Abstract

Geological characteristics of the Red Sea coastline of Saudi Arabia were evaluated to assess the technical feasibility of designing and constructing seabed gallery intake systems to provide feed water for seawater reverse osmosis (SWRO) desalination plants. Five sites were investigated in detail at King Abdullah Economic City, Om Al Misk Island, Jeddah, Shoaiba, and Shuqaiq. It was found that a large part of the Red Sea nearshore area contains a low-sloping inner reef area from the beach seaward to the reef tract. Water depth ranges from 0 to 2 m in this shelf area and there is minimal coral growth and a small percentage of seagrass cover. There is a carbonate or siliciclastic sand cover over a moderately hard to soft limestone. It was found that seabed gallery systems could be designed and constructed at each of the sites investigated. The site-specific conditions varied which necessitated different designs of the filter with the upper, reactive layer varying with regard to the mean grain diameter of the media to match the site conditions and the layer thickness to provide adequate water treatment. Preliminary design infiltration rates varied between 5 and 10 m/d with hydraulic retention times ranging from 3.4 to 7 h. Each gallery intake design was divided into a number of cells, each to be equipped with a pump to achieve overall high system reliability. The Saudi Arabia nearshore area of the Red Sea appears to be an ideal location for the development of seabed gallery intake systems based on the shallow water and relative ease of construction.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The Red Sea coastline has a complex set of features that make the development of subsurface intake systems difficult in some areas (Dehwah et al. 2014). Of the many types of subsurface intake systems, the only design that can be used to supply large-capacity seawater reverse osmosis (SWRO) water treatment plants is the seabed gallery (Dehwah et al. 2014). Large-capacity SWRO plants are defined as those with a capacity >100,000 m3/d.

Design of seabed gallery intakes has been documented beginning in the early 1980s, when a proto-type design was suggested in a draft tender for a SWRO plant on the coast of the Arabian Gulf (Missimer 2009). Preliminary design concepts for seabed filtration or a seabed galley intake system were published by Missimer and Horvath (1991), and Missimer (1994, 2009). After many years, the proposed use of seabed gallery intake systems has undergone renewed interest in Japan (Fukami 2002; Okamoto et al. 2005) and California (Wang et al. 2007, 2009; Allen et al. 2008). In 2005, the first large-scale seabed gallery intake system was installed at Fukuoka, Japan (Hamano et al. 2006; Pankratz 2006; Shimokawa 2012; Fig. 11.1). This facility has operated quite successfully for a period of nearly 8 years without the need to perform maintenance on the surface of the filter.

All subsurface intake systems tend to provide some degree of pretreatment of the feed water before it enters a SWRO plant. This concept is very important because the greatest challenge to operation of SWRO facilities is the control of membrane biofouling, which tends to reduce the life-expectancy of membranes, increase operational cost, cause the necessity to use large amounts of chemicals in the pretreatment process train (e.g., chlorine, ferric chloride, and others), increase the energy consumption of the facility by use of more energy expenditure in the pretreatment process train, and increase labor cost due to the number of processes and some basic issues involving the handling and processing of marine waste, such as accumulated plant and animal matter entrained into the system.

Open-ocean intake systems also have the potential to create environmental impacts associated with the impingement and entrainment of living marine organisms in the facility (Missimer 2009; Chap. 4). The controversy and debate surrounding this issue necessitate the performance of long-term, very expensive environmental impact analyses on the marine environment in proximity to proposed intake systems. In Australia, large tunnels have been designed and constructed at great cost to minimize the disruption of the marine bottom (Chaps. 2 and 3). In California, open-ocean intake systems have been nearly banned unless a subsurface intake system is deemed to not be technically feasible. Large-scale seabed gallery intake systems are being evaluated by the City of Long Beach (Wang et al. 2007, 2009) and by the California Coastal Commission at the City of Huntington Beach.

Despite great effort in design of pretreatment systems, biofouling is still a pervasive operational problem in many facilities. Recent research has suggested that the concentrations of algae, bacteria, total organic carbon (TOC), transparent exopolymer particles (TEP), and various fractions of natural organic matter (NOM) in the raw seawater are general indicators of biofouling potential. In particular, the occurrence of TEP and other biopolymers, which tend to coat and precondition the membrane surface, lead to the formation of biofilms on membrane surfaces (Berman 2010; Berman et al. 2011). TEP is formed by the self-assembly of precursor substances, such as dissolved acidic polysaccharides, that are produced by algae and bacteria (Passow and Alldredge 1994; Passow 2000). The engineered pretreatment process train is designed to remove as much of these organic substances as possible, but at great expense.

It is well known that subsurface intakes tend to improve the feedwater quality by removal of algae, bacteria, TOC, TEP, and various fractions of natural organic matter (NOM) with the highest molecular weight fraction being removed at the highest percentage (Missimer et al. 2013; Rachman et al. 2014). Most investigations on subsurface intake systems have focused on wells with little direct research being conducted on gallery intake systems. Because there are inherent limitations on the capacity of all well intake systems, new research has been focused on gallery intakes because they have the potential to meet the intake requirements for virtually any SWRO treatment plant capacity.

While the basic concept of the seabed gallery is analogous to slow sand filtration, a technology used in the water industry for nearly two centuries, there are subtle, but significant differences in the design and operation of filters that treat seawater and are constructed within the marine environment. Slow sand filters operate by gravity feed, but seabed galleries operate by creating suction head loss across the filter media using a pumping system. Related aspects of design concepts for seabed filtration systems are presented herein, especially with regard to the design of the filter media and the balance of infiltration through the surface of the filter. General marine systems analysis is coupled with aspects of the function of benthic marine ecology as it affects the design and operation of seabed gallery intake systems.

This chapter provides a summary of the latest research on the feasibility assessment, design and construction of seabed gallery intake systems. The current greatest concentration of investigations being conducted on gallery intake systems is along the Red Sea coast of Saudi Arabia, because this region is projected to have the greatest increase in seawater desalination capacity over the next 20 years.

2 Methods

2.1 Site-Specific Investigations to Assess Technical Feasibility

In all natural system filtration methods, the site-specific geologic and hydrologic conditions dictate the feasibility of using a specific intake type. There are a number of issues that affect the feasibility of an intake design for any SWRO facility. To demonstrate feasibility an investigation needs to show that: (1) feed water flow will be provided under all operating conditions, (2) the intake system will operate under extreme natural system conditions, such as during harmful algal blooms (HAB’s), (3) the intake will operate without causing significant environmental impacts or harm, (4) the intake can operate in coordination with the process design to minimize energy consumption, (5) the intake will minimize the use of chemicals in the pretreatment systems, (6) the intake will minimize interruption and/or maintenance caused by biofouling, (7) the intake will operate the entire system within a competitive economic mode, and (8) the intake design will convince the owners, operators, and financiers that the intake components meet an acceptable reliability standard.

A methodology for coastal classification and general screening for technical feasibility for all subsurface intake systems based on geologic and hydrologic conditions has been developed by Dehwah et al. (2014) (Chap. 7). Seabed gallery intakes, in general, have a larger range in site-specific conditions in which they can successfully operate. There are some fundamental feasibility issues that must be addressed when assessing any specific site. The gallery must be covered with water under all conditions so the filtration is constant. The selected marine bottom must not occur within an environmentally high-sensitivity zone, such as living coral reefs or heavy concentration of seagrass beds. The area of siting must have a limited rate of sediment deposition, especially with fine-grained muds, which could decrease the infiltration rate below operational minimums. The marine bottom at the selected site must not be subject to extreme excavation during storms. Construction of the seabed gallery must be feasible. A comprehensive checklist of factors that may need to be considered for assessment during the feasibility and design process is included in Table 11.1.

