Abstract

In China and South America, severe fouling problems caused by Limnoperna fortunei have been reported for a number of industrial facilities, including water and wastewater processing plants, power plants (nuclear, hydroelectric, thermal), refineries, steel mills, fish culture facilities, water transfer canals and aqueducts, and watercraft. In Japan, biofouling chiefly affects agricultural irrigation systems, balancing reservoirs and balancing tanks. However, most available reports furnish little detail on the components affected and on the measures taken to cope with the nuisance. Objective estimates of the economic losses involved are extremely rare. Although fouling by the golden mussel has occasionally derived in operation at below-standard regimes and even temporary plant shutoffs, as maintenance personnel acquired experience in curtailing mussel growth in sensitive areas, serious incidents have become less common. Fouling by L. fortunei has not caused a single definitive plant shutdown. Control methods assessed (either in laboratory settings or in actual plant operating conditions) include antifouling materials and coatings, chemical treatments, manual/mechanical cleaning, filtration, thermal shock, anoxia and hypoxia, desiccation, ozonation, ultraviolet treatment, electric currents, ultrasound, manipulations of flow speed, biological control, and various miscellaneous methods.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

In contrast to its known effects on ecosystems, which often differ from those of the zebra mussel (Boltovskoy and Correa 2015; see Chapter “Ecology and Environmental Impact of Limnoperna fortunei: Introduction” in this volume), the impacts of Limnoperna fortunei on man-made structures and facilities are almost identical to those described for dreissenid species. Hundreds of papers and several excellent reviews have been published concerning these impacts during the long history of the invasion of Western Europe and North America by the zebra and quagga mussels that began in the nineteenth century (Claudi and Mackie 1994; McMahon et al. 1994; Sprecher and Getsinger 2000; Rajagopal et al. 2000; Nalepa and Schloesser 2014). The comprehensive manual by Mackie and Claudi (2010) provides a detailed review of the problems caused by freshwater fouling mussels around the world, for which reason we will not repeat this information here.

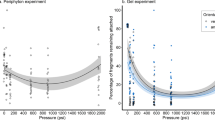

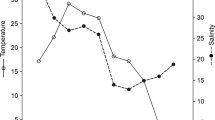

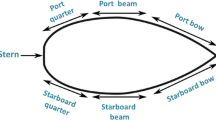

Location of some industrial facilities in a China and c South America that have experienced mussel-fouling problems. Power plants include hydroelectric, thermal and nuclear facilities. “Other facilities” include refineries, steel factories, water and food processing plants, etc. b Japanese prefectures where L. fortunei is present but does not cause major harm (yellow), where it was a nuisance in the past (pink), and where it presently represents a problem (red)

History, Spread, and General Appraisal of Macrofouling Problems Caused by the Golden Mussel

Although in its native range (China) the golden mussel has likely been a nuisance for centuries, information in the older Chinese scientific literature is oddly absent regarding L. fortunei and reports on macrofouling-related problems are restricted to marine mussels (e.g., Lou and Liu 1958). The presence of L. fortunei had been mentioned (Tchang et al. 1965), but information on its impacts on man-made structures is only found in isolated internal reports (GPS (Pipeline Study Group) 1973). This is partly due to the fact that until the first half of the twentieth century, the geographic range of the golden mussel was restricted to southern China, Thailand, Laos, Cambodia, and Vietnam. In the latter four countries, it was probably introduced through human actions (Morton and Dinesen 2010), and the range of L. fortunei started expanding greatly in the 1980s (Fig. 1). According to Xu (2013), L. fortunei was originally only found in southern China with the Yangtze River as its northern boundary. In the 1980s, it appeared in the Yellow River basin, and recently it has been found in the waters in and around Beijing (Ye et al. 2011) (see Chapter “Distribution and Spread of Limnoperna fortunei in China” in this volume). Thus, the first publications to point out the potentially harmful nature of the golden mussel (Morton 1973, 1975), as well as the first investigation on alternatives to control its fouling of raw water pipelines (Morton et al. 1976) are associated with the colonization of Hong Kong’s freshwater supply system through water diversion works from the East River, a tributary of the Pearl River, which forms part of the native range of the mussel. At approximately the same time, fouling by L. fortunei was reported in cooling water pipes of one of the largest steel mills in China—the Wuhan Iron and Steel Corporation (GPS (Pipeline Study Group) 1973), and in the 1980s problems became widespread affecting many industrial and water transfer facilities, like those of Handan in Hebei Province (Xiang 1985), Xiamen in Fujian Province, Wuxi and Suzhou in Jiangsu Province. Some, like the water treatment plant in Suzhou, had temporary shutoffs due to pipe clogging by L. fortunei (Luo 2006).

In order to facilitate the fast industrialization and modernization process of the last decades, numerous inter-basin water diversion projects have been undertaken in China, thus improving the distribution of water across the country. While beneficial for the country’s development, these aqueducts became a major vector for the mussel’s geographic spread (Xu et al. 2009a). Vivid examples of these problems are the water diversion works that draw water from the East River, a tributary of the Pearl River (Morton 1975; Xu 2013). One of these pipelines supplies water to Hong Kong and the western part of Shenzhen (Morton 1975), while another, “the East River Water Source Project,” transfers water to Huizhou, Dongguan, and the eastern part of Shenzhen (Xu 2013). All the reservoirs, lakes, and water transfer systems connected with these two water diversion works have already been colonized by golden mussels, thus requiring maintenance and cleaning tasks which, according to some estimates, amount to over US$ 1 million per year. Significantly, there are at least 30 such long-distance water diversion works in the Pearl river basin, built at a total estimated cost of US$ 12.4 billion (Guangdong Government 2010), almost all of which are potentially at risk of fouling by the golden mussel. Additional large aqueducts, in particular the huge “South-to-North Water Transfer Project” (Fig. 1), aimed at connecting the water-rich areas of the middle and lower Yangtze River with water-poor Beijing (see Fig. 1 in Chapter “Distribution and spread of Limnoperna fortunei in China” in this volume), will further worsen biofouling problems by L. fortunei.

In recent years, L. fortunei-related fouling became increasingly common in hydroelectric power stations. One of us (M. Xu) has had first hand contact with four of these power plants: Shisanling (in Beijing), Langyashan (in Anhui Province), Tianhuangping (in Zhejiang Province), and Guangxu (in Canton Province). This last one requested assistance for controlling the mussel. Fouling is common on concrete underwater structures, valves, trash racks, gates, etc. Dense mussel beds ca. 10 cm in thickness significantly increase resistance to water flow, enhance corrosion, clog pipes, jam mobile components, and pose serious safety risks for the plant’s personnel (Li and Su 2007; Yao and Xu 2013).

