Abstract

Electroactive materials are becoming an increasingly important component of many electronic devices designed to interface with biological systems. While much of this work has been driven towards developing electrical stimulation protocols and novel electroactive materials to enhance interfacing with mammalian cells and tissues for therapeutic biomedical applications, electrically driven processes have been shown to be highly tailorable and effective at preventing microbial fouling of the electrode surface. In this chapter we review the range of electrical stimulation paradigms that have been investigated to deactivate and/or repel microbial organisms from electrode surfaces. The mechanisms through which electrical stimulation acts to kill bacterial cells will be discussed, and the application of new polymeric electroactive materials that offer great scope to modulate materials chemistry and fabrication processes to further enhance antimicrobial activity will be reviewed. Finally we look forward towards the innovations that will bring forth the next generation of electroactive antimicrobial materials that promise to provide solutions for a range of diverse applications.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

Conductive electroactive materials designed to interface with their environment are being developed to provide a suite of cutting edge technologies that promise to revolutionise numerous industries. For example, electrodes and electroactive materials are already finding uses in biomedical applications. Metallic electrodes, composed generally of platinum, iridium or titanium nitride, are being used to deliver electrical stimuli directly to the cochlea in the inner ear to provide a sense of sound for the profoundly deaf, for vagus nerve stimulation to control epilepsy or Parkinson’s disease, and in pacemakers to regulate cardiac rhythm (Clark and Hallworth 1976; Norlin et al. 2005; Rose and Robblee 1990). Electrochemical sensors are highly effective tools for monitoring chemical composition and process control in both liquids and gas for a range of industries (e.g. food preparation, environmental and biomedical), providing real-time remote monitoring without the need for sampling. Electrodes are also being continually developed for a suite of industries in the energy sector, including water splitting, energy storage and conversion. For all of the above applications, charge must be transmitted between the electrode and the interfacial environment where a range of electrochemical processes take place. These may be in the form of sensing an analyte or microbial organism through the measurement of electrochemical processes at the electrode surface (Ronkainen et al. 2010), transferring charge from the electrode to excitable tissues such as nerves to evoke nerve action potentials and/or cellular developmental and behavioural responses (Balint et al. 2012; Merrill et al. 2005), or converting liquid water into its constituent components (hydrogen and oxygen) through electrochemically driven water splitting processes (Doyle et al. 2013).

It has been known since the late 1700s that electrical stimuli can be used to interface and communicate with biological systems thanks to the seminal studies of Luigi Galvani. He demonstrated the capacity to generate movement in the legs of deceased frogs using an electrical stimuli (Galvani and Aldini 1792; Piccolino 1998). While this early work would spawn what would become the field of electrophysiology, it also highlighted our ability to interact directly with biological systems using electrical stimulation . It is thus no surprise that researchers eventually turned to probing the ability to use electrochemically driven control processes to prevent the development of biological fouling layers on surfaces, and as a method for microbial sterilisation.

Exploiting electrochemical processes for the inactivation, or killing, of microbial organisms has been investigated for several decades. Early work in this area focused on the efficacy of pulsed electric fields (PEFs) to kill a range of microbial organisms in an electrolyte suspension (Sale and Hamilton 1967; Hülsheger et al. 1981, 1983). PEF treatment involves the insertion of two electrodes in an electrolyte solution containing the relevant microbial organism, with a high potential (kV range) pulsed across the two electrodes. Electrical stimulation conditions of up to 20 kV/cm2 and pulse durations in the μs range have demonstrated greater than 99 % lethal action against bacteria and yeast cells suspended in solution (Hülsheger et al. 1981, 1983; Sale and Hamilton 1967; Grahl and Märkl 1996). Electric field strength and the pulse duration both significantly impacted the lethal efficiency of the treatment, with cell mortality determined to result from electroporation of the microbial cell wall, leading to increased permeability, cell inactivation and death (Hülsheger et al. 1983). PEF treatment has been shown to be effective against a range of microbial organisms, including bacteria (Hülsheger et al. 1981, 1983; Grahl and Märkl 1996; Beveridge et al. 2005; Pervez et al. 2013), yeasts (Hülsheger et al. 1983; Grahl and Märkl 1996) and algae (Satirapipathkul et al. 2008; Zhou et al. 2013), making this a potentially viable technique for a diverse range of industries and applications. In recent years it has been touted as a promising method to pasteurize foods at room temperature without modifying the food quality and taste (Barbosa-Cánovas et al. 2001), and has been investigated for use in industries including fruit juice production (Saldaña et al. 2011) and wine making (Puértolas et al. 2009, 2010).

PEF treatment is a particularly mild-treatment for the inactivation of microbial organisms in suspension, compared to other treatments such as heat treatment or the use of toxic compounds such as chlorine, that is realising new opportunities in a number of niche industries. However the high potentials required make this technique are only applicable for use under highly controlled conditions, and therefore preclude its safe application to a number of biologically sensitive systems, including most biomedical (in vitro and in vivo) and environmental applications. As such, the ability to use alternative electrical stimuli protocols and processes delivered from conductive substrates and materials to inhibit the development of microbial fouling layers specifically on surfaces has attracted considerable interest in the literature. These technologies have the potential to replace, or enhance, existing technologies, or in some cases provide solutions to microbial fouling of surfaces and structures that cannot be addressed efficiently using currently available methodologies.

This chapter aims to provide an insight into the work that has been performed in developing low-fouling conductive surfaces, and their potential development and application in a variety of industries. We will probe the observed effect of different modes of electrical stimulation, including constant current/potential, as well as an alternating current/potential, on adhered microbes on the electrode surface. The use of different conductive materials, including metals, electroactive composites, and organic conductors such as conducting polymers and graphene, will be discussed, along with ways by which these materials are being adapted to provide specific functionality for desired applications. Finally, we glance into the future to forecast where research in electroactive anti-microbial surfaces is likely to be heading, providing insights into the next wave of promising technologies that may emanate from this research field.

