Abstract

In this chapter, we discuss a variety of chemical reactions introduced for GO. Among all studies on the chemistry of GO, the largest portion focused on the reduction of GO back to graphene, mainly due to its high relevance to graphene and the gold rush of graphene research over the last decade. However, doping, functionalization and cross-linking of GO are equally, if not more, interesting to chemists, since GO is a giant model compound of polycyclic aromatic hydrocarbon (PAH) oxides. Here, we start with a thorough comparison between various reducing recipes for GO, and follow with some theoretical simulations and predictions on its convertibility toward graphene. In addition to that, we elaborate on extended chemical modifications (covalent and non-covalent), cross-linking, and doping recipes for this macromolecule shown in literature. After all, we intend to show you that GO became a relatively hot research topic, not only due to its relevance to graphene, but also for its high chemical activity and tunability, which enabled the prosperity of its research in various fields led by chemists, materials scientists, biologists, physicists, as well as engineers. It is a perfect paradigm for young researchers as an important subject thrived in interdisciplinary research. After all, when real-life problems come, potential solutions do not impose boundaries between disciplines. All relevant disciplines can offer their input, and contribute together to the final solutions, in which cases communications and collaborations between different researchers need to be encouraged and appreciated.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Graphene oxide

- Reduction

- Functionalization

- Covalent

- Non-covalent

- Doping

- Cross-linking

- Toxicity

- Hygroscopicity

3.1 Reduction

As mentioned in Chap. 1, the initial motivation of GO reduction is to produce graphene on a large scale. However, the reduction products of GO are relatively poor in crystallinity and hence carrier mobility, though they are incautiously claimed by many researchers as “graphene.” In this chapter, we name them as reduced graphene oxides (rGOs), to distinguish them from CVD-grown or mechanically exfoliated graphene products. Some researcher would also like to call them chemically converted graphene (CCGs), which might be a more accurate term, since some chemical treatments do not involve any reducing reagent, and the reactions happened are basically disproportionation of GO itself. This section summarizes and compares different reduction recipes introduced for GO, in order to gain deeper understanding on reaction mechanisms with the help of modeling and theoretical analysis.

3.1.1 Comparison of Reduction Recipes

The most common reaction medium for GO is water, and there are different ways to disperse GO into water, including sonication and mechanical stirring. Sonication has been reported to create defects and decrease the sheet size of GO from several microns to few hundred nanometers, and also widen the size distributions, hence less favorable than mechanical stirring in many applications [1–3]. The dispersibility of GO in water is typically on the order of 1–4 mg/mL [4]. On the other hand, GO can also be dispersed in organic solvents such as dimethylformamide (DMF), N-methylpyrrolidone (NMP), and tetrahydrofuran (THF) [5, 6], and thus is also believed to be amphiphilic with the core more hydrophobic and edges more hydrophilic, acting just like a surfactant [7]. As a giant molecule with amphiphilicity, GO can be assembled into continuous single-layer films by the Langmuir–Blodgett method [8–10].

Independent of the dispersion medium, a stable colloidal dispersion of GO is readily reactive with a variety of chemicals, most of which have been reducing reagents. The first example was the hydrogen sulfide reduction introduced by Hofmann in 1934 [11]. Only one report on lithium aluminum hydride (LiAlH4) reduction has come out [12], probably due to the strong reactivity of LiAlH4 with the common dispersing media water. In their case, THF was used as a solvent and methanol was used to wash. They named the reduction product G–OH, indicating lots of –OH groups remaining on GO after LiAlH4 treatment, and thus poor reduction effectiveness. On the other hand, although NaBH4 is slowly reactive with water, the reaction is kinetically slow enough to allow GO reduction to happen; however, the strongly reducing BH4 − ions usually create a lot of defects on GO basal planes. So far, the most popular reductant for GO has been hydrazine [13]. The reduction mechanism was proposed at least for one of the functional groups on GO, as shown in Scheme 3.1 [13].

Besides these, GO was believed to be one of the most important precursors to graphene; thus in literature, lots of chemical/physical reduction protocols have been demonstrated, and to compare their effectiveness, characterizations of products with conductivity measurement, elemental analysis, SS13CNMR, XPS, FTIR, Raman, XRD, TEM, near-edge X-ray absorption fine structure (NEXAFS) spectroscopy, etc. have been widely reported. Comparisons between different recipes have also been discussed [14–16]. Here we summarize most chemical and physical treatments and the product characterizations in Table 3.1, in order to provide a facile comparison of numerous methods demonstrated so far.

The restoration of π conjugation can be verified by changes between GO and rGO in UV–Vis spectra, XPS data, and electrical conductivities. The red shifts of UV adsorption peaks suggested the extension of π–π conjugation according to Hückel’s rule. The appearance of the π–π satellite peak in XPS was also a good indication. Electrical conductivity would be another good criterion to judge the degree of the restoration. As shown in Table 3.1, more than 30 chemicals have been reported as reducing reagent for GO, and so far the product with highest electrical conductivity is produced by hydroiodic acid with acetic acid treatment [40]. As mentioned before, we need to emphasize that all these chemical treatments worked as reduction protocols to GO, but their products were far from the firstly made graphene in their crystallinities [100], since the carrier mobility in these products is at least three orders of magnitude lower than that of graphene. In this case, we would like to conclude that GO as a chemically active compound is highly prone to reduction, but the defects and disordered structures in GO are very hard to be recovered. This can also be verified by Raman data in Table 3.1. All of those Raman spectra reported on rGOs have prominent D peaks, indicating highly defected structures in rGOs. In addition, most of them have higher D/G than that of GO, and researchers like to explain this higher D/G ratio by the increased sp 2/sp 3 carbon interfaces due to reduction, which seems a little bit farfetched. The argument against this explanation is that most of the highly reduced GO samples, where oxygen content is already pretty low (<0.5 wt%) [17], still have a higher D/G ratio than that in GO. Such a low oxygen content is just not enough to offer more sp 2/sp 3 carbon interfaces in the rGO sample. Theoretical modeling or simulations are needed for better understanding of this issue.

On the other hand, the reduction processes usually come with heteroatom incorporation into final products, further complicating structure and pushing rGOs further away from pristine graphenes. As shown in Table 3.1, both elemental analysis and XPS data show the existence of heteroatoms in final products, including oxygen, nitrogen, sulfur, boron, and hydrogen. Thus, people also tried to compare the purity of their products by comparing the ratio of C/O, C/(O + N), etc. These heteroatoms do influence the electrical conductivity as well, such as residual C–N groups can act as n-type dopants [74].

In order to elucidate the reduction mechanisms as well as we can, we have summarized how those functional groups on GO would react with various chemicals, as shown in Table 3.2. Most of these reactions are explained based on fundamental organic chemistry on the aspect of reactivity of individual functional groups. As we can see from the table, even the most popular reagent “hydrazine” would still leave some functional groups intact. Therefore, though the sp 2 carbon lattice structure is thermodynamically favorable over GO, the complete restoration of π conjugation is really hard, let alone the refilling of carbon vacancies that have been created in the harsh oxidation processes.

3.1.2 Theoretical Simulations and Predictions

Early in 2008, Boukhalov et al. modeled the chemical structure of GO, and the process of its deoxygenation [103]. They claimed that C8(OH)4O is the most energetically favored composition for GO, and the coexistence of –OH and epoxy groups is also highly possible. It is relatively easy to convert C8(OH)4O to C32(OH)2, since the energy difference between the two is less than 1 eV. But it is really hard to push the reduction further. As shown in Fig. 3.1, the authors believe that most of the chemical reductions will lead to the more stable product with an interlayer coupling energy of 17 meV, much lower than the 35 meV for graphene. Because of this weak coupling, the electronic structure of GO or partially reduced GO is almost the same for single layer and multiple layers, in contrast to the cases of mechanically exfoliated graphenes [103].

Optimized geometric structures of strongly reduced GO. Numbers are distances, in Å, for the periodic structure (and for bilayer in parentheses). Right upper corner: a top view. Carbon, oxygen, and hydrogen atoms are shown in green, blue, and violet, respectively.. (Adapted with permission from Ref [103]. Copyright (2008) American Chemical Society)

In 2009, Gao et al. investigated the deoxygenation process of GO with hydrazine or heat treatment based on density functional theory [104]. They found in both treatments that oxygenated moieties on basal planes are easier, both kinetically and thermodynamically, to remove than those on the peripheries. Hydrazine reduction tends to stay at the form of hydrazino alcohols. As shown in Fig. 3.2, four routes (routes 1, 2, 2′, and 3) were proposed for hydrazine reduction, and another four routes (4–7) were proposed for thermal annealing. Energy profiles (relative enthalpies and Gibbs free energies) were calculated for each route. The prediction of residual functional groups in GO after different treatments was also made available.