This issue has drawn increasing attention since 2000. As of 2013, at least eight major scientific and technological projects associated with freshwater mussel fouling are underway. Several control strategies have been attempted, either on experimental scales, and/or under plant operating conditions, with variable success (Table 1).

Outside of mainland China, reports of problems associated with fouling by L. fortunei in industrial and water-treatment facilities started appearing a few years after the mussel’s invasion. In Taiwan, Tan et al. (1987) reported heavy clogging of water intake grates at a water treatment facility, but they also mentioned that L. fortunei was first described from the island in 1941 (Kuroda 1941, as Volsella (Limnoperna) lacustris; although this record was subsequently questioned by Huang (2008). Interestingly, it was not included in the catalogue of Taiwanese terrestrial and freshwater mussels produced by Pilsbry and Hirase in 1905, which suggests the possibility that it was introduced between the turn of the century and 1940. In Korea, where it was introduced in the late 1970s to early 1980s, Kojima (1982) was the first to review its biology, fouling-related problems, and control alternatives. Some years later, it was reported from South America (Pastorino et al. 1993), and from Japan (Kimura 1994; Nakai et al. 1994).

In Japan, L. fortunei-related fouling problems are similar to those in other areas invaded. Affected facilities are chiefly water intake structures of drinking water treatment plants, hydroelectric power plants, and agricultural irrigation facilities.

Several water treatment plants have been affected by L. fortunei biofouling in the Yodo River system in Japan (Nakanishi and Mukai 1997). Problems included mass attachment of mussels on raw water screening structures, obstruction in strainers and pipes for water quality monitoring, accumulation of dead mussels in settling and flocculation chambers, and blockage of cooling system pipes for intake pumps. Control and mitigation strategies included several approaches. Where possible, mussels obstructing pipes and other components were removed by manual or mechanical cleaning with subsequent disposal of the mussels. Further clogging was deterred by (1) treating the water with chlorine, (2) adding filters and strainers at the intake in order to prevent larvae from entering the system, and (3) duplicating some components in order to allow for the decommissioning and cleaning of one while maintaining the second in operation.

As almost all thermal and nuclear power plants in Japan are located on the coast and use salt water for cooling purposes, biofouling by L. fortunei is restricted to hydroelectric power plants. Here, the main problems are mussel growth on intake screens and headrace channels. Manual and mechanical cleaning has traditionally been used to cope with the problem, although disposal of waste materials is still a major cause of concern. Obstruction of bulwark pipes, which protect water-level monitoring instruments, has resulted in gauge malfunctions and failures. These problems were solved by replacing regular bulwark pipes with new ones made of copper alloy. Blockage of electric generator cooling water pipes has occurred in some plants. Mechanical cleaning during routine inspection and maintenance operations has mitigated the problems, but some plants plan on installing alternative control methods such as self-cleaning microstrainers and thermal shock treatments, depending on plant characteristics.

Biofouling by L. fortunei has been extensive in agricultural irrigation systems of the Kanto (Katayama et al. 2005) and Tokai (Akehoshi 2011) regions. Mass attachment of L. fortunei has occurred on intake screens, irrigation channels, balancing reservoirs, and balancing tanks. Obstruction by L. fortunei is also common in strainers and pipeworks (especially small diameter, terminal pipes) of irrigation systems (Ministry of Agriculture Forestry and Fisheries of Japan 2012). Fouling of gauging instruments for water-level monitoring has resulted in their malfunction. Manual and mechanical removal of the mussels is the main control method so far, although alternative strategies, such as desiccation and antifouling coatings, are being considered (Ministry of Agriculture Forestry and Fisheries of Japan 2012).

In South America, the earliest cases of fouling by L. fortunei date from around 1994 (Darrigran 1995), ca. 3–4 years after its introduction in Argentina (see Chapter “Colonization and Spread of Limnoperna fortunei in South America” in this volume). Subsequently, literature mentioning problems in various industrial facilities grew exponentially, but many of these reports furnish little detail on the components affected and on the measures taken to cope with the nuisance. Many of these publications are based on circumstantial and ancillary data or on previous reports, and are basically restricted to general comments on the perils and harm brought about by the golden mussel. Given the fact that most of the available information on L. fortunei comes from biological journals, and that in-depth analyses of its impacts are more technological than biological in nature, this outcome is hardly surprising. Indeed, biological journals shun strictly technological issues, whereas technologically oriented publications normally cover topics of wider interest, rather than in-depth accounts of problems of a single industrial plant. Thus, detailed information on fouling by L. fortunei in man-made installations is largely restricted to internal reports of limited distribution, most of which are not accessible to the scientific community.

Furthermore, plant engineers, the chief actors in possession of first hand information, are not encouraged (and often not allowed to), trained for, or interested in publishing descriptions of the problems they encounter or their solutions. Availability of these internal reports is further restricted by the fact that control measures are in some cases potentially harmful to the environment (especially in the case of chemical control methods), in which case disclosure of these operations is avoided. There are a few notable exceptions, where researchers or technical personnel of infested facilities described their experience at regional meetings (Cepero 2003; Bendati et al. 2004; Oviedo Antunes and de Madrinag 2005; Figueiredo de Resende and Martinez 2008; Glaser 2011) or in various other publications (GPS (Pipeline Study Group) 1973; Magara et al. 2001; Portella Kleber et al. 2009; Mata 2011; Netto 2011). However, most literature where fouling-related problems in Argentina (Darrigran et al. 2002; Darrigran et al. 2007b); Brazil (Colares et al. 2002; Simeão et al. 2006; Rolla and Mota 2010; Borges et al. 2013); China (Morton 1975; Liu et al. 2011a; Liu et al. 2011b; Ye et al. 2011; Xu et al. 2012; see Table 1); Japan (Magara et al. 1999; Magara et al. 2001; Goto 2002; Yoshida 2006; Hamada 2008; 2010; Sawada and Nakamura 2010; Akehoshi 2011); Korea (Kojima 1982) and Uruguay (Brugnoli et al. 2012) are addressed (see also publications on control methods listed below) furnish limited information on affected plant components. Objective estimates of economic losses involved are extremely rare.