4.2 Electrical Stimulation Paradigms to Prevent Biofouling on Electroactive Substrates

4.2.1 Constant Electrical Stimulation

Polarising an electroactive surface with either a positive or negative charge represents the earliest approach to employing electrical stimuli to prevent microbial fouling directly on electroactive surfaces. Initial work in this area focused on the application of a constant electrical charge, either by controlling the potential or the current, supplied to the electrod e. These studies identified that both current density and the choice of electrode material play an important role in guiding the inhibition of microbial adhesion to the electrode surface and the subsequent cell mortality. In some of the earliest work, silver, platinum, gold, stainless steel and copper electrodes were tested against Escherichia coli and Staphylococcus aureus cultured in agar medium (Spadaro et al. 1974). Constant currents in the range of 0.02–20 μA/mm2 were used, with currents in the higher range resulting either in severe corrosion of the metal and/or the generation of deleterious electrolytic products. At lower potentials (0.4–4 μA/mm2), where no changes in pH, gas production or corrosion were observed, the silver electrode demonstrated the best antimicrobial performance, not only preventing bacterial adhesion, but also generating a zone of inhibition around the electrode. The primary mechanism of action was determined to be iontophoresis, with a positive current generating the release of silver ions from the electrode surface at a concentration that was sufficiently lethal to bacterial cells resident near the electrode interface to render them inactive. This mechanism has been shown to be operative with other metal types, such as gold and platinum (Davis et al. 1991), however the ability for non-metallic electrodes, such as carbon (Davis et al. 1991), to also present antimicrobial activity under the same electrically stimulated conditions revealed the likelihood that other mechanisms were also at play.

The application of constant negative currents has also been shown to exhibit a significant repulsive effect on bacterial cells on or near the electrode surface. This perhaps is not surprising given that most bacteria present an overall negative charge at their physiological pH (Jucker et al. 1996), and thus this would result in electrostatic repulsion between the bacterial cell wall and the electrode surface. Several studies have investigated the use of negative currents to prevent bacterial colonisation of the inner surface of cannulae used in a range of medical procedures, with cannula-related infections making up a significant proportion of all hospital related infections (Spelman 2002). Carbon impregnated polyurethane (15 % loading) was employed to provide a conductive inner surface on a cannula, which when charged with a constant negative electric current, to repel bacteria from the electrode surface (Crocker et al. 1992; Liu et al. 1993). A constant negative current of −10 μA was sufficient to cause the migration of bacterial cells away from the cannulae surface when immersed in an agar plate supporting a lawn of bacterial cells within minutes, with all bacteria (Staphylococcus epidermidis, S. aureus, Enterococcus faecalis, Proteus mirabilis, Pseudomonas aeruginosa and Candida albicans) migrating at least 100 μm from the cannulae surface within 15 min of the current being applied (Crocker et al. 1992) (Fig. 4.1). Varying the current strength directly influenced the size of the zone of inhibition, with −2, –10 and −50 μA generating zones of 4.0 ± 1.2 mm, 10 ± 2.4 mm and 14 ± 2.8 mm for C. albicans, respectively. The well-defined regions of inhibition surrounding the negative current carrying cannulae were determined to result from electrophoretic action against the microbial cells, protecting the cannulae from colonisation by the bacteria. In a following study, a −10 μA current applied to the carbon impregnated cannulae generated a zone of inhibition when the negatively charged end was placed into agar supporting a bacterial lawn (Liu et al. 1993), however this effect was not demonstrated for cannulae charged with a positive current. They found that bacteria were more resilient to the effects of the applied negative current if allowed to incubate around the cannulae prior to the application of the electrical stimuli. Furthermore, with currents of −10 μA having shown no obvious side effects whe n delivered directly into the human heart (Liu et al. 1993), these electrical stimulation paradigms were deemed suitable for in vivo applications.

Light micrograph of a nutrient agar plate seeded with Staphylococcus epidermidis showing a well-defined zone of inhibition around the site of a current carrying cannula. The cannula has been removed to facilitate demonstration of the zone (10× magnification) (Reproduced with permission from (Crocker et al. 1992))

Although a majority of the work on applying constant electrical charge to prevent microbial fouling has used electrical current, constant potential has similarly been demonstrated to be effective at deactivating and/or repelling bacteria from the electrode surface. A modest imposed surface potential of −66 mV (versus a saturated colomel electrode (SCE)) on an indium tin oxide (ITO) electrode resulted in an 88 % reduction in bacterial fouling on the electrode from a heterogeneous marine bacterial population in seawater (Kerr et al. 1998). The negatively charged electrode was found to both repel bacteria, and kill cells that remained within the vicinity of the electrode surface. In another study, 10 day old biofilms of P. aeruginosa showed partial removal of the biofilm on stainless steel on the application of −1.5 V versus Ag|AgCl (Dargahi et al. 2014). The partial removal of the biofilm, during a 1 min application of the imposed potential, was driven by electrostatic repulsion between the biofilm and the electrode. At potentials negative of −1.5 V, biofilms were removed from the electrode surface within seconds, however this was attributed to the vigorous evolution of hydrogen gas at the electrode surface under these stimulation conditions, resulting in the violent mechanic al removal of the biofilm from the substrate.

The strength of the applied negative potential has been correlated with the removal of cells adhered at the electrode surface (Poortinga et al. 2001). Therein it was shown that while initial cell adhesion to an ITO electrode was independent of the potential applied during cell adhesion to the electrode (−0.2, 0.1, and 0.5 V versus Ag|AgCl), applying a more negative potential post-adhesion resulted in an increase in desorption of cells from the electrode surface. One bacterial strain deviated from this trend, which was attributed to the presence of long cellular appendages on the cell surface that were able to penetrate the repulsive energy barrier towards adhesion at the electrode-solution interface, allowing it to adhere while the other cells were more easily removed.

4.2.2 Alternating Electrical Stimulation

Alternating the polarity of char ge delivered to an electrode surface between positive and negative has been developed as a method for killing and releasing microbial fouling organisms on an electroactive substrate. Employing alternating potentials as a method to kill and release microbial organisms from the electrode surface has been tested as a method to reduce micro- and macro-fouling in the marine environment (Nakayama et al. 1998a, b; Matsunaga et al. 1998; Okochi et al. 1998). The marine bacterium Vibrio alginolyticus was allowed to adhere to an ITO electrode, and was first subjected to a positive potential for 30 min, followed by exposure to a negative potential for 10 min (Okochi et al. 1998). A positive potential of 1.1 V versus SCE was shown to kill 70 % of cells adhered to the electrode surface, without producing changes in pH or generation of chlorine. Subsequent application of a negative potential of −0.43 V resulted in 73 % desorption of cells resident on the electrode. In a separate study, a nylon plate and polyethylene terephthalate (PET) film were coated with a conductive paint composed of graphite and carbon black mixed with urethane, and tested in the laboratory against fouling by V. alginolyticus (Matsunaga et al. 1998). Applying a potential of 1.2 V versus SCE for 30 min killed all cells adhered to the electrode surface, with a subsequent negative potential (−0.6 V) found to promote the subsequent removal of cells from the electrode interface. As observed in the previous study, the potentials investigated (−0.6 to 1.2 V) did not result in changes in pH or chlorine production. Field studies were conducted on the nylon netting coated in the conductive paint, with an alternating potential electrical stimulation protocol of 1.2 V versus Ag|AgCl for 60 min, followed by −0.6 V versus Ag|AgCl for 10 min, applied each day. After 158 days, the wet weight on the control nets were 65.5 g, while the netting with the applied potentials resulted in only 3.5 g of fouling, demonstrating the efficacy of the electroactive system at preventing marine fouling.