2.2 Literature Search and Site Inspection to Assess Tidal Range and Environmental Conditions

During the process of feasibility assessment and design for a seabed gallery intake system, a detailed literature search can be used to obtain general coastal characteristics and sometimes published coastal classifications are available (see Chap. 7). Perhaps the most useful tool today is Google Earth which allows reasonably recent, rectified satellite aerial photography to be viewed for almost any coastline of the world. This information can be used along with existing geologic and oceanographic studies to assess many of the issues raised in Table 11.1.

After the site screening process, it is necessary to conduct a physical inspection of the final sites being considered for a gallery intake. The site inspection should be conducted by a multi-disciplinary team, commonly consisting of an engineer (civil or with a coastal engineering specialty), a geologist, a marine biologist, and a land acquisition or access (easement) specialist. The specific composition of the inspection team will vary based on the capacity of the SWRO facility under consideration and the complexity of the coastline being evaluated. Where there are only a few sites under consideration, the team should begin the process of field data collection and possible bottom mapping to save field costs.

An example of a literature search containing relevant information for development of seabed gallery intake systems is contained in Dehwah et al. (2014). A series of marine biology, sediment, and geomorphology investigations were documented. These types of research are important to the siting and feasibility assessment for seabed gallery intake systems.

2.3 Sediment Investigations

There are several issues related to sedimentation rate and sediment grain size characterization that require assessment and analysis. The key issue is the long term viability of the surface and near-surface part of the gallery. Any sediment deposition that will potentially affect the hydraulic conductivity of the uppermost layer of the filter during future operation will require assessment. The excavation required for gallery construction must also be practically and economically possible at a feasible site. Therefore, the occurrence of a hard rock bottom or the occurrence of boulders would not be conductive for gallery development.

Deposition of fine-grained sediment is a major issue that affects site feasibility. If a site is subject to short-term mud deposition events, commonly associated with either storms or floods discharging sediment into the sea, then the site is unlikely to be useful for gallery development. Locations near perennial stream discharges to the sea, such as deltas, are large-scale mud depositional areas and should be screened out in the initial feasibility assessment stage. Some marine areas that are relatively remote from delta locations are also mud deposition areas caused by transport of fine sediments parallel to the coastline by ocean currents. Current maps and a remote inspection of the seafloor using side-scan sonar can reveal these “mud belt” areas.

The marine bottom should be relatively stable in terms of sediment deposition or erosion even if the bottom is predominately sandy. Seasonal changes in the bottom profile across a gallery site can be incorporated in a gallery design as long as the changes anticipated are not too extreme. For example, if the area is subject to slow erosion at a few centimeters per year, the upper gallery layer could be designed to have greater thickness. Seasonal oscillations in erosion and deposition can be expected in most areas and storm excavation with reestablishment of the original bottom profile is also common. Again, extreme change decreases the potential for a site to be feasible for gallery design and construction.

Since sandy sediment is expected to move across the seabed by current transport, oscillatory wave action, or storm wave drag on the bottom, it is important to understand and map the grain size characteristics of the surface sediments. This has two useful purposes; understanding of deposition patterns that may not be obvious from initial scans of the area and for design of the upper layer of the filter. The upper engineered filter layer should be compatible with the sediment grain size characteristics or the top of the gallery could be scoured or may stand high after extreme events. It is desirable to have the engineered filter blend in with the bottom sediments so that no bathymetric change on the bottom is produced across the filter during operation.

A relatively new consideration is the potential impact of sea level change related to global warming. Accelerated sea level rise should be considered within the gallery feasibility and design process. The typical life cycle maximum consideration for a SWRO plant is 30 years, so the sea level rise for this timeframe or up to 50 years may require analysis. Depending on which climate scenario is used, the expected sea level rise by the year 2100 will be somewhere between 0.4 and 1 m (IPCC 2013). This magnitude of increase will not likely change the sedimentation patterns along most coastlines within the offshore area. The gallery function will not be harmed based on increasing water depth, but could be harmed under shoaling depths in terms of storm excavation. Sea level change should be considered during system design to ensure that intakes are robust enough to accommodate variations in the rate of change. The pipeline connected an offshore seabed gallery could be at risk from sea level rise and should be designed to accommodate the projected range of change.

2.4 Red Sea Nearshore Sedimentology Investigation

The Red Sea shoreline has been studied in detail to assess the feasibility of developing seabed gallery intake systems (Fig. 11.2).

A series of diverse sediment types occurs along the shoreline and nearshore areas of the Red Sea. Some pure carbonate sand environments occur where the fringing coral reefs are the predominant nearshore environment. Mixed carbonate and siliciclastic sediments occur adjacent to areas where wadi discharges have carried siliciclastic sediments into the nearshore marine environment and have mixed with the locally generated carbonate sediments. Pure siliciclastic sediments occur within channel discharge features located along the shoreline. Many of these features are a special type of alluvial fan (fan deltas) that intersects with the sea (Wescott and Etheridge 1980; Hayward 1985).

To establish a sedimentological assessment at site-specific locations, a linear section of the beach was selected. A sample grid was then established with the collection of samples beginning at the beach and moving seaward at horizontal increments of 10 or 20 m. Within the five sites investigated, between 50 and 91 sediment samples from the shoreline and offshore were collected along transects running perpendicular to the beach. The spacing between transects was based on the desired segment of the shoreline and nearshore area to be investigated (Fig. 11.3).

Sediment sampling grids of the site-specific investigations along the Red Sea. Om Al Misk Island study (from Sesler and Missimer 2012)

After collection, the sediment samples were carefully washed with fresh water in order to remove salts without removing any fine sediment. Washed samples were analyzed for hydraulic conductivity, porosity and grain size distribution using standard laboratory methods (ASTM 2006; Wenzel 1942; Tanner and Balsallie 1995).

2.5 Background Red Sea Water Quality

Data on background quality of the local seawater should be obtained regardless of the type of intake design is being considered. While a seabed gallery is perhaps a more forgiving intake design compared to a conventional open-ocean intake, it still can have operational difficulties related to seawater quality. The most significant issue is the average turbidity of the seawater over time and event-related turbidity, such as after storms. Also, the occurrence and impact of HAB’s should be assessed. Therefore, some background turbidity measurements should be collected. However, the percentage of mud in the surface sediments is a good proxy for the potential impact of turbidity events or long-term turbidity impacts to the filter top.

The Red Sea has a restricted circulation, which results in seawater with a generally higher salinity than the global average of about 34,500 mg/L. It is necessary to assess the local seasonal variations in salinity and the nearshore circulation to be sure that the salinity does not vary outside of the acceptable range of SWRO treatment. Based on investigations conducted by Mantilla and Missimer (2014), Rachman et al. (2014), Dehwah et al. (2014), the common average salinity in the nearshore shallow water is 41,000 mg/L. Some offshore and deep water salinity data are presented in Chap. 6. Surface salinity offshore is about 38,000 mg/L and increases to about 40,000 mg/L at 90 m below surface.

At very shallow water sites along the shoreline, measurement of salinity during different seasons may be necessary to assure that periods of higher salinity do not occur. The evaporation loss rate along the nearshore area is up to 6.5 m/year (Lopez et al. 2014). In areas where very limited circulation occurs, the salinity may rise during the summer season, particularly when it is not windy. Fortunately, there is an onshore wind along the Red Sea shoreline during a large part of the year. This tends to cause nearshore mixing and limits short-term salinity increases.

3 Results of Investigations

3.1 Red Sea Water Quality and SWRO Treatment Facility Operating Difficulties

Operational difficulties have been reported from a number of SWRO facilities located along the Red Sea coastline. Membrane fouling has been a pervasive problem at the Shuqaiq facility as reported by operators. A number of smaller capacity SWRO plants in the Jeddah area have reported clogging of cartridge filters and some membrane biofouling. Facilities that use subsurface intake systems have had better operational experience compared to facilities using open-ocean intake systems (Dehwah et al. 2014; Rachman et al. 2014).

