Abstract

Over the past several decades, many improvements have been made in the design and operation of seawater reverse osmosis desalination systems (SWRO), including the intakes that provide feed water. The invention of the velocity-cap offshore intake system reduced the entrainment of fish due to their sensing of horizontal flow versus vertical flow. Use of passive screen intakes further lessened the environmental impacts of open-ocean surface intake systems by near elimination of impingement and a reduction in entrainment caused by the low inflow velocity and the small slot size of the screens. Further reduction of environmental impacts of intake systems can be achieved by careful location of the intake systems (away from sensitive marine areas such as estuaries). Subsurface intake systems in the form of conventional vertical wells produced high-quality feed water for small and medium capacity SWRO plants. Well intake systems force seawater to infiltrate through the seabed into a porous aquifer. The transport of the raw seawater in the aquifer results in a significant reduction in the raw water organic matter content. Relatively new well types, such as slant wells, horizontal wells, and radial collectors, have been introduced to provide feed water for SWRO facilities. Some types performed better than others and experimentation is still ongoing. Gallery intake systems were developed for use in a wider range of required capacities from medium to large. A major seabed gallery intake system was constructed in Japan and has produced a very high-quality feed water and other similar systems are being planned for construction. The concept of the self-cleaning beach gallery intake was developed and has not yet been installed for use in a medium or large capacity SWRO facility, but this intake design has high potential for success. Considerable additional research is merited on improving existing intake designs and creating new ones that can reduce SWRO operational costs by reducing the intensity of pretreatment.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The quality of feed water entering a seawater reverse osmosis (SWRO) water treatment facility has significant impacts on facility operation, economics of treatment, and possibly also on environmental impacts. Many innovations have occurred over the past two decades that have improved feed water quality and have lessened environmental impacts in obtaining feed water from the sea. This remains a very important issue in the continuing quest to reduce the overall energy usage and cost of SWRO desalination.

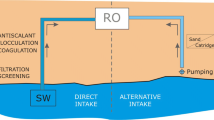

Many SWRO plants use open-ocean intake systems either in channels at the shoreline, often collocated with power plants, or from offshore pipes. In these intake systems, marine life is carried into the plant and has to be removed by extensive pretreatment processes. Many of the early intake system designs had significant impacts caused by impingement and entrainment of marine organisms caught within the intake structure because the entrance velocities were generally high. The simple change to increased intake pipeline diameter to reduce the inflow velocity had a positive impact on reducing impingement and entrainment of marine organisms.

Over the years it has become apparent that the location of an intake has a significant effect on the environmental impacts, such as impingement and entrainment, and on the overall content of organic matter than enters a SWRO plant (Chap. 4). Placement of intakes within estuarine areas or other nearshore high marine productivity zones tends to increase impingement and entrainment, simply because of the higher density of marine organisms in these locations. Very high concentrations of total organic carbon (TOC) and natural organic matter (NOM) also occur in the estuarine areas. Placement of the intake in offshore areas that have sand bottoms with generally lower biological productivity tends to reduce impingement and entrainment and lessens real or perceived environmental impacts.

Use of subsurface intake systems was found to be quite effective in reducing environmental impacts and producing a higher quality feed water that requires less pretreatment. In the past, subsurface intake systems were considered only for small capacity (<10,000 m3/d) systems, commonly located in carbonate aquifers in the Caribbean Islands. Application of subsurface intake systems to larger capacity SWRO systems is now occurring (Missimer et al. 2013).

2 Innovations in Open-Ocean Intake Systems

Improvement in the design and operation of open-ocean intake systems is on-going. Earlier innovations to reduce entrance velocity into SWRO facilities were to increase pipeline diameters and the invention of the velocity cap-type intake structure. A velocity cap is a behavioral deterrent technology that changes what would otherwise be vertical flow vectors at an uncapped offshore intake riser to horizontal flow vectors (see Chaps. 1 and 4). A velocity cap is an effective means for reducing impingement and entrainment because it has been shown that horizontal flow vectors are more easily sensed and avoided by fish (Beck et al. 2007; Lifton and Storr 1978; Weight 1958).

Various devices have also been installed within velocity cap intakes to “scare” the fish away. These devices include sound-emitting mechanisms and electrical currents. Few quantitative data are available on the effectiveness of these methods. Commonly, large fish will congregate within the upper layer of the intake below the cap and inside of the bar screen. The large fish can easy swim away from the low-velocity inflowing seawater. These large fish tend to scare away smaller fish that have limited ability to escape low-velocity inflows. The velocity cap intake design itself has been an environmental improvement in lowering entrainment of small fish.