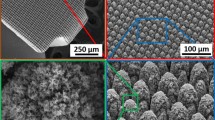

The nature of the electrode material has also been proposed to be critical in influencing the efficacy of electrical stimulation to act upon adhered microbial fouling organisms. Titanium Nitride (TiN) electrodes were shown to electrochemically inactivate V. alginolyticus cells at a lower potential than that demonstrated on conductive urethane coatings, illustrating that 98.7 % of cells were deactivated, or killed, on the electrode surface at a potential of 0.8 V versus Ag|AgCl for 30 min (Nakayama et al. 1998a). The efficacy of using TiN as a substrate to prevent biofouling was demonstrated by using a radio-frequency arc spraying technique (RFAS) to deposit the metal electrode on a PET plate, with the application of 0.8 V for 30 min killing 95.5 % of adhered V. alginolyticus cells in sterile seawater (Nakayama et al. 1998b). Field tests over 209 days demonstrated an alternating potential (1.0 V versus Ag|AgCl for 60 min, followed by −0.6 V Ag|AgCl for 10 min per day) to reduce biofouling by 96.3 % on the TiN electrode exposed to the alternating potential (5.1 g) versus the untreated electrode (134.7 g) (Fig. 4.2).

Polyethylene terephthalate plates coated in a TiN electrode after 209 days with (a) and without (b) application of an alternating potential of 1.0 V against Ag|AgCl for 60 min and −0.6 V against Ag|AgCl for 10 min. The experimental period was 9th July 1997 to 3rd February 1998 (Reproduced with permission from (Nakayama et al. 1998b))

Alternating the cu rrent, as opposed to potential, has similarly been demonstrated to an effective means to deactivate and remove cells from an electrode surface. One study compared the effectiveness of applying negative, positive, and alternating currents to inhibit the adhesion of the bacteria P. aeruginosa to an ITO electrode (Shim et al. 2011). Therein P. aeruginosa cells exposed to a negative current of 15 μA/cm2 exhibited a reduction of ~81 %, while positive currents illustrated comparable cell numbers to that on the unstimulated controls. Alternating the current between ±15 μA/cm2 with 1 min intervals for each stimulation condition resulted in a similar reduction in adhered bacteria to the negative current treatment, however additionally resulted in a bactericidal effect on the adhered bacteria, making it the most suitable of the three electrical stimulation conditions (Fig. 4.3).

(a) The numbers of adhered bacteria depending on the type of electric current (90 min, 15 μA.cm2, [KH2PO4]0 = 20 mM as base electrolyte, shear rate: 1.11 s−1). Adhered bacteria were measured after switching off electric currents. n = 3; standard deviation shown; control: 100 % ± 1.7, negative current: 19.2 % ± 13.1, positive current: 80.4 % ± 18.9, alternating current: 27.0 % ± 2.9. (b, c) Bacterial adhesion during the application of the negative current depending on the electric current density and the time ([KH2PO4]0 = 20 mM as base electrolyte, shear rate: 1.11 s−1). (b) The numbers of adhered bacteria compared with non-polarization (at 90 min). n = 3; standard deviation shown; zero current: 100.0 % ± 7.5, 7.5 μA.cm2: 81.8 % ± 5.0, 9.0 μA.cm2: 41.1 % ± 6.5, 11 μA.cm2: 29.5 % ± 7.6, 15 μA.cm2: 19.2 % ± 3.1. (c) Images of adhered bacterial cells (scale bar=10 μm) (Reproduced with permission from (Shim et al. 2011))

An altern ating current electrical stimulation protocol, versus a constant current paradigm, was tested against biofilms of S. epidermis adhered onto surgical stainless steel electrodes for 200 min (van der Borden et al. 2004). S. epidermis is a common biofilm-forming bacteria that is a major cause of infection for orthopaedic implants. Four currents were investigated, −60 and −100 μA of constant current, and −60 and −100 μA of alternating current (50 % duty cycle, 1 Hz), applied for 360 min. Constant currents were found to be the most effective for removing adhered bacterial cells from the electrode surface at both current levels, with alternating currents demonstrating 24 % and 31 %, and constant currents 37 % and 78 %, for −60 μA and −100 μA, respectively. In addition, bacteria remaining on the electrode surface after the electrical stimulation were found to be less viable than prior to the treatment (97 % viability without treatment, 3 % and 2 % after −100 μA constant current and −100 μA alternating current treatments, respectively).

While most studies employ currents in the μA range, there have been investigations that apply even smaller currents, in the nA scale, in order to gauge their ability to act on biological fouling at the electrode interface. Microcurrents have been tested to inhibit the development of a conditioning film from urinary deposits, which aid in bacterial adhesion (Gabi et al. 2011). The development of the conditioning film and bacterial adhesion on platinum, proposed as a possible surface coating for urological stents, was studied using atomic force microscopy and quartz crystal microbalance. Alternating currents of +75, +320, and +750 nA/cm2 (4 s stimulation cycle) resulted in either minimal or transient adsorption of compounds from the artificial urine. While a constant positive current resulted in relatively high adsorption of compounds from the artificial urine, only marginal film formation was observed upon the application of negative currents, even up to comparatively high current densities (−750 nA/cm2). The application of mild alternating currents (75 and 320 nA/cm2) was determined to reduce the bacterial colonisation of the platinum electrode surface by mediating the c onditioning film formation, and alternating the microenvironment at the electrode interface (Fig. 4.4).