In order to assess the viability of seabed gallery intake systems along the nearshore region of the Red Sea, a detailed survey of the coastline was conducted and over a hundred sites were visited and sediment samples were collected. Based on the preliminary field data collected and proximity to various existing large-capacity SWRO plants, five site-specific investigations were conducted to perform detailed technical feasibility assessments targeted at seabed gallery intakes (Fig. 11.2).

3.2 Locations of Site-Specific Investigations

The five site-specific investigations were conducted at Om Al Misk Island (Sesler and Missimer 2012), King Abdullah Economic City (Dehwah and Missimer 2013), Shuqaiq (Mantilla and Missimer 2014), Shoaiba (Lujan and Missimer 2014) and near Jeddah (Al-Mashharawi et al. 2014). Each of these sites contains an existing SWRO plant that has a plan for expansion or has some type of operational difficulty (Table 11.2; Fig. 11.2).

3.3 General Offshore Bathymetry and Nearshore Bottom Conditions

Three of the five sites, Om Al-Misk Island, King Abdullah Economic City, and Shoaiba, contained a very low-gradient nearshore bottom profile from the beach seaward. The distance from the beach at mean low water to a depth of 1 m was roughly 100 m and to 2 m was an additional 100–150 m. The bottom was covered with a veneer of predominantly sandy carbonate sediments setting atop a soft to moderately hard marine hardground. The hardground can be classified as the inner reef and consists of modern marine cemented limestone. A fringing reef occurs seaward of the inner reef at a water depths ranging from 2 to 10 m. A very sharp increase in water depth occurs seaward of the reef. A vertical wall commonly drops into 450–600 m of water (see Chap. 6; Fig. 6.1). A generalized profile is shown in Fig. 11.4. A considerable percentage of the Red Sea beach and nearshore profile from Jeddah north to the Saudi Arabia-Jordan border shares a similar character.

At two of the sites investigated, Shuqaiq and Jeddah, the nearshore bottom conditions and bathymetric profiles were different. These environments contained predominantly quartz sand with some skeletal carbonates. The profiles showed a rather abrupt change in water depth at about 1.2–2 m dropping to over 3 m. No hardground or inner reef environment exists across all or parts of these sites. Shuqaiq contained more seagrass compared to the other sites. These sites were located near intersections of wadi channels with the shoreline.

The inner reef in the sites investigated contained both non-sensitive and sensitive environments. The non-sensitive environments consist of barren sand or hardground bottoms with no significant coral or marine grass cover. There is a tendency for the bottom coral density to increase in water depths greater than 2 m, especially where the bottom is rocky. The density of seagrass is quite variable and occurs typically in patches where water circulation is enhanced (Fig. 11.5). Very large variations in the seagrass density occur within the inner reef area. Seagrass does not occur in bare hardground areas.

The sandy bottom contains a variety of infauna including mollusks, benthic foraminifera, some red and green (rare) algae, and polychaete worms. Sesler and Missimer (2012) reported that measured polychaete worm densities can be up to 2500 individuals/m2. The high density of polychaetes occurs primarily where the bottom sediment is thickest and the water circulation is relatively good.

Areas with a low degree of environmental sensitivity were found at all five investigated sites that would allow the design and construction of a seabed gallery intake system without causing significant impacts. The sites contain shallow water with a relatively flat bottom. In all cases the season tide range was a maximum of 0.15–0.3 m. Therefore, the seabed gallery would be covered with seawater at all times of the year. Observed wave action, even during windy days, was rarely more than 0.5 m in height.

3.4 Sediment Properties at the Sites and Effects on Seabed Gallery Design

A large number of sediment samples were collected and analyzed from each site. The measured parameters included grain size distribution and mean grain diameter, porosity, mud percentage (sediment fraction with a grain size <0.0625 mm), and hydraulic conductivity. There was considerable variation in the mean grain diameter and mud percentage at each site. Examples of the spatial grain size distribution at two sites, one predominantly carbonate and the other siliciclastic, are shown in Fig. 11.6a, b. The sediment found is classified as medium to fine grained sand.

Based on the predominantly sand-sized nature of the sediment, the percentage of mud was also mapped to locate any areas where fine-grained sediment is being deposited. The mud percentage at the Om Al Misk Island and Jeddah sites is shown in Fig. 11.7. In both cases, the percentage is relatively low, but there are a few areas where it is higher for some reason.

The sediment porosity was measured across the sites investigated. Generally, it ranged from 0.3 to 0.45 based on the laboratory methodology used. The porosity is related to the distribution of grain size found in the sediment. Commonly, fine-grained sediments have a higher porosity compared to sandy sediments, especially as packing density increases.

There are important relationships between all four sediment parameters measured. The spatial distribution of all four parameters are shown for a carbonate sand site (Om Al Misk Island) in Fig. 11.8 and a predominantly siliciclastic site (Jeddah) in Fig. 11.9. A distinct relationship between hydraulic conductivity and mud percentage is evident at both sites.

Comparison of selected measured sediment parameters of a predominately carbonate sediment site at Om Al Misk Island (modified from Sesler and Missimer 2012)

Comparison of all four measured sediment parameters of a predominately siliciclastic sediment site at Jeddah (modified from Al-Mashharawi et al. 2014)

4 Discussion

4.1 General Feasibility Criteria and Site Assessments Along the Red Sea Coast of Saudi Arabia

Based on the criteria listed in Table 11.1 and the findings of the five site-specific investigations conducted along the Red Sea coast of Saudi Arabia, the design and construction of seabed gallery intake systems was found to be technically feasible at each site. The geological conditions were demonstrated to be very good for gallery design at each site with the surface sediment consisting of medium to fine sand with a low mud percentage, which results in a moderate hydraulic conductivity. The unlithified sediment has properties that would not interfere with the operation of a gallery and the sedimentation rate is low. Minor areas of mud deposition were found, but the gallery cells could be constructed away from those areas.

The bottom contained a veneer of unlithified sand setting atop a carbonate marine hardground at three locations. This limestone could be easily excavated to create the depth required to construct gallery cells. In fact, the shallow water and stable bottom may allow construction without using sheet-piling. The water depth ranges from 1 to 1.5 m which would allow the placement of a temporary road seaward from the beach. This would facilitate construction and could be removed after completion. Water depth is sufficient to maintain submergence of the gallery cells under all tidal conditions.

The bottom sediment and water depth at the sites with occurrence of siliciclastic sands also showed technical feasibility for gallery construction. The sand generally contained a minimum percentage of mud, moderate hydraulic conductivity, and the water depth was sufficient in the nearshore area to maintain submergence of the filters. Construction would require sheet piling and dewatering at these sites, but temporary roads from the beach to the seaward maximum position of the gallery cells could be used to facilitate construction.

Based on data collected at the sites and nearby locations, water circulation appears to be sufficient to maintain the nearshore salinity of between 41,000 and 42,000 mg/L. Strong onshore winds causes mixing of the water to offset high evaporation rates, particularly during summer months. The calcium carbonate saturation will be high and careful monitoring of the uppermost gallery sand layer will have to be done to assess any potential lithification caused by marine cement formation.

The nearshore hardgrounds which form the inner reef contain very low density of corals from the beach to a water depth of about 2 m. The density of seagrass within the sites studied is minimal and higher density areas can be avoided by selective siting of gallery cells. Therefore, the construction of gallery cells would not have a high impact on the marine environment and after completion of the gallery cells, the productivity of the infauna may actually be improved based on the water movement through the sands of the filters (more food for the polychaetes).

4.2 Compatibility of the Gallery Type with the Coastal Geology and Sediment Deposition in Relationship to Siting

All of the sites assessed are compatible with the coastal geology and processes that affect the nearshore bottom. None of the sites investigated were located directly seaward of a wadi intersection where flash floods could discharge large quantities of sediment in a single event that could cover the gallery top. The sites are located in areas where longshore and nearshore transport of sediment would move over the top of the gallery active layer. The continued survival of the offshore fringing reef and coral clusters in water depths of 1.5–2 m are indicators of the low sediment deposition rate.

