Abstract

Australia has embarked on the development of several large capacity seawater reverse osmosis (SWRO) facilities to meet future water demands and to provide water security during severe drought conditions. Two of these SWRO facilities, Sydney and Gold Coast, have installed permeate capacities of 266,000 and 133,000 m3/day respectively. The coastal areas of Sydney and Gold Coast contain sensitive marine environments that necessitated the development of intake systems that connect tunnels from the SWRO plant to offshore capacity cap intake structures. The design of these tunnel intake systems is quite unique and has been successfully designed and constructed. The design of the tunnels and intake structures are herein documented with an initial operational assessment.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The Sydney and Gold Coast seawater reverse osmosis (SWRO) desalination plants are among the largest desalination plants in Australia and provide water to major urban centres of Sydney, Gold Coast and Brisbane. The plants were designed and are operated by Veolia.

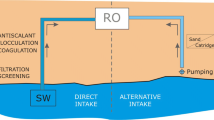

A key aspect of the design was the selection of the intake type and design for these large plants to provide suitable seawater quality and quantity to the plants and minimise any environmental impacts from the intake (Craig 2013).

2 Sydney Plant Overview

The Sydney Desalination plant has a capacity of 266,000 m3/day and is located in the southern part of Sydney at Kurnell (Figs. 3.1 and 3.2). The plant can supply up to 15 % of Sydney’s water supply and was built following a prolonged drought period.

The Sydney plant is a seawater reverse osmosis process and is divided into two 133,000 m3/day modules. The treatment includes:

-

Open intake with screening

-

Sulphuric acid

-

Ferric chloride and polydadmaac coagulants

-

Dual media filtration pre-treatment

-

Cartridge filtration

-

Two pass RO

-

Remineralisation with lime, carbon dioxide and

-

Chlorination, fluoridation then chloramination

The plant was placed into full operation in June 2010. The plant is owned by the Sydney Desalination Company and operated by Veolia.

3 Sydney Plant Intake

The size of the Sydney plant together with the nature of the coastline at the intake site had a major influence on the selection of an open intake system for the delivery of sufficient seawater to the desalination plant.

The coast consists of 25 m sandstone cliffs with a rocky seabed that drops within a few hundred metres of the shoreline to a 25 m depth. The coastline is within Botany Bay National Park in an area frequented by migrating whales with a wide range of marine flora and fauna associated with the rocky seabed. Modelling of specific local wave climate was required to assess the influence of the steeply rising floor and cliff face on the extreme wave height which includes the high energy incidents and reflected waves (extreme height 7.5 m) experienced in the area.

Inputs to the coastline and oceanic waters off Sydney include stormwater and sewer overflows during major storms emerging from Botany Bay, and sewage effluent discharges from the deep ocean outfalls. There is significant influence of the flood and ebb tides from Botany Bay on the northern end of the headland of the Kurnell peninsula, however, modelling of storm flows from Botany Bay indicate that these are likely to bypass the intake site.

Trenched pipelines were never considered for the intake because of the cliff profile, sandstone geology and marine conditions. The construction of a tunnel was considered the best solution for the intake based on the geology and environmental sensitivity of the marine environment (Evans 2011).

The tunnel design was for a shallow shaft via a box cut at the plant where the tunnel boring machine (TBM) was launched, then a downward slopping tunnel to the intake location in the ocean. This allowed a reduced time period for the tunnel construction. The ultimate capacity of any future plant upgrade on the site was used in sizing the intake tunnel allowing for a 500,000 m3/day output capacity at the site. The tunnel excavated diameter was 4.15 m with a finished internal diameter of 3.4 m and an overall length tunnel of 2.5 km (Fig. 3.3). Pre-fabricated concrete tunnel liners (1200 sections) were employed with each liner being 225 mm thick and weighing 1.5 metric tons.

The intake is located 300 m offshore in 25 m of water and consists of four intake risers (Fig. 3.4). The multiple risers provided security for the operations around blockage and other issues.

