:313–316

Kim JR, Sharma S (2012) The development and comparison of bio-thermoset plastics from epoxidized plant oils. Ind Crops Prod 36:485–499

Ting C-C, Chen C-C (2011) Viscosity and working efficiency analysis of soybean oil based bio-lubricants. Measurements 44:1337–1341

Arumugam S, Sriram G, Rajmohan T (2014) Multi response optimization of epoxidation process parameters of rapeseed oil using response surface methodology (RSM) based desirability analysis. Arab J Sci Eng 39:2277–2287

Arumugam S, Sriram G (2013) Synthesis and characterization of rapeseed oil bio-lubricant—its effect on wear and frictional behaviour of piston ring-cylinder liner combination. Proc IMechE Part J: J Eng Tribol 227:3–15

Arumugam S, Sriram G (2014) Synthesis and characterization of rapeseed oil bio-lubricant dispersed with nano copper oxide—its effect on wear and frictional behaviour of piston ring-cylinder liner combination. Proc IMechE Part J: J Eng Tribol. doi:10.1177/1350650114535384

Mohanraj T, Murugu Mohankumar K (2013) Operating characteristics of a variable compression ratio engine using esterified tamanu oil. Int J Green Energy 10:285–301

Agarwal AK (2005) Experimental investigation of the effect of biodiesel utilization on lubricating oil tribology in diesel engines. Proc IMechE Part J: J Eng Tribol 219:703–713

Mumtaz MW, Adnan A, Mahmood Z, Mukhtar H, Malik MF, Qureshi Fahim Ashraf, Raza Ahtisham (2012) Biodiesel from waste cooking oil: optimization of production and monitoring of exhaust emission levels from its combustion in a diesel engine. Int J Green Energy 9:685–701

Karnwal A, Hasan MM, Kumar N, Siddiquee AN, Khan ZA (2011) Multi-response optimization of diesel engine performance parameters using thumba biodiesel-diesel blends by applying the Taguchi method and grey relational analysis. Int J Automot Technol 12:599–610

Maheshwari N, Balaji C, Ramesh A (2011) A nonlinear regression based multi-objective optimization of parameters based on experimental data from an IC engine fueled with biodiesel blends. Biomass Bioenergy 35:2171–2183

Alonso JM, Alvarruiz F, Deantesjm Hernandez L, Hernandez LV, Molto G (2007) Combining neural networks and genetic algorithms to predict and reduce diesel engine emission. IEEE Trans 11:46–55

Wu H-W, Wu Z-Y (2013) Using Taguchi method on combustion performance of a diesel engine with diesel/biodiesel blend and port-inducting H2. Appl Energy 104:362–370

Arumugam S, Sriram G, Ellappan R (2014) Biolubricant—biodiesel combination of rapeseed oil: an experimental investigation on engine oil tribology, performance and emission of variable compression engine. Energy 72:618–627

Kuo Y, Yang T, Huang GW (2008) The use of grey based Taguchi method to optimize multi response simulation problems. Eng Optim 40:517–528

Labeckas G, Slavinskas S (2005) The effect of diesel fuel blending with rapeseed oil and rapeseed oil methyl ester on engine performance and exhaust emissions. J KONES Int Combust Eng 12:1–12

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Arumugam, S., Sriram, G., Rajmohan, T., Paulo Davim, J. (2016). Multi-objective Optimization of Engine Parameters While Bio-lubricant–Biofuel Combination of VCR Engine Using Taguchi-Grey Approach. In: Davim, J. (eds) Ecotribology. Materials Forming, Machining and Tribology. Springer, Cham. https://doi.org/10.1007/978-3-319-24007-7_4

Download citation

DOI: https://doi.org/10.1007/978-3-319-24007-7_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-24005-3

Online ISBN: 978-3-319-24007-7

eBook Packages: EngineeringEngineering (R0)