4.3 Filter Media Design and Modification for the Site-Specific Condition

Seabed galleries are similar in design to slow sand filters that have been used in freshwater treatment since 1804 in Scotland and in 1829 at the Chelsea Waterworks Company in London (Huisman and Wood 1974; Christman 1998; Buchan 2003). The fundamental principle of the slow sand filter is to transmit water by gravity feed though a porous media to remove suspended solids, algae, and some bacteria by straining (and perhaps sedimentation), and small bacteria and some NOM via biological processes. A comparison between modern design of a slow sand filter versus a rapid sand filter is given in Table 11.3. Note that slow sand filtration only operates effectively with a range of natural turbidities ranging between 10 and 50 NTU within a freshwater environment. Note that no pretreatment of the water occurs within a slow sand filtration system and is required within rapid sand filtration. Operation of slow sand filtration for prolonged periods with influent turbidity above 50 NTU can cause breakthrough of poor quality water and/or system clogging.

An important aspect of the slow sand filter design is the quality of the water to be treated, and the hydraulic retention time of the water within the filter. There are limits on the turbidity of the raw water that can be effectively treated by slow sand filtration. Crittenden et al. (2005) suggest that the slow sand filtration process is effective for raw water with a turbidity range of 10–50 NTU. The hydraulic retention time of most slow sand filter systems ranges from 5 to 6 h. Hydraulic retention times for a slow sand filter with differing active layer thicknesses and an assumed uniform hydraulic conductivity are given in Table 11.4. There is an offset between the lower hydraulic conductivity of the surficial active layer and the increasing hydraulic conductivity with depth in the media. The key issues controlling the hydraulic retention time are the design infiltration rate and the upper active bed thickness. The methodology for proper calculation of hydraulic retention time is discussed in Sect. 11.4.4. Increased hydraulic retention time tends to increase the degree of water treatment in that more NOM is removed.

In freshwater systems, a biologically active gelatinous mat, composed of deposited and synthesized material, forms at the top of the filter sand. This unit is called the schmutzdecke (German for ‘dirty skin’) layer. The schmutzdecke layer is an important part of the filtration process and is where much of the biological treatment occurs. Growth of the schmutzdecke layer increases hydraulic resistance across the slow sand filter and it must be periodically scrapped off in order to maintain acceptable filtration rates. To maintain the same degree of biological treatment, the scrapped filter must be given time to “ripen”. This process can take between 12 h and several days in freshwater systems. Repeated cleanings by scrapping also reduces the thickness of the filter and changes the hydraulic retention time. New sand can be added to the surface of the filter to replace the material removed. A considerable amount of treatment occurs within this layer as water passes through it. Biological activity declined with depth within the filter. Huisman and Wood (1974) point out that in 1 m3 of sand media, there is over 13,000 m2 of surface area available for attachment of particulates and contaminants.

A recent discovery is that in seawater systems, a schmutzdecke layer does not form at the top of the filter and biological activity occurs throughout the active layer and perhaps into the lower support layers of the gallery filter (Abdullah Dehwah, personal communication, Water Desalination and Reuse Center, King Abdullah University of Science and Technology). Crittenden et al. (2005) suggest that the slow sand filter ripening period in freshwater systems requires a few days of operation, while column experiments conducted by Abdullah Dehwah at the King Abdullah University of Science and Technology determined that several months of ripening was required in seawater filtration before large quantities of the TOC were removed by biological activity. Therefore, there are some significant differences in the operation of slow sand filtration within difference salinity regimes.

The typical run length before reconstruction of the full filter bed is 1–6 months. Because of the development of the schmutzdecke layer in freshwater systems, most of the water treatment occurs within the upper 10 cm of the filter, so the hydraulic retention time is not so important. The longer ripening period in seawater slow sand filtration suggests that increasing the hydraulic retention time may be useful in improving the pretreatment capabilities of the gallery.

The regeneration of a slow sand filter is by scraping of the uppermost layer to remove the schmutzdecke. Operational experience at the Fukuoka facility in Japan shows that no clogging of the filter has occurred during an 8 year run. Sesler and Missimer (2012) suggest that marine infauna that are sediment-deposit feeders may clean the upper part of the filter by the fixing of the organic carbon and fine-grain sediment as hard fecal pellets that act hydraulically similar to sand grains.

The filter media needs to be fine enough to provide sufficient filtration of suspended material of concern and NOM (Barrett et al. 1991). Hendricks (1991, 2011) recommended that the d10 of the filter sand (sieve size that permits 10 % of the sand to pass through) should be 0.2–0.3 mm with a corresponding uniformity coefficient (UC, d60/d10) between 1.5 and 2.0. Coarser sand may be used (0.3–0.4 mm) if the uniformity coefficient is less than 3. Crittenden et al. (2005) suggest that average grain size of the media can range from 0.3 to 0.45 mm and the bed depth is normally 0.9–1.5 m. Huisman and Wood (1974) point out that the bed thickness must also contain support media, graded sand and gravel layers, to facilitate the capture of the supernatant water at the base of the filter.

Design of the slow sand filter media requires that the grain size distribution of the created layers allow proper support without breakthrough of fine grains into the next lower layer. The gravel support consists of multiple layers with an upwardly decreasing grain size. The layers need to be designed so that they are stable, minimizing settling of finer grained sand and gravel into underlying layers. Huisman and Wood (1974) proposed the following general rules for the design of the gravel support, which are still widely accepted:

-

1.

d90/d10 for a given layer ≤1.4

-

2.

d10 lower layer/d10 upper layer ≤4

-

3.

d10 top layers/d15 filter sand ≥4

-

4.

d10 top layer/d85 filter sand ≤4

-

5.

d10 bottom layers ≥2d (drain orifice or screen slot diameter)

Huisman and Wood (1974) noted that the requirement for a highly uniform sand (d90/d10 <1.4) may be too restrictive (i.e., expensive to meet) and that a ratio of 2 would be acceptable if the ratio of d10 values between layers is less than 3. The recommended minimum thickness of the gravel layers is three times the diameter of the largest grains or 5–7 mm for finer materials and 8–12 mm for coarse gravel (Huisman and Wood 1974). The use of fine sand in the top layer tends to provide a higher degree of removal of algae, bacteria, and viruses (Amy et al. 2006; Jenkins et al. 2011; Lujan and Missimer 2014). The upper sand layer, however, must be compatible with the natural bottom sand or it would be rapidly scoured away. In some cases, a finer layer may have to be placed below the upper active layer with a downward coarsening below that level, or the uppermost layer must be significantly thickened, to increase hydraulic retention time.

Each of the preliminary gallery media designs developed for the five sites along the Red Sea contained differing layer thickness and sediment mean grain diameter based on the local conditions found at each site (Table 11.5). Four of the five sites used a five layer structure and the other used six layers. Three typical designs are shown in Fig. 11.10. A wide range of bed thicknesses were developed from 2.5 to 5 m. The active layer thickness in the designs ranged from 1.0 to 3.0 m. The design infiltration rates ranged from 5 to 10 m/d. The media mean grain diameter ranged from 0.1 to 0.45 mm based on the local site conditions.

These site assessments were completed as MS thesis projects at King Abdullah University of Science and Technology. The students developed preliminary designs based on the current knowledge of slow sand filtration processes in the marine environment at the time the research was completed. Therefore, the optimal design at each site would likely be different based on the current state of knowledge. However, the thick upper active layer, where most of the treatment occurs, and the graded sand and gravel support layer structure would be unchanged. The optimal infiltration rate for the Red Sea of Saudi Arabia, based on average turbidity measurements, would likely be between 7 and 8 m/d. The hydraulic retention time should likely be between 7 and 8 h to yield the optimal pretreatment result for the design infiltration rates.