GO reduction mechanisms. Routes 1–3 and 2′ represent the mechanisms for the hydrazine de-epoxidation of GO. Routes 4 and 5 refer to the mechanism for the thermal de-hydroxylation of GO. Routes 6 and 7, respectively, show the mechanisms for thermal de-carbonylation and thermal decarboxylation of GO. (Adapted with permission from Ref. [104]. Copyright (2010) American Chemical Society)

Later in the year, gradient-corrected spin-polarized density-functional theory was used by Kim et al. to further clarify the reaction mechanisms for epoxide reduction with hydrazine [105]. Eley–Rideal mechanism was favored over Langmuir–Hinshelwood mechanism for the epoxide reduction. In detail, epoxide is reduced to form H2O by two successive hydrogenation reactions while two hydrogen atoms come from hydrazine molecules or its derivatives. However, as noted by the authors, the calculation they did was for vapor phase, whereas most reduction of GO with hydrazine happens in aqueous solutions. Further clarifications for solution-phase reactions are needed.

Whereas theoretical modeling and simulations or even predictions greatly helped GO chemists understand the structure and reduction pathways for GO, the matching between theoretical predictions and real experimental experiences is still hard to obtain. The authors of this book are eager to see more efforts in both theory and experiments, so that thorough understanding and accurate modeling can be demonstrated along with various experiments. It would be very interesting to see experimentally that intermediates in different reaction pathways predicted are separated and analyzed to ultimately prove the theoretical profiles proposed.

3.2 Functionalization

The addition of other functional groups directly onto GO, forming either covalent or non-covalent attachments, falls into another big category of GO chemistry. Due to the ambiguity of GO structure, we emphasize here that functionalization chemistry of GO is complex and not well understood. According to the widely accepted Lerf–Klinowski model, reactive functional groups on GO are epoxy, hydroxyl, organosulfate, carbonyl, carboxyl, and ester moieties. It would be nice if one can selectively react with one of these groups and keep others intact; however, so far such kind of orthogonal reactions have not been demonstrated. Most of the functionalizations occurred on more than one type of oxygenated groups and resulted in very complicated products with separation and purification almost impossible. Regardless of vague chemical characterizations, most of these products showed interesting applications in various fields.

3.2.1 Covalent

Among different functional moieties, carboxylic acid might be the most active one, since it is mostly located on the peripheries of GO sheets. The activation the –COOH is usually led by treatment with SOCl2, followed by various nucleophilic attacks with different nucleophiles (Fig. 3.3) [107–110].

Activation of GO’s peripheral carboxylic acid groups with either SOCl2 or a carbodiimide, and subsequent condensation with an alcohol or an amine. (Reproduced from Ref. [106] with permission of The Royal Society of Chemistry)

1-Ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) [111], N,N′-dicyclohexylcarbodiimide (DCC) [71], or 2-(7-aza-1H-benzotriazole-l-yl)-1,1,3,3,-tetramethyluronium hexafluorophosphate (HATU) [8] can also activate –COOH, and attacks by nucleophiles such as amines or hydroxyl groups are usually followed in order to form covalent attachments. The resulted amides have shown possible applications in optoelectronics [108, 110, 112, 113], catalysis [114], biodevices [8, 115], drug-delivery vehicles [111, 116], supercapacitors [117], and polymer composites [118–120]. A more complicated case involves the attachment of diamine, further covalently binding with bromide-terminated initiators, and subsequent polymerization on GO surface [118]. The resulted GO/polymer composites usually offer better dispersibility in many solvents. Besides that, isocyanate derivatives have also been shown to react with carboxyl and hydroxyl groups leading to amide and carbamate esters [121]. The products here can be well dispersed in polar aprotic organic solvents. Chitosan chains also reacted with the carboxyl groups on GO-forming amino bonds with only microwave assistance, offering possible biomedical applications [93].

Epoxy group is another major functionality on GO. The epoxy rings can be easily opened under acidic conditions or by nucleophilic attack. For example, octadecylamine was used to react with GO and offered a colloidal dispersion of functionalized GO (FGO) in organic solvents [122]. Hexylamine was also used to attack the epoxy rings on GO to form alkylated GO which can further be reduced into alkylated conductive graphene paper [74]. Ethylenediamino-β-cyclodextrin was also introduced to attach cyclodextrin onto GO surface via amine-epoxy reaction (Fig. 3.4) [123]. An ionic liquid (1-(3-aminopropyl)-3-methylmidazolium bromide, RNH2) was attached to GO via the end amine group in a nucleophilic attack of the epoxy groups [124]. Another example involved 3-aminopropyltriethoxysilane (APTS) attachment onto epoxy via a SN2 reaction and of course ring opening of epoxy groups, while reinforcement in the mechanical properties of the resulted silica composite was demonstrated [125]. Interestingly, inspired by the synthetic polymer chemistry or biochemical systems, cross-linking of GO with poly(allylamine) or sodium borate, via epoxy and hydroxyl groups, has also been investigated [126, 127], and mechanical enhancement of the resulted GO film was observed in both cases. Unfortunately these cross-linking strategies cannot stabilize GO in solvents especially in water, unlike the case for polymers, where cross-linked GO paper still breaks down when in contact with water, and hence other chemical methodologies are needed to tackle this problem.

Synthetic route of CD-G and the corresponding photos of aqueous solutions of GO and CD-G. (Reprinted with permission from Ref. [123]. Copyright (2011) American Chemical Society)

Hydroxyl groups on GO can act as nucleophiles to attack ketones. For instance, 2-bromo-2-methylpropanoyl bromide was used to react with hydroxyl groups on GO to form an initiator for atom transfer radical polymerization (ATRP), offering GO-polymethyl methacrylate (GO-PMMA) as the final product (see Fig. 3.5) [128]. Another interesting example is to react hydroxyl groups with nitriles by McGrail et al. [129]. The advantages of their recipe include the following: (1) the reaction can be done easily and rapidly in aqueous solution with a variety of small molecules and polymer nitriles; and (2) the products can be separated with centrifugation or filtration, and maintain tunable solubility and functionalities.

Reaction of GO with NaN3 in solid state. (Adapted from Ref. [130], published by The Royal Society of Chemistry)

As we mentioned in Chap. 1, a small amount of organosulfate groups are present in as-synthesized GO. These moieties have been replaced with azide anions in solid state in Eigler’s report (Fig. 3.5) [130]. The biggest advantage of this reaction recipe is that the thermally unstable functional groups in GO, such as hydroxyls and epoxides, are preserved in the mild reaction conditions.

It is also worthwhile to mention the covalent functionalization of rGOs with diazonium salts [4, 131, 132]. The aryl diazonium salt was believed to react with the sp 2 carbon domain in rGOs [56] and yield highly functionalized rGOs with superior dispersibilities. Direct reacting of diazonium salts with GO was also reported by Gao et al. [133] (Fig. 3.7), rendering thiophenol functionalized GO with high mercuric ion adsorption capability. Another example of sp 2 carbon reaction in GO was shown by Ballesteros-Garrido et al., where phenothiazinyl units were attached to graphitic carbon via nitrene insertion [134]. All these reactions mentioned above lead to strong covalent bonding between GO and the other chemical, and most of them happen with more than one type of functionalities on GO, proving GO to be a very active compound. However, also due to the complex environment on GO surfaces, especially the existence of long pairs of electrons on most oxygen atoms, the actual reaction pathways are highly complex, and the covalent attachments of functional molecules to sp 2 carbons are yet to be verified. So far, even with the powerful solid-state NMR techniques, the formation of this type of covalent bonds is still hard to be evidenced. Therefore, although these literatures claimed such type of chemistry on GO, further investigations are desired to fully understand the reaction details on these giant molecules.

Diazonium salt functionalization of GO. (Reprinted with permission from Ref. [133]. Copyright (2011) American Chemical Society)

3.2.2 Non-covalent

Additionally, non-covalent functionalization of GO has also been demonstrated. Non-covalent interactions such as hydrogen bonding, π–π stacking, cation-π, or van der Waals interactions mainly happen on oxidized or sp 2 carbon domains of GO. The strength of a π–π interaction depends on the number of aromatic rings in the π-electron system of adsorption molecules and on the contact curvature between the aromatic region of the molecule and the surface of graphitic materials. The activation energy of this process is reported to be higher than that of physical adsorption processes (5–40 kJ mol−1) [135]. For instance, 0.7 wt% of GO in poly(vinyl alcohol) (PVA) resulted in a 76 % increase in tensile strength and a 62 % increase in Young’s modulus, both of which are due to the hydrogen bonding formed between PVA polymer chains and functional groups on GO [136]. Another example involves silk fibroin with pristine GO flakes introduced by Tsukruk and coworkers [137]. A spin-assisted layer-by-layer technique was used to fabricate the GO/fibroin composite membranes with varying ratio of GO (e.g., 3.0, 6.0, 9.0, 11.5, and 23.5 vol.%), and a Young’s modulus as high as 145 GPa was obtained with 23.5 vol.% of GO, as compared to 10 GPa for original fibroin. Fibroin is a protein found in silk, which usually contains both hydrophilic and hydrophobic regions. The authors believe that the synergy of multiple non-covalent interactions between fibroin and GO is the major reason for the enhanced mechanical properties (Fig. 3.8) [137].