Another innovation in reduction of environmental impacts is the use of conveyance tunnels from the SWRO plant site to the offshore intake. Offshore construction using trenching techniques to install the pipeline from the SWRO plant to the intake is a very disruptive process, which produces large volumes of suspended sediment and excess sediment excavated from the trench. Both can have impacts to the marine bottom ecology. In Australia, tunnels have been designed and constructed to convey the intake and outfall pipelines (Chaps. 2 and 3). These large-diameter tunnels are constructed using a tunneling machine and have no impact to the seabed. A vertical riser pipe is constructed from the seabed surface down to intersect with the tunnel and the velocity cap-type intake structure is attached. While the tunnel intake and outfall systems reduce environmental impacts, they adversely impact the project capital cost.

To exclude small fish and a significant part of the ictheoplankton, which includes larvae and eggs, the passive screen intake system, commonly used at power plant cooling water intakes, has been applied to SWRO intakes. This intake type is commonly used in surface water intake systems in freshwater rivers and streams. Passive screen intake technology has been extended to use for SWRO intakes in both onshore canal systems and offshore stand-alone systems. Passive screen systems can significantly reduce the impingement and entrainment of small fish and larvae by basic size exclusion and by shear forces caused by water currents passing over the screens (Chaps. 4 and 5). Impingement is virtually eliminated by use of passive screens intakes, but some entrainment of ictheoplankton will always remain.

A key issue in the use of passive screen intake systems, particular at significant distances offshore, is the ability to maintain the screens. New alloys have been invented that are both corrosion resistant and anti-fouling in nature (copper-super duplex stainless steel alloys). Many of these intakes are located at a distance from the shore that makes air-burst cleaning using a shore-based compressor impractical. In Chap. 5, the use of an anchoring system to allow a boat-mounted cleaning system for air-burst cleaning of stand-alone passive screen intakes is suggested. This would facilitate cleaning and reduce the need for divers to perform the task.

Another issue that is being evaluated is the use of deep open-ocean intakes. It is generally recognized that oceanic biological productivity decreases with depth in the sea, but not regularly. If a reliable and structurally sound intake system could be designed and constructed to extract seawater from a depth >100 m, there is a reasonable possibility that the water would have generally lower concentrations of algae, bacteria, and other organic compounds that cause membrane biofouling. A study of deep intake system feasibility in the Red Sea indeed shows a significant decline in the concentrations of algae, bacteria, TOC, transparent exopolymer particles, and NOM between the sea surface and a depth of 90 m (Chap. 6). However, the bathymetry of the Red Sea (cliffed margins) would make the construction and maintenance of a deep intake system very risky and perhaps not feasible. Another key issue is the change of water temperature between the surface and the proposed depth of the deep intake. In the Red Sea, the decrease in temperature with depth is only about 5 °C, which is insignificant as far as its impacts on the SWRO treatment process. However, at other locations the decrease in temperature could materially increase the cost of SWRO treatment. Perhaps the most difficult element of deep intake development concerns how to maintain the intake below a depth to which normal scuba divers can safely work. Additional research on this issue will be required, probably in consultation with the offshore petroleum industry which uses deep submersible systems to maintain deep-water infrastructure. Cost would be a key feasibility issue.

3 Innovations in Well Intake Systems

Conventional vertical well intake systems have been used for decades to supply low capacity (<10,000 m3/d) SWRO systems (Missimer 2009; Chap. 8). Vertical well intake systems have a demonstrated positive effect on feed water quality by resulting in significant reductions in algae, bacterial, transparent exopolymer particles (TEP), and fractions of NOM during transport of water from the sea into the wells (Chap. 9). While vertical well construction and maintenance is a mature technology, some innovations have occurred in materials that can be used for well casings and screen, as well as for the well pumps. Non-metallic fiberglass casing and screens can now be used in deep wells that previously required the use of more expensive stainless steel. New super duplex stainless steel alloys are now be used in well pumps. The corrosion resistance of duplex steel alloys increases the life-expectancy of the pumps, which was commonly 1–3 years in the past.