In South America, the large majority of the plants impacted by mussel fouling are located along the upper Río de la Plata estuary, Paraná, Paraguay, and Uruguay rivers, and their tributaries. There are also infested facilities (including a nuclear power station) in central Argentina (Córdoba province), chiefly along reservoirs connected with the Paraná waterway by the Tercero-Carcarañá rivers (Río de la Plata basin), as well as San Roque Reservoir (31.37°S, 64.47°W), which is fed by a small endorheic basin (see Chapter “Colonization and Spread of Limnoperna fortunei in South America” in this volume). Although practically all facilities using river, lake, or reservoir waters colonized by the mussel experience some difficulties, most acute problems affect those that use raw, untreated water, usually for cooling purposes. Water used for potabilization or closed-system cooling circuits (like the Argentine thermal power plant Termoeléctrica General Belgrano, in Campana, Buenos Aires Province) is subject to treatment (addition of chemicals, filtration) immediately after intake, thus eliminating or significantly reducing densities of mussel larvae before they reach other plant components. In this case, clogging and overgrowth problems are normally restricted to the intake piping systems, pumps, trash racks, grates, and screens. Typically, power plants (hydroelectric, thermal, nuclear) use untreated water to eliminate excess heat, and are therefore affected the most by mussel fouling (O’Neill 1997).

While problems have been described throughout the area colonized by the mussel, Brazil has been impacted more severely because of the large number of hydroelectric plants involved. As of 2013, the mussel was present in at least 33 Brazilian hydroelectric power plants along the Paraná River and its tributaries (Borges et al. 2013; Fig. 1c). Netto (2011) estimated that shutoff of a single 40 MW turbine for servicing may cost as much as US$ 17,000 per day in lost power generation alone.

It is noteworthy that not all installations using raw water from mussel-infested areas are equally prone to fouling. The mode in which water is used may largely determine whether a system will get fouled or not. For example, large gated communities in the vicinity of major cities, like Buenos Aires, often process their own water when a nearby source is available. These settlements usually have separate lines for potable water and irrigation water; the latter is only filtered, but not made potable. Thus, irrigation pipes are in principle vulnerable to mussel fouling. However, normally they are not affected because, as opposed to potable water, which is used permanently, irrigation water is used intermittently, often with long gaps during rainy weather. During these stagnant periods, water in the pipes becomes anoxic rapidly, thus killing organisms trapped inside, including L. fortunei larvae and settled individuals (Boltovskoy and Correa 2006).

Facilities and Components Affected

The problems caused by L. fortunei are practically identical to those reported for Dreissena species (but not the efficacy of many of the control methods; see following chapters), which allows extrapolating from the extensive literature for the dreissenids (Mackie and Claudi 2010; Prescott et al. 2014). Any facility drawing raw water from a surficial source colonized by the mussel (rivers, lakes, reservoirs) can be affected. In Asia and South America, some of the installations that reported problems associated with mussel fouling include the following (Fig. 1):

Water and wastewater processing plants. China: Suzhou; Japan: Hanshin Water Supply Authority, Lake Biwa-Yodo River system, Osaka Prefectural Water Works Department; Argentina: AySA La Plata, AySA Palermo, AySA Bernal, Aguas Santafesinas, Aguas Cordobesas; Taiwan: Jyr-Tan pumping station

Nuclear power plants. Argentina: Central Nuclear Embalse, Central Nuclear Atucha I

Hydroelectric plants. China: Shisanling (Beijing), Langyashan (Anhui Province), Tianhuangping (Zhejiang Province), Guangxu (Shenzhen); Japan: Yahagi River; South America: Itaipu (Brazil/Paraguay), Yacyretá (Argentina/Paraguay), Salto Grande (Argentina/Uruguay), Fitz Simon, Cassafousth, Reolín, Piedras Moras, San Roque, La Calera (Argentina), Constitución (Uruguay), over 30 plants on the upper Paraná River and its tributaries (Paranaíba, Aporé, Claro, etc., Brazil)

Thermal power plants. Argentina: Central Puerto

Refineries. Argentina: Shell CAPSA (Dock Sud), ESSO (Campana)

Steel mills. China: Wuhan Iron and Steel Corporation; Argentina: Acindar

Food processing plants. Argentina: Tres Cruces

Fish culture facilities. China: Longtan Reservoir in Guangxi Province; South America: Itaipu Reservoir (clogging of net cages for pacu—Piaractus mesopotamicus), Esturiones del Río Negro (clogging of fish farming components for sturgeon—Acipenser baerii baerii in Río Negro, Uruguay)

Irrigation canals. Widespread in China and Japan

Water transfer canals, pipelines, drainage systems, and aqueducts. China: Shenzhen Dongjiang, East River to Plover Cove, Xizhijiang River, and many others

Navigation dams. Brazil

Stream level gauging components. Widespread in Japan

Watercraft (commercial and leisure boats, ships). Widespread in Argentina, Brazil, Paraguay, Uruguay

Fish diversion components. Widespread in Japan

Various industrial plant components fouled by L. fortunei. a and b Heat exchange elements clean (a) and fouled (b) (Embalse de Río Tercero nuclear power plant, Argentina). c and d Steel grate protecting the raw water intake at the Atucha I nuclear power plant (Argentina) clean (c) and heavily fouled (d). e Grit chamber at Yonghu Pump Station in Huizhou, Guangdong Province, China (notice accumulation of dead L. fortunei shells on the bottom). f Internal wall of water transfer pipe of the East River Water Source Project. g Screen at the water intake of Dongjiang Pump Station in Huizhou (Guangdong Province, China). h Propeller shaft and supporting structure fouled by L. fortunei (leisure boat, Embalse de Río Tercero, Argentina). i Raw water pipe (drinking water processing plant in Villa del Dique, Argentina; from Anonymous 2006). j Fouling of hydroelectric plant components in Itaipú (Brazil/Paraguay; from http://sosriosdobrasil.blogspot.com.ar/2011/04/praga-do-mexilhao-dourado-deixa-em.html). k Fouled gate slots at Xizhijiang Pump Station in Huizhou (Guangdong Province, China). l Fouled filters of a transformer cooling unit, Salto Grande hydroelectric plant (Argentina/Uruguay). m Clogged hole in butterfly valve at Xizhijiang Pump Station in Huizhou (Guangdong Province, China). n Steel grates protecting the raw water intake at the Embalse de Río Tercero nuclear power plant (Argentina)

The most common raw water components affected by mussel fouling include the following (see McMahon et al. 1994; Prescott et al. 2014):

Heat exchangers and condensers (Fig. 2a, b, j, l);

Strainers, filters, trash racks, grates, screens (Fig. 2c, d, g, n);

Penstocks;

Holding ponds, storage tanks, pump suction chambers, pump wells;

Water intake tunnels (Fig. 2f);

Sand filtration systems;

Pumps, nozzles, and sprinklers;

Vent lines, and air release valves;

Fire protection equipment;

Grit chambers, flocculators (Fig. 2e);

Submerged monitoring instrumentation, level gauges;

Pump and turbine shafts, seals, and wear rings;

Boat engines (cooling water ducts, filters, pumps) and submerged rudder and propulsion components (Fig. 2h).