Molecular models of silk fibroin hydrophilic segments with polar interactions (a, upper part) and GO (a, bottom part: side view; b: top view). Elements in the ball-and-stick model are grayscale coded: H: white, C: light gray, O: dark gray, N: black. (c) The layered structure of nanocomposite silk fibroin-graphene oxide membrane. (Adapted from Ref. [137]. Copyright (2014) John Wiley & Sons Inc.)

A GO-based biosensor has been demonstrated utilizing the GO-protein/DNA π–π interactions [111]. Doxorubicin hydrochloride was also reported to form hybrid with GO via non-covalent interactions [138]. Sulfonated poly(ether-ether-ketone) was also used to non-covalently functionalize GO and the resulted product showed increased Young’s modulus by 160 % and decreased oxygen permeability by 91 % as compared to pure poly(vinylidene fluoride) [139]. Sulfonated polyaniline was used to improve the water dispersibility of rGOs [140], where π–π stacking and cation-π interactions are probably involved, and high conductivity, good electrocatalytic activity, and stability were also obtained. π–π stacking of pyrene molecules with a functional segmented polymer chain onto rGO surfaces resulted in a remarkable improvement in the thermal conductivity of graphene nanosheet-filled epoxy composites [141].

3.3 Cross-linking

As expected, freestanding GO films can offer numerous benefits such as easy handling; certain mechanical strength; thermal, electrical, and ionic conductivities via modifications; water permeability; catalytic activity; biocompatibility; and light sensitivity. However, GO films only maintain less than 10 % of the stiffness and less than 1 % of the ultimate tensile strength of that in an individual graphene oxide sheet [142], mainly due to the predominate hydrogen-bonding interactions in between stacked GO sheets. Furthermore, GO films are susceptible to water. One drop of aqueous solution can easily lead to their deformation or even disintegration. Therefore, to fully utilize all possible functions of GO films and its composites, effective cross-linking of GO is highly demanded. The first cross-linking recipe introduced was with poly(allylamine) (PAA) [126] in 2009, in which Park et al. [126] and later on Satti et al. [143] produced composite GO/PAA papers with enhanced tensile strength up to 146 MPa.

Starting in 2011, several bio-inspired cross-linking recipes emerged in literature [127, 144–146]. The first inspiration offered by An et al. was from borate ions in higher order plants [127]. ~0.001–0.01 dry wt% [147] of borate ions present in those plant tissues enhance their mechanical properties, via covalent bonding with oxygen-containing functional groups in a variety of pH and counterion environments. In the case of GO, the authors believed that the borate ions covalently bound with the hydroxyl groups on GO, which resulted in 255 % and 20 % increase in stiffness and strength, respectively (Fig. 3.9) [127].

Left: Schematic illustration of the formation of the borate-cross-linked network across two adjacent graphene oxide nanosheets in a thin film. (a) Water molecules form hydrogen bonds with epoxide and hydroxyl groups to bridge nanosheets in an unmodified graphene oxide thin film. (b) In addition to forming hydrogen bonds, borate anions react with surface-bound hydroxyl groups to give borate orthoester bonds, improving the mechanical properties beyond those of the unmodified film. (c) Thermal annealing drives the formation of more covalent bonds within the intersheet gallery, affording an ultra-stiff thin film. Right: Mechanical properties of respective films, demonstrating that ultra-stiff films are only obtained after annealing borate-modified films under a flow of dry N2. (Adapted from Ref. [127]. Copyright (2011) John Wiley & Sons Inc.)

Another interesting inspiration from nacre came out in 2012 by Li et al. [144], where they mixed GO dispersion with poly(vinyl alcohol) (PVA) followed by reduction with hydroiodic acid (HI). They obtained a nacre-like lamella structure with improved mechanical properties and high electrical conductivity. Cheng et al. got similar inspiration from nacre, while in their case, 10,12-pentacosadiyn-1-ol was used as the cross-linking agent [145]. The advantage of this recipe is the decreased polymer content and improved tensile strength and toughness. Tian et al. demonstrated the use of dopamine, inspired by the adhesive proteins of mussels [146]. With the fine-tuning of pH in their systems, they obtained a cross-linked GO/polyetherimide (PEI) composite film with 550 % increase in Young’s modulus over pristine GO films [146].

Besides bio-inspirations, several pure chemical protocols also emerged around the same time [148–150]. Glutaraldehyde/resorcinol [148], Fe3O4 nanospheres [149], and poly(oxypropylene) diamines [150] have been exploited in these studies, and the products show interesting applications in CO2 storage, lithium ion batteries, and biomedical systems. In addition to that, many recent reports have been focused on GO-based aerogels and hydrogels [151–157]. As for aerogels, freeze-drying [151], supercritical drying [152], or lyophilization [153] are typically used to produce aerogel monoliths with extremely low density (0.16–60 mg/cm3) (Fig. 3.10). Several cross-linking reagents, such as CNTs [151], La(OH)3 [152], polyethylenimine (PEI) [152], and ethylenediamine (EDA) [153], were used in these systems to improve the mechanical properties of the products.

Macroscopic and microscopic structures of ultra-flyweight aerogels (UFAs). (a) Digital photograph of UFAs with diverse shapes. (b) A 100 cm3 UFA cylinder standing on a flower like dog’s tail (Setaria viridis (L.) Beauv). (c) A ∼1,000 cm3 UFA cylinder (21 cm in diameter and 3 cm in thickness). (d) Microscopic SEM image of a UFA showing CNT-coated graphene cell walls. (Adapted from Ref. [151]. Copyright (2013) John Wiley & Sons Inc.)

Unlike aerogels, hydrogels are cross-linked networks that absorb large quantities of water without dissolving and are traditionally formed by physical or chemical cross-linking of natural or synthetic polymers [158]. Hydrogels made from GO or rGOs show interesting mechanical and electrical properties [154–156]. Chemical reduction or cross-linking with polyacrylamide [155] or N,N′-methylenebis(acrylamide) [156] was involved in order to make these hydrogels more conductive or elastic. Furthermore, external magnetic field was introduced to force the anisotropic alignment of GO flakes in the hydrogel [156], and the following cross-linking was able to retain the orientation of GO flakes even in the absence of magnetic field. This work has shed light on the desired manipulation of the group of 2D materials in closely related field.

In summary, a variety of cross-linking recipes have been introduced for GO and rGOs, resulting in mechanically enhanced membranes or composites with many promising applications. However, as mentioned in the beginning of this section, one of the major concerns about GO films is their susceptibility to water, aqueous media, and other polar solvents. Most of the reports on GO cross-linking are lack of information on this aspect. Actually, many of the recipes did not address this issue. In addition to that, some recipes unpreventably resulted in chemical reduction of GO due to GO’s high chemical activity, while for some potential applications, reduction is not desired. At this point, GO researchers are still looking forward to solutions on those issues.

3.4 Doping

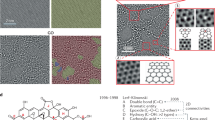

Due to the high catalytic activities of nitrogen(N)-containing carbon structures in several key chemical reactions, such as oxygen reduction reaction (ORR), oxygen evolution reaction (OER), and hydrogen evolution reaction (HER), N-doped GO is at the center of GO doping chemistry in literature. Several doping recipes have been introduced [49, 159–164], and more detailed discussions along with applications are offered in Chapter 3. Here we would like to show a simple example of N or S doping into GO for ORR catalysis (Fig. 3.11) [165]. The thermal reaction of GO and guest gas (NH3 or H2S) was exploited for the doping. In their studies, nitrogen was incorporated into graphene lattice with three types of binding configurations including pyridinic-N, pyrrolic-N, and graphitic-N, whereas sulfur was doped in a major form of thiophene-like structure. Interestingly, both N- and S-doped products showed enhanced ORR catalytic activity in alkaline media (0.1 M KOH) [165].

Schematic illustration of the fabrication of N- and S-doped graphene: (1 , 2) hydrolysis of TEOS around the surface of graphene oxide with the aid of a cationic surfactant, cetyltrimethyl ammonium bromide (CTAB); (3-1) thermal annealing of GO-silica sheets in ammonia at 600, 800, 900, and 1,000 °C, respectively; (3-2) thermal annealing of GO-silica sheets in H2S gas at 500, 700, and 900 °C, respectively; and (4-1 , 4-2) removal of silica by HF or NaOH solution. (Adapted from Ref. [165]. Copyright (2012) John Wiley & Sons Inc.)

Like most of the reports on doping of GO or graphene, the structure characterizations of the doped atoms are usually limited with XPS analysis. Typically a high-resolution XPS scan for the targeted elements is obtained, followed by numerical deconvolution of the signals and subsequently assignments to different structures. We have to share our experience here that XPS deconvolution is not quite enough for accurate assignments of those chemical states, and other more subtle analyses are needed before any solid statement can be made. In our own experience, the binding energy position of XPS signals is easily influenced by the calibration methods used, as well as the substrate and contaminations from the ambient. Deconvolution is also quiet case dependent, easily manipulated by analysts. We would like to suggest solid-state NMR, for the dopant elements such as N, B, and S, to be a better resolve for this issue.