Fluorescence microscopy images of four different study groups are shown after staining with fluorescein diacetate and propidium iodide to distinguish between viable (green) and dead (red) bacteria. Different current densities were applied to the platinum electrodes exposed for 6 days to artificial urine containing Proteus mirabilis. (a) No current I = 0 applied. (b) alternating current I = 320 nA/mm2. (c) anodic current I = 75 nA/mm2. (d) anodic current I = 750 nA/mm2 (Reproduced with permission from (Gabi et al. 2011))

4.3 Redox Mediators

Several researchers have probed the principal mechanism of action through which electrical stimulation, either via current or potential, is able to deactivate or kill bacteria and other microbial organisms adhered to an electrode surface. Detection of bacterial cells using a cyclic voltammetry technique (CV) illustrated the ability to measure direct current transfer between cells from the bacteria Saccharomyces cerevisiae and a graphite electrode (Matsunaga and Namba 1984). The electron transfer peak at 0.74 V versus SCE was determined to be mediated by coenzyme A (CoA) which is associated with the bacterium cell wall. Subsequent work by this group found that the respiratory activity of S. cerevisiae decreased by up to 25 % when the electrode potential was held at 0.74 V (Matsunaga et al. 1984). The loss of respiratory activity was linked to the electrochemical oxidation of CoA in the bacterium cell wall, forming the dimeric CoA, resulting in the inhibition of respiratory activity leading to cell death.

Several research groups have investigated the use of redox mediators to improve the efficiency of electron transfer between the electrode and the microbial cell, allowing for a reduction in the potentials required to kill organisms, and therefore also reducing the likelihood of generating toxic substances such as hydrogen peroxide and chlorine (Okochi and Matsunaga 1997). Ferrocene is a fast and reversible redox mediator that is used in a number of industries, including those producing biosensors and organic solar cells (Yang et al. 2007; Daeneke et al. 2011). A graphite electrode modified via physisorption of ferrocene was found to deactivate and kill a greater percentage of adhered V. alginolyticus cells (0 % survival) at a far lower potential (0.2 V) compared to that of an unmodified electrode (5 % survival at 1.0 V) when treated for 30 min (Okochi and Matsunaga 1997). The presence of the ferrocene improved the electrochemical reaction efficiency, with cells adhered to the electrode surface during CV analysis generating an increase in the anodic peak current, indicating the ferrocene was mediating electron transfer between the electrode and the cells – a process that resulted in the efficient sterilization of the marine bacteria. Further work by this group determined that the lethal activity of the electrical potential did not result from an increase in the permeability of the cell membrane, but rather the electrocatalytic oxidation of intracellular substances (Okochi et al. 2000).

4.4 Innovative Electroactive Materials

Inherently conducting polymers (ICPs) are an exciting class of materials that possess a highly tuneable chemistry through which a range of polymer properties, including chemistry, conductivity, porosity, morphology, and surface energy, may be modulated and tailored for specific applications. ICPs such as pyrrole , aniline , and thiophene have been a particular focus for researchers due to their high conductivity, and their ability to engage a range of polymer synthesis methods (Wallace et al. 2002). ICP synthesis can be performed either electrochemically directly on an electrode surface, or chemically, forming a polymer nano-dispersion that can be used to fabricate ICP coatings, or composite coatings by employing them as an additive to a primary polymer system. ICP synthesis is facilitated by the oxidation of the monomer unit, forming a positively charged conjugated polymer backbone. This positive charge is counter balanced by the inclusion of an anionic species, termed the dopant (Wallace et al. 2002). A range of variables may be tailored to alter the fundamental material physicochemical and electrochemical properties, including the choice of dopant, synthesis method (chemical, electrochemical or vapour phase), and specific synthesis conditions (constant current, constant potential, CV, polymerisation time, charge density), making ICPs a highly flexible and tuneable polymer platform material.

Over the past decade, ICPs have attracted enormous interest in the areas of biomaterials and biological interfacing due to their good biocompatibility, as well as their ability to perform a range of biologically relevant functions, including delivery of electrical stimuli to excitable cells, controlled drug delivery, and guided cell growth. In addition to their ability to deliver faradaic charge at the electrode surface as per standard metallic electrodes, ICPs can undergo changes in polymer redox state, which, given the appropriate ICP chemistry, can result in a dramatic modulation of the polymer physicochemical properties (Halldorsson et al. 2009, 2011; Teh et al. 2009). Given this exciting array of adaptable polymer properties, it is surprising that researchers have only in recent years investigated the potential of employing electroactive ICPs in antimicrobial technologies and coatings.

The ICP polyaniline (PANI) is an excellent candidate material for many antimicrobial applications given its demonstrated high environmental stability and excellent anticorrosive properties (Kulkarni et al. 1989; Ansari and Keivani 2006; Biallozor and Kupniewska 2005). PANI used either as a dispersion, or as an additive in a range of traditional and novel composite marine coating systems, has demonstrated strong antimicrobial activity. Chemically polymerised polyaniline dispersions and nanoparticles have displayed strong inherent antibacterial properties against a range of bacterial strains (Gizdavic-Nikolaidis et al. 2011, 2012; Prasad et al. 2012; Jotiram et al. 2012). In one study, the antibacterial properties of PANI nanofibers were tested by analysing their effect on bacteria cultured in agar containing different concentrations of the nanofibers (5, 10, 15, 20 and 30 μg/mL) (Jotiram et al. 2012) (Fig. 4.5). The neat nanofibers were compared with fibers containing the antibiotic drug mupirocin (0.05 μg in 1 μg PANI nanofibers). PANI nanofibers alone demonstrated good antibacterial properties, generating zones of inhibition of 5 mm (5 μg/mL), 5.67 mm (10 μg/mL), 6 mm (15 μg/mL), 6.3 mm (20 μg/mL) and 7.3 mm (30 μg/mL) (Fig. 4.5). The antibacterial properties of the neat PANI were enhanced with the addition of mupirocin, increasing the zone of inhibition by between 6 and 21 %. A study into the mechanism/s behind the antimicrobial activity of PANI has determined that the polymer triggered oxidative stress in the bacterial cells, suppressing the formation of the bacterial cell wall (Gizdavic-Nikolaidis et al. 2011), providing an insight into the source of their potent antimicrobial properties.

Photographic image of zones of inhibition at various concentrations of PANI and PANI-mupirocin on Staphylococcus epidermidis. The antibacterial activity of PANI on Staphylococcus epidermidis: (a) Control dimethyl sulfoxide (DMSO) and PANI at 30 and 20 μg mL−1. (b) PANI at 15, 10 and 5 μg mL−1. (c) Control DMSO, PANI-mupirocin at 30 and 20 μg mL−1. (d) PANI-mupirocin at 15, 10 and 5 μg mL−1 (Reproduced with permission from (Jotiram et al. 2012)).