There was a major challenge to design and undertake ocean floor construction within a coastal surf zone on a turbulent, shallow rock platform within a marine national park. Day to day marine work was constrained with the work site only 250 m away from the coastline and subject to wave refraction and turbulence greatly limiting operating times. The site was also subject to extremely strong currents severely limiting suitable work days. Divers worked in water depths of 25–28 m from a crane barge anchored in position above the riser locations. The divers cleared loose rock off the seabed and placed grout between large grout filled geofabric socks pinned to the rock. This formed level bases on which to accurately position the riser structures. The riser structures were precast on-shore at Port Botany and delivered to site by an A-Frame barge towed by a tug.

Riser construction and drilling was carried out from the Seafox 6, a self elevating platform (SEP) or jack-up barge (Fig. 3.5). The methodology for drilling of risers required the SEP to be relocated for the drilling of every riser. To minimise the weather-dependent relocation of the SEP, methods and techniques such as the use of airbags, frame structures and underwater lifting techniques were developed, which allowed the team to install riser structures for an adjacent hole already drilled, whilst positioned over another hole. This gave the optimum program outcome.

A recirculation method for offshore drilling work was adopted which involved the use of a drill casing assembled on the SEP and lowered to a steel ring located within each riser structure on the seabed. Drilling was undertaken in a completely contained operational environment, by reverse circulation of seawater. Spoil collected via recirculation was brought up through the drill sleeve, deposited and separated from the water in different skips on the SEP. This greatly minimised the environmental and visual impacts of the operation.

Extensive monitoring of seawater quality over approximately two years confirmed the best location for the intake and quality of the seawater for the design of the desalination processes stages and in particular the pre-treatment stage (Sydney Water Interim Report 2006). Pre-treatment pilot plant studies were undertaken using a temporary test intake near the location of the proposed full scale plant intake which enabled detailed long term monitoring of seawater quality in the region and optimisation of the pre-treatment process design. The seawater quality in the defined intake zone was generally of high quality with low turbidity, total dissolved solids (TSS) concentrations, silt density index (SDI), organics concentrations, little or no algae and no hydrocarbons (Table 3.1).

The requirements of the seabed intake structure performance included:

-

Upper limit on the velocity between screen bars

-

A minimum spacing between screen bars

-

Minimum height above the seabed

-

A minimum depth below the sea surface

-

Non-corrosive or antifouling bar materials

-

In-built redundancy (for security or over capacity for future augmentations)

The velocity cap placed over the intake riser converts the vertical flow of seawater into a horizontal flow entering the intake riser (Fig. 3.6). It has been noted in full scale operations that fish would avoid rapid changes to the horizontal flow and velocity cap intakes have been shown to provide significant reduction in fish impingement (see Chap. 4).

The inflow velocity for the Sydney plant is designed for <0.1 m/s to reduce entrainment and impingement of marine organisms. Shock chlorination capability was provided to control biofouling in the intake and tunnel. The intake screen had an aperture spacing of 300 mm and was made of cupronickel to reduce marine growth and minimise the requirement for screen cleaning by divers.

Onshore two 3 mm drums screens were constructed to remove any entrained marine debris (Fig. 3.7). Each screen is capable of treating the maximum flow rate, but normally both operate together in parallel before the pumping station.

To confirm there were negligible impacts on the marine environment from both the intake and outfall a Marine Monitoring Program (MMP) was developed. The program included three phases of design, baselines studies pre-commissioning and post commissioning or verification studies. The impact monitoring included measurements of water quality, surveys of reef habitat and recruitment of sessile organisms. A fish census surveys was undertaken at three locations over four calendar seasons both prior to commissioning and post commissioning to determine if the operation of plant affected fish populations in the area (Fig. 3.8).

The intake performance has shown minimal effect on the marine ecology and there has been only a small quantity of solids collected on the onshore drum screens. A remote operating vehicle (ROV) inspection is used periodically to monitor the tunnel condition during operation and the effectiveness of the shock chlorination to control biofouling in the intake system. The result of successive ROV inspections has shown the absence of significant marine growth in the tunnel. After two years of operation a growth of approximately 1 cm (thickness) located at the distal end of the tunnel near the riser was measured. This is likely enhanced by the presence of light which was measured during the ROV inspection. The growth was not significant along the remainder of the tunnel length.

Inspection of the intake within the velocity cap shows that abundant marine life is present (Fig. 3.9). Fish were observed swimming freely inside of the intake structure.