3.5 Toxicity and Hygroscopicity

3.5.1 Toxicity

GO and RGO were reported to be toxic to bacteria (Escherichia and Staphylococcus) due to the cell membrane damage of the bacteria in contact with the sharp edges in GO and RGO by Akhaven et al., and hydrazine-reduced GO was more toxic than pristine GO [111]; inhibition of bacteria growth with minimal toxicity to human alveolar epithelial A549 cells was also shown by Hu et al. [166]. Wang et al. demonstrated that GO has dose-dependent toxicity to human fibroblast cells with obvious toxicity observed at doses above 50 μg/mL [167]. GO toxicity and blood compatibility were also reported to be dependent on dose, extent of exfoliation, and sheet size [168–170]. RGO was demonstrated to be less toxic than carbon nanotubes to PC12 cells at high concentrations by Zhang et al. [171]. PEGylated nano-sized GO only exhibited mild toxicity toward Raji cells at concentrations as high as 100 mg/L [172]. Paradoxically, other recent reports showed the high biocompatibility of GO or RGO [173–177]. To address these discrepancies, Ruiz et al. reported the nonspecific enhancement of cellular growth of GO, thus verifying that GO is nontoxic to both bacteria and mammalian cells, and attributing the previous reported toxicity as effects from carry-on impurities in GO [178]. However, incorporating Ag nanoparticles onto GO matrix significantly activated its antibacterial activity [179, 180].

3.5.2 Hygroscopicity

The hydroxyl, epoxy, and carboxyl groups on GO make it very hydrophilic, and adsorbed water molecules tend to present in the interlayer voids even after prolonged drying [181]. Therefore, GO turns out to be quite hygroscopic, with water content strongly depending on the humidity of the environment [182]. When a large amount of interlamellar water is present in stacked GO films, a network of hydrogen bonds (H-bonds) forms between water molecules and those oxygenated groups on GO, thus significantly influencing its structural, mechanical, and electronic properties [181–184]. For example, as the humidity level rises, GO film swells in volume [182, 183] and tensile modulus decreases [181]. Some theoretical simulation predicted that the interlayer distance between GO flakes arises from 5.1 to 9.0 Å when water content increases from nearly zero to 26 wt%, and that as the water content exceeds 15 wt%, the H-bond network is dominated by water–water H-bonds while functional groups are indirectly connected via a chain of water molecules [185]. The dynamics of the interlamellar water has also been studied by neutron scattering, and a “two-site” jump motion mechanism has been proposed [182]. Interestingly, when water is replaced by D2O, a lower interlayer distance was always observed, probably due to the lower solubility, lower reactivity, and stronger bonding of D2O compared with H2O [182]. The presence of water has also been accounted for the carbonyl formation and hole formation during GO reduction processes [186].

3.6 Concluding Remarks

GO is highly active chemically, mainly due to the partial coverage of its basal planes and edges with various functional groups, listed as epoxy, hydroxyl, ketone, ester, organosulfate, and lactol structures in dry state. When dispersed in polar solvents like water, it can hydrolyze to offer carboxylic acid groups or sulfate groups, which can be heavily functionalized with various chemicals as shown in literature. Activations and reactions with other moieties on GO are also well explored. The removal of these functional groups is another important topic that is inevitably related to the mass production of graphene, and hence the gold rush of graphene research in the last decade. It leads to large number of literature reports as summarized in Table 3.1. Doping and cross-linking of GO are relatively new focuses recently, and thus the investigations and explorations are in the early stage of growth.

In this chapter, we have summarized and discussed a variety of chemistry so far happened on GO, namely its reduction, functionalization, cross-linking, and doping, most of which are closely related to various applications, such as catalysis, composites, water purification, and energy conversion and storage. A detailed comparison of different reduction recipes was summarized, mainly focusing on the characterizations of a variety of reduction products. Although numerous strategies and recipes have been introduced, complete conversion of GO back to perfect graphene structure is still considered to be mission impossible. Reconstruction of highly defected rGO structures into more ordered sp 2 carbon grains remains to be the major obstacle, although high-temperature annealing (1,100–2,000 °C) has already been explored [187].

In addition, as it comes to applications, the high activity of GO brought problems such as selectivity and tunability of its functions. These challenges shed light on synthesis of its smaller molecular analogues, which might be more controllable if bottom-up organic synthetic strategies are explored. The blossom of GO research, partly due to its versatility in chemistry, can be successfully transferred to the oxides of other two-dimensional materials such as boron nitride (BN), graphitic carbon nitride (g-C3N4), or even small polycyclic aromatic hydrocarbons (PAHs), which are constituted of a group of materials with well-defined structures. Taking GO’s ability to function as a protonic conductor [188–190] as an example, the conduction pathways and mechanisms are unclear due to the complex nature of GO structure, namely multiple functional groups that can all participate or contribute to the proton transport. The clarification of this process can be significantly simplified if investigations can be done with a well-defined PAH oxide that has only one type of functional groups present in the structure. The same scenario also works for many other applications such as catalysis and sensing.

After all, it is our hope that the analysis and comparisons in this chapter will stimulate more intensive research on GO and its related chemistry and applications. Multidisciplinary research can particularly benefit from this convergence, and we believe that substantive advances are to occur at the interfaces of chemistry, materials science, and other disciplines.

References

Becerril HA, Mao J, Liu Z, Stoltenberg RM, Bao Z, Chen Y (2008) Evaluation of solution-processed reduced graphene oxide films as transparent conductors. ACS Nano 2:463–470

Gomez-Navarro C, Weitz RT, Bittner AM, Scolari M, Mews A, Burghard M, Kern K (2007) Electronic transport properties of individual chemically reduced graphene oxide sheets. Nano Lett 7:3499–3503

Stankovich S, Piner RD, Chen XQ, Wu NQ, Nguyen ST, Ruoff RS (2006) Stable aqueous dispersions of graphitic nanoplatelets via the reduction of exfoliated graphite oxide in the presence of poly(sodium 4-styrenesulfonate). J Mater Chem 16:155–158

Si Y, Samulski ET (2008) Synthesis of water soluble graphene. Nano Lett 8:1679–1682

Kim J, Cote LJ, Kim F, Yuan W, Shull KR, Huang J (2010) Graphene oxide sheets at interfaces. J Am Chem Soc 132:8180–8186

Paredes JI, Villar-Rodil S, Martinez-Alonso A, Tascon JMD (2008) Graphene oxide dispersions in organic solvents. Langmuir 24:10560–10564

Cote LJ, Kim J, Tung VC, Luo JY, Kim F, Huang JX (2011) Graphene oxide as surfactant sheets. Pure Appl Chem 83:95–110

Cote LJ, Kim F, Huang J (2008) Langmuir-Blodgett assembly of graphite oxide single layers. J Am Chem Soc 131:1043–1049

Cote LJ, Kim J, Zhang Z, Sun C, Huang J (2010) Tunable assembly of graphene oxide surfactant sheets: wrinkles, overlaps and impacts on thin film properties. Soft Matter 6

Kim F, Cote LJ, Huang J (2009) Graphene oxide: surface activity and two-dimensional assembly. Adv Mater 22:1954–1958

Hofmann U, Frenzel A (1934) The reduction of graphite oxide with hydrogen sulphide. Koll Zeitschr 68:149–151

Kim J, Im H, Kim J-M, Kim J (2012) Thermal and electrical conductivity of Al(OH)3 covered graphene oxide nanosheet/epoxy composites. J Mater Sci 47:1418–1426

Stankovich S, Dikin DA, Piner RD, Kohlhaas KA, Kleinhammes A, Jia Y, Wu Y, Nguyen ST, Ruoff RS (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Kuila T, Mishra AK, Khanra P, Kim NH, Lee JH (2013) Recent advances in the efficient reduction of graphene oxide and its application as energy storage electrode materials. Nanoscale 5:52–71

Luo D, Zhang G, Liu J, Sun X (2011) Evaluation criteria for reduced graphene oxide. J Phys Chem C 115:11327–11335

Pei S, Cheng H-M (2012) The reduction of graphene oxide. Carbon 50:3210–3228

Gao W, Alemany LB, Ci L, Ajayan PM (2009) New insights into the structure and reduction of graphite oxide. Nat Chem 1:403–408

Park S, An JH, Piner RD, Jung I, Yang DX, Velamakanni A, Nguyen ST, Ruoff RS (2008) Aqueous suspension and characterization of chemically modified graphene sheets. Chem Mater 20:6592–6594

Shin HJ, Kim KK, Benayad A, Yoon SM, Park HK, Jung IS, Jin MH, Jeong HK, Kim JM, Choi JY, Lee YH (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Funct Mater 19:1987–1992

Park S, An J, Potts JR, Velamakanni A, Murali S, Ruoff RS (2011) Hydrazine-reduction of graphite-and graphene oxide. Carbon 49:3019–3023

Obata S, Tanaka H, Saiki K (2013) Electrical and spectroscopic investigations on the reduction mechanism of graphene oxide. Carbon 55:126–132