Slant and horizontal wells have the great advantage that multiple wells could be drilled from a single pad, which is an important consideration at the sites where shore access is limited. The use of slant wells and horizontal wells is relatively new for use as SWRO intakes. Slant well technology for SWRO intakes is being developed primarily in California (Chap. 13). Used in the proper type of hydrogeologic conditions, this emerging technology may have wide-spread application for medium capacity (10,000–50,000 m3/d) SWRO facilities. As some new SWRO systems use this technology, data will become available concerning operational issues, such as the susceptibility of the wells to clogging, the ability to cost-effectively maintain (rehabilitate) the wells, and geochemical compatibility (redox reactions). Horizontal drilling technology has been a useful tool in the engineering world for over 50 years for the installation of pipelines, but it is new technology in applications for SWRO intake systems. The Neodren™ horizontal well technology has been used for medium-capacity intake systems in Spain, but the operational results are mixed at this time. Future refinement of drilling technologies may produce another useful intake type that may be applied under specific types of local geological conditions.

4 Innovations in Gallery Intake Systems

Gallery intake systems are another relatively new application for development of SWRO systems (Missimer et al. 2013). Seabed and beach gallery systems have the potential to provide feed water volumes to a larger range of SWRO plant capacities (Maliva and Missimer 2010; Chaps. 11 and 12). These intake types are based on the concept of slow sand filtration, which has been used in water treatment for nearly two centuries. Gallery intakes are engineered filters installed into the seabed or the active intertidal zone of the beach (surf zone). The concept of seabed galleries has been introduced over 25 years ago, but large-scale development of an SWRO intake in Fukuoka, Japan is a recent development (Shimokawa 2012).

Considerable effort has been conducted into the design and construction of seabed gallery intake systems with the Fukuoka, Japan system being the largest capacity system in operation to date. The City of Long Beach seabed gallery system was used for testing purposes, but is not in operation. Improved design of the seabed gallery intake systems is to divide the intake capacity into modules termed cells (Sesler and Missimer 2012; Dehwah and Missimer 2013; Lujan and Missimer 2014; Mantilla and Missimer 2014; Rachman et al. 2014; Al-Mashharawi et al. 2014; Chap. 12). The issue of proper filter design for these systems was discussed in Lujan and Missimer (2014) and the infiltration flow balance design problem was addressed in Mantilla and Missimer (2014). Key innovations for the future will be in developing better and more economic construction methods, such as the new concept of using an artificial fill peninsula in the Red Sea with bounding gallery cells (Fig. 11.13).

Beach gallery system intakes have been used in very small capacity SWRO systems in the Caribbean, but no other significant capacity systems have been developed elsewhere. The important innovation of this intake type is the self-cleaning nature of the face of the filter which is located in the surf zone. Wave turbulence tends to churn the sediments and particulate organic matter trapped in the sand and suspends it for transport longshore. Beach gallery intakes may be constructed in moderate energy, stable shorelines in regions requiring desalinated water.

Siting of gallery intakes must be based on sound science and knowledge of the processes acting on the shoreline and nearshore environments. A methodology is presented in Chap. 14 that illustrates the type of investigation that needs to be conducted when siting a high capacity gallery intake system. This is another technical innovation.

5 New SWRO Subsurface Intake Design Concepts

New innovations in SWRO intake systems design is occurring and will continue to grow. The tunnel intake system used in Alicante, Spain (Chap. 9) is a design modification based on the Louisville, Kentucky (USA) tunnel intake system described in Missimer (2009). Another design of this intake type has been proposed for use in southern California (RBF Consultants 2005; Fig. 15.1). Some basic design modifications will be required to improve the economics of construction of tunnel intakes and also, some innovations will be required in cleaning of the horizontal inflow “spines”. Perhaps some type of tunnel isolation system could be used to take parts of it out of service during required maintenance.

Water tunnel intake system conceptual design (from RBF Consultants 2005)

Another type of subsurface/surface hybrid intake has been described by Pankratz (Chap. 1), which involves the excavation of the deep pit in limestone that is hydraulically connected to the sea. Seawater is extracted from the pit using high capacity pumps. The raw water is forced through the aquifer between the sea and the excavation, thereby receiving filtration and treatment. The excavation could be covered or not covered. Care would have to be taken to avoid the introduction of fish and other marine life into the excavation or there would be additional pretreatment requirements.