4 Gold Coast Plant Overview

The Gold Coast Desalination plant has a permeate capacity of 133,000 m3/day and is located at Tugun on the Gold Coast of Queensland (Figs. 3.10 and 3.11). The plant can supply the Gold Coast as well as supplementing the water supply of Brisbane during drought periods. It is an SWRO plant and the pretreatment, treatment, and post-treatment stages include:

-

Open intake with screening

-

Sulphuric acid feed

-

Ferric sulphate and polydadmaac coagulants feed

-

Dual media filtration pre-treatment

-

Cartridge filtration

-

Two pass RO

-

Remineralisation with lime, carbon dioxide and

-

Chlorination, fluoridation then chlorination

The Gold Coast plant is a key part Seqwater Grid and Regional Drought Strategy Contingency Supply Plan developed to secure the future water supply to the region. The plant was in full operation in March 2009 and is owned by Seqwater and operated by Veolia.

5 Gold Coast Plant Intake

The Gold Coast is a renowned tourist destination with pristine white sandy beaches. The coast is densely populated with a high real estate value and no ocean front industrial land is available. This offered significant challenges in terms of design, construction and operation. The site selected, 500 m inland at the southern end of the Gold Coast, is located on a former uncontrolled landfill site and is also directly adjacent to a busy international airport. Furthermore, residents are located only 300 m away from the site and sports fields are located next to the plant fence. In line with the goals of the project, it was essential to minimise any direct impacts to the neighbouring community, as well as the environment. This encompasses power sourcing, impacts to the environment at and around the site, and impact to the marine environment at the points of intake and discharge.

The requirements for this location hence included no marine infrastructure to be visible on the coast and construction could not be allowed to disrupt any community and tourist activities. Given these conditions and the large capacity of the plant, an open intake was evaluated as the most viable intake option.

Trench options for installation of the intake conveyance pipeline were considered and compared to bored tunnels and infiltration systems during the site assessment. The tunnel option to an open intake was selected based on the program, environmental and visual impacts during construction, minimisation of marine construction risk and an intake pump station located at the plant.

The plant intake location is in an open embayment with water circulation in the embayment driven primarily by wind drift and the East Australian Current which flows in a south-easterly direction. The most significant potential land-based influences on the receiving environment are discharges from Currumbin Creek, located 3.4 km to the north of the project location, and the Tweed River, 5 km to the south. The embayment has a gently sloping, uniform bottom of primarily fine to medium grain quartz sand, with some shell and small amounts of silt and clay.

Marine issues at the intake site included:

-

Summer cyclone occurrence

-

Ocean currents typically to a maximum velocity of 0.5 m/s

-

High storm event waves (up to 8 m in height)

The siting of the intake in a stable seabed at depths below 18 m was determined to minimize sand and sediment entry into the intake, and maintain the intake works clear of the active coastal zone. The intake seabed contains little marine vegetation. However, it still has high environmental value, containing a variety of marine life. The seabed is primarily bare sand, with some widely scattered tube anemones, sipunculid worms, sea stars, and burrowing sponges. Bottom fishes, including shovelnose rays, flathead, flounder, and skates, have been observed. Epibenthic fauna and flora in the diffuser location are not abundant. Video surveys indicate that no seagrass or macroalgal (seaweed) beds occur in the area, although drift algae are sometimes observed (Viskovich et al. 2013).

A pre-treatment pilot plant study was undertaken with an intake system in the general area of the full-scale plant intake which enabled ongoing monitoring of seawater quality and measurement of variation over the seasons. The data collected allowed the optimization of the pre-treatment design of the plant.

The tunnel construction for the full scale plant was via a 70 m deep shaft at the plant site with a 2.8 m diameter 2.2 km tunnel (Fig. 3.12). A tunnel boring machine (TBM) was used to construct the tunnel and pre-fabricated fibre reinforced concrete tunnel liners were used as liners to give longer design life. The intake tunnel runs 1.5 km offshore and 40 m under the seabed. The intake velocity-cap structure is located in 22 m of water and 6 m above the seabed.