The problems most commonly reported are associated with the following:

Clogging (by colonies of living L. fortunei and/or by dead, dislodged shell clusters), pressure loss, overheating;

Corrosion, erosion, and abrasion;

Deterioration of metal, concrete and other materials from fouling by organisms associated with mussel beds (bacteria, fungi);

Wear (pump/turbine shaft seals, pumps and turbine wear rings, slurry pump seals);

Jamming of moving components, poor sealing (stop logs, valves, boat underwater rudder and propulsion components);

Sediment accumulation;

Accumulation of dead specimens (e.g., in grit chambers, flocculators);

Nuisance to bathers (in recreational areas from colonization of submerged rocks);

Promotion of Microcystis growth, hindering use of the waterbodies for recreation, causing fish mortality, hampering potabilization, etc.;

Pollution, water quality deterioration from decomposition of dead mussels and mussel waste products.

While the economic losses involved are probably significant, with very few exceptions detailed information on the extra costs of dealing with the golden mussel have not been reported. Fouling problems invariably involve an increase in the number of man-hours devoted to cleaning and other maintenance procedures. For example, at the Salto Grande (Argentina/Uruguay) hydroelectric power plant each turbine is subject to a cleaning and maintenance routine every 7 years. Before the introduction of L. fortunei cleaning the penstock walls took 2 days of work. With the establishment of the mussel in the reservoir, the same operation now requires 10 days (Glaser 2011). Additional maintenance procedures not only involve higher costs from increased man-hour expenditures, but they also affect the lifetimes of the components that decrease from additional handling. In some cases, partial blockage of cooling systems involves operation at below-standard regimes, which may significantly affect power production and, consequently, revenues (e.g., the Central Puerto thermal power plant in Buenos Aires, Argentina). Chemical control strategies involve the costs of initial design and installation of the dosage components, and the costs of the chemical products. In many cases, detoxification of the water may be required before returning it to the lake or river, which further increases costs. Environmentally friendlier treatments, like UV, are limited by the turbidity of the water and, when viable, may use large amounts of electric power (Perepelizin and Boltovskoy 2014).

Through consulting work and personal contacts, we know that some plants have had serious fouling-related problems leading to temporary shutoffs (e.g., a water treatment plant in Suzhou, China; the nuclear power plants Atucha I and Embalse in Argentina; the hydroelectric plant Yacyretá in Argentina/Paraguay, a water treatment plant in the Yodo River area, Osaka, Japan, etc.). However, as maintenance personnel became familiar with the problem and acquired experience in curtailing mussel growth in sensitive areas, serious incidents have become less common. To our knowledge, fouling by L. fortunei has not caused a single definitive plant shut down. All plants have developed alternatives for curtailing the impacts of fouling and remain operational (see Chapter “Control of Limnoperna fortunei Fouling: Antifouling Materials and Coatings” in this volume).

Control Strategies Assayed

As of 2013, there are around 100 publications dedicated specifically to the investigation of various methods aimed at eliminating L. fortunei fouling in industrial installations, over half of them centered on chemical treatments and antifouling materials and coatings. Most are based on laboratory studies, and a smaller number present studies in actual operating plants. The following listing summarizes the most relevant works, grouped thematically (see also Table 1):

Antifouling materials and coatings: Stupak et al. (1996); Gemini (1999); Matsui et al. (1999); Ohkawa et al. (1999); Garcia Sola et al. (2000); Matsui et al. (2001); Nagaya et al. (2001); Ohkawa et al. (2001); Caprari and Lecot (2002); Matsui et al. (2002); Caprari (2006); Faria et al. (2006); Luo (2006); Zhuang (2006); Perez Bergmann et al. (2010a); Perez Bergmann et al. (2010b)

Chemical treatments: Morton et al. (1976); Darrigran et al. (2001); Cataldo et al. (2003); Luo et al. (2006); Zhuang (2006); Darrigran et al. (2007a); Xu et al. (2009b); Asolkar et al. (2010); Kim et al. (2011); Netto (2011); Pereyra et al. (2011); Calazans and Fernandes (2012); Calazans et al. (2012); Godoy Fernandes et al. (2012); Liu et al. (2012); Pereira and Soares (2012); Pereyra et al. (2012); Calazans et al. (2013); Netto (2013); Mata et al. (2013); Montresor et al. (2013)

Manual/mechanical cleaning: Glaser (2011); Ye et al. (2011); Ministry of Agriculture Forestry and Fisheries of Japan (2012)

Filtration: Zhuang (2006)

Thermal shock: Montalto and Marchese (2003); Perepelizin (2011); Perepelizin and Boltovskoy (2011a); Perepelizin and Boltovskoy (2011c)

Anoxia and hypoxia: Liu et al. (2006); Perepelizin (2011); Perepelizin and Boltovskoy (2011b); Ye et al. (2011)

Desiccation: Iwasaki (1997); Montalto and Ezcurra de Drago (2003); Darrigran et al. (2004)

Ozonation: Xu et al. (2009b)

Ultraviolet treatment: Santos (2011); Santos et al. (2012a); Perepelizin and Boltovskoy (2014)

Electric currents: Maeda et al. (2003); Katsuyama et al. (2005)

Ultrasound: Santos et al. (2012b)

Manipulations of flow speed: Xiang (1985); Nagaya et al. (2001); Matsui et al. (2002); Oviedo Antunes and de Madrinag (2005); Ye et al. (2011); Xu et al. (2012)

Biological control: Luo et al. (2006); Xu (2013)

Miscellaneous methods: Ratkiewicz (2006); Padula Paz et al. (2012); Rackl et al. (2012); Xu (2013); Xu et al. (2013); Dengo and Carraro (2013)

These methods are treated in detail in the sections that follow.

References

Akehoshi Y (2011) Study of ecological features and prevention of damage of Limnoperna fortunei in the irrigation institution. Rep Yahagi Riv Inst 15:55–63 [In Japanese]

Anonymous (2006) El mejillón dorado (Limnoperna fortunei). Los serios problemas que origina en la planta potabilizadora. NotiCoop (Boletín Informativo de la Cooperativa de Obras y Servicios Públicos Limitada de Villa del Dique, Provincia de Córdoba, Argentina) 42:22–23

Asolkar R, Dow H, Huang M, Koivunen D, Marrone P, Shu S (2010) Chemical and biological agents for the control of molluscs. The United States Patent and Trademark Office (Pub. No.: 2010/0266717A1)

Bendati MMA, Suminski M, Colares ERC (2004) Avaliação da operação dos sistemas de abastecimento de água do DMAE (Porto Alegre, Brasil) em decorrência da presença do mexilhão-dourado (Limnoperna fortunei). In: I Congresso Interamericano de Saúde Ambiental, Porto Alegre (Brazil)