Another design issue that requires careful attention is the need to maintain vertical flow within the seabed gallery and not to induce horizontal inflow from sediments outside of the constructed filter below the sea bottom. This horizontal flow could cause anoxic interstitial water to mix with oxygenated seawater within the filter and could lead to adverse chemical reactions that could impact the downstream membrane process. This issue can be avoided by using a geofabric liner at the bottom and edges of the gallery cells (Cook 2003; Rollin 2004). In extreme cases, the gallery cells could be pre-fabricated as cement vaults and placed on the seabed in excavated trenches or above the seabed, but below the wave orbital or current scouring depth.

4.4 Proper Calculation of the Hydraulic Retention Time for a Seabed Gallery Intake System

Hydraulic retention time in seabed filtration systems is important to maximize the removal of TEP and various fractions of NOM. As stated throughout this chapter, it is important to strike a balance between the infiltration rate and the degree of pretreatment desired. Unfortunately, there is a discrepancy on the method of how to calculate the hydraulic retention time.

Within a slow sand filter, the gravel support layer lying beneath the primary media is quite thin and the simple estimate of the hydraulic retention time can be calculated by dividing the full bed thickness by the infiltration rate, so a slow sand filter with a bed thickness of 1.5 m and an infiltration rate of 4.8 m/d will have a hydraulic retention time of 0.3125 days or 7.5 h based on the mass balance of flow across the full thickness of the filter media. The head loss within a slow bed filter treating freshwater occurs mostly at the water-sediment interface where the schmutzdecke layer forms.

Seabed gallery designs tend to have greater thickness compared to conventional slow sand filters because they need to have a design robust enough to function under a wide variety of natural systems conditions, such as compatibility with the adjacent marine sediments that will move across the top of the gallery by various transport mechanisms, periodic excavation of the upper part of the filter media by storms, and bioturbation by burrowing and deposit feeding marine organisms. Therefore, the uppermost media layer will require a greater thickness compared to slow sand filters, may have a finer mean grain diameter, and will likely require a series of graded sand and gravel beds to allow a transition of grain size from the active upper layer through the lower collection layer to inhibit fine sediment infiltration.

Since the uppermost layer or layers of the seabed filter are the most active removal zone for all processes, including bacterial degradation of organic compounds, the best method to estimate hydraulic retention time is to use only the thickness of the active treatment layer(s) in the calculation. Therefore, a 2 m thick uppermost layer with an 8 m/d infiltration rate will yield an active zone hydraulic retention time of 6 h, even if the full filtration thickness is 4 m. The full thickness of the filter would yield a total hydraulic retention time greater that the active zone. The rate of volumetric flow through all layers will be the same (assuming no lateral flow) although average flow velocity may vary depending on effective porosity. To obtain an accurate estimate of the hydraulic retention time for the active layer, a Darcy flow model can be developed using all layers of the model design and could be coupled to the computer program used to estimate layer hydraulic conductivity and initial head loss through the filter.

4.5 Balance of the Surface Infiltration Rate with Proper Underdrain Design

Design of seabed gallery intake systems requires that the infiltration into the top of the filter media should be as uniform as possible. Since the head pressure loss within the basal collection layer induces the vertical flow of seawater, the pressure distribution with this layer must be carefully controlled. If the pressure is unevenly distributed, this will cause high, low, and perhaps no infiltration rates locally across the filter surface.

A critical part of the design is the configuration of the collection pipe, pipe intersections, the screen configuration, and the screen slot apertures. When a pipe is attached to a length of screen, the pressure head loss caused by pumping is transmitted from the pipe into some length of screen. Missimer (2009) showed that within a uniform screen cross-sectional diameter and uniform distribution of slots of the same aperture, the highest inflow will occur at the proximal end of the screen (Fig. 11.11). The friction head loss caused by flow of seawater across the rough screen and the inflow of water through the slots cause the available suction head to dissipate toward the distal end of the screen, thereby causing a very uneven inflow pattern and the probability that little or no inflow will occur at the distal end of the pipe. This problem becomes greater as the length of the screen is increased. Therefore, the screen length must be controlled so that flow stays relatively uniform.

Head loss and flow in a screen collector with a single proximal head loss (from Missimer 2009)

Mantilla and Missimer (2014) found that the collection pipe diameter, configuration, and type of intersection also effects the internal head loss and the distribution of suction head that is transmitted to the screens. The collection pipe and screen system should be designed to minimize head losses. The piping system must be evaluated by dividing it into segments and evaluating each segment in terms of head loss, especially where there are transitions from laminar to turbulent flow (White 2011). The head losses within a given design can be evaluated using the Darcey-Weisbach equation for the pipeline and screen segments and the corrections developed by Hager (2010) for the intersections of pipes. A general approach to calculation of the friction head loss and the method to optimize the gallery design is contained in Mantilla and Missimer (2014).

Based on the research contained in Mantilla and Missimer (2014), it is clear that additional research is required in the development of a computer program to optimize the design of gallery cells for maintaining an equalized head within the collection layer. In the absence of this optimization program some basic principles should be applied in the design of the underdrain system which include: (1) the gravel within the collection layer should have a very high hydraulic conductively to effectively cause spreading of the pressure loss within layer away from the proximal pipe attachments to the screens, (2) the length of the screens from the header point to the distal end should be limited, (3) the area of slot within the screens could be expanded from the proximal to distal end of the screen to encourage uniform inflow of water, and (4) the slot aperture could be increased from the proximal to distal end of the screens to maintain uniform inflow.

Since there is only one large-scale seabed gallery intake system in operation today (Fukuoka, Japan), there is a small quantity of operational data available for evaluation of system hydraulic issues. Based on the research by Mantilla and Missimer (2014), it is clear that additional research is required to optimize the design of large seabed gallery intake systems in the future. Also, it can be concluded that using a single gallery cell with long headers and screen lengths is not a viable design in term of operational reliability. Breaking the system into multiple cells with individual pumps is more logical in terms of operational hydraulics and reliability.

4.6 Concept of Modular Gallery Cells, Coordination with SWRO Plant Design, and Reliability Design Issues

For many years, water treatment plant designers abided by a general rule that no part of the facility could cause a more than 10 % operational loss if a component failed. The issue of operational reliability of a SWRO plant must consider all of the internal facility components, but also must consider the intake. A seabed gallery can be designed as a single feed water source to supply a pressurized header that conveys seawater to all of the high pressure pumps feeding the membrane trains. A single gallery with a very high capacity pump can be designed to meet the full feed water capacity requirement. This design type, however, is risky and does not meet an acceptable reliability standard.

The capacity required from any gallery intake system should be divided into a series of units in a modular configuration. A series of gallery “cells” should be designed and constructed to achieve reliable system hydraulics (see Sect. 11.4.5) and to subdivide the flow to improve operational reliability. An example of the gallery cell concept is shown for the Shuqaiq site developed in the site technical feasibility investigation (Fig. 11.12; Mantilla and Missimer 2014). A single cell would be equipped with a pump and could be used to feed a single corresponding SWRO process train or perhaps two trains depending upon the plant capacity. The failure of a feed water pump or required maintenance of the gallery surface could be accommodated, especially if a standby gallery cell is constructed.

Schematic diagram showing the design configuration of seabed gallery cells located along the coast of the Red Sea at Shuqaiq (from Mantilla and Missimer 2014). Each cell would be equipped with a single pump that would feed one SWRO train at this site

The number and configuration of gallery cells should be controlled by a combination of the site geological characteristics, environmental considerations, constructability or construction methods, and the SWRO plant design. Space limitations or the avoidance of high environmental impact areas could cause some significant separation distance between cells. Innovations in construction could also cause changes in the cell geometry and configuration. The correspondence between the number of cells and the SWRO plant design should consider the desired reliability factor.

