Abstract

We report the results of the development of an electron source , based on the emission of electrons from plasma . The plasma electron source delivers emission currents of more than 1 A, based on a laser-induced discharge plasma and grid-controlled electron emission. Circuit times of less than 1 µs and temporal modulation strongly connected to laser burst duration were measured. X-ray imaging verified high brightness and low emittance of the electron beam.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The next generation of computed tomography (CT) is the so-called non-mechanical CT (NM-CT). The advantages of NM-CTs are an increase in temporal and spatial resolution of the 3-D images and simultaneously a decrease in dose rate for patients. Here, detector, X-ray source , power supplies and data-logging electronics, which are now mounted on a rotating gantry, are replaced by a stationary setup [1]. For this conception, where about a thousand separate emitters are on one gantry and which can be individually activated, one of the key components are locally-excited X-ray sources. Each emits X-ray radiation for a duration of a few tens to a few hundreds of microseconds with a switching time less than one microsecond.

X-ray sources comprise of an electron source, a high voltage to accelerate the electrons and an anode, where the electrons are decelerated and the X-rays are generated. Nowadays used thermionic sources have a high power consumption due to the fact that heating of the cathode is not only necessary during emission but at any time. Therefore an alternative has to be developed, overcoming this problem. Beside the above mentioned temporal modulation capability, the newly developed source has to deliver emission currents up to one Ampere and modulation of the current from ten to hundred percent during microseconds, combined with high brightness, long life-time and low power consumption.

Laser-driven cathodes are of high interest for this application due to the capability of fast switching (temporal and spatial) of lasers. Therefore, two different approaches for electron emission were investigated, the photoelectric effect and a plasma electron source. Additionally, some experiments were carried out to use laser-induced plasma as a high-voltage switch.

2 Laser-Induced Electron Emission via Photoelectric Effect

Figure 15.1 shows the setup to measure electron emission by means of the photoelectric effect consisting of a vacuum chamber, a cathode with sample holder, integrated resistor heating and a cylindrical anode made of stainless steel. The anode is operated at high voltage and the cathode signal is detected by means of a linear power resistor with an oscilloscope.

The photoelectric effect was investigated on copper with frequency-tripled femtosecond laser radiation (wavelength λ = 266 nm, pulse duration τ = 200 fs). The temporal resolution of the electrode was determined at approx. 200 ps, which corresponds to the resolution of the detector (oscilloscopes Tektronix 300 MHz and 1 GHz; see Fig. 15.2).

The laser radiation was focused on the cathode using a lens (f = 150 mm) and the characteristic curves were recorded as a variation of pulse energy and voltage (Fig. 15.3). At the maximum available field strength of 700 V mm−1 an electron current of approx. 5 mA is achieved from 140 µm2 of a copper cathode at 5.5 MW incident laser power.

Further materials were also examined. It was found, however, that owing to low quantum efficiency, lasers with a very high mean and pulse peak output would be required to emit a mean current of 1 A.

The photoelectric effect is a surface effect, which means that the performance of a photocathode essentially depends on the vacuum conditions. Since electrical outputs of more than 100 kW are envisaged with the target specifications of the X-ray tubes to be developed, these outputs lead to temperatures in excess of 2000 °C on the anode surface. The necessary vacuum condition of 10−9 bar is not fulfilled because of the resultant evaporation of the anode. In the test set-ups used, this was observed at electrical outputs of not more than 100 W, which led to a distinct reduction in quantum efficiency as well as to non-reproducible measurement results. Several methods described in the literature for achieving self-cleaning effects (like heating) were tried, but none could be successfully employed.

In view of these results as well as the fact that a 1 A DC current requires mean laser outputs that are technologically not available at present, the investigations into the photoelectric effect as an electron source for an optically induced X-ray tube were not pursued any further.

3 Electron Emission from Laser-Induced Plasma

3.1 Single-Shot Experiments

For the emission of free electrons from laser-induced plasma , initially single pulse tests were conducted and subsequently tests were performed in burst operation. Here it was found that the currents and current densities generated in this way are more likely to achieve the required specifications than with the other effects.