Boltovskoy D, Correa G (2006) Informe sobre la vulnerabilidad potencial de los sistemas de agua de riego de Nordelta a las incrustaciones del bivalvo Limnoperna fortunei. Nordelta, pp 1–77

Boltovskoy D, Correa N (2015) Ecosystem impacts of the invasive bivalve Limnoperna fortunei (golden mussel) in South America. Hydrobiologia. 746:81–95

Borges P, Mäder O, Ludwig S, Duarte J, Bastos L, Lima F, Cardoso C, Nakayama D, Borba R (2013) Atual distribuição do molusco invasor Limnoperna fortunei (Dunker, 1857) no Brasil: registros em usinas hidrelétricas. In: 1 Congreso Argentino de Malacología, La Plata (Argentina)

Brugnoli E, Russo R, Mandiá M, Muñiz P (2012) Estudios para la mitigación del macrofouling ocasionado por especies invasoras acuáticas en áreas industriales y de servicio en Uruguay. In: Aber A, Ferrari G, Porcile JF, Rodríquez E, Zerbino S (eds) Identificación de prioridades para la gestión nacional de las especies exóticas invasoras, Comité Nacional de Especies Exóticas Invasoras, Montevideo, pp 62–83

Calazans SHC, Fernandes FC (2012) Microencapsulados. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 299–302

Calazans SHC, Godoy Fernandes LV, Fernandes FC (2012) Outros compostos. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 311–315

Calazans SHC, Americo JA, Fernandes FD, Aldridge DC, Rebelo MD (2013) Assessment of toxicity of dissolved and microencapsulated biocides for control of the golden mussel Limnoperna fortunei. Mar Environ Res 91:104–108

Caprari JJ (2006) Pinturas antiincrustantes. In: Darrigran G, Damborenea C (eds) Bio-invasión del mejillón dorado en el continente americano. Editorial de la Universidad de La Plata, La Plata, pp 183–213

Caprari JJ, Lecot CJ (2002) El control de bivalvos invasores Limnoperna fortunei (Dunker, 1857) en la central hidroeléctrica Yaciretá mediante pinturas. In: Seminario Internacional—Gestión Ambiental e Hidroelectricidad, Salto Grande

Cataldo D, Boltovskoy D, Pose M (2003) Toxicity of chlorine and three non-oxidizing molluscicides to the invasive pest mussel Limnoperna fortunei. J Am Water Work Assoc 95:66–78

Cepero E (2003) Control de Limnoperna fortunei. Infestación de plantas potabilizadoras de agua. In: 13 Congreso Argentino de Saneamiento y Medio Ambiente, Buenos Aires (Argentina)

Claudi R, Mackie GL (1994) Controlling zebra mussels at water treatment plant intakes. CRS Press, Boca Raton, pp 1–227

Colares ERC, Suminski M, Bendati MMA (2002) Diagnóstico e controle do mexilhão-dourado, Limnoperna fortunei, em sistemas de tratamento de água em Porto Alegre (RS, Brasil). In: VI Simpósio Ítalo-Brasileiro de Engenharia Sanitária e Ambiental, Vitória (Brazil)

Darrigran GA (1995) Limnoperna fortunei: ¿un problema para los sistemas naturales de agua dulce del Mercosur? Museo (Revista de la Fundación Museo de La Plata “Francisco Pascasio Moreno”) 5:85–87

Darrigran GA, Maroñas ME, Colautti DC (2001) Primeras estimaciones de concentraciones letales de un biocida para el molusco invasor Limnoperna fortunei (Mytilidae). In: Seminario Internacional—Gestión Ambiental e Hidroelectricidad, Salto Grande

Darrigran GA, Penchaszadeh PE, Damborenea C, Greco N (2002) Abundance and distribution of golden mussel (Limnoperna fortunei ) larvae in a hydroelectric power plant in South America. In: 11th International Conference on Aquatic Invasives Species, Alexandria

Darrigran GA, Maroñas ME, Colautti DC (2004) Air exposure as a control mechanism for the golden mussel, Limnopema fortunei, (Bivalvia: Mytilidae). J Freshw Ecol 19:461–464

Darrigran GA, Colautti DC, Maroñas ME (2007a) Potential biocide for control of the golden mussel, Limnoperna fortunei. J Freshw Ecol 22:359–360

Darrigran GA, Damborenea C, Greco N (2007b) An evaluation pattern for antimacrofouling procedures: Limnoperna fortunei larvae study in a hydroelectric power plant in South America. Ambio 36:575–579

Dengo RR, Carraro I (2013) Controle preventivo do mexilhão dourado em sistemas de abastecimento de água da CORSAN. Trabalho prévio de seleção de tecnologias de controle. CORSAN Report. Porto Alegre (Brazil), pp 1–38

Faria EA, Tavares Branco JR, Campos MCS, Oliveira MD, Rolla ME (2006) Estudo das características antiincrustantes de materiais. Relatorio Escola de Minas, Ouro Preto 59:233–238

Figueiredo de Resende M, Martinez CB (2008) Impacto da infestação de condutos forçados de PCH’s pelo Limnoperna fortunei. In: VI Simpósio Brasileiro sobre Pequenas e Médias Centrais Hidrelétricas, Belo Horizonte (Brazil)

Garcia Sola E, Leiva Azuaga A, Niveyro G (2000) Evolución de los moluscos invasores “Limnoperna fortunei” en la región. Universidad Nacional del Nordeste. Comunicaciones Científicas y Tecnológicas de la Universidad Nacional del Nordeste, Universidad Nacional del Nordeste, pp 1–4

Gemini H (1999) Ensayo con pintura antifouling en calle UE2. Nuceoeléctrica Argentina Sociedad Anónima, Central Nuclear Atucha I. Lima (Argentina), pp 1–12

Glaser R (2011) Descripción de la invasión del mejillón dorado en instalaciones mecánicas de la represa de Salto Grande. In: Jornada de Difusión, Programas Ambientales de Salto Grande, Salto Grande (Uruguay)

Godoy Fernandes LV, Calazans SHC, Fernandes FC (2012) Formas de Cloro. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 303–306

Goto Y (2002) Behavior of nuisance mussel, Limnoperna fortunei, in water supply facilities. Water Sci Technol 46:45–50

GPS (Pipeline Study Group) (1973) Biology of golden mussel (Limnoperna fortunei ). Animal’s use and prevention. Institute of Aquatic Organisms of the Chinese Academy of Sciences, Beijing, pp 33–36 [In Chinese]

Guangdong Government (2010) The pearl river delta infrastructure integration planning (2009–2020). http://www.gd.gov.cn/govpub/rdzt/ghgy2/wjzl/201008/t20100816_127497.htm. Accessed: 20 Jan 2014 [In Chinese]