Recently there has been growing interest in the application of PANI in marine surface coatings due to its ability to present both antimicrobial and anticorrosive properties (Wang et al. 1999; Mostafaei and Nasirpouri 2013; Yang et al. 2009). PANI and sulphonated PANI (sPANI) added to polyurethane (PU) and epoxy resin (EP)-based coatings were found to possess significant antifouling properties when the PANI comprised greater than 20 wt% of the coating (Wang et al. 1999). Additionally, the antifouling properties of the PANI were found to be closely related to its conductivity, with coatings possessing the doped conductive forms of the emeraldine salt demonstrating enhanced antifouling properties compared to the non-conductive dedoped forms. Both PANI and sPANI also demonstrated a synergistic behaviour when combined with toxic compounds, with an overall enhancement of the efficacy of coatings when containing either cuprous oxide or dichlorodiphenyltrichloroethane (DDT). While cuprous oxide – EP based coatings were effective for 2–3 months, the addition of doped PANI increased the effective life span of the coating for up to 9–12 months. The mechanism of enhancement of the antimicrobial effect of the copper oxide with the addition of the PANI was unclear, however was suggested to result from the PANI additive providing a local environment in the coating of ~pH 4–5, presenting a weak acidic microenvironment that enhanced the redox process of cuprous (I) – cupric (II) ion, improving its antifouling behaviour.

Films composed of nanocomposite blends of PANI with and without zinc oxide (ZnO) nanorods were demonstrated to present excellent antifouling properties when tested against marine fouling in the field over a period of 9 months, with EP coatings containing 4.5 wt% of PANI resulting in a significant decrease in marine biofouling from algae and barnacles compared to surfaces containing a lower wt% PANI and control EP coatings (Mostafaei and Nasirpouri 2013). Coatings containing 4.5 wt% PANI along with ZnO nanorods (up to 2 wt%) provided additional antifouling activity, likely due to the photocatalytic properties of the ZnO generating antibacterial agents such as superoxide ions, hydro-peroxide radical and OH; compounds that oxidatively stress the bacterial cells. The antimicrobial properties of both the PANI based EP coatings were supported by laboratory studies with the bacteria E. coli and S. epidermis, with the PANI-EP coating significantly inhibiting the growth of both bacterial strains compared to the EP control.

While ICPs such as PANI have been demonstrated to possess inherent antifouling qualities, such properties can be easily complemented by the incorporation of additional surface chemical functionalization via the use of thiol chemistry (Molino et al. 2012, 2013; Bergman and Hanks 2000). Such surface modification may have significant applications in preventing the fouling of ICP based electrochemical sensors, preventing the fouling of stimulation and recording electrodes for biomedical applications, and providing enhanced antimicrobial properties to ICP materials engineered towards bestowing both anticorrosive and antimicrobial qualities to polymeric coatings. PANI and polypyrrole (PPy) have been shown to react readily with hydrophobic thiols to generate surfaces of dramatically decreased surface energy (Bergman and Hanks 2000; Molino et al. 2012). More recently, thiolated polymer brushes such as poly(ethylene glycol) have been employed to render the polymer surface resistant from protein and cellular interactions, providing a low fouling ICP electrode surface (Molino et al. 2013). PPy doped with the biological dopant dextran sulphate, an electroactive and biocompatible ICP that has exhibited excellent properties for bio-interfacing with cells and tissues, was functionalised to present a highly fouling resistant surface interface through the tethering of thiolated PEG (PEG-SH). Under optimal surface modification conditions, tethering of 40,000 Da PEG-SH reduced the nonspecific protein adsorption from HAMS F10 cell culture media containing 20 % foetal bovine serum (FBS) by 88 %, completely inhibiting the adhesion of mammalian skeletal muscle cells (Fig. 4.6). This approach is amenable to both the surface modification of ICP dispersions, as well as preformed films on a substrate, with the latter allowing the prospect of highly tuneable surface modification and patterning techniques such as inkjet printing of surface reactive chemistries such as PEG-SH, allowing control over the spatial distribution of low fouling chemistries on the ICP surface.

(a) Colonisation of polyethylene glycol thiol (PEG-SH) modified polypyrrole-dodecyl sulfate (PPy-DS by primary mouse skeletal muscle cells (unmodified (left) and modified (right) polymer regions). (Scale bar represents 400 μm). (b) Mass of protein adsorption to PPy-DS polymer films with/without modification with PEG. PEG-SH modification undertaken with 40 k MW PEG at 1 mM concentration at pH 9 and 45 °C. Protein adsorption studied using Fibronectin (FN)(50 μg/mL in PBS) or full medium (HAMS F10 with 20 % foetal bovine serum). Error bars represent 95 % confidence intervals around the mean (Reproduced with permission from (Molino et al. 2013))

4.5 Conclusions and Future Directions

Electroactive materials have attracted significant interest in the field of antimicrobial coatings, where both electrical stimulation paradigms and electroactive materials chemistry are being explored to provide surfaces and devices that can be used to develop potent antimicrobial surfaces. While our ability to dissuade and impact microbial colonisation on metallic electrodes remains critical for many applications (particularly in the biomedical sector where choice of electrode is often restricted due to several factors), our ability to employ more flexible and tuneable conductors presents an enormous opportunity for their application in numerous industries. Organic conductors, such as carbon nanotubes and graphene, are being actively investigated as electrode materials for biological interfacing, and have already been shown to present inherent antifouling properties even without application of electrical stimuli (Hu et al. 2010; Kang et al. 2007). Further work on employing various electrical stimulation paradigms using these materials will be of great interest. As discussed, ICPs are an exciting class of materials that are highly processable and tuneable, and for which both electrically driven faradaic charge transfer, and modulation of polymer redox state to drive dynamic changes in polymer physicochemical and mechanical surface properties, may be exploited to act against the development of biofouling layers. Additionally, other electrochemically driven process may be utilised. For example, ICPs have been widely investigated for use in controlled drug delivery systems, where electrochemically controlled processes may be used to actively release drug compounds incorporated into the polymer. Such a process may be utilized to provide the controlled release of antimicrobial compounds from ICPs, which could be used individually or in concert with other mechanisms, to challenge microbial fouling organisms attempting to adhere to the electrode surface. Work by Esrafilzadeh and co-workers (Esrafilzadeh et al. 2013) have demonstrated the electrochemical release of the antibiotic drug ciprofloxacin from a PPy film in which the drug had been incorporated as the dopant species during electrochemical polymerisation . Application of a reducing potential to the polymer resulted in an excess negative charge on the polymer backbone, prompting the expulsion of the negatively charged ciprofloxacin from the polymer film and into the surrounding media. Ciprofloxacin release was shown to be effective against E. coli and Streptococcus pyogenes, generating a significant zone of inhibition around the stimulated ICP electrodes.