Figure 15.4 shows the set-up for the cathode and the calculated field distribution used in the single-pulse tests. The laser is focused vertically from the top onto the cathode. In its initial approach the plasma generated by the laser moves vertically to the cathode surface. A ceramic disk made of macor prevents the plasma from spreading directly to the anode. The coaxial arrangement is designed so as to allow rapid measurements and to apply an even electric field in the area of the cathode. The cathode current is measured by shunt resistors.

The emission of electrons takes place perpendicularly to the direction of plasma propagation. This corresponds to the Plasma Edge Cathode concept, as expounded by Zieher et al. [2–4]. The electrons are emitted from the open plasma surface. The emission cannot, however, be maintained for periods longer than a few microseconds, because space charge layers form within the plasma which shield the electrons from the field applied. This arrangement is therefore only suitable for single-pulse investigations.

The laser used for the single-pulse tests is a titanium:sapphire laser. The central wavelength is 810 nm. The pulse durations can be set between 100 and 900 fs, with pulse energies in the range of a few µJ. Repetition rates of up to 1 kHz are possible with this laser.

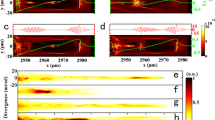

In the single-pulse tests, measurements were taken of the cathode current as a function of the cathode material, the anode voltage, the focus diameter, the pulse length and the laser energy. Exemplarily Fig. 15.5 shows the dependence of the current curve at different focal radii and different laser pulse durations for WTh as the cathode material.

Here the emission duration is in the range of a few 10 ns. The same length of time also applies to other materials. Cu, Al, W, WTh, WLa, WCe, FeCe, Sm, and Fe were tested. It was found that the elements with low ionization energy and small photoelectric work function show advantages concerning the maximum current and the required pulse energy at the ablation threshold.

The dependence of the electron emission and the ablation threshold on the pulse duration proved to be almost negligible for the range from about 100 to 900 fs. As expected, an increase in the anode voltages and the pulse energies corresponds to an increase in the emission current.

3.2 Electron Emission in Burst Mode

Due to the electron emission duration, or the plasma life-time, respectively, measured in the single-shot experiments, for continuous emission of electrons an ultra-short pulse laser with a repetition rate of at least 20 MHz has to be applied (in our case 86 MHz). This ensures that there are no interruptions between individual laser pulses during the emission of every single emitter.

As emission durations in the range of 100 µs cannot be achieved with the Plasma Edge Cathode (PEC) [3], grid-controlled emitters were developed [5–7]. Although, the regimes were completely different from those required here: plasma produced by gas discharges, poor vacuum conditions (10−3 bar), size and cross section of the electrodes in the range of meters.

The use of an intermediate electrode (grid) prevents a positively charged marginal layer from forming which would shield the acceleration field from the electrons. As a result, DC currents can also be generated in contrast to PEC.

In the set-up the cathode, onto which the laser is focused, is located inside a closed tube. This enables the individual emitters to be separated from each other and also prevents the plasma from spreading in the direction of the anode. There is an opening at only one point. Here the grid is attached in such a way that a discharge takes place between the cathode and the grid when a plasma is present. The emission takes place from this discharge directly at the grid location. Part of the cathode current therefore flows over the grid while the other part is accelerated through the grid to the anode.

Several factors are decisive for the electron emission. To achieve an even current, suitable combinations of the set-up and adjustment parameters have to be found. On the one hand, the size of the electron exit hole or the open emission area significantly influences the current strength. Larger emission holes and areas lead to higher currents. On the other hand, the shape of the electron exit hole also determines the shape of the X-ray beam focal point and therefore cannot be randomly selected (target value is a spot cross section of one by 10 mm).

Moreover, the open emission area (depending on the wire diameter and mesh size of the grid) in part determines the uniformity of the current. Larger relative apertures lead to timely uneven and strong currents and vice versa). Furthermore, the uniformity and the current strength depend on the resistor connected in series with the grid. Here, the high resistor leads to small and even currents and vice versa.

