Abstract

The olive oil industry is a significant productive sector in the European Union and the related production process is characterised by a variety of different practices and techniques for the agricultural production of olives and for their processing into olive oil. Depending on these different procedures, olive oil production is associated with several adverse effects on the environment, both in the agricultural and in the olive oil production phase. As a consequence, tools such as LCA are becoming increasingly important for this type of industry. Following an overview of the characteristics of the olive oil supply chain and its main environmental problems, the authors of this chapter provide a description of the international state of the art of LCA implementation in this specific sector, as well as briefly describing other life cycle thinking methodologies and tools (such as simplified LCA, footprint labels and Environmental Product Declarations). Then, the methodological problems connected with the application of LCA in the olive oil production sector are analysed in depth, starting from a critical comparative analysis of the applicative LCA case studies in the olive oil production supply chain. Finally, guidelines for the application of LCA in the olive oil production sector are proposed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Olive oil production is an important agri-industrial sector (in terms of both production and consumption) in many Mediterranean regions (IOC 2013; Vossen 2007). Furthermore, the olive groves and olive production are increasing yearly (FAOSTAT 2013) and, recently, the importance of olive oil has also been growing in new producing countries located in America, Africa and Australia (IOC 2013). On a global scale, most olive cultivation areasFootnote 1 can be found in Mediterranean countries, such as Spain (2,503,675 ha), Italy (1,144,422 ha), Tunisia (1,779,947 ha), Greece (850,000 ha), etc. (FAOSTAT 2013). The leader of the international market is the EU, which produces over 70 % of the world’s olive oil. As concerns importing countries, the most important are the USA, Japan, etc. With regard to exports, the most relevant are the main EU countries, exporting over 440,000 t of olive oil, followed by Tunisia, Syria and others (Table 2.1).

Despite the economic importance of this food product in many countries, olive oil production is associated with several adverse effects on the environment that cause resource depletion, land degradation, air emissions and waste generation. The impacts may vary significantly as a result of the practices and techniques employed in olive cultivation and olive oil production (Salomone and Ioppolo 2012) and life cycle thinking approaches and assessment methods have increasingly been applied in order to gain a better understanding of their role from a life cycle perspective.

In the following sections, these different practices and techniques, along with the relative environmental consequences, are briefly described (Sect. 2.2). Then, a description of the international state of the art of life cycle thinking methodologies and tools, suitable for the environmental assessment of products and implemented in this specific sector, is presented (Sect. 2.3), with a specific focus on life cycle assessment (LCA). The methodological problems connected with the application of LCA in the olive oil production sector are analysed in depth, starting from a critical comparative analysis of the applicative LCA case studies in the olive oil production supply chain (Sect. 2.4). Finally, guidelines for the implementation of LCA in this sector are proposed (Sect. 2.5), in order to deal with and manage best the methodological problems presented above.

2.2 The Olive Oil Supply Chain: Production Processes, Technologies, Product Characteristics and Main Environmental Problems

A supply chain is a network of organisations that are involved, through upstream and downstream linkages, in the different processes and activities that produce value in the form of products and services delivered to the ultimate consumer (Christopher 1992). According to this definition, the olive oil supply chain can be briefly described as follows (IOC 2013; Niaounakis and Halvadakis 2006; PROSODOL 2011), using the different life cycle phases of the olive oil product: cultivation, olive oil production, by-product management, product transportation and distribution, consumption and waste management.

The cultivation phase includes the cultivation of olives using different treatments, such as soil management, pruning, fertilisation, irrigation, pest treatment and harvesting. Each of these treatmentsFootnote 2 can be carried out in different ways depending on whether:

-

the cultivation derives from centuries-old trees—traditional systems—or new intensive plants (in the latter option, the supply chain study must include plant breeding and tree planting);

-

the irrigation system uses the dry farming or the drip irrigation method;

-

the cultivation practices are conventional, organic or integrated, using different typologies of fertilisers and pest treatments;

-

the soil management, pruning and harvesting are manual or mechanised.