Hamada M (2008) The ecology of the golden mussel that has Invaded the Yahagi River System. Technol Dev News 130:21–22 [In Japanese]

Hamada M (2010) History of invasion and present status of the golden mussel Limnoperna fortunei in Central Japan. Sessile Org 27:7–16 [In Japanese]

Huang CW (2008) Population genetic structure of Limnoperna fortunei (Dunker, 1857) in Taiwan based on sequences of mitochondrial cytochrome C oxidase subunit I. MSc Thesis, National Changhua University of Education (Taiwan), pp 1–60

Iwasaki K (1997) Climbing behaviour and tolerance to aerial exposure of a freshwater mussel, Limnoperna fortunei. Venus (Jpn J Malacol) 56:15–25

Katayama M, Shimizu R, Matsumoto H (2005) The first record of Limnoperna fortunei (Bivalvia, Mytilidae) in Gunma. Field Biol 14:35–40 [In Japanese]

Katsuyama I, Satuito CG, Maeda T, Oonishi M, Kumagai T (2005) The effect of DC-pulse electric stimulus on the swimming behavior of larvae of the freshwater mussel Limnoperna fortunei in flowing water within a pipe. Sessile Org 2:1–5 [In Japanese]

Kim D, Suok H, Eunjae J, Changsoo S, Youngbeom Y, Seungkwan H (2011) Prechlorination at water intake for the quality improvement of raw water. J Korean Soc Water Qual 27:110–114 [In Korean]

Kimura T (1994) The earliest record of Limnoperna fortunei (Dunker) from Japan. Chiribotan (J Malacol Soc Jpn) 25:34–35 [In Japanese]

Kojima S (1982) The trouble by fresh water shell (Limnoperna fortunei ) and its control. Jpn J Water Treat Biol 18:29–33 [In Japanese]

Kuroda T (1941) A catalogue of molluscan shells from Taiwan (Formosa), with descriptions of new species. Mem Fac Sci Agric, Taihoku Imp Univ 22:65–216

Li MJ, Su XM (2007) Analysis and evaluation of countermeasures to mussel fouling in the long distance water transport canal, Pearl River. Pearl River 3:29–30 [In Chinese]

Liu L, You Z, Luo F, Zhang J, Ouyang S (2006) Killing and removing Limnoperna fortunei from raw water pipe by isolating oxygen. Water Wastewater Eng 22:40–42, 47

Liu D, Hong J, Wang R, Cui F (2011a) Current solution to Limnoperna fortunei problem in water and pipelines. In: Second international conference on artificial intelligence, management science and electronic commerce (Aimsec 2011), Deng Feng

Liu D, Wang R, Cui F, Zhao Y, Hong J, Chen W, Wang C (2011b) The harm and control technology of Limnoperna fortunei. In: International conference on remote sensing, environment and transportation engineering, Nanjing [In Chinese]

Liu D-M, Wang R, Hong J, Cui F-Y, Chen W-X, Wang C-H, Chen C-X (2012) Experimental studies of inactivation effect on Limnoperna fortunei with potassium permanganate. J Harbin Inst Technol 44:46–49

Lou KH, Liu J (1958) Study on prevention and extermination of mussel growths in pipelines. Oceanologia et Limnologia Sinica 1:316–324 [In Chinese]

Luo FM (2006) Studies on biology and control techniques of Limnoperna fortunei (Duker) in water supply system of Shenzhen city. MSc Thesis, Nanchang University (China), pp 1–108 [In Chinese]

Luo F, Liu L, You Z, Huang W, Deng H, Ouyang S (2006) Study on solvability of Limnoperna fortunei byssus cohering in raw water pipe. Water Wastewater Eng 3:29–32 [In Chinese]

Mackie GL, Claudi R (2010) Monitoring and control of macrofouling mollusks in fresh water systems. CRC Press, Boca Raton, pp 1–508

Maeda T, Matsui N, Onishi M (2003) Development of prevention system against pollution by bivalve, Limnoperna lacustris. R & D News Kansai 417:20–21

Magara Y, Matsui Y, Nagaya K, Yuasa A (1999) Japanese experience with the freshwater adhesive mussel, Limnoperna fortunei. In: 9th international zebra Mussel and aquatic nuisance species conference, Duluth

Magara Y, Matsui Y, Goto Y, Yuasa A (2001) Invasion of the non-indigenous nuisance mussel, Limnoperna fortunei, into water supply facilities in Japan. J Water Supply: Res Technol—Aqua 50:113–124

Mata FAR (2011) Abundância e distribuição temporal de Limnoperna fortunei Dunker, 1857 (Mollusca, Bivalvia) e os impactos da incrustação em usinas geradoras de energia elétrica. MSc Thesis, Universidade Federal de Ouro Preto (Brazil), pp 1–91

Mata FAR, Dias C, Mader O (2013) Utilização do remediador MXD-100 para controle de incrustação em sistemas de resfriamento de usinas hidrelétricas, ocasionada por Limnoperna fortunei (Dunker, 1857). In: 1 Congreso Argentino de Malacología, La Plata (Argentina)

Matsui Y, Nagaya K, Yuasa A, Yamamoto H, Ohkawa K, Magara Y (1999) Control efficacy of the Asian freshwater mussel Limnoperna fortunei for coating and materials. In: 9th international zebra mussel and aquatic nuisance species conference, Duluth

Matsui Y, Nagaya K, Yuasa A, Naruto H, Yamamoto H, Ohkawa K, Magara Y (2001) Attachment strength of Limnoperna fortunei on substrates, and their surface properties. Biofouling 17:29–39

Matsui Y, Nagaya K, Funahashi G, Goto Y, Yuasa A, Yamamoto H, Ohkawa K, Magara Y (2002) Effectiveness of antifouling coatings and water flow in controlling attachment of the nuisance mussel Limnoperna fortunei. Biofouling 18:137–148

McMahon RF, Ussery TA, Clarke M (1994) Review of zebra mussel control methods (Technical Note ZMR-2-14). US Army Corps of Engineers, Waterways Experiment Station (Vicksburg, MS), Report ZMR-2-14. Vicksburg, pp 1–12

Ministry of Agriculture Forestry and Fisheries of Japan (2012) Practical manual for Limnoperna fortunei. http://www.maff.go.jp/j/nousin/kankyo/kankyo_hozen/k_hozen/pdf/kawahibarimanual.pdf. Accessed: 9 May 2014 [In Japanese]

Montalto L, Ezcurra de Drago I (2003) Tolerance to desiccation of an invasive mussel, Limnoperna fortunei (Dunker, 1857) (Bivalvia, Mytilidae), under experimental conditions. Hydrobiologia 498:161–167