Entrainment and impingement of adult marine organisms can be avoided by minimizing the water velocity at the mouth of the intake structure with the California Coastal Commission recommending in the past that intake velocities below 0.15 m/s constituting “Best Technology Available” to minimize impingement (see Chap. 5). The intake was designed as a velocity cap over the intake pipe with the intake velocity kept below 0.15 m/s. The actual velocity generally is around 0.05 m/s as modeled at 100 % flow (Fig. 3.13). In addition to velocity considerations, the spacing of the screen bars (140 mm) on the intake was selected to avoid impingement, allowing fish to swim freely across the structure (Fig. 3.14). The edges of the bars were also rounded to eliminate the presence of any sharp angles or surfaces that could potentially injure fish or other free-swimming animals (Cannesson et al. 2009).

The seawater at the intake zone was generally of high quality with low turbidity, TSS, SDI, organics with little algae and no hydrocarbons (Table 3.2).

The seawater passes through fine screening (3 mm) via rotating drum screens located onshore to remove any entrained marine debris. The intake is also intermittently chlorinated typically once per day to control biofouling in the intake tunnel and structure.

The suitability of the intake structure design has been confirmed by a diver’s inspection upon start-up of the plant. Fish were observed to be swimming unhindered across the intake mushroom (Fig. 3.15). After the first 10 months of plant intake operation, only 20 kg of organisms were collected from the onshore rotating drum screens. This consisted mainly of small fish 20 cm in length and is thought to be due to the growth of fish in the intake shaft during a 4-week plant shutdown. Since plant inception the entrainment of only around 160 kg marine life has been collected from the 3 mm onshore drum screens and consisted of predominantly cornflake seaweed and a few blue blubber jellyfish. Ongoing marine monitoring is being undertaken to evaluate environmental performance of the intake over time.

ROV inspections are carried out annually to monitor the tunnel condition during operation and the effectiveness of the shock chlorination to control biofouling in the intake system. The results of successive ROV inspections have shown limited marine growth and good condition of the intake system (Fig. 3.16).

6 Conclusions

The use of bored tunnels with open intakes for two Australian SWRO plants at Sydney and the Gold Coast has allowed the plants to be built to program standards, to provide water capacity and quality to meet the plant feed water requirements, and to minimize environmental impacts.

Different coastal conditions at the two plant sites resulted in differences in siting of the intake structures in terms of distance offshore and water depth. The sites were chosen based on pre-design environmental investigations to ensure good seawater quality, minimization of sediment entrainment, and minimization of environmental impacts.

The velocity caps and screen design have been effective and the low inlet velocities have minimised any entrainment and impingement of marine organisms. The use of shock chlorination has been effective in controlling biofouling in the tunnels as evidenced by the regular ROV inspections.

Ongoing environmental monitoring has shown minimal impacts on the marine ecology.

References

Craig, K. (2013). Sydney and the Gold Coast Intakes. Thuwal, Saudi Arabia: KAUST Intakes and Outfall Seminar Presentation.

Evans, R. (2011). Sydney Desalination Plant. ACCA Technical Paper.

Cannesson, N., Johnstone, P. M., Mitchell, M. A., & Boerlage, S. E. E. (2009). Community, environmental and marine impact minimisation at the Gold Coast desalination plant. In Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse. Dubai UAE.

Sydney Water Corporation (2006). Desalination planning study ocean sampling water quality 2005–2006 interim report.

Viskovich, P. G., Gordon, H. F., & Walker, S. J. (2013). Light at the end of the tunnel—a benthic community perspective. In Proceeding of the International Desalination Association (IDA) World Congress on Desalination and Water Reuse World Congress on Desalination and Water Reuse. Tianjin, China.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Craig, K. (2015). Sydney and Gold Coast Desalination Plant Intake Design, Construction and Operating Experience. In: Missimer, T., Jones, B., Maliva, R. (eds) Intakes and Outfalls for Seawater Reverse-Osmosis Desalination Facilities. Environmental Science and Engineering(). Springer, Cham. https://doi.org/10.1007/978-3-319-13203-7_3

Download citation

DOI: https://doi.org/10.1007/978-3-319-13203-7_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-13202-0

Online ISBN: 978-3-319-13203-7

eBook Packages: EngineeringEngineering (R0)