Niu Z, Chen J, Hng HH, Ma J, Chen X (2012) A leavening strategy to prepare reduced graphene oxide foams. Adv Mater 24:4144–4150

Tung VC, Allen MJ, Yang Y, Kaner RB (2009) High-throughput solution processing of large-scale graphene. Nat Nanotechnol 4:25–29

Gilje S, Han S, Wang M, Wang KL, Kaner RB (2007) A chemical route to graphene for device applications. Nano Lett 7:3394–3398

Stankovich S, Dikin DA, Dommett GHB, Kohlhaas KM, Zimney EJ, Stach EA, Piner RD, Nguyen ST, Ruoff RS (2006) Graphene-based composite materials. Nature 442:282–286

Yun JM, Yeo JS, Kim J, Jeong HG, Kim DY, Noh YJ, Kim SS, Ku BC, Na SI (2011) Solution-processable reduced graphene oxide as a novel alternative to PEDOT:PSS hole transport layers for highly efficient and stable polymer solar cells. Adv Mater 23:4923–4928

Liu J, Jeong H, Liu J, Lee K, Park JY, Ahn YH, Lee S (2010) Reduction of functionalized graphite oxides by trioctylphosphine in non-polar organic solvents. Carbon 48:2282–2289

Moon IK, Lee J, Ruoff RS, Lee H (2010) Reduced graphene oxide by chemical graphitization. Nat Commun 1:73

Cataldo F, Ursini O, Angelini G (2011) Graphite oxide and graphene nanoribbons reduction with hydrogen iodide. Fuller Nanotub Car N 19:461–468

Das AK, Srivastav M, Layek RK, Uddin ME, Jung D, Kim NH, Lee JH (2014) Iodide-mediated room temperature reduction of graphene oxide: a rapid chemical route for the synthesis of a bifunctional electrocatalyst. J Mater Chem A 2:1332–1340

Esfandiar A, Akhavan O, Irajizad A (2011) Melatonin as a powerful bio-antioxidant for reduction of graphene oxide. J Mater Chem 21:10907–10914

Liao KH, Mittal A, Bose S, Leighton C, Mkhoyan KA, Macosko CW (2011) Aqueous only route toward graphene from graphite oxide. ACS Nano 5:1253–1258

Han TH, Huang Y-K, Tan ATL, Dravid VP, Huang J (2011) Steam etched porous graphene oxide network for chemical sensing. J Am Chem Soc 133:15264–15267

Thakur S, Karak N (2012) Green reduction of graphene oxide by aqueous phytoextracts. Carbon 50:5331–5339

Long Y, Zhang CC, Wang XX, Gao JP, Wang W, Liu Y (2011) Oxidation of SO(2) to SO(3) catalyzed by graphene oxide foams. J Mater Chem 21:13934–13941

Moon IK, Lee J, Lee H (2011) Highly qualified reduced graphene oxides: the best chemical reduction. Chem Commun 47:9681–9683

Jung H, Yang SJ, Kim T, Kang JH, Park CR (2013) Ultrafast room-temperature reduction of graphene oxide to graphene with excellent dispersibility by lithium naphthalenide. Carbon 63:165–174

Zhang S, Shao Y, Liao H, Engelhard MH, Yin G, Lin Y (2011) Polyelectrolyte-induced reduction of exfoliated graphite oxide: a facile route to synthesis of soluble graphene nanosheets. ACS Nano 5:1785–1791

Pei S, Zhao J, Du J, Ren W, Cheng H-M (2010) Direct reduction of graphene oxide films into highly conductive and flexible graphene films by hydrohalic acids. Carbon 48:4466–4474

Byon HR, Suntivich J, Shao-Horn Y (2011) Graphene-based non-noble-metal catalysts for oxygen reduction reaction in acid. Chem Mater 23:3421–3428

Zhou X, Zhang J, Wu H, Yang H, Zhang J, Guo S (2011) Reducing graphene oxide via hydroxylamine: a simple and efficient route to graphene. J Phys Chem C 115:11957–11961

Liu S, Tian J, Wang L, Sun X (2011) A method for the production of reduced graphene oxide using benzylamine as a reducing and stabilizing agent and its subsequent decoration with Ag nanoparticles for enzymeless hydrogen peroxide detection. Carbon 49:3158–3164

Xu LQ, Yang WJ, Neoh K-G, Kang E-T, Fu GD (2010) Dopamine-induced reduction and functionalization of graphene oxide nanosheets. Macromolecules 43:8336–8339

Tran DN, Kabiri S, Losic D (2014) A green approach for the reduction of graphene oxide nanosheets using non-aromatic amino acids. Carbon 76:193–202

Chua CK, Pumera M (2013) Selective removal of hydroxyl groups from graphene oxide. Chem Eur J 19:2005–2011

Wang K, Feng T, Qian M, Ding HI, Chen YW, Sun ZO (2011) The field emission of vacuum filtered graphene films reduced by microwave. Appl Surf Sci 257:5808–5812

Murugan AV, Muraliganth T, Manthiram A (2009) Rapid, facile microwave-solvothermal synthesis of graphene nanosheets and their polyaniline nanocomposites for energy storage. Chem Mater 21:5004–5006

Chen WF, Yan LF, Bangal PR (2010) Preparation of graphene by the rapid and mild thermal reduction of graphene oxide induced by microwaves. Carbon 48:1146–1152

Wang D-W, Wu K-H, Gentle IR, Lu GQ (2012) Anodic chlorine/nitrogen co-doping of reduced graphene oxide films at room temperature. Carbon 50:3333–3341

Zhou TN, Chen F, Liu K, Deng H, Zhang Q, Feng JW, Fu QA (2011) A simple and efficient method to prepare graphene by reduction of graphite oxide with sodium hydrosulfite. Nanotechnology 22:045704

Liao RJ, Tang ZH, Lei YD, Guo BC (2011) Polyphenol-reduced graphene oxide: mechanism and derivatization. J Phys Chem C 115:20740–20746

Seo M, Yoon D, Hwang KS, Kang JW, Kim J (2013) Supercritical alcohols as solvents and reducing agents for the synthesis of reduced graphene oxide. Carbon 64:207–218

Chen C, Chen T, Wang H, Sun G, Yang X (2011) A rapid, one-step, variable-valence metal ion assisted reduction method for graphene oxide. Nanotechnology 22(40):405602

Jung I, Dikin DA, Piner RD, Ruoff RS (2008) Tunable electrical conductivity of individual graphene oxide sheets reduced at “low” temperatures. Nano Lett 8:4283–4287

Wang S, Ang PK, Wang Z, Tang ALL, Thong JTL, Loh KP (2009) High mobility, printable, and solution-processed graphene electronics. Nano Lett 10:92–98

Chen WF, Yan LF (2010) Preparation of graphene by a low-temperature thermal reduction at atmosphere pressure. Nanoscale 2:559–563

Zhu YW, Stoller MD, Cai WW, Velamakanni A, Piner RD, Chen D, Ruoff RS (2010) Exfoliation of graphite oxide in propylene carbonate and thermal reduction of the resulting graphene oxide platelets. ACS Nano 4:1227–1233

Nethravathi C, Rajamathi M (2008) Chemically modified graphene sheets produced by the solvothermal reduction of colloidal dispersions of graphite oxide. Carbon 46:1994–1998

Zhou M, Wang YL, Zhai YM, Zhai JF, Ren W, Wang FA, Dong SJ (2009) Controlled synthesis of large-area and patterned electrochemically reduced graphene oxide films. Chem Eur J 15:6116–6120

Chen WF, Yan LF, Bangal PR (2010) Chemical reduction of graphene oxide to graphene by sulfur-containing compounds. J Phys Chem C 114:19885–19890

Gao X, Tang XS (2014) Effective reduction of graphene oxide thin films by a fluorinating agent: diethylaminosulfur trifluoride. Carbon 76:133–140

Ahmed MS, Han HS, Jeon S (2013) One-step chemical reduction of graphene oxide with oligothiophene for improved electrocatalytic oxygen reduction reactions. Carbon 61:164–172

Ma Q, Song J, Jin C, Li Z, Liu J, Meng S, Zhao J, Guo Y (2013) A rapid and easy approach for the reduction of graphene oxide by formamidinesulfinic acid. Carbon 54:36–41

Fernandez-Merino MJ, Guardia L, Paredes JI, Villar-Rodil S, Solis-Fernandez P, Martinez-Alonso A, Tascon JMD (2010) Vitamin C is an ideal substitute for hydrazine in the reduction of graphene oxide suspensions. J Phys Chem C 114:6426–6432

Sui Z, Zhang X, Lei Y, Luo Y (2011) Easy and green synthesis of reduced graphite oxide-based hydrogels. Carbon 49:4314–4321

Gao J, Liu F, Liu YL, Ma N, Wang ZQ, Zhang X (2010) Environment-friendly method to produce graphene that employs vitamin C and amino acid. Chem Mater 22:2213–2218