Harvesting is a very important process, because changes in the acidity level of olives occur after harvesting and other changes occur depending on the harvest methods: hand harvesting is the best method, but very expensive, while mechanical harvesting, if properly conducted (avoiding the breaking of the fruit skin), can give good results. After harvesting, the olives are sent to olive oil mills and processed within 24 h, in order to avoid fermentation phenomena.

Because the cultivation of olives can be carried out by means of various treatments, the environmental impacts can be very different in the various olive farming areas. However, by simplifying, three types of plantation can be considered: low-input traditional plantations (randomly planted and/or terrace-planted ancient trees managed with few or no chemical inputs and high manual work input); intensified traditional plantations (they have the same characteristics as the first type together with an increase in the tree density and the weed control, soil management using artificial fertilisers and irrigation, the use of pesticides and mechanical harvesting); and intensive modern plantations (high small-tree density managed with extensive use of mechanised systems and irrigation). The low-input traditional plantations have the lowest environmental impact and, moreover, they play a role in safeguarding the biodiversity and landscape value. Instead, the other two types of plantations can give rise to various environmental problems (i.e. soil erosion, run-off to water courses, degradation of habitats and landscapes and exploitation of scarce water resources) (Beaufoy 2000).

Much of the international olive production is transformed into olive oil. Different methods are used to extract oil from the olives and these processes create large volumes of liquid and solid waste. The waste stream is highly hazardous to the environment and presents a number of treatment challenges to olive oil producers.

The olive oil production phase includes two main phases: the preparation of a homogeneous paste and the oil extraction from the olives. First, the olives are classified and separated by quality; then, they are washed in order to remove the pesticides, dirt and impurities collected during harvesting (stems, leaves, twigs, etc.). A few olive oil mills do not wash olives, which are processed ‘as they are’ to overcome the problems connected with water consumption and the treatment of the polluted washing water. This is often motivated by the fact that extra moisture can involve problems (extractability and lower polyphenol content). However, these advantages should be cautiously compared with the disadvantages, since the pollution load of washing water demonstrates that olives need to be cleaned, otherwise pesticide and impurities remain on the olives and in the olive oil. After washing, crushing (tearing of the flesh cells to facilitate the release of the oil from the vacuoles) and malaxing (mixing the paste, allowing small oil droplets to combine into bigger ones) are essential steps. The next step consists of separating the oil from the rest of the olive components: oil is extracted using a press or a decanter, by pressing (the traditional or classical system) or by centrifugal separator (a continuous system), which can further use a three-phase or a two-phase decanter.

Traditional pressing (a discontinuous process) is still in use in some small mills that use a hydraulic press, but it is a relatively obsolete technology that has mainly been replaced with centrifugation systems, allowing lower manufacturing costs, better oil quality and shorter storage time of olives before processing. This process generates a solid fraction (olive husk or olive pomace) and an emulsion containing the olive oil, which is separated by decantation from the remaining wastewater.

Continuous centrifugation with a three-phase system, even though offering a higher production capacity with respect to traditional pressing, has some disadvantages, such as greater water and energy consumption (due to the addition of warm water to dilute the olive paste). This process uses a three-phase decanter that generates solid waste (olive husk or olive pomace), olive oil and wastewater.

Continuous centrifugation with a two-phase system allows the separation of oil from olive paste without the addition of water and this leads to the elimination of the problem of vegetable water. In fact, the two-phase system generates only olive oil and a semi-solid waste called olive wet husk or wet pomace (or two-phase olive mill waste).

Continuous centrifugation with a two-and-a-half-phase system (also called a modified system or water-saving system) exists; between a three-phase system and a two-phase one, it brings together the advantages of the two different systems (it requires the addition of a small amount of water and generates a solid fraction (olive wet husk or olive wet pomace) that includes part of the vegetation water and a smaller quantity of olive mill wastewater.