Montalto L, Marchese M (2003) Limnoperna fortunei (Dunker, 1857) (Bivalvia, Mytilidae) tolerance to temperature and pH in experimental conditions. Neotropica 49:26–34

Montresor LC, Miranda-Filho KC, Paglia A, Luz DM, Araujo JM, Silva MJS, Gerhard L, Martinez CB, Vidigal TH (2013) Short-term toxicity of ammonia, sodium hydroxide and a commercial biocide to golden mussel Limnoperna fortunei (Dunker, 1857). Ecotoxicol Environ Saf 92:150–154

Morton B (1973) Some aspects of the biology and functional morphology of the organs of feeding and digestion of Limnoperna fortunei (Dunker) (Bivalvia: Mytilacea). Malacol 12:265–281

Morton B (1975) The colonization of Hong Kong’s raw water supply system by Limnoperna fortunei (Dunker 1857) (Bivalvia: Mytilacea) from China. Malacol Rev 8:91–105

Morton B, Dinesen G (2010) Colonization of Asian freshwaters by the Mytilidae (Bivalvia): a comparison of Sinomytilus harmandi from the Tonle-Sap River, Phnom Penh, Cambodia, with Limnoperna fortunei. Molluscan Res 30:57–72

Morton B, Au CS, Lam WW (1976) Control of Limnoperna fortunei. J Inst Water Eng Sci 30:147–156

Nagaya K, Matsui Y, Ohira H, Yuasa A, Yamamoto H, Ohkawa K, Magara Y (2001) Attachment strength of an adhesive nuisance mussel, Limnoperna fortunei, against water flow. Biofouling 17:263–274

Nakai K, Niimura Y, Yamada J (1994) Distribution of the freshwater mytilid mussel, Limnoperna fortunei, in the rivers, Nagara-gawa and Ibi-gawa, central Japan. Venus (Jpn J Malacol) 53:139–140 [In Japanese]

Nakanishi M, Mukai S (1997) Growth and extermination of Limnoperna fortunei (Dunker 1857) at water purification facilities. Yousui to Haisui [J Water Waste] 39:1017–1020 [In Japanese]

Nalepa TF, Schloesser DW (eds) (2014) Quagga and zebra mussels: biology, impacts, and control, 2nd edn. CRC Press, Boca Raton, pp 1–815

Netto OSM (2011) Controle da incrustação de organismos invasores em materiais de sistemas de resfriamento de usinas hidrelétricas. MSc Thesis, Universidade Federal de Curitiba (Brazil), pp 1–113

Netto OSM (2013) Impactos econômicos e métodos de controle de moluscos invasores em plantas industriais. In: 1 Congreso Argentino de Malacología, La Plata (Argentina)

O’Neill JR (1997) Economic impact of zebra mussels: results of the 1995 national zebra mussel information clearinghouse study. Gt Lakes Res Rev 3:35–42

Ohkawa K, Nishida A, Honma R, Matsui Y, Nagaya K, Yuasa A, Yamamoto H (1999) Studies on fouling by the freshwater mussel Limnoperna fortunei and the antifouling effects of low energy surfaces. Biofouling 13:337–350

Ohkawa K, Ichimiya K, Nishida A, Yamamoto H (2001) Synthesis and surface chemical properties of adhesive protein of the Asian freshwater mussel, Limnoperna fortunei. Macromol Biosci 1:376–386

Oviedo Antunes H, de Madrinag TG (2005) La presencia del bivalvo Limnoperna fortunei (mejillón dorado) en la Central Hidroeléctrica de Itaipu. Itaipú Binacional. Informe Técnico. Itaipu (Brazil-Praguay), pp 1–7

Padula Paz IC, Pereira D, Souza AMS (2012) Controle Microbiano. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 351–356

Pastorino G, Darrigran GA, Martín SM, Lunaschi L (1993) Limnoperna fortunei (Dunker, 1857) (Mytilidae), nuevo bivalvo invasor en aguas del Río de la Plata. Neotropica 39:101–102

Pereira D, Soares MF (2012) Sulfato de Cobre. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 307–309

Perepelizin PV (2011) Alternativas ambientalmente inocuas (no químicas) para el control del mejillón incrustante Limnoperna fortunei en instalaciones industriales. PhD Thesis, Universidad de Buenos Aires (Argentina), pp 1–126

Perepelizin PV, Boltovskoy D (2011a) Hot water treatment (chronic upper lethal temperature) mitigates biofouling by the invasive Asian mussel Limnoperna fortunei in industrial installations. Environ Sci Technol 45:7868–7873

Perepelizin PV, Boltovskoy D (2011b) Resistance of the invasive pest mussel Limnoperna fortunei to anoxia. J Am Water Works Assoc 103:79–85

Perepelizin PV, Boltovskoy D (2011c) Thermal tolerance of Limnoperna fortunei to gradual temperature increase and its applications for biofouling control. Biofouling 27:667–674

Perepelizin PV, Boltovskoy D (2014) Effects of 254 nm UV irradiation on the mobility and survival of larvae of the fouling invasive mussel Limnoperna fortunei. Biofouling 30:197–202

Pereyra PJ, Rossini GB, Darrigran GA (2011) Toxicity of three commercial tannins to the nuisance invasive species Limnoperna fortunei (Dunker, 1857): implications for control. Fresenius Environ Bull 20:1432–1437

Pereyra PJ, Rossini GB, Darrigran GA (2012) Toxicity of Neem’s oil, a potential biocide against the invasive mussel Limnoperna fortunei (Dunker 1857). Anais da Academia Brasileira de Ciências 84:1065–1071

Perez Bergmann C, Mansur MCD, Bergonci PEA, Pereira D, Santos CP, Basegio T, Vicenzi J, Santos SCA (2010a) Seleção de materiais e revestimentos para o controle de incrustações do mexilhão dourado na Usina Hidrelétrica de Ibitinga (SP, Brasil). Revista Matéria 15:21–30

Perez Bergmann C, Mansur MCD, Pereira P, Bergonci PEA, Santos CP, Basegio T, Vicenzi J, Santos SCA (2010b) Avaliação de materiais e revestimentos para o controle de incrustações do mexilhão dourado Limnoperna fortunei (Dunker, 1857). Biotemas 23:87–100

Pilsbry HA, Hirase Y (1905) Catalogue of the land and fresh-water Mollusca of Taiwan (Formosa), with descriptions of new species. Proc Acad Nat Sci Phila 57:720–752

Portella Kleber F, Joukoski A, Sheffer da Silva A, Machuca Brassac N, Belz CE (2009) Biofouling e biodeterioração química de argamassa de cimento portland em reservatório de usina hidroelétrica. Quimica Nova 32:1047–1051