Dua V, Surwade SP, Ammu S, Agnihotra SR, Jain S, Roberts KE, Park S, Ruoff RS, Manohar SK (2010) All-organic vapor sensor using inkjet-printed reduced graphene oxide. Angew Chem Int Ed 49:2154–2157

Chen Y, Shen Y, Sun D, Zhang H, Tian D, Zhang J, Zhu J-J (2011) Fabrication of a dispersible graphene/gold nanoclusters hybrid and its potential application in electrogenerated chemiluminescence. Chem Commun (Camb) 47:11733–5

Kuila T, Bose S, Khanra P, Mishra AK, Kim NH, Lee JH (2012) A green approach for the reduction of graphene oxide by wild carrot root. Carbon 50:914–921

Chu H-J, Lee C-Y, Tai N-H (2014) Green reduction of graphene oxide by Hibiscus sabdariffa L. to fabricate flexible graphene electrode. Carbon 80:725–733

Fan XB, Peng WC, Li Y, Li XY, Wang SL, Zhang GL, Zhang FB (2008) Deoxygenation of exfoliated graphite oxide under alkaline conditions: a green route to graphene preparation. Adv Mater 20:4490–4493

Zhu CZ, Guo SJ, Fang YX, Dong SJ (2010) Reducing sugar: new functional molecules for the green synthesis of graphene nanosheets. ACS Nano 4:2429–2437

Liu JB, Fu SH, Yuan B, Li YL, Deng ZX (2010) Toward a universal “adhesive nanosheet” for the assembly of multiple nanoparticles based on a protein-induced reduction/decoration of graphene oxide. J Am Chem Soc 132:7279–7281

Chen JL, Yan XP (2010) A dehydration and stabilizer-free approach to production of stable water dispersions of graphene nanosheets. J Mater Chem 20:4328–4332

Guo HL, Wang XF, Qian QY, Wang FB, Xia XH (2009) A green approach to the synthesis of graphene nanosheets. ACS Nano 3:2653–2659

Sundaram RS, Gomez-Navarro C, Balasubramanian K, Burghard M, Kern K (2008) Electrochemical modification of graphene. Adv Mater 20:3050–3053

Ping J, Wang Y, Fan K, Wu J, Ying Y (2011) Direct electrochemical reduction of graphene oxide on ionic liquid doped screen-printed electrode and its electrochemical biosensing application. Biosens Bioelectron 28:204–209

Guo Y, Wu B, Liu H, Ma Y, Yang Y, Zheng J, Yu G, Liu Y (2011) Electrical assembly and reduction of graphene oxide in a single solution step for use in flexible sensors. Adv Mater 23:4626–30

Ramesha GK, Sampath S (2009) Electrochemical reduction of oriented graphene oxide films: an in situ Raman spectroelectrochemical study. J Phys Chem C 113:7985–7989

Shao YY, Wang J, Engelhard M, Wang CM, Lin YH (2010) Facile and controllable electrochemical reduction of graphene oxide and its applications. J Mater Chem 20:743–748

Pang H, Lu Q, Gao F (2011) Graphene oxide induced growth of one-dimensional fusiform zirconia nanostructures for highly selective capture of phosphopeptides. Chem Commun (Camb) 47:11772–4

Ambrosi A, Pumera M (2013) Precise tuning of surface composition and electron‐transfer properties of graphene oxide films through electroreduction. Chem Eur J 19:4748–4753

Cui J, Lai Y, Wang W, Li H, Ma X, Zhan J (2014) Galvanic displacement induced reduction of graphene oxide. Carbon 66:738–741

Fan Z, Wang K, Wei T, Yan J, Song L, Shao B (2011) An environmentally friendly and efficient route for the reduction of graphene oxide by aluminum powder. Carbon 48:1686–1689

Mei X, Ouyang J (2011) Ultrasonication-assisted ultrafast reduction of graphene oxide by zinc powder at room temperature. Carbon 49:5389–5397

Wang G, Yang J, Park J, Gou X, Wang B, Liu H, Yao J (2008) Facile synthesis and characterization of graphene nanosheets. J Phys Chem C 112:8192–8195

Wu ZS, Ren WC, Gao LB, Liu BL, Jiang CB, Cheng HM (2009) Synthesis of high-quality graphene with a pre-determined number of layers. Carbon 47:493–499

Li CC, Yu H, Yan Q, Hng HH (2015) Green synthesis of highly reduced graphene oxide by compressed hydrogen gas towards energy storage devices. J Power Sources 274:310–317

Matsumoto Y, Koinuma M, Ida S, Hayami S, Taniguchi T, Hatakeyama K, Tateishi H, Watanabe Y, Amano S (2011) Photoreaction of graphene oxide nanosheets in water. J Phys Chem C 115:19280–19286

Williams G, Seger B, Kamat PV (2008) TiO2-graphene nanocomposites. UV-Assisted photocatalytic reduction of graphene oxide. ACS Nano 2:1487–1491

Ji T, Hua Y, Sun M, Ma N (2013) The mechanism of the reaction of graphite oxide to reduced graphene oxide under ultraviolet irradiation. Carbon 54:412–418

Prezioso S, Perrozzi F, Donarelli M, Stagnini E, Treossi E, Palermo V, Santucci S, Nardone M, Moras P, Ottaviano L (2014) Dose and wavelength dependent study of graphene oxide photoreduction with VUV synchrotron radiation. Carbon 79:478–485

Cote LJ, Cruz-Silva R, Huang JX (2009) Flash reduction and patterning of graphite oxide and its polymer composite. J Am Chem Soc 131:11027–11032

Le Borgne V, Bazi H, Hayashi T, Kim YA, Endo M, El Khakani MA (2014) Hydrogen-assisted pulsed KrF-laser irradiation for the in situ photoreduction of graphene oxide films. Carbon 77:857–867

Trusovas R, Ratautas K, Račiukaitis G, Barkauskas J, Stankevičienė I, Niaura G, Mažeikienė R (2013) Reduction of graphite oxide to graphene with laser irradiation. Carbon 52:574–582

Huang L, Liu Y, Ji L-C, Xie Y-Q, Wang T, Shi W-Z (2011) Pulsed laser assisted reduction of graphene oxide. Carbon 49:2431–2436

Dumée LF, Feng C, He L, Yi Z, She F, Peng Z, Gao W, Banos C, Davies JB, Huynh C (2014) Single step preparation of meso-porous and reduced graphene oxide by gamma-ray irradiation in gaseous phase. Carbon 70:313–318

Zhang Y, Li D, Tan X, Zhang B, Ruan X, Liu H, Pan C, Liao L, Zhai T, Bando Y (2013) High quality graphene sheets from graphene oxide by hot-pressing. Carbon 54:143–148

Chang DW, Choi H-J, Jeon I-Y, Seo J-M, Dai L, Baek J-B (2014) Solvent-free mechanochemical reduction of graphene oxide. Carbon 77:501–507

Eigler S, Dotzer C, Hirsch A (2012) Visualization of defect densities in reduced graphene oxide. Carbon 50:3666–3673

Berger C, Song Z, Li X, Wu X, Brown N, Naud C, Mayou D, Li T, Hass J, Marchenkov AN, Conrad EH, First PN, de Heer WA (2006) Electronic confinement and coherence in patterned epitaxial graphene. Science 312:1191–1196

Behera SK (2011) Enhanced rate performance and cyclic stability of Fe(3)O(4)-graphene nanocomposites for Li ion battery anodes. Chem Commun 47:10371–10373

Boukhvalov DW, Katsnelson MI (2008) Modeling of graphite oxide. J Am Chem Soc 130:10697–10701

Gao X, Jang J, Nagase S (2009) Hydrazine and thermal reduction of graphene oxide: reaction mechanisms, product structures, and reaction design. J Phys Chem C 114:832–842

Kim MC, Hwang GS, Ruoff RS (2009) Epoxide reduction with hydrazine on graphene: a first principles study. J Chem Phys 131:064704

Dreyer DR, Todd AD, Bielawski CW (2014) Harnessing the chemistry of graphene oxide. Chem Soc Rev 43:5288–5301

Tang X-Z, Li W, Yu Z-Z, Rafiee MA, Rafiee J, Yavari F, Koratkar N (2011) Enhanced thermal stability in graphene oxide covalently functionalized with 2-amino-4, 6-didodecylamino-1, 3, 5-triazine. Carbon 49:1258–1265

Liu ZB, Xu YF, Zhang XY, Zhang XL, Chen YS, Tian JG (2009) Porphyrin and fullerene covalently functionalized graphene hybrid materials with large nonlinear optical properties. J Phys Chem B 113:9681–9686

Niyogi S, Bekyarova E, Itkis ME, McWilliams JL, Hamon MA, Haddon RC (2006) Solution properties of graphite and graphene. J Am Chem Soc 128:7720–7721

Xu YF, Liu ZB, Zhang XL, Wang Y, Tian JG, Huang Y, Ma YF, Zhang XY, Chen YS (2009) A graphene hybrid material covalently functionalized with porphyrin: synthesis and optical limiting property. Adv Mater 21:1275–1279

Akhavan O, Ghaderi E (2010) Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 4:5731–5736