Another innovative technology is oil extraction from de-stoned olives. In the de-stoning process, the pits are removed before the kneading; some authors state that this process improves the quality of the extra virgin olive oil (better sensory qualities and shelf life) (Del Caro et al. 2006; Pattara et al. 2010). However, other authors (Di Giovacchino 2010) believe that this technology produces lower yields with a similar chemical sensory quality. Oil extraction from de-stoned olives can be made with both the three-phase and the two-phase system.

On average, the above-described techniques can produce around 200 kg of olive oil from 1 t of processed olives (Arvanitoyanni and Kassaveti 2008).

Therefore, as the average annual world production of olive oil in the 2007/2008–2012/2013 olive crop six-year period was equal to 2,862,800 t (IOC 2013), on the basis of the data available in the literature, it is possible to estimate that, on average in a year, the olive oil industry needs 572,560,000–1,674,738,000 kWh of energy and 1,431,400–16,045,994 m3 of water, generating 5,725,600–8,588,400 t of solid waste and 8,588,400–17,176,800 t of wastewater (estimation from Arvanitoyanni and Kassaveti 2008).

The designation of virgin olive oil is solely recognised as the olive oil obtained from the fruit of the olive tree by mechanical or other physical means under conditions, particularly thermal conditions, that do not lead to alterations in the oil, which has not undergone any treatment other than washing, decantation, centrifugation and filtration, excluding oil obtained using solvents or re-esterification processes and any mixture with oils of other kinds (EC 1991, 2007, 2008, 2013a). In particular, in accordance with the standards of the International Olive Council (IOC n. d.) and the EC regulations, virgin olive oils are classified into:

-

extra virgin olive oil, which is a higher quality olive oil with no more than 0.8 g per 100 g of free acidity (expressed as oleic acid) and a superior taste (fruitiness and no sensory defect). It must be produced entirely by mechanical means without the use of any solvents, and under temperatures that will not degrade the oil (lower than 30 °C);

-

virgin olive oil, which has no more than 2 g per 100 g of free acidity and a good taste;

-

lampante olive oil, which is virgin olive oil with free acidity, in terms of oleic acid, of more than 2 g per 100 g, and/or the other characteristics of which comply with those laid down for this category use.

Other classifications are related to the definition of olive oil, distinguishing:

-

refined olive oil, obtained by the refining of virgin olive oil using methods that do not lead to alterations in the initial glyceridic structure; it has no more than 0.3 g per 100 g of free acidity;

-

olive oil, which is a blend of refined oil and virgin oil (excluding the lampante virgin oil), fit for consumption as it is and having no more than 1 g per 100 g of free acidity;

-

olive pomace oil, obtained by treating olive pomace with solvents or other physical treatments. This oil can be sold as crude olive pomace oil, which is intended for refining (then designated for human consumption) or for technical use, and refined olive pomace oil, which is obtained from crude olive pomace oil by refining methods, producing an oil with no more than 0.3 g per 100 g of free acidity.

In the olive oil production phase, the packaging process is also included, even though the olive oil is often sold unbottled (to final consumers or to national or multinational bottling companies) and only a few mills directly bottle olive oil with their own label. Olive oil is generally bottled in stainless steel containers or, better, in glass bottles (in order to preserve better the stability of virgin olive oil), although there are cases of the use of innovative packaging, e.g. bottles made of polyethylene terephthalate (PET), which are 100 % recyclable (Salomone et al. 2013a).