4.7 Design Robustness to Overcome Possible Field Condition Changes

Seabed gallery intakes occur within the natural system are subject to the intense physical and biological processes of the nearshore marine environment. Depending upon the geographic location, a seabed gallery could be exposed to intense storm activity (hurricanes and typhoons), earthquakes, river or stream sediment discharges, harmful algal blooms, and man-induced contamination events. Each of these natural and anthropogenic factors should be considered in the design of the gallery intake system. The design needs to be robust enough to survive and remain operational during and after these events. Most of the possible impact events should have been considered during the technical feasibility and design phases of the project. However, not all factors can be considered, so the design should be robust enough to eliminate possible failures caused by unexpected events or such factors as sea level rise caused by global warming.

In regions where there are possible events that could cause temporary bottom excavation by storm activity, the upper active layer could be designed with a greater thickness to avoid damage to the graded filter. Some sediment deposition over the top of the intake may not cause a significant operational change unless the sediment is muddy or very thick. A slight increase in the upper bed thickness could cause a reduction in the head loss. Earthquake impacts, such as induced filter compaction, could also increase the head loss across the filter bed. A solution to this issue is to have the pump system designed to accommodate changes in the head loss by using a variable frequency drive (VFD) to maintain a constant flow rate. For extreme events, a small maintenance dredge may be required to clean a site while plant damage is being repaired. Many marine events would not only impact the intake, but would also impact the SWRO plant and support infrastructure. Therefore, the design considerations that affect the intake must be considered within the context of the entire SWRO facility.

4.8 Intake Pump Location, Design, and Operation

There are a variety of approaches to the design of a pumping system to withdraw seawater from an offshore gallery cell. The pump could be located close to the gallery near the shoreline and placed within a pump house or could be located at the SWRO plant site which could be some distance from the shoreline. A deep vault or sub-basement at the SWRO plant could be used to house the pumps and could also be used to produce the required suction head to maintain the inflow through the gallery cells. The key issue is to develop the least energy-intensive pump design that has high reliability.

4.9 Combining Rapid Infiltration with Membrane Filtration as a Complete Pretreatment System

Niizato et al. (2013) have recently suggested a hybrid pretreatment system consisting of a rapid seabed filter gallery system coupled with ultrafiltration and have termed the technology a high-speed seabed infiltration system (HiSIS). In a series of bench-scale column tests using a seawater feed, they tested infiltration rates ranging from 5 to 150 m/d. Some of their results are rather questionable in that the SDI reduction for a 5 m/d infiltration rate was only 5 % and increased to 22 % at 50 m/d and then declined to 12 % at 150 m/d. It is possible that some media compaction occurred due to the head loss experienced within the column. The experiment reductions in turbidity of the raw seawater ranged from 81 % at 5 m/d to 88 % at 50 m/d to 82 % at 150 m/d. A proxy for biofouling potential using ATP (Vesa et al. 2008) showed an average reduction at 5 m/d of 59 %, at 50 m/d of 79.4 %, and 70.6 % at 150 m/d. The head losses measured seemed to be rather low with all being less than 40 mm. However, only 200 m3 of raw seawater was filtered during the experiments.

If larger-scale experiments are run at greater duration and produce similar results, the combined HiSIS system coupled with ultrafiltration could be a hybrid worth consideration. Pilot testing using the discharge from a HiSIS system should be conducted to ascertain if the system is truly producing a reduction in TEP concentration and the rate of membrane biofouling. Another question arises concerning its ability to operate during HAB’s.

4.10 Constructability of Gallery Intake Systems Along the Red Sea Coast of Saudi Arabia

Comparative assessment of any subsurface intake versus a conventional open-ocean intake focuses on two primary issues; constructability and economics. Construction in the marine environment is generally complex and requires careful planning and sometime innovative methods. Even offshore velocity-cap intake structures are not simple to construct and create challenges for placement of the connecting pipeline, particularly in locations where high-energy beaches must be crossed.

There are several different approaches that can be used to construct a seabed gallery intake system. Three different types are herein explored which include: (1) temporary road construction from the beach and excavation and installation of the gallery cells in wet conditions, (2) use of sheet piling and construction of the gallery cells in a dewatered condition, and (3) dredging of an offshore trench and placement of prefabricated cells into the trench with some emergence above the bottom.

Gallery construction along the Red Sea nearshore of Saudi Arabia is less complicated and costly compared to many other regions. Because the nearshore sites occur in very shallow water (1–1.5 m) and the bottom is relatively stable, consisting of soft limestone with a veneer of unlithified sediments, a temporary access road could be constructed to reduce construction difficulty. The option would exist as to whether to construct the gallery cells either in a dry mode or in the wet, if the soft rock is suitably stable to allow the excavated trenches to remain open during placement of the engineered filter material and collection system. Another configuration would be to use a concept similar to the South Jeddah Corniche wellfield intake system, which is constructed on a permanent offshore artificial fill area (Fig. 11.13).

Gallery cells constructed in deeper water would generally require the use of sheet piling to allow excavation and filter construction. This type of marine construction has been used for over a century in the construction of support structure for large bridges across bay and shallow seas. An example is the City of Long Beach, California seabed gallery systems (Fig. 11.14). Perhaps an innovation would be to drive tong-and-groove concrete sheet piling with an upper fastener attachment that would extend from the concrete placed flush with the seabed to above the sea surface. This would allow dewatering during construction and would isolate the gallery walls from the subsea sediments.

Another approach would be to dredge a long linear area parallel to the shoreline with dimensions large enough to allow placement of a series of prefabricated gallery cells constructed with pre-cast concrete (boxes without tops and holes from the collection pipe fittings). The dredging could be used to move some of the sediment to a stockpile location with some sediment stored near the site to be used to backfill the excavated gap between the hard galley cells and the far edges of the trench. The prefabricated cells could be lowered from a construction barge into the excavated trench with cranes. The prefabricated concrete walls of the gallery cells could be designed to be flush with the sea floor or could be elevated above the seafloor to some extent. The design would have to match the offshore energy condition and consider potential scouring of the filter face (top) or the sediment around the edges of the gallery structure.

As the use of seabed gallery intake structure becomes more common, construction innovation will occur to ease the process and to reduce cost. Each new large capacity system will allow design and construction improvements to be made that will affect the project capital cost.

4.11 Capacity Limitations and Economics

The issue of capacity limitation is raised commonly when considering a subsurface intake system to meet the feed water requirements of large-capacity SWRO facilities, defined as those with a permeate production of over 100,000 m3/d. While all well intake types do have practical capacity limitations, gallery intakes can be effectively designed and constructed to meet very high capacities. The key issues in gallery capacity limitation involve constructability and economics, particularly the capital cost of seabed gallery construction.

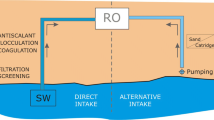

Evaluation of construction cost should take into consideration the pre-treatment processes that occur with the gallery intake system versus the construction and operation of these processes at a SWRO water treatment facility. Therefore, a life-cycle cost analysis should consider the cost savings from the elimination of many or all of the pretreatment processes used to treat seawater coming from an open-ocean intake. Missimer et al. (2013) show a variety of pretreatment process trains for a SWRO facility and the goal process, which is the use of a subsurface intake system to treat the raw water for direct placement into the cartridge filters or use a fine mesh screen to eliminate the risk of particulates entering the cartridge filters or process train (Fig. 11.15).

Pretreatment complexity reduction using subsurface intake systems (modified from Missimer et al. 2013). a Conventional pretreatment. b Alternative pretreatment. c Alternative pretreatment. d Alternative intake

A considerable volume of literature has documented the improvements in raw seawater quality that occur when using subsurface intake systems (Missimer and Winters 2003; Schwartz 2003; Bartak et al. 2012; Choules et al. 2007; Laparc et al. 2007; Missimer et al. 2013; Dehwah et al. 2014; Rachman et al. 2014). Therefore, many of the goals for reduction in the concentration of suspended solids, silt density index (SDI), algae, bacteria, NOM, and TEP are achieved by subsurface intake systems. The intensity of the in-plant pretreatment processes can be reduced with a consummate reduction in chemical usage, energy, and operational cost.