6 Planning for Use of Subsurface SWRO Intake Systems

A major reason why subsurface intake systems have not been used to supply feed water to a larger number of medium to high capacity SWRO plants is the issue of contract and operational risk. Governmental bodies that manage design, construct, and operate a SWRO facility have the ability to evaluate all types of intakes in terms of environmental impacts and economics before a request for proposal for design is issued and construction bids are solicited. However, in most tenders for new SWRO facilities that involve coupled construction and long-term operation bids [build-own-operate (BOO) or build-own-operate-transfer (BOOT)], no information on local site subsurface conditions is provided in the bid package. Therefore, the bidder would have to accept the risk for using a subsurface intake system using few data, or absorb the cost of conducting the proper testing program before the bid is prepared which is commonly a short period of time. Often there is insufficient time for a program to pilot test alternative intake system design options.

Governments or regions that will require large-scale development of SWRO facilities have the ability to conduct coastal planning investigations that evaluate the use of subsurface intake. An example of a planning level investigation of subsurface intake use (or non-use where not feasible) is given in Chap. 7. The methods provided in this chapter, as well as in Dehwah et al. (2014), provide a method that can be applied to other coastal regions of the world. Maps could be produced that link specific locations along a shoreline or nearshore area with various feasible subsurface intake types. Also, the owner of the project could provide the bidders with sufficient site-specific data on which a bid could be developed that allows the bidder to develop innovations that could substantially reduce the cost of the water to the consumers.

7 Operational Innovations

One very important operational issue is the recognition that continuous chlorination of the intake water in an open-ocean intake facilitates biofouling of SWRO membranes (Winters 1994, 1997; Winters and Isquith 1995). The switch to episodic chlorination of the intake pipeline from the intake to the plant for biofouling control has reduced the rate of biofouling at some SWRO plants. However, the total elimination of chlorination reduces the biofouling rate of the membranes even further. Subsurface intake systems require no chlorination to operate.

Various combinations of pretreatment systems with an intake could improve facilities operation in certain cases. For example, it has been proposed that using a rapid infiltration offshore gallery linked with a membrane filtration pretreatment process could improve the overall SWRO plant operational efficiency (Niizato et al. 2013; Chap. 11). The overall cost of this possible innovation has yet to be evaluated.

The concept of elimination of in-plant pretreatment processes when using a subsurface intake system must be considered to be an innovation. Well intakes have been used for decades to supply small capacity SWRO plants with the full elimination of any pretreatment, except for the cartridge filters positioned before the membrane trains. The seabed gallery operated at Fukuoka, Japan produces a very high quality feed water, which is the pretreated with a membrane filtration system before it enters the cartridge filters. Based on the quite low silt density index values coming from the feed water, it appears that the pretreatment process using membrane filtration could be bypassed without loss of plant efficiency. Continued research on the effectiveness of subsurface intake systems to actually provide pretreatment exterior to the SWRO plant needs to be conducted to ascertain the need for any in-plant pretreatment from the influent of the intake.

8 Discussion and Conclusions

The intake into a SWRO plant provides the feed water that controls the design and operation of many aspects of the plant, including the pretreatment process train and the desired flux through the SWRO membranes. Innovations in the development of intake systems that provide the highest possible feed water quality are key factors in reducing the environmental impacts, and cost of SWRO desalination.

In this section of the book, a number of innovations in intake design and operation of intake systems have been described including both open-ocean or surface intake systems and subsurface intake systems. The continued improvements and innovations that can be achieved in intake design and operation are in peril at this time. The danger of the “commodity engineering” approach to the design of SWRO plants is becoming an issue. As the SWRO industry becomes mature, and ‘standard’ SWRO designs are being used due to bidding schemes that are believed to lower costs, there is the danger of losing innovation which is the backbone of technological improvement and long-term energy and cost reduction in desalination.

References

Al-Mashharawi, S., Dehwah, A. H. A., Bandar, K. B., & Missimer, T. M. (2014). Feasibility of using a subsurface intake for SWRO facility south of Jeddah, Saudi Arabia. Desalination and Water Treatment, doi:10.1080/19443994.2014.939870

Beck, S. E., Miller, D., Bailey, D., Steinbeck, J. (2007). Quantification of effectiveness of velocity caps. In Presented at American Fisheries Society 137th Annual Meeting, San Francisco, CA. September 2–6, 2007.

Dehwah, A. H. E., & Missimer, T. M. (2013). Technical feasibility of using gallery intakes for seawater RO facilities, northern Red Sea coast of Saudi Arabia: The king Abdullah Economic City site. Desalination and Water Treatment, 51( 34−36), 6472–6481. doi:10.1080/19443994.2013.770949

Dehwah, A. H. A., Al-Mashhawari, S., & Missimer, T. M. (2014). Mapping to assess feasibility of using subsurface intakes for SWRO, Red Sea coast of Saudi Arabia. Desalination and Water Treatment, 52, 2351–2361. doi:10.1080/19443994.2013.862035.