In the by-product management phase, two methods are used to extract pomace oil. Olive pomace oil obtained from two-phase processing, with a moisture content close to 70 %, is physically extracted by centrifugation. The process also produces a residual water solution containing mineral salts, sugars and polyphenols (EC 2010). To extract pomace oil from the traditional and three-phase production methods, solvents are used. The olive pomace is mixed with the solvent hexane, which dissolves any residual oil. The exhausted pomace is then separated from the oil and hexane solution (called miscella) by filtration. Any hexane residues in the solid pomace are removed by means of a desolventiser, which evaporates the solvent (then captured for reuse). The oil and hexane solution is distilled, allowing the hexane to be recovered and reused, whilst the solvent-free oil undergoes further processing, such as refining. The solid waste from olive oil mills is also referred to as ‘olive cake’ and the liquid waste streams are termed olive mill wastewater. In recent years, the by-product management has been considered a strategic phase in the olive oil supply chain, because each of the different olive oil production methods creates different amounts and types of by-products, all of which are potentially hazardous to the environment. Therefore, the above-mentioned environmental problems have given rise to a series of studies for the development of methods for the treatment and valorisation of olive mill wastewater (Demerche et al. 2013; Kapellakis et al. 2008; Stamatelatou et al. 2012) and olive stones from de-pitted virgin olive oil (Pattara et al. 2010). In particular, the olive oil mill wastes have a great impact on land and water environments due to their high phytotoxicity (Roig et al. 2006) and their management is one of the main problems of the olive oil industry. Many options have been proposed for their treatment, disposal or valorisation (Niaounakis and Halvadakis 2006; Roig et al. 2006; Vlyssides et al. 2004):

-

Olive mill wastewater (OMW), deriving from traditional pressing and from the three-phase system, is the main polluting mill waste. This is constituted by vegetable water from the olives and the water used in the oil extraction and its chemical composition is variable depending on the olive varieties, growing practices, harvesting period and oil extraction technology. In any case, it is highly polluting due to the presence of organic compounds (organic acids, lipids, alcohols and polyphenols), even though it also contains valuable substances such as nutrients (especially potassium). Untreated olive mill wastewater is a major ecological issue for olive oil producing countries due to its highly toxic organic loads. Olive mill wastewater can lead to serious environmental damage, ranging from colouring natural waters, altering soil quality, phytotoxicity and odour nuisance. Traditional olive oil processing methods are estimated to produce between 400 and 600 litres of alpechin (OMW—olive mill wastewater) for each ton of processed olives (Di Giovacchino 2010; EC 2010). The olive mill wastewater levels from three-phase processes are much higher, producing between 800 and 1000 L of OMW for each ton of processed olives. Virtually no wastewater is produced by the two-phase process, although its wet pomace waste streams tend to have high liquid contents that remain costly to treat. The olive mill wastewater is composed essentially of water (80–83 %), organic compounds (mainly phenols, polyphenols and tannins) that account for a further 15–18 % of the wastewater content and inorganic elements (such as potassium salts and phosphates) that make up the remaining 2 %. These proportions can vary depending on factors related to the climatic and soil conditions, farm management, harvesting methods and oil extraction processes. The presence of proteins, minerals and polysaccharides in OMW means that it has potential for use as a fertiliser and in irrigation. However, the reuse opportunities are restricted by the abundance of phenolic compounds, which are both antimicrobial and phytotoxic. These phenols are difficult to purify and do not respond well to conventional degradation using bacteria-based techniques. The olive oil mill polluting loads are therefore significant, revealing levels of both BOD5 (biological oxygen demand in 5 days) and COD (chemical oxygen demand) between 20,000 and 35,000 mg per litre. This represents a notably large organic matter load compared with standard municipal wastewater, which exhibits levels between 400 and 800 mg per litre. Anaerobic digestion of alpechin results in only 80–90 % COD removal and this treatment remains insufficient to permit olive mill wastewater effluent to be discharged back into the environment. Discharging unsafe olive mill wastewater back into natural water systems can result in a rapid rise in the number of microorganisms. These microorganisms consume large amounts of dissolved oxygen in the water and so reduce the share available for other living organisms. This could quickly offset the equilibrium of an entire ecosystem. Further concerns are caused by the high concentrations of phosphorus in olive mill wastewater, since if released into water courses this can encourage and accelerate the growth of algae. The knock-on impacts include eutrophication, which can destroy the ecological balance in both ground and surface water systems. Phosphorous remains difficult to degrade and tends to be dispersed only in small amounts via deposits through food chains (plants–invertebrates–fish–birds, etc.). The presence of large quantities of phosphorous nutrients in olive mill wastewater provides a medium for pathogens to multiply and infect waters. This can have severe consequences for local aquatic life, as well as the humans and animals coming into contact with the water. Several other environmental problems can be caused by olive mill wastewater. These include lipids in the olive mill wastewater producing an impenetrable film on the surface of rivers, their banks and surrounding farmland.