Within the life-cycle cost analysis, there will likely be a higher capital cost for constructing a seabed gallery intake system compared to any type of open-ocean intake system. However, the reduced operating cost over a 20 or 30 year operating period will make the seabed gallery system cost-effective depending on the percentage of operating cost saved by using this intake system. The reduced environment impacts associated with a reduction in impingement and entrainment of marine life also has an associated cost that should be factored into the life-cycle economic analysis. In conclusion, a life-cycle cost analysis should help justify the higher capital cost of the seabed gallery intake if there is real pretreatment cost savings included in the analysis.

5 Conclusions

Seabed gallery intake systems can be successfully designed and operated to meet the demands of virtually any capacity SWRO system. The feasibility of gallery development can be assessed at the screening level first and later at specific sites to assure that a gallery system can be successfully developed. A series of investigations of the Red Sea coastline and nearshore area were documented to illustrate the types of post-screening, site-specific feasibility investigations that should be conducted and the parameters that need to be measured to assure feasibility. The Red Sea nearshore area contains a large number of feasible sites that could be used to design, construct, and operate seabed gallery intakes as evidenced by shallow water with a low offshore slope, moderate to low wave energy, low and predictable range in tidal fluctuations, generally sandy nature of the offshore bottom, ease of bottom excavation for gallery construction, lack of environmental sensitivity of the offshore marine environment, and constructability of gallery cells.

Considerable care must be used in the design of seabed galleries to assure operational reliability. The engineered filter media needs to be designed to assure that infiltration of finer sand from the upper to lower layers does not occur. While a geotextile fabric could be used to separate the active sandy upper layer from the underlying coarse gravel collection layer, this is not recommended because of concerns related to potential clogging caused by bacterial growth. The thickness of the uppermost, active filter layer must be considered to assure that the correct hydraulic retention time is achieved and that it is sufficiently thick to function after a storm excavation event and can withstand churning of the sediment caused by marine infauna, such as polychaete worms and burrowing shrimp.

Within the design of the gallery filter media, a balance must be achieved between the desired degree of treatment and the filter hydraulics. A range in active zone hydraulic retention time between 6 and 10 h is desirable. The hydraulic retention time can be estimated by dividing the active upper layer(s) by the infiltration rate. A hydraulic retention time in this range should allow the gallery intake to remove a large percentage of organic material and act as a part of the pretreatment system.

The hydraulic head loss based on the media hydraulic conductivity and design infiltration rate should be no greater than 1–1.5 m in most cases. The thickness of the upper active layer will generally range from 1 to 3 m depending of the site-specific conditions. The sediment grain size distribution in this layer must be compatible with the nature grain size distribution of the marine bottom in which it is placed (surface mobile sand).

Another key design aspect is the need to achieve as uniform as possible distribution of the infiltration rate across the surface of the gallery. The design of the underdrain system controls the head loss within the bottom layer that induces the vertical flow. The gravel in this lower collection layer must have a high hydraulic conductivity and the geometry of the collection header system and screens should be designed to keep the head loss with the system as uniform as possible. Extreme variation in the surface infiltration rate will cause the potential risk of clogging of the filter surface to increase, particularly in the surface areas overlying the proximal areas where the header attaches to the lateral screens.

The reliability of a seabed gallery system is a key design consideration. While the Fukuoka system uses a single gallery for its intake, it cannot be considered as the model design for reliability due to the potential failure of a single pipe or pump would curtail operation of the SWRO plant. Seabed gallery intakes should be designed using a series of “cells” which are independent galleries, each with a pump. The design of the SWRO plant should be coordinated with the gallery design so each train or set of trains receives feed water from a single gallery cell. At least one standby or emergency cell should be constructed to improve reliability, especially if a pump failure were to occur. Also, additional capacity could be used to reduce the overall infiltration rate during extreme events, such as an HAB.

Seabed gallery intake systems will become an important class of SWRO intakes in the future. Design innovations will be required to reduce the construction costs and increase the reliability so that they are considered for use in the large-capacity SWRO systems of the future. As more research is completed on the degree of pretreatment achieved and operational experience is obtained, the risk factor perceived by project designers, operators, and owners will be reduced.

References

Allen, J. B., Tseng, T. J., Cheng, R. C., & Wattier, K. I. (2008). Pilot and demonstration-scale research evaluation of under-ocean floor seawater intake and discharge. Proceedings of the American Water Works Association Water Quality Technology Conference. Cincinnati, Ohio Nov 16–20, 2008.

Al-Mashharawi, S., Dehwah, A. H. A., Bandar, K. B., & Missimer, T. M. (2014). Feasibility of using a subsurface intake for SWRO facility south of Jeddah, Saudi Arabia. Desalination and Water Treatment. doi:10.1080/19443994.2014.939870.

American Society for Testing and Materials (ASTM). (2006). Standard test method for permeability of granular soils. Standard D2434-682006, ASTM, West Conshohocken, Pa.

Amy, G., Carlson, K., Collins, M. R., Drewes, J., Gruenheid, M., & Jekel, M. (2006). Integrated comparison of biofiltration in engineered versus natural systems. In R. Gimbel, N. J. D. Graham, & M. R. Collins (Eds.), Recent progress in slow sand filtration and alternative biofiltration processes (pp. 3–11). London: IWA Publishing.

Barrett, J. M., Bryck, J., Collins, M. R., Jamois, B. A., & Logsdon, G. S. (1991). Manual of design for slow sand filtration. Denver, Colorado: American Water Works Association Research Foundation and American Water Works Association.

Bartak, R., Grischek, T., Ghodeif, K., & Ray, C. (2012). Beach sand filtration as pre-treatment for RO desalination. International Journal of Water Science, 1(2), 1–10.

Berman, T. (2010). Biofouling: TEP-a major challenge for water separation. Filtration and Separation, 47(2), 20–22.

Berman, T., Mizrahi, R., & Dosoretz, C. G. (2011). Transparent exopolymer particles (TEP): A critical factor in aquatic biofilm initiation and fouling on filtration membranes. Desalination, 276, 184–190.

Buchan, J. (2003). Crowed with genius: The Scottish enlightenment: Edininburgh’s moment of the mind. New York: Harper Collins.

Choules, P., Schotter, J.-C., Leparc, J., Gai, K., & Lafon, D. (2007). Operation experience from seawater reverse osmosis plants. Proceedings, American Membrane Technology Conference and Exposition. Las Vegas, Nevada.

Christman, K. (1998). The history of chlorine. Waterworld, 14(8), 66–67.

Cook, D.I. (2003). Geosynthetics. Rapra Review Reports No. 58, Rapra Technology Limited, Shrewsbury, 132 pp.

Crittenden, J. C., Trussell, R. R., Hand, D. W., Howe, K. J., & Tchobanoglous, G. (2005). Water treatment: Principles and design. Hoboken: Wiley.

Dehwah, A. H. A., Li, S., Al-Mashharawi, S., Rachman, R. M., Winters, H., & Missimer, T. M. (2014). The influence of beach well and deep ocean intakes on TEP reduction in SWRO desalination systems, Jeddah, Saudi Arabia. AWWA/AMTA Membrane Technology Conference Proceedings. Las Vegas, Nevada, March 10–13, 2013, 18 pp.

Dehwah, A. H. A., & Missimer, T. M. (2013). Technical feasibility of using gallery intakes for seawater RO facilities, northern Red Sea coast of Saudi Arabia: The king Abdullah Economic City site. Desalination and Water Treatment, 51(34–36), 6472–6481. doi:10.1080/19443994.2013.770949.

Fukami, H. (2002). Feature of the seawater infiltration water intake, and water quality variation at the time of pilot plant. Journal of the Japan Society of Civil Engineers, 75–76 (in Japanese).