The specific development of electrically switchable surface chemistries may also provide promising opportunities for the generation of dynamic, electrically controllable antimicrobial surfaces and coatings. Switchable surface chemistries have been developed for use in biological systems, having been engineered to employ chemical, thermal, optical and electrochemical stimuli to transform the interfacial material properties (for review, see (Mendes 2008; Liu et al. 2005; Cole et al. 2009)). In particular, several studies have engineered surfaces that employ environmental stimuli, such as hydration, to trigger the reorganisation of surface chemistries to release microbial organisms such as bacteria from the material surface (Jiang and Cao 2010). Surprisingly few studies have tested electrically switchable surfaces against microbial fouling organisms. Pranzetti et al. (2013) studied the early stages of bacterial cell adhesion to a switchable SAM surface that could modulate between attractive and repellent states. Their system was based on electrochemically switching the negatively charged 11-mercaptoundecanoic-acid (MUA), which was tethered to a gold surface along with a second thiol (mercaptoethanol (MET)) that acted as a spacer, by changing the polarity of the applied potential. Application of a negative potential exposed the anionic head group of the MUA, presenting an interface attractive to bacterial adhesion, while a positive potential resulted in the concealment of this head group towards the electrode surface, providing a bacterial repelling surface (Fig. 4.7). When in the bacterial repellent conformation, adhesion of the marine bacterium Marinobacter hydrocarbonoclasticus was reduced by ~83 % compared to surfaces switched to the attractive state. This study demonstrated the ability to exert fine electrical control over polymeric surface chemistries with antimicrobial activity, with the further development of surface chemistries that, rather than provide attractive – repulsive switchability, provide different or changeable antimicrobial properties (i.e. microbial killing (cationic ammonium quaternary system) and release (i.e. PEG , zwitterion functionality)) could provide promising intelligent surfaces for both the deactivation and release of microbes from the electrode coating surface. This approach forecasts the development of electrically switchable surface chemistries that provide fast and on-demand modulation of surface properties for effective release and/or killing of microbial organisms.

Schematic representation of an electrically switchable two-component SAM that is able to reversibly and rapidly switch its molecular conformation in response to an applied potential. The change in molecular conformation induces either bacterial adhesion (anionic head group exposed) or repellence (anionic head group concealed) (Reproduced with permission from (Pranzetti et al. 2013))

The testing and development of new electrical stimulation paradigms, coupled with the ongoing development of ‘smart’ and ‘switchable’ conductive electroactive materials and coatings may pave the way for the future development of electroactive materials that, in concert with the myriad of fabrication techniques that are under active investigation for these materials (i.e. wet spinning, electro-spinning, printing, knitting and braiding), provide flexible and highly tuneable materials that present innovative solutions applicable for a range of industries.

References

Ansari R, Keivani M (2006) Polyaniline conducting electroactive polymers thermal and environmental stability studies. J Chem 3(4):202–217

Balint R, Cassidy NJ, Cartmell SH (2012) Electrical stimulation: a novel tool for tissue engineering. Tissue Eng Part B Rev 19(1):48–57

Barbosa-Cánovas GV, Fernandez-Molina JJ, Swanson BG (2001) Pulsed electric fields: a novel technology for food preservation. Agron Food Ind Hi-Tech 12(2):9–14

Bergman B, Hanks TW (2000) Spectroscopic, microscopic, and surface analysis of alkanethiol- and fluoroalkanethiol-modified conducting polymer thin films. Macromolecules 33(21):8035–8042. doi:10.1021/ma000659p

Beveridge JR, MacGregor SJ, Anderson JG, Fouracre RA (2005) The influence of pulse duration on the inactivation of bacteria using monopolar and bipolar profile pulsed electric fields. IEEE Trans Plasma Sci 33(4):1287–1293. doi:10.1109/TPS.2005.852345

Biallozor S, Kupniewska A (2005) Conducting polymers electrodeposited on active metals. Synth Met 155(3):443–449. http://dx.doi.org/10.1016/j.synthmet.2005.09.002

Clark GM, Hallworth RJ (1976) A multiple-electrode array for a cochlear implant. J Laryngol Otol 90(07):623–627. doi:10.1017/S0022215100082529

Cole MA, Voelcker NH, Thissen H, Griesser HJ (2009) Stimuli-responsive interfaces and systems for the control of protein–surface and cell–surface interactions. Biomaterials 30(9):1827–1850. http://dx.doi.org/10.1016/j.biomaterials.2008.12.026

Crocker IC, Liu WK, Byrne PO, Elliott TSJ (1992) A novel electrical method for the prevention of microbial colonization of intravascular cannulae. J Hosp Infect 22(1):7–17. http://dx.doi.org/10.1016/0195-6701(92)90126-7

Daeneke T, Kwon T-H, Holmes AB, Duffy NW, Bach U, Spiccia L (2011) High-efficiency dye-sensitized solar cells with ferrocene-based electrolytes. Nat Chem 3(3):211–215. http://www.nature.com/nchem/journal/v3/n3/abs/nchem.966.html#supplementary-information

Dargahi M, Hosseinidoust Z, Tufenkji N, Omanovic S (2014) Investigating electrochemical removal of bacterial biofilms from stainless steel substrates. Colloids Surf B Biointerfaces 117(0):152–157. http://dx.doi.org/10.1016/j.colsurfb.2014.02.021

Davis CP, Wagle N, Anderson MD, Warren MM (1991) Bacterial and fungal killing by iontophoresis with long-lived electrodes. Antimicrob Agents Chemother 35(10):2131–2134. doi:10.1128/aac.35.10.2131

Doyle RL, Godwin IJ, Brandon MP, Lyons MEG (2013) Redox and electrochemical water splitting catalytic properties of hydrated metal oxide modified electrodes. Phys Chem Chem Phys 15(33):13737–13783. doi:10.1039/C3CP51213D

Esrafilzadeh D, Razal JM, Moulton SE, Stewart EM, Wallace GG (2013) Multifunctional conducting fibres with electrically controlled release of ciprofloxacin. J Control Release 169(3):313–320. http://dx.doi.org/10.1016/j.jconrel.2013.01.022

Gabi M, Hefermehl L, Lukic D, Zahn R, Vörös J, Eberli D (2011) Electrical microcurrent to prevent conditioning film and bacterial adhesion to urological stents. Urol Res 39(2):81–88. doi:10.1007/s00240-010-0284-3