Zhang YJ, Hu WB, Li B, Peng C, Fan CH, Huang Q (2011) Synthesis of polymer-protected graphene by solvent-assisted thermal reduction process. Nanotechnology 22

Zhu J, Li Y, Chen Y, Wang J, Zhang B, Zhang J, Blau WJ (2011) Graphene oxide covalently functionalized with zinc phthalocyanine for broadband optical limiting. Carbon 49:1900–1905

Hu X, Mu L, Wen J, Zhou Q (2012) Covalently synthesized graphene oxide-aptamer nanosheets for efficient visible-light photocatalysis of nucleic acids and proteins of viruses. Carbon 50:2772–2781

Mejias Carpio IE, Mangadlao JD, Nguyen HN, Advincula RC, Rodrigues DF (2014) Graphene oxide functionalized with ethylenediamine triacetic acid for heavy metal adsorption and anti-microbial applications. Carbon 77:289–301

Wu H, Shi H, Wang Y, Jia X, Tang C, Zhang J, Yang S (2014) Hyaluronic acid conjugated graphene oxide for targeted drug delivery. Carbon 69:379–389

Li Z-F, Zhang H, Liu Q, Liu Y, Stanciu L, Xie J (2014) Covalently-grafted polyaniline on graphene oxide sheets for high performance electrochemical supercapacitors. Carbon 71:257–267

Veca LM, Lu FS, Meziani MJ, Cao L, Zhang PY, Qi G, Qu LW, Shrestha M, Sun YP (2009) Polymer functionalization and solubilization of carbon nanosheets. Chem Commun 2565–2567

Yang YF, Wang J, Zhang J, Liu JC, Yang XL, Zhao HY (2009) Exfoliated graphite oxide decorated by PDMAEMA chains and polymer particles. Langmuir 25:11808–11814

Wan Y-J, Tang L-C, Gong L-X, Yan D, Li Y-B, Wu L-B, Jiang J-X, Lai G-Q (2014) Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 69:467–480

Dreyer DR, Jarvis KA, Ferreira PJ, Bielawski CW (2011) Graphite oxide as a dehydrative polymerization catalyst: a one-step synthesis of carbon-reinforced poly(phenylene methylene) composites. Macromolecules 44:7659–7667

Eda G, Mattevi C, Yamaguchi H, Kim H, Chhowalla M (2009) Insulator to semimetal transition in graphene oxide. J Phys Chem C 113:15768–15771

Liu J, Chen G, Jiang M (2011) Supramolecular hybrid hydrogels from noncovalently functionalized graphene with block copolymers. Macromolecules 44:7682–7691

Krueger M, Berg S, Stone DA, Strelcov E, Dikin DA, Kim J, Cote LJ, Huang J, Kolmakov A (2011) Drop-casted self-assembling graphene oxide membranes for scanning electron microscopy on wet and dense gaseous samples. ACS Nano 5:10047–10054

Hu HT, Wang XB, Wang JC, Liu FM, Zhang M, Xu CH (2011) Microwave-assisted covalent modification of graphene nanosheets with chitosan and its electrorheological characteristics. Appl Surf Sci 257:2637–2642

Park S, Dikin DA, Nguyen ST, Ruoff RS (2009) Graphene oxide sheets chemically cross-linked by polyallylamine. J Phys Chem C 113:15801–15804

An Z, Compton OC, Putz KW, Brinson LC, Nguyen ST (2011) Bio‐inspired borate cross‐linking in ultra‐stiff graphene oxide thin films. Adv Mater 23:3842–3846

Gonçalves G, Marques PAAP, Barros-Timmons A, Bdkin I, Singh MK, Emami N, Grácio J (2010) Graphene oxide modified with PMMA via ATRP as a reinforcement filler. J Mater Chem 20:9927–9934

McGrail BT, Rodier BJ, Pentzer E (2014) Rapid functionalization of graphene oxide in water. Chem Mater 26:5806–5811

Eigler S, Hu Y, Ishii Y, Hirsch A (2013) Controlled functionalization of graphene oxide with sodium azide. Nanoscale 5:12136–12139

Kamada S, Nomoto H, Fukuda K, Fukawa T, Shirai H, Kimura M (2011) Noncovalent wrapping of chemically modified graphene with pi-conjugated disk-like molecules. Colloid Polym Sci 289:925–932

Lomeda JR, Doyle CD, Kosynkin DV, Hwang WF, Tour JM (2008) Diazonium functionalization of surfactant-wrapped chemically converted graphene sheets. J Am Chem Soc 130:16201–16206

Gao W, Majumder M, Alemany LB, Narayanan TN, Ibarra MA, Pradhan BK, Ajayan PM (2011) Engineered graphite oxide materials for application in water purification. Acs Appl Mater Inter 3:1821–1826

Ballesteros-Garrido R, Rodriguez R, Álvaro M, Garcia H (2014) Photochemistry of covalently functionalized graphene oxide with phenothiazinyl units. Carbon 74:113–119

Liu F, Chung S, Oh G, Seo TS (2011) Three-dimensional graphene oxide nanostructure for fast and efficient water-soluble dye removal. Acs Appl Mater Inter 4:922–927

Liang J, Huang Y, Zhang L, Wang Y, Ma Y, Guo T, Chen Y (2009) Molecular‐level dispersion of graphene into poly (vinyl alcohol) and effective reinforcement of their nanocomposites. Adv Funct Mater 19:2297–2302

Hu K, Gupta MK, Kulkarni DD, Tsukruk VV (2013) Ultra-robust graphene oxide-silk fibroin nanocomposite membranes. Adv Mater 25:2301–2307

An SJ, Zhu YW, Lee SH, Stoller MD, Emilsson T, Park S, Velamakanni A, An JH, Ruoff RS (2010) Thin film fabrication and simultaneous anodic reduction of deposited graphene oxide platelets by electrophoretic deposition. J Phys Chem Lett 1:1259–1263

Layek RK, Das AK, Park MJ, Kim NH, Lee JH (2015) Enhancement of physical, mechanical, and gas barrier properties in noncovalently functionalized graphene oxide/poly (vinylidene fluoride) composites. Carbon 81:329–338

Bai H, Xu Y, Zhao L, Li C, Shi G (2009) Non-covalent functionalization of graphene sheets by sulfonated polyaniline. Chem Commun 1667–1669

Teng C-C, Ma C-CM LC-H, Yang S-Y, Lee S-H, Hsiao M-C, Yen M-Y, Chiou K-C, Lee T-M (2011) Thermal conductivity and structure of non-covalent functionalized graphene/epoxy composites. Carbon 49:5107–5116

Paci JT, Belytschko T, Schatz GC (2007) Computational studies of the structure, behavior upon heating, and mechanical properties of graphite oxide. J Phys Chem C 111:18099–18111

Satti A, Larpent P, Gun’ko Y (2010) Improvement of mechanical properties of graphene oxide/poly (allylamine) composites by chemical crosslinking. Carbon 48:3376–3381

Li YQ, Yu T, Yang TY, Zheng LX, Liao K (2012) Bio‐inspired nacre‐like composite films based on graphene with superior mechanical, electrical, and biocompatible properties. Adv Mater 24:3426–3431

Cheng Q, Wu M, Li M, Jiang L, Tang Z (2013) Ultratough artificial nacre based on conjugated cross‐linked graphene oxide. Angew Chem Int Ed 125:3838–3843

Tian Y, Cao Y, Wang Y, Yang W, Feng J (2013) Realizing ultrahigh modulus and high strength of macroscopic graphene oxide papers through crosslinking of mussel‐inspired polymers. Adv Mater 25:2980–2983

Hu H, Brown PH, Labavitch JM (1996) Species variability in boron requirement is correlated with cell wall pectin. J Exp Bot 47:227–232

Sudeep PM, Narayanan TN, Ganesan A, Shaijumon MM, Yang H, Ozden S, Patra PK, Pasquali M, Vajtai R, Ganguli S, Roy AK, Anantharaman MR, Ajayan PM (2013) Covalently interconnected three-dimensional graphene oxide solids. ACS Nano 7:7034–7040

Wei W, Yang S, Zhou H, Lieberwirth I, Feng X, Müllen K (2013) 3D graphene foams cross‐linked with pre‐encapsulated Fe3O4 nanospheres for enhanced lithium storage. Adv Mater 25:2909–2914

Wan W, Li L, Zhao Z, Hu H, Hao X, Winkler DA, Xi L, Hughes TC, Qiu J (2014) Ultrafast fabrication of covalently cross‐linked multifunctional graphene oxide monoliths. Adv. Funct, Mater

Sun H, Xu Z, Gao C (2013) Synergistically assembled carbon aerogels. Adv Mater 25:2554–2560

Huang H, Chen P, Zhang X, Lu Y, Zhan W (2013) Edge‐to‐edge assembled graphene oxide aerogels with outstanding mechanical performance and superhigh chemical activity. Small 9:1397–1404

Hu H, Zhao Z, Wan W, Gogotsi Y, Qiu J (2013) Ultralight and highly compressible graphene aerogels. Adv Mater 25:2219–2223