Hager, W. H. (2010). Wastewater hydraulics: theory and practice. New York: Springer.

Hamano, T., Tsuge, H., & Goto, T. (2006). Innovations perform well in first year of operation. Desalination and Water Treatment, 16(1), 31–37.

Hayward, A. B. (1985). Coastal alluvial fans (fan deltas) of the Gulf of Aqaba (Gulf of Eilat), Red Sea. Sedimentary Geology, 43(1–4), 241–260.

Hendricks, D. W. (Ed.). (1991). Manual of design for slow sand filtration (p. 247). Denver: AWWA Research Foundation and American Water Works Association.

Henricks, D. W. (2011). Fundamentals of water treatment unit processes: Physical, chemical, and biological (p. 883). Boca Raton: CRC Press.

Huisman, L., & Wood, W. E. (1974). Slow sand filtration (p. 122). Geneva: World Health Organization.

Intergovernmental Panel on Climate Change (IPCC). (2013). Working Group I contribution to the IPCC Fifth Assessment Report (AR5), Climate change 2013: The physical science basis. Intergovernmental Panel on Climate Change. Geneva, Switzerland.

Jenkins, M. W., Tiwari, S. K., & Darby, J. (2011). Bacterial, viral and turbidity removal by intermittent slow sand filtration for households in developing countries: experimental investigation and modeling. Water Research, 45(18), 6227–6239.

Laparc, J., Schotter, J.-C., Rapenne, S., Croue, J. P., Lebaron, P., Lafon, D., et al. (2007). Use of advanced analytical tools for monitoring performance of seawater pretreatment processes. Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse. Maspalomas, Gran Canaria, Spain, Oct 21–26, 2007, IDAWC/MP07-124.

Lopez, O., Stenchikov, G., & Missimer, T. M. (2014). Climate change water management using aquifer storage and recovery of stormwater: Environmental Research Letters 9, 075008, 8 p. doi:10.1088/1748-9326/9/7/075008.

Lujan, L. R., & Missimer, T. M. (2014). Technical feasibility of a seabed gallery system for SWRO facilities at Shoaiba, Saudi Arabia and regions with similar geology. Desalination and Water Treatment, doi:10.1080/19443994.2014.909630.

Mantilla, D., & Missimer, T. M. (2014). Seabed gallery intake technical feasibility for SWRO facilities at Shuqaiq, Saudi Arabia and other global locations with similar coastal characteristics. Journal of Applied Water Engineering and Research, http://dx.doi.org/10.1080/2349676.2014.895686.

Missimer, T. M. (1994). Water supply development for membrane water treatment facilities (1st ed.). Boca Raton, Florida: Lewis Publishers.

Missimer, T. M. (2009). Water supply development, aquifer storage, and concentrate disposal for membrane water treatment facilities (2nd ed.). Methods in Water Resources Evaluation Series No. 1. Schlumberger Water Services. Sugar Land, Texas.

Missimer, T. M., Ghaffour, N., Dehwah, A. H. A., Rachman, R., Maliva, R. G., & Amy, G. (2013). Subsurface intakes for seawater reverse osmosis facilities: Capacity limitation, water quality improvement, and economics. Desalination, 322, 37–51. doi:10.1016/j.desal.2013.04.021.

Missimer, T. M., & Horvath, L. E. (1991). Alternative designs to replace conventional water-water intakes for membrane treatment facilities. Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse, pp. 131–140.

Missimer, T. M., & Winters, H. (2003). Reduction of biofouling at a seawater RO plant in the Cayman Islands. Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse, Paper BAH03-190.

Niizato, H., Inui, M., Kira, N., Inoue, T., Oiwa, T., Cai, H., et al. (2013). Innovative SWRO desalination technology introducing high-speed seabed infiltration system (HiSIS). Proceedings of the International Desalination Association World Congress on Desalination and Water Reuse. Tianjin, China, Paper IDAWC/TIAN13-033, Oct 20–25, 2013.

Okamoto, H., et al. (2005). Feature of the seawater infiltration water intake, and water quality variation at the time of test operation. Journal of Japan Society of Civil Engineers, 25–26 (in Japanese).

Pankratz, T. (2006). Seawater desalination technology overview. Presentation to the Georgia Joint Comprehensive Desalination Study Committee. St. Simons Island, Georgia, Aug 22–23, 2006.

Passow, U. (2000). Formation of transparent exopolymer particles, TEP, from dissolved precursor material. Marine Ecology Progress Series, 192, 1–11.

Passow, U., & Alldredge, A. L. (1994). Distribution, size and bacterial-colonization of transparent exopolymer particles (TEP) in the ocean. Marine Ecology Progress Series, 113(1–2), 185–198.

Rachman, R. M., Li, S., & Missimer, T. M. (2014). SWRO feed water quality improvement using subsurface intakes in Oman, Spain, Turks and Caicos Islands, and Saudi Arabia. Desalination, 251, 88–100.

Rollin, A. L. (2004). Long term performance of geotextiles. Proceedings 57th Canadian Geotechnical Conference. Quebec City, Quebec, Session 4D, pp. 15–20.

Schwartz, J. (2003). Beach well intakes improve feed-water quality. Water & Wastewater International, 18(8).

Sesler, K., & Missimer, T. M. (2012). Technical feasibility of using seabed galleries for seawater RO intakes and pretreatment: Om Al Misk Island, Red Sea, Saudi Arabia. IDA Journal: Desalination and Water Reuse, 4(4), 42–48.

Shimokawa, A. (2012). Fukuoka District desalination system with some unique methods. Proceedings of the International Desalination Workshop on Intakes and Outfalls. National Centre of Excellance in Desalination, Adelaide, Australia, May 16–17, 2012.

Tanner, W. F., & Balsillie, J. H. (1995). Environmental clastic granulometry. Tallahassee: Florida Geological Survey, Special Publication 40, 142 p.

Vesa, M. J., Ortiz, M., Sadhwani, J. J., Gonzalez, J. E., & Sanatana, F. J. (2008). Measurement of biofouling in seawater: Some practical tests. Desalination, 220, 326–334.

Wang, S., Allen, J., Tseng, T., Cheng, R., Carlson, D., & Henson, J. (2009). Design and performance update of LBWD’s under ocean floor intake and discharge system. Proceedings of the Alden Desalination Intake/Outfall Workshop. Holden, Massachusetts, Oct 16, 2009.

Wang, S., Leung, E., Cheng, R., Tseng, T., Vuong, D., Carlson, D., et al. (2007). Under sea floor intake and discharge systems. Proceedings of the Interbational Desalination Association World Congress on Desalination and Water Reuse. Maspalomas, Gran Canaria, Spain, Paper IDAWC/MP07-104, Oct 21–26, 2007.

Wenzel, L. K. (1942). Methods for determining permeability of water-bearing materials with special reference to discharging-well methods. U.S. Geological Survey Water-Supply, Paper 887.

Wescott, W. A., & Ethridge, F. G. (1980). Fan-delta sedimentology and tectonic setting-Yallahs fan delta, southeast Jamaica. Bulletin American Association of Petroleum Geologists, 64, 374–399.

White, F. (2011). Fluid mechanics. New York: McGraw-Hill.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Missimer, T.M., Dehwah, A.H.A., Lujan, L., Mantilla, D., Al-Mashharawi, S. (2015). Feasibility and Design of Seabed Gallery Intake Systems Along the Red Sea Coast of Saudi Arabia with Discussion of Design Criteria and Methods. In: Missimer, T., Jones, B., Maliva, R. (eds) Intakes and Outfalls for Seawater Reverse-Osmosis Desalination Facilities. Environmental Science and Engineering(). Springer, Cham. https://doi.org/10.1007/978-3-319-13203-7_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-13203-7_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-13202-0

Online ISBN: 978-3-319-13203-7

eBook Packages: EngineeringEngineering (R0)