Galvani L, Aldini G (1792) De Viribus Electricitatis In Motu Musculari Comentarius Cum Joannis Aldini Dissertatione Et Notis; Accesserunt Epistolae ad animalis electricitatis theoriam pertinentes. Apud Societatem Typographicam

Gizdavic-Nikolaidis MR, Bennett JR, Swift S, Easteal AJ, Ambrose M (2011) Broad spectrum antimicrobial activity of functionalized polyanilines. Acta Biomater 7(12):4204–4209. http://dx.doi.org/10.1016/j.actbio.2011.07.018

Gizdavic-Nikolaidis MR, Bennett J, Zujovic Z, Swift S, Bowmaker GA (2012) Characterization and antimicrobial efficacy of acetone extracted aniline oligomers. Synth Met 162(13–14):1114–1119. http://dx.doi.org/10.1016/j.synthmet.2012.04.031

Grahl T, Märkl H (1996) Killing of microorganisms by pulsed electric fields. Appl Microbiol Biotechnol 45(1–2):148–157. doi:10.1007/s002530050663

Halldorsson JA, Little SJ, Diamond D, Spinks G, Wallace G (2009) Controlled transport of droplets using conducting polymers. Langmuir 25(18):11137–11141. doi:10.1021/la900835w

Halldorsson JA, Wu Y, Brown HR, Spinks GM, Wallace GG (2011) Surfactant-controlled shape change of organic droplets using polypyrrole. Thin Solid Films 519(19):6486–6491

Hu W, Peng C, Luo W, Lv M, Li X, Li D, Huang Q, Fan C (2010) Graphene-based antibacterial paper. ACS Nano 4(7):4317–4323. doi:10.1021/nn101097v

Hülsheger H, Potel J, Niemann EG (1981) Killing of bacteria with electric pulses of high field strength. Radiat Environ Biophys 20(1):53–65. doi:10.1007/BF01323926

Hülsheger H, Potel J, Niemann EG (1983) Electric field effects on bacteria and yeast cells. Radiat Environ Biophys 22(2):149–162. doi:10.1007/BF01338893

Jiang S, Cao Z (2010) Ultralow-fouling, functionalizable, and hydrolyzable zwitterionic materials and their derivatives for biological applications. Adv Mater 22(9):920–932. doi:10.1002/adma.200901407

Jotiram KP, Prasad RGSV, Jakka VS, Aparna RSL, Phani AR (2012) Antibacterial activity of nanostructured polyaniline combined with mupirocin. Nano Biomed Eng 4(3): 144–149

Jucker BA, Harms H, Zehnder AJ (1996) Adhesion of the positively charged bacterium Stenotrophomonas (Xanthomonas) maltophilia 70401 to glass and Teflon. J Bacteriol 178(18):5472–5479

Kang S, Pinault M, Pfefferle LD, Elimelech M (2007) Single-walled carbon nanotubes exhibit strong antimicrobial activity. Langmuir 23(17):8670–8673. doi:10.1021/la701067r

Kerr A, Hodgkiess T, Cowling MJ, Beveridge CM, Smith MJ, Parr ACS (1998) A novel technique to prevent bacterial fouling, using imposed surface potential. J Appl Microbiol 85(6):1067–1072. doi:10.1111/j.1365-2672.1998.tb05272.x

Kulkarni VG, Campbell LD, Mathew WR (1989) Thermal stability of polyaniline. Synth Met 30(3):321–325. http://dx.doi.org/10.1016/0379-6779(89)90654-1

Liu W-K, Tebbs SE, Byrne PO, Elliott TSJ (1993) The effects of electric current on bacteria colonising intravenous catheters. J Infect 27(3):261–269. http://dx.doi.org/10.1016/0163-4453(93)92068-8

Liu Y, Mu L, Liu B, Kong J (2005) Controlled switchable surface. Chem A Eur J 11(9):2622–2631. doi:10.1002/chem.200400931

Matsunaga T, Namba Y (1984) Detection of microbial cells by cyclic voltammetry. Anal Chem 56(4):798–801. doi:10.1021/ac00268a047

Matsunaga T, Namba Y, Nakajima T (1984) 751—electrochemical sterilization of microbial cells. Bioelectrochem Bioenerg 13(4–6):393–400. http://dx.doi.org/10.1016/0302-4598(84)87040-3

Matsunaga T, Nakayama T, Wake H, Takahashi M, Okochi M, Nakamura N (1998) Prevention of marine biofouling using a conductive paint electrode. Biotechnol Bioeng 59(3):374–378. doi:10.1002/(SICI)1097-0290(19980805)59:3<374::AID-BIT14>3.0.CO;2-E

Mendes PM (2008) Stimuli-responsive surfaces for bio-applications. Chem Soc Rev 37(11):2512–2529. doi:10.1039/B714635N

Merrill DR, Bikson M, Jefferys JGR (2005) Electrical stimulation of excitable tissue: design of efficacious and safe protocols. J Neurosci Methods 141(2):171–198. http://dx.doi.org/10.1016/j.jneumeth.2004.10.020

Molino PJ, Wallace GG, Hanks TW (2012) Hydrophobic conducting polymer films from post deposition thiol exposure. Synth Met 162(15–16):1464–1470. http://dx.doi.org/10.1016/j.synthmet.2012.06.013

Molino PJ, Zhang B, Wallace GG, Hanks TW (2013) Surface modification of polypyrrole/biopolymer composites for controlled protein and cellular adhesion. Biofouling 29(10):1155–1167. doi:10.1080/08927014.2013.830110

Mostafaei A, Nasirpouri F (2013) Preparation and characterization of a novel conducting nanocomposite blended with epoxy coating for antifouling and antibacterial applications. J Coat Technol Res 10(5):679–694. doi:10.1007/s11998-013-9487-1

Nakayama T, Wake H, Ozawa K, Kodama H, Nakamura N, Matsunaga T (1998a) Use of a titanium nitride for electrochemical inactivation of marine bacteria. Environ Sci Technol 32(6):798–801. doi:10.1021/es970578h

Nakayama T, Wake H, Ozawa K, Nakamura N, Matsunaga T (1998b) Electrochemical prevention of marine biofouling on a novel titanium-nitride-coated plate formed by radio-frequency arc spraying. Appl Microbiol Biotechnol 50(4):502–508. doi:10.1007/s002530051327

Norlin A, Pan J, Leygraf C (2005) Investigation of electrochemical behavior of stimulation/sensing materials for pacemaker electrode applications: I. Pt, Ti, and TiN coated electrodes. J Electrochem Soc 152(2):J7–J15. doi:10.1149/1.1842092