Yang X, Qiu L, Cheng C, Wu Y, Ma ZF, Li D (2011) Ordered gelation of chemically converted graphene for next‐generation electroconductive hydrogel films. Angew Chem Int Ed 50:7325–7328

Cong HP, Wang P, Yu SH (2014) Highly elastic and superstretchable graphene oxide/polyacrylamide hydrogels. Small 10:448–453

Wu L, Ohtani M, Takata M, Saeki A, Seki S, Ishida Y, Aida T (2014) Magnetically induced anisotropic orientation of graphene oxide locked by in situ hydrogelation. ACS Nano 8(5):4640–9

Compton OC, Cranford SW, Putz KW, An Z, Brinson LC, Buehler MJ, Nguyen ST (2012) Tuning the mechanical properties of graphene oxide paper and its associated polymer nanocomposites by controlling cooperative intersheet hydrogen bonding. ACS Nano 6:2008–2019

Arndt KF (2006) Hydrogel sensors and actuators. Frontiers 4

Zhang H, Kuila T, Kim NH, Yu DS, Lee JH (2014) Simultaneous reduction, exfoliation, and nitrogen doping of graphene oxide via a hydrothermal reaction for energy storage electrode materials. Carbon 69:66–78

Van Khai T, Na HG, Kwak DS, Kwon YJ, Ham H, Shim KB, Kim HW (2012) Influence of N-doping on the structural and photoluminescence properties of graphene oxide films. Carbon 50:3799–3806

Li M, Wu Z, Ren W, Cheng H, Tang N, Wu W, Zhong W, Du Y (2012) The doping of reduced graphene oxide with nitrogen and its effect on the quenching of the material’s photoluminescence. Carbon 50:5286–5291

Liu Y, Feng Q, Tang N, Wan X, Liu F, Lv L, Du Y (2013) Increased magnetization of reduced graphene oxide by nitrogen-doping. Carbon 60:549–551

Liu Y, Feng Q, Xu Q, Li M, Tang N, Du Y (2013) Synthesis and photoluminescence of F and N co-doped reduced graphene oxide. Carbon 61:436–440

Yang J, Jo MR, Kang M, Huh YS, Jung H, Kang Y-M (2014) Rapid and controllable synthesis of nitrogen doped reduced graphene oxide using microwave-assisted hydrothermal reaction for high power-density supercapacitors. Carbon 73:106–113

Yang S, Zhi L, Tang K, Feng X, Maier J, Müllen K (2012) Efficient synthesis of heteroatom (N or S)-doped graphene based on ultrathin graphene oxide-porous silica sheets for oxygen reduction reactions. Adv Funct Mater 22:3634–3640

Chen S, Chen P, Wang Y (2011) Carbon nanotubes grown in situ on graphene nanosheets as superior anodes for Li-ion batteries. Nanoscale 3:4323–4329

Wang K, Ruan J, Song H, Zhang JL, Wo Y, Guo SW, Cui DX (2013) Biocompatibility of graphene oxide. Nanoscale Res Lett 8(1):393

Liao KH, Lin YS, Macosko CW, Haynes CL (2011) Cytotoxicity of graphene oxide and graphene in human erythrocytes and skin fibroblasts. Acs Appl Mater Inter 3:2607–2615

Wojtoniszak M, Chen X, Kalenczuk RJ, Wajda A, Lapczuk J, Kurzewski M, Drozdzik M, Chu PK, Borowiak-Palen E (2012) Synthesis, dispersion, and cytocompatibility of graphene oxide and reduced graphene oxide. Colloids Surf B Biointerfaces 89:79–85

Begurn P, Ikhtiari R, Fugetsu B (2011) Graphene phytotoxicity in the seedling stage of cabbage, tomato, red spinach, and lettuce. Carbon 49:3907–3919

Pan DY, Wang S, Zhao B, Wu MH, Zhang HJ, Wang Y, Jiao Z (2009) Li storage properties of disordered graphene nanosheets. Chem Mater 21:3136–3142

Sun XM, Liu Z, Welsher K, Robinson JT, Goodwin A, Zaric S, Dai HJ (2008) Nano-graphene oxide for cellular imaging and drug delivery. Nano Res 1:203–212

Agarwal S, Zhou XZ, Ye F, He QY, Chen GCK, Soo J, Boey F, Zhang H, Chen P (2010) Interfacing live cells with nanocarbon substrates. Langmuir 26:2244–2247, http://pubs.rsc.org/en/content/articlehtml/2010/jm/c0jm01674h

Chang YL, Yang ST, Liu JH, Dong E, Wang YW, Cao AN, Liu YF, Wang HF (2011) In vitro toxicity evaluation of graphene oxide on A549 cells. Toxicol Lett 200:201–210

Ryoo SR, Kim YK, Kim MH, Min DH (2010) Behaviors of NIH-3 T3 fibroblasts on graphene/carbon nanotubes: proliferation, focal adhesion, and gene transfection studies. ACS Nano 4:6587–6598

Park S, Mohanty N, Suk JW, Nagaraja A, An JH, Piner RD, Cai WW, Dreyer DR, Berry V, Ruoff RS (2010) Biocompatible, robust free-standing paper composed of a TWEEN/graphene composite. Adv Mater 22:1736–40

Chen H, Muller MB, Gilmore KJ, Wallace GG, Li D (2008) Mechanically strong, electrically conductive, and biocompatible graphene paper. Adv Mater 20:3557–61

Ruiz ON, Fernando KAS, Wang BJ, Brown NA, Luo PG, McNamara ND, Vangsness M, Sun YP, Bunker CE (2011) Graphene oxide: a nonspecific enhancer of cellular growth. ACS Nano 5:8100–8107

Bao Q, Zhang D, Qi P (2011) Synthesis and characterization of silver nanoparticle and graphene oxide nanosheet composites as a bactericidal agent for water disinfection. J Colloid Interface Sci 360:463–470

Das MR, Sarma RK, Saikia R, Kale VS, Shelke MV, Sengupta P (2011) Synthesis of silver nanoparticles in an aqueous suspension of graphene oxide sheets and its antimicrobial activity. Coll Surf B Biointerf 83:16–22

Dikin DA, Stankovich S, Zimney EJ, Piner RD, Dommett GHB, Evmenenko G, Nguyen ST, Ruoff RS (2007) Preparation and characterization of graphene oxide paper. Nature 448:457–460

Buchsteiner A, Lerf A, Pieper J (2006) Water dynamics in graphite oxide investigated with neutron scattering. J Phys Chem B 110:22328–22338

Lerf A, Buchsteiner A, Pieper J, Sch枚ttl S, Dekany I, Szabo T, Boehm HP (2006) Hydration behavior and dynamics of water molecules in graphite oxide. J Phys Chem Solid 67:1106–1110

Jung I, Dikin D, Park S, Cai W, Mielke SL, Ruoff RS (2008) Effect of water vapor on electrical properties of individual reduced graphene oxide sheets. J Phys Chem C 112:20264–20268

Medhekar NV, Ramasubramaniam A, Ruoff RS, Shenoy VB (2010) Hydrogen bond networks in graphene oxide composite paper: structure and mechanical properties. ACS Nano 4:2300–2306

Acik M, Mattevi C, Gong C, Lee G, Cho K, Chhowalla M, Chabal YJ (2010) The role of intercalated water in multilayered graphene oxide. ACS Nano 4:5861–5868

Song L, Khoerunnisa F, Gao W, Dou W, Hayashi T, Kaneko K, Endo M, Ajayan PM (2013) Effect of high-temperature thermal treatment on the structure and adsorption properties of reduced graphene oxide. Carbon 52:608–612

Gao W, Singh N, Song L, Liu Z, Reddy ALM, Ci LJ, Vajtai R, Zhang Q, Wei BQ, Ajayan PM (2011) Direct laser writing of micro-supercapacitors on hydrated graphite oxide films. Nat Nanotechnol 6:496–500

Gao W, Wu G, Janicke MT, Cullen DA, Mukundan R, Baldwin JK, Brosha EL, Galande C, Ajayan PM, More KL (2014) Ozonated graphene oxide film as a proton‐exchange membrane. Angew Chem Int Ed 53:3588–3593

Karim MR, Hatakeyama K, Matsui T, Takehira H, Taniguchi T, Koinuma M, Matsumoto Y, Akutagawa T, Nakamura T, Noro S-I (2013) Graphene oxide nanosheet with high proton conductivity. J Am Chem Soc 135:8097–8100

Acknowledgement

W. G. sincerely thank for the start-up funding support from the Department of Textile Engineering, Chemistry and Science at North Carolina State University, Raleigh, NC.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Gao, W. (2015). The Chemistry of Graphene Oxide. In: Gao, W. (eds) Graphene Oxide. Springer, Cham. https://doi.org/10.1007/978-3-319-15500-5_3

Download citation

DOI: https://doi.org/10.1007/978-3-319-15500-5_3

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-15499-2

Online ISBN: 978-3-319-15500-5

eBook Packages: EnergyEnergy (R0)