At a glance, the most common treatment methods of OMW are:

-

a.

evaporation in storage ponds in the open—this method produces sludge that may be disposed of in landfill sites or used as a fertiliser in agriculture (after a composting process with other agricultural by-products);

-

b.

direct application to soil—this is a positive valorisation method of OMW considering its high nutrient content and its high antimicrobial capacity, but it also causes negative effects on soil associated with its high mineral salt content, low pH and presence of polyphenols. Land spreading of waste arising from olive processing is specifically regulated by law (e.g. in Italy by the Ministerial Decree—MIPAF 2005);

-

c.

co-composting—this method refers to the co-composting of OMW with olive pomace or olive wet pomace; it allows the return of nutrients to cropland and avoids the negative effects previously cited when OMW is directly applied to soil (Cappelletti and Nicoletti 2006; Salomone and Ioppolo 2012);

-

d.

the extraction of valuable organic compounds—the recovery of high-value compounds (phenolic compounds, squalene and tocopherols, triterpenes, pectins and oligosaccharides, mannitol, polymerin) or the utilisation of OMW as raw matter for new products is a particularly attractive way to reuse it, as the recovery process is of economic and practical interest (Fernández-Bolaños et al. 2006).

-

Olive husk (OH), deriving from traditional pressing and from the three-phase system, is usually sent to oil factories (oil husk extraction mills) that, after a drying process, extract oil with specific solvents (traditionally hexane). This treatment process produces oil and a solid waste called exhausted olive husk, which is used as fuel since the dried OH presents high calorific power.

-

Olive wet husk (OWH) derives from the two-phase system. In this case, olive vegetation waters are included in the OWH. Compared with the OH, the higher moisture level in the OWH creates more difficulties for its treatment in oil factories (mainly the higher energy demand for the drying process causing higher costs). For this reason, there are other methods for the treatment of the OWH and the most common are:

-

1.

Direct application to soil—due to its high potassium concentration and its low economic value, it can be directly applied to soil on land near the production site, but this practice could cause a negative effect on the soil even if it is less phytotoxic than wastewater (Cichelli and Cappelletti 2007);

-

2.

Composting (with or without the de-stoning process to obtain biomass for heat or electricity)—this method consists of the co-composting of OWH with other agricultural wastes (straw, leaves, etc.) or with manure used as a bulking agent. The compost obtained has a good degree of humification, no phytotoxic effect and a good amount of mineral nutrients (Cappelletti and Nicoletti 2006; Russo et al. 2008).

-

1.

The packaging phase includes bottling olive oil in glass, tin or PET containers. As the average annual world consumption of olive oil in the 2007/2008–2012/2013 olive crop six-year period was equal to 2,862,800 t (IOC 2013), assuming that only containers capable of holding 1 kg of olive oil are used, the packages in circulation could amount to more than 2,860,000,000 per year.

The transportation and distribution phase includes the transport activities (related to raw materials, by-products and wastes) and the distribution of the product in local, regional, national or international markets. Transport activities can also occur elsewhere in the life cycle (other than those instances already mentioned), either between any two subsequent life cycle stages or within a given stage, depending on the site-specific means of processing and the level of supply chain integration.

The consumer phase, in the case of olive oil, is certainly not significant from a life cycle perspective, considering that the product consumption does not need further preparation or treatments. Table 2.1 shows that the consumption of olive oil is quite widespread on the international scale in countries such as Italy, Spain, the USA, Greece, Turkey, Syria, etc.