Prescott TH, Claudi R, Prescott KL (2014) Impact of dreissenid mussels on the infrastructure of dams and hydroelectric power plants. In: Nalepa TF, Schloesser DW (eds) Quagga and zebra mussels: biology, impacts, and control, 2nd edn. CRC Press, Boca Raton, pp 244–257

Rackl S, Koivunen M, Marrone P, Huang H, Asolkar R (2012) Agents for the control of Limnoperna sp. United States Patent and Trademark Office (Pub. No. 20120121745A1)

Rajagopal S, Jenner HA, Venugopalan VP (eds) (2012) Operational and environmental consequences of large industrial cooling water systems. Springer, New York, pp 1–477

Ratkiewicz MLA (2006) Relatório da experiência piloto dos equipamentos da LGM-DANSUL para controle da infestação por mexilhões dourados na EBAB e incrustações na adutora de água bruta da US de Barra do Ribeiro. DEPEDET/SUMOP/CORSAN. Porto Alegre, pp 1–18

Rolla ME, Mota HR (2010) Response of a major Brazilian utility to the golden mussel invasion. In: Mackie GL, Claudi R (eds) Monitoring and control of macrofouling mollusks in fresh water systems. CRC Press, Boca Raton, pp 396–403

Santos CP (2011) Desenvolvimento de metodologia para controle das larvas de Limnoperna fortunei com o uso de radiação ultravioleta e seus impactos sobre Microscystis aeruginosa potencialmente presentes na água superficial. PhD Thesis, Universidade Federal do Rio Grande do Sul (Brazil), pp 1–83

Santos CP, Raya Rodriguez MT, Mansur MCD, Vilar Nehrke M, Leite Zurita ML (2012a) Controle de Limnoperna fortunei com aplicação de radiação ultravioleta. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 335–338

Santos CP, Vicenzi J, Berutti FA, Mansur MCD, Perez Bergmann C, Raya Rodriguez MT, Vilar Nehrke M, Leite Zurita ML (2012b) Controle de bivalves com a utilização do ultrassom. In: Mansur MCD, Santos CP, Pereira D, Padula Paz IC, Leite Zurita ML, Raya Rodriguez MT, Vilar Nehrke M, Aydos Bergonci PE (eds) Moluscos límnicos invasores no Brasil. Biologia, prevenção, controle, Redes Editora, Porto Alegre, pp 339–341

Sawada T, Nakamura Y (2010) Breeding damages and adhesive characteristics of Limnoperna fortunei in an irrigation canal. In: Rural engineering society national conference, Tokyo [In Japanese]

Simeão CMG, Barreira Martinez C, Formagio PS (2006) Limnoperna fortunei : situação atual e perspectivas futuras. In: V Simpósio Brasileiro Sobre Pequenas e Médias Centrais Hidrelétricas, Florianópolis (Brazil)

Sprecher SL, Getsinger KD (2000) Zebra mussel chemical control guide. Erdc/El Tr-00-1, U.S. Army Engineer Research and Development Center, Vicksburg (USA). Erdc/El Tr-00-1, U.S. Army Engineer Research and Development Center, Vicksburg (USA), pp 1–89

Stupak M, Pérez MC, García MT, Solá EG, Azuaga AL, Mendivil A, Niveyro G (1996) Preliminary study of the biofouling of the Parana River (Argentina). Corros Rev 14:145–155

Tan T-H, Pai J-Y, Hsha KC (1987) The recovery of fouling clam, Limnoperna fortunei from Taiwan. Bull Malacol, Repub China 13:97–100 [In Chinese]

Tchang S, Li SC, Liu YY (1965) Bivalves (Mollusca) of Tung-Ting Lake and its surrounding waters, Hunan Province, China. Acta Zoologica Sinica 17:212–213 [In Chinese]

Xiang YL (1985) Study of the harm and prevention measures of mussel growth in pipelines in power generation plants. N China Electr Power 4:24–27 [In Chinese]

Xu M (2013) Experimental study of bio-fouling control of Limnoperna fortunei in water transfer tunnels. In: 35 international association of hydraulic engineering & research congress, Chengdu

Xu M, Wang ZY, Duan XH, Zhuang MQ, de Souza FT (2009a) Ecological measures of controlling invasion of golden mussel (Limnoperna fortunei ) in water transfer systems. In: 33 international association of hydraulic engineering & research congress: water engineering for a sustainable environment, Vancouver

Xu M, Wang ZY, Duan XZ (2009b) Prevention and treatment of the freshwater mussel in water-transmission line. Water Wastewater Eng 35:205–208

Xu M, Cao XW, Wang ZY, Wang XZ (2012) Attachment characteristics of golden mussels (Limnoperna fortunei ) in water transport projects. J Tsinghua Univ [Qinghua Daxue Xuebao] 52:170–176 [In Chinese]

Xu M, Wang ZY, Lin CC, Pan BZ, Zhao N (2013) Experimental study of invasion and biofouling of freshwater mussel Limnoperna fortunei. Int J Geosci 4:1–7

Yao GY, Xu M (2013) Limnoperna fouling and water quality impact in Guangxu water-storage hydropower station in Shenzhen. Tsinghua University, Research Project Proposal Tsinghua, China, pp 1–18 [In Chinese]

Ye BM, Cao XW, Xu M, Wang ZY, Lin CC (2011) Study of Limnoperna fortunei invasion in long distance water transmission project. Water Wastewater Eng 37:99–102 [In Chinese]

Yoshida M (2006) Case study for removing the Limnoperna fortunei (Dunker, 1856) from the irrigation tunnel for canal in Kaburagawa LID. J Jpn Soc Irrig Drain Reclam Eng 74:435–436 [In Japanese]

Zhuang MQ (2006) Study of growth rhythm and controlling of mollusks in long distance water transfer pipelines. Shenzhen (China). East river water source project management division of Shenzhen. Report, pp 1–142 [In Chinese]

Acknowledgements

This work was partially financed by grants from the University of Buenos Aires, Argentina (UBA X-020 and 20020100100035) and from the Argentine Agencia Nacional de Promoción Científica y Tecnológica, Argentina (PICT 2007 1968) to DB.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Boltovskoy, D., Xu, M., Nakano, D. (2015). Impacts of Limnoperna Fortunei on Man-Made Structures and Control Strategies: General Overview. In: Boltovskoy, D. (eds) Limnoperna Fortunei. Invading Nature - Springer Series in Invasion Ecology, vol 10. Springer, Cham. https://doi.org/10.1007/978-3-319-13494-9_21

Download citation

DOI: https://doi.org/10.1007/978-3-319-13494-9_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-13493-2

Online ISBN: 978-3-319-13494-9

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)