Furthermore, the emission current strength is set via the grid current, and the grid current can be set via the potential of the grid relative to the cathode or the grid series resistor. Figure 15.6 shows as examples two current signals for two different series resistors with otherwise identical parameters. The combination of the settable parameters therefore has a decisive influence.

The cathode surface is heavily processed by ablation with the laser radiation. As a result, different conditions apply before each pulse burst . Two approaches were therefore taken to solve this problem and to achieve a longer service life with corresponding reproducibility.

A metal (InGa) that is liquid at room temperature was used as cathode material. Here it was found that for long periods the current signal does not disappear, even during continuous irradiation on one place on the cathode. The depressions left by ablation of the material are always filled up again owing to the liquid nature of the cathode. Nevertheless, the ablation pressure causes movements on the surface which prevent an even current signal. Especially in the region of the first 100–300 µs after switching on the laser, there are interruptions in the generation of plasma and thus also in the current.

A second approach is an arrangement which makes it possible to scan the surface of the cathode with the laser. As a result, the surface material is removed layer by layer and drilling of deep holes is avoided.

For the purpose of optimization, the distance between the grid and cathode was varied, work was performed with differently sized pinholes on the inside of the tube, and different tube diameters were tested. The relative easily changeable parameters are the resistor, which is connected in series between the grid and the HV power supply unit of the grid, the mesh size and the wire diameter of the grid as well as the emission area and the voltages applied.

Figure 15.7 shows some of the measured current curves. Graph (a) presents some current curves for different areas of the emission opening with otherwise identical parameters. In graph (b) the anode voltage is varied. At low voltages the current curve is very stable and even; at higher currents the fluctuations increase slightly. The rising and falling slopes at higher current values are not of fundamental importance as they are caused by the transient reactions of the power supply units.

In Fig. 15.8 current/voltage characteristic curves are presented. In graph (a) one can see that with increasing anode voltages the current does not increase as it should in accordance with the Child-Langmuir Law, but reaches a saturation level. The emission is therefore source-limited. In graph (b) a linear dependence of the cathode current on the grid voltage (synonymous with the grid current) can be recognized. The current/voltage characteristic curves were drawn for different combinations of resistors, grids and electron exit openings.

The parameter variations resulted in considerable differences in some cases. Nevertheless the combinations were found which lead to electron currents of more than 1 A (see Fig. 15.8). When larger emission openings areas were used, up to 1.75 A was attained.

3.3 X-Ray Radiation

To investigate the emittance, the X-ray radiation generated was studied. By imaging the X-ray beams using a simple pinhole aperture on X-ray films or XCCD cameras it is possible to determine the size of the electron beam on the anode.

In Fig. 15.9 the image of an X-ray focal point on the anode is shown. The distribution was captured using an XCCD camera, which detects photons from about 30 keV. In this example the mean current is 600 mA and the anode voltage is 60 kV. The dimensions of the electron beam on the anode amount at 20 % of the maximum to about 10 mm × 1.3 mm. As a result, the focal point is only slightly bigger than the dimensions of the exit opening of (1 × 10) mm2.

The size of the X-ray focal point is crucial for diagnostic imaging as it determines the resolution in the investigations. To ensure this, the electric field between the electron source and the anode must be designed in such a way that in their trajectories the electrons are focused on a focal point that is as small as possible on the anode. By calculating the field distribution for different designs and thus of the electron trajectories it is ensured that the electron beam is not defocused.

4 Plasma-Based High-Voltage Switch

In contrast to the grid-controlled plasma cathode, where the grid has direct contact to the cathode via the plasma, control grids are used in thermionic or field emitters which primarily influence the field strength on the cathode through appropriate selection of the grid potential. A change in the grid potential may cause considerable difficulties if the changes occur at very short intervals or potentials of several kilovolts have to be switched. A plasma-based solution can be used here as a high-voltage switch.