Finally, the waste management phase (end of life) includes the treatment of bottles and packaging waste (cardboard boxes, etc.). This phase can also have great impacts on the environment depending on the method of waste management chosen (for example, reuse, recycling, landfilling, etc.).

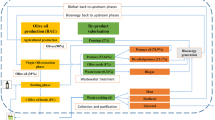

The phases of the olive oil supply chain with the related main environmental consequences are synthetically represented in Fig. 2.1.

As far as the materials and energy balance related to the oil production are concerned, it is possible to highlight that the production (agricultural and industrial phases) of 1 kg of olive oil (double pressed) involves the consumption of 0.0264 kg of fertilisers (N2, P2O5, K2O), 0.019 kg of pesticides, 0.00855 kg of fuel, 0.243 kg of lube oil and 0.359 kWh of electrical energy (Nicoletti and Notarnicola 2000).

2.3 Life Cycle Thinking Approaches in the Olive Oil Production Sector: The State of the Art of the International Practices

As exhaustively reported in Chap. 1, the growing awareness of food sustainability is driving an increase in research activities in the agri-food sector and, among these studies, over the last 15 years or more, numerous life cycle thinking (LCT) approaches have been followed (mainly life cycle assessment studies), evaluating food products and processes in order to identify and pursue sustainable food production and consumption systems.

The specific sector of olive and the olive oil supply chain has been investigated by several LCT studies since 2000. A critical analysis and state of the art of LCA studies applied in the olive oil sector was, firstly, conducted in 2008 (Salomone 2008) and then updated in 2010 (Salomone et al. 2010a), but contained only a comparative analysis of Italian studies, with the aim of highlighting the features of and/or differences in the fundamental aspects of Italian LCA studies; the first review included 13 Italian LCA case studies, while the second one contained 23 case studies. On the contrary, the literature review presented in this paragraph is a wider and deeper analysis with respect to the previous ones, because it includes:

-

international case studies, not only Italian ones;

-

life cycle thinking tools, not only LCA ones;

-

‘olive industry’ case studies, not only olive oil ones.

In particular, this literature review includes LCA studies that directly or indirectly refer to the wider term ‘olive industry’, therefore including applications not only to olive oil production, but also to olives in general (for oil or table use), to olive oil mill waste treatment and valorisation, and to table olive and olive oil packaging. The review refers to book chapters and articles published in international and Italian scientific journals and conference proceedings from 2000 to 2013; grey literature or other published papers could be missing.

In Table 2.2, the identified articles are listed, specifying the LCT tool used for the analysis and the product being investigated: 42 used LCA, 7 applied both LCA and life cycle costing (LCC) or another kind of economic analysis, 2 implemented simplified LCA (S-LCA), 9 dealt with environmental footprints (the carbon, water or ecological footprint) or energy balance or analysis and carbon balance, 10 were EPDs (Environmental Product Declarations) or papers reporting on EPDs and 2 reported on the integrated use of LCA and multi-criteria analysis (MCA).

In the following, a state-of-the-art analysis of the literature on life cycle thinking studies implemented in olive and olive oil production is presented, discerning between scientific articles including only the LCA methodology and articles concerning other LCT tools (LCC, S-LCA, footprint labels, EPD, etc.).