Lifton, W. S., Storr, J. F. (1978). The effect of environmental variables on fish impingement. In: L. D. Jensen (Ed.), Proceedings of the fourth national workshop on entrainment and impingement. EA Communications. ISBN: 0-931842-01-8.

Lujan, L. R., & Missimer, T. M. (2014). Technical feasibility of a seabed gallery system for SWRO facilities at Shoaiba, Saudi Arabia and regions with similar geology. Desalination and Water Treatment, 52(40–42), 7431–7442. doi:10.1080/19443994.2014.909630

Maliva, R. G., & Missimer, T. M. (2010). Self-cleaning beach-gallery design for seawater desalination plants. Desalination and Water Treatment, 13, 88–95.

Mantilla, D., & Missimer, T. M. (2014). Seabed gallery intake technical feasibility for SWRO facilities at Shuqaiq, Saudi Arabia and other global locations with similar coastal characteristics. Journal of Applied Water Engineering and Research, http://dx.doi.org/10.1080/2349676.2014.895686

Missimer, T. M. (2009). Water supply development, aquifer storage, and concentrate disposal for membrane water treatment facilities. Houston, Texas, Schlumberger Water Services, Methods in Water Resources Evaluation Series No. 1, 390 pp.

Missimer, T. M., Ghaffour, N., Dehwah, A. H. A., Rachman, R., Maliva, R. G., & Amy, G. (2013). Subsurface intakes for seawater reverse osmosis facilities: Capacity limitation, water quality improvement, and economics. Desalination, 322, 37–51. doi:10.1016/j.desal.2013.04.021.

Niizato, H., Inui, M., Kira, N., Inoue, T., Oiwa, T., Cai, H., Yanagimoto, Y., Nishimura, T. (2013). Innovative SWRO desalination technology introducing high-speed seabed infiltration system (HiSIS). In Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse, October 20–25, Tianjin, China, Paper IDAWC/TIAN13-033.

Rachman, R., Al-Mashhawari, S., & Missimer, T. M. (2014). Technical feasibility for development of a seabed gallery intake for SWRO at Abu Ali, Arabian Gulf, Saudi Arabia. Desalination and Water Treatment, doi: 10.1080/19443994.2014.940221

RBF Consultants. (2005). Camp Pendleton seawater desalination project feasibility study. Consultant’s report to the San Diego County Water Authority.

Sesler, K., & Missimer, T. M. (2012). Technical feasibility of using seabed galleries for seawater RO intakes and pretreatment: Om Al Misk Island, Red Sea, Saudi Arabia: IDA. Journal: Desalination and Water Reuse, 4(4), 42–48.

Shimokawa, A. (2012). Fukuoka District desalination system with some unique methods. National Centre of Excellence in Desalination. In International Desalination Intakes and Outfalls Workshop Proceedings, Adelaide, South Australia, May 16–17, 2012.

Weight, R. H. (1958). Ocean cooling water system for 800 MW power station. Journal of the Power Division of the American Society of Civil Engineers Paper, 1888, 22.

Winters, H. (1994). Biofouling status of the Saline Water Conversion Corporation (SWCC) reverse osmosis (RO) plants in the Kingdom of Saudi Arabia, Unpublished consultant’s report to SWCC, 23 pp.

Winters, H. (1997). Twenty years experience in seawater reverse osmosis and how chemicals in pretreatment affect fouling of membranes. Desalination, 110, 93–95.

Winters, H., & Isquith, L. (1995). A critical evaluation of pretreatment to control fouling in open seawater reverse osmosis—has it been a success? In Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse, Abu Dhabi, UAE (Vol. 1, pp. 255–264), November 18–24, 1995.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Missimer, T.M., Maliva, R.G., Pankratz, T. (2015). Innovations in Design and Operation of SWRO Intake Systems. In: Missimer, T., Jones, B., Maliva, R. (eds) Intakes and Outfalls for Seawater Reverse-Osmosis Desalination Facilities. Environmental Science and Engineering(). Springer, Cham. https://doi.org/10.1007/978-3-319-13203-7_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-13203-7_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-13202-0

Online ISBN: 978-3-319-13203-7

eBook Packages: EngineeringEngineering (R0)