Okochi M, Matsunaga T (1997) Electrochemical sterilization of bacteria using a graphite electrode modified with adsorbed ferrocene. Electrochim Acta 42(20–22):3247–3250. http://dx.doi.org/10.1016/S0013-4686(97)00174-6

Okochi M, Nakamura N, Matsunaga T (1998) Electrochemical control of bacterial cell accumulation on submerged glass surfaces. Clean Prod Process 1(1):53–59. doi:10.1007/s100980050008

Okochi M, Nakamura N, Matsunaga T (2000) Electrochemical killing of vibrio alginolyticus using ferrocene-modified electrode. Electrochim Acta 45(18):2917–2921. http://dx.doi.org/10.1016/S0013-4686(00)00368-6

Pervez N, Rasheed A, Pervez A, Rashid A, Mahmood Q (2013) Microbial inactivation utilizing impulse waveform. Desalination Water Treat 52(13–15):2662–2667. doi:10.1080/19443994.2013.794708

Piccolino M (1998) Animal electricity and the birth of electrophysiology: the legacy of Luigi Galvani. Brain Res Bull 46(5):381–407. http://dx.doi.org/10.1016/S0361-9230(98)00026-4

Poortinga AT, Bos R, Busscher HJ (2001) Reversibility of bacterial adhesion at an electrode surface. Langmuir 17(9):2851–2856. doi:10.1021/la001673y

Pranzetti A, Mieszkin S, Iqbal P, Rawson FJ, Callow ME, Callow JA, Koelsch P, Preece JA, Mendes PM (2013) An electrically reversible switchable surface to control and study early bacterial adhesion dynamics in real-time. Adv Mater 25(15):2181–2185. doi:10.1002/adma.201204880

Prasad RGSV, Chaitanya KSV, Tejoram M, Basavaraju D, Rao KN, Kumar RR, Sreenivasan S, Phani AR (2012) Antibacterial properties of nanofiber structured conducting polyaniline synthesized by cost effective wet chemical process. J Pharmacol Res 5(1):370–373

Puértolas E, López N, Condón S, Raso J, Álvarez I (2009) Pulsed electric fields inactivation of wine spoilage yeast and bacteria. Int J Food Microbiol 130(1):49–55. http://dx.doi.org/10.1016/j.ijfoodmicro.2008.12.035

Puértolas E, López N, Condón S, Álvarez I, Raso J (2010) Potential applications of PEF to improve red wine quality. Trends Food Sci Technol 21(5):247–255. http://dx.doi.org/10.1016/j.tifs.2010.02.002

Ronkainen NJ, Halsall HB, Heineman WR (2010) Electrochemical biosensors. Chem Soc Rev 39(5):1747–1763. doi:10.1039/B714449K

Rose TL, Robblee LS (1990) Electrical stimulation with Pt electrodes. VIII. Electrochemically safe charge injection limits with 0.2 ms pulses (neuronal application). IEEE Trans Biomed Eng 37(11):1118–1120. doi:10.1109/10.61038

Saldaña G, Puértolas E, Monfort S, Raso J, Álvarez I (2011) Defining treatment conditions for pulsed electric field pasteurization of apple juice. Int J Food Microbiol 151(1):29–35. http://dx.doi.org/10.1016/j.ijfoodmicro.2011.07.033

Sale AJH, Hamilton WA (1967) Effects of high electric fields on microorganisms: I. Killing of bacteria and yeasts. Biochim Biophys Acta (BBA) Gen Subj 148(3):781–788. http://dx.doi.org/10.1016/0304-4165(67)90052-9

Satirapipathkul C, Iwakabe K, Habaki H, Kawasaki J (2008) Inactivation of harmful dinoflagellate (Alexandrium catenella) in ballast water by electric treatment. Ann Microbiol 58(2):297–301. doi:10.1007/BF03175333

Shim S, Hong SH, Tak Y, Yoon J (2011) Prevention of Pseudomonas aeruginosa adhesion by electric currents. Biofouling 27(2):217–224. doi:10.1080/08927014.2011.554831

Spadaro JA, Berger TJ, Barranco SD, Chapin SE, Becker RO (1974) Antibacterial effects of silver electrodes with weak direct current. Antimicrob Agents Chemother 6(5):637–642. doi:10.1128/aac.6.5.637

Spelman DW (2002) 2: hospital-acquired infections. Med J Aust 176(6):286–295

Teh KS, Takahashi Y, Yao Z, Lu Y-W (2009) Influence of redox-induced restructuring of polypyrrole on its surface morphology and wettability. Sensors Actuators A: Phys 155(1):113–119. http://dx.doi.org/10.1016/j.sna.2009.07.006

van der Borden AJ, van der Werf H, van der Mei HC, Busscher HJ (2004) Electric current-induced detachment of Staphylococcus epidermidis biofilms from surgical stainless steel. Appl Environ Microbiol 70(11):6871–6874. doi:10.1128/aem.70.11.6871-6874.2004

Wallace GG, Teasdale PR, Spinks GM, Kane-Maguire LAP (2002) Conductive electroactive polymers: intelligent materials systems. CRC Press, Boca Raton

Wang XH, Li J, Zhang JY, Sun ZC, Yu L, Jing XB, Wang FS, Sun ZX, Ye ZJ (1999) Polyaniline as marine antifouling and corrosion-prevention agent. Synth Met 102(1–3):1377–1380. http://dx.doi.org/10.1016/S0379-6779(98)00384-1

Yang X, Lu Y, Ma Y, Liu Z, Du F, Chen Y (2007) DNA electrochemical sensor based on an adduct of single-walled carbon nanotubes and ferrocene. Biotechnol Lett 29(11):1775–1779

Yang SC, Brown R, Ramotowski T, Tucker W, Maranda L, Chena R, Shen M (2009) New anti fouling coatings based on conductive polymers. No. URITC Project No. 0001032

Zhou JF, Xu LP, Feng DL, Hu AB, Xie TF (2013) Study on inactivation of microalgae in ship ballast water by pulsed electric field and heat treatment. Adv Mater Res 610:3163–3166

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Molino, P.J., Zhang, B., Higgins, M.J. (2015). Electroactive Anti-microbial Surfaces. In: Ivanova, E., Crawford, R. (eds) Antibacterial Surfaces. Springer, Cham. https://doi.org/10.1007/978-3-319-18594-1_4

Download citation

DOI: https://doi.org/10.1007/978-3-319-18594-1_4

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-18593-4

Online ISBN: 978-3-319-18594-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)