Some tests were carried out to investigate a laser-controlled plasma switch with the aim of switching voltages of up to 100 kV with low jitter in less than 1 µs. Applying a plasma-based switch the current strength of a conventional cathode is controlled via the grid between the cathode and the anode. Additionally, the X-ray energy can be set directly by controlling the anode voltage.

Such a plasma switch used for control purposes is shown in Fig. 15.10. The laser produces a plasma which creates a conducting contact between two electrodes. A flashover occurs in which the potentials of the electrodes come close to each other via the conducting plasma. For switching off, a second plasma is produced by means of a second laser pulse on a second electrode which is oppositely charged to the first electrode.

A fs-laser was used in these experiments with the following parameters: wavelength λ = 800 nm, pulse duration τ ≈ 80 fs, repetition rate ν = 1 kHz, average power P ≈ 1.5 W. It was found that laser radiation with a relatively low mean output of 30 mW was enough to close the gap between the electrodes. The charging of the grid is shown by way of example in Fig. 15.11. The grid charges up within 200 ns to a potential of 2 kV, which corresponded to the voltage applied on the opposite electrode.

Figure 15.12 shows a typical voltage curve for an interval between the two laser pulses of approx. 280 and 435 ns, respectively. It can be seen that the voltage remains constant over the same period. The asymmetrical curve during charging and discharging can be explained by the greater difference in potential during switching off.

In addition, tests with liquid cathode materials were conducted. The advantage, as already mentioned, is a constant surface from shot to shot which is not knocked out of focus by the ablation. For this purpose a gallium-indium alloy, liquid at room temperature, was used and reproducible results were obtained over several million individual pulses.

5 Conclusions

In conclusion, an X-ray source was developed based on the emission of electrons from laser-induced plasma. Reproducible pulses of electrons were generated with pulse length in the range of 300 µs. The duration of the electron pulses is strongly connected to the duration of the plasma-generating laser burst. With adapted sets of parameters currents of more than one ampere were accelerated to the anode. The beam cross section was measured by imaging the X-ray beams with a XCCD-camera.

Additionally, some investigations were carried out to use this setup with some changes as a high voltage switch. Here, the laser-induced plasma closes the gap between two electrodes and shifts the potential of one electrode to the level of the other one. At shifting times in the range of 200 ns several kilovolts were switched. In principle the voltage could be increased to higher values.

References

Patents: EP0466956A1 und EP0564292A2

K.W. Zieher, A plasma edge cathode scheme, in 1986 IEEE International Conference on Plasma Science, IEEE, Saskatoon, Sask, Canada, New York, NY, USA, 19–21 May 1986. Cat. No. 86CH2317-6, p. 12

M.G. Grothaus, K.W. Zieher, Experimental investigation of a plasma edge cathode scheme for pulsed electron beam extraction. J. Appl. Phys. 70, 7223 (1991)

R. Stemprok, K.W. Zieher, Plasma edge cathode for high electron current density, in 9th IEEE International Pulsed Power Conference, Albuquerque, New Mexico, 1993, 9th IEEE International Pulsed Power Conference, vol. 2. Digest of Technical Papers. IEEE, New York, NY, USA, 1993, pt. 2, pp. 1002–1005 (Cat.No.93CH3350-6)

E. Oks, Plasma Cathode Electron Sources (Wiley-VCH, Berlin, 2006). ISBN 9783527406340

Y.E. Kreindel, Plasma Electron Source (Atomizdat, Moscow, 1977)

E.M. Oks, P.M. Schanin, Development of plasma cathode electron guns. Phys. Plasmas 6(5), 1649–1654 (1999)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Wueppen, J. et al. (2016). Laser-Triggered Electron Source for X-Ray Applications. In: Nolte, S., Schrempel, F., Dausinger, F. (eds) Ultrashort Pulse Laser Technology. Springer Series in Optical Sciences, vol 195. Springer, Cham. https://doi.org/10.1007/978-3-319-17659-8_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-17659-8_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-17658-1

Online ISBN: 978-3-319-17659-8

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)