2.3.1 Life Cycle Assessment

The literature review shows that the most-used LCA analysis applied in the olive oil sector presents a comparative nature. Indeed, the first LCA study applied in this sector dates back to 2000 (Nicoletti and Notarnicola 2000) and focuses on the comparison between irrigated and dry olive cultivation systems, together with different olive oil extraction techniques. The comparison allows the evaluation of six different systems, obtained from the combination of two agricultural practices (dry and wet systems) and three extraction processes (single pressure, double pressure and centrifugation). This analysis structure, differently combining various systems and methods, was lately applied in other papers (such as Busset et al. 2012; De Gennaro et al. 2005; Salomone and Ioppolo 2012; Salomone et al. 2010a), also adding alternative treatments of olive oil mill waste, thus offering an articulated comparative LCA of very different olive oil production scenarios. In particular, De Gennaro et al. (2005) analysed various processes of the olive oil production chain, combining different oil extraction methods of extra virgin olive oil and different disposal and/or reuse treatments of pomace and other olive oil mill waste. The analysis indicates as the most eco-compatible production chain the one that uses continuous two-phase transformation and the pomace treatment for the production of fuel, while the least eco-compatible system is the system entailing three-phase continuous production, composting of the pomace and spreading on the ground of the oil mill waste water. In Salomone and Ioppolo (2012) and Salomone et al. (2010a), comparisons of eight different scenarios, including different combinations of cultivation practices, oil extraction methods and olive oil mill waste treatment, are presented. The analysis highlights a higher environmental load for conventional scenarios (except for impact categories associated with land use), an important environmental load associated with some sub-processes (such as fertilisation, the use of pesticides and the combustion of exhausted pomace), the higher environmental contribution of the sub-process of co-composting of olive wet pomace (OWP) with manure on fields rather than co-composting olive mill wastewater (OMW) and OWP with composter machines and a significant positive contribution (in terms of environmental credits for avoided production) associated with the use of by-products such as fuels or fertilisers. Busset et al. (2012) defined all the scenarios for olive oil production in France based on the different olive cultivation techniques, the different extraction processes and the different kinds of waste. Another paper, by Cavallaro and Salomone (2010), has a similar structure but provides new insights, because the LCA was implemented with MCA (see Sect. 2.3.6).

A different kind of comparative LCA study is dated 2001 (Nicoletti et al. 2001), presenting an evaluation of olive oil and sunflower seed oil. The results indicate that olive oil is more eco-compatible for all the categories except land use. The phase with the greatest impact is the agricultural phase for both systems (the main differences in this phase occur for the ODP category, caused by halon emission due to the production of pesticides from the sunflower cultivation). Concerning the industrial phase, higher impacts are connected with sunflower oil due to the VOC emissions occurring during sunflower oil chemical extraction. Another scientific article presents a comparison of olive oil with other kinds of vegetable oil (Özilgen and Sorgüven 2011), but it conducts an energy analysis rather than an LCA study (see Sect. 2.3.4).

Other comparative LCA studies focus on specific life cycle steps. For example, Russo et al. (2009) focused on the comparison of two processes of production of extra virgin olive oil using whole or de-stoned olives. The two processes present similar environmental performances, even though the process in which de-stoned olives are used has a lower impact: the real advantage of the de-pitting process is to obtain fragments of olive stone, which is an important by-product (much appreciated as fuel) both from an environmental and from an economic point of view. Similarly, Romani et al. (2004) focused on specific life cycle steps but reported on two diverse LCA applications: a comparison of organic and conventional virgin oil production and a comparison of two different applications for olive oil mill wastewater. The comparison of organic and conventional olive oil production is an aspect that had already been investigated by integrating the LCA and LCC methodologies (see Sect. 2.3.2), and other studies have been performed to compare these cultivation practices. Indeed, Cecchini et al. (2005) compared integrated, organic and conventional production of olive oil in Southern Italy and Neri et al. (2012) compared two organic and conventional farms in the central part of Italy, highlighting higher impacts for the agricultural phase in both case studies: in organic production, the impacts are related to a huge amount of fuel consumption (because of the use of old and low-efficiency machinery), whereas in conventional production, the main impacting input is the use of chemicals.

Olivieri et al. (2005a, b) applied LCA with a particular focus on the olive cultivation phase, for both conventional and organic farming, with the aim of quantifying numerically the environmental damage of the olive cultivation process and estimating the opportunities to reduce the impacts by comparison with organic olive cultivation (sensitivity analysis). Generally, these studies highlight higher impacts of conventional cultivation (except for the land use impact category). The other LCA presented by Romani et al. (2004), entailing the comparison of different wastewater treatments, falls into another widespread kind of LCA analysis that refers to waste treatment. Indeed, in 2002, the first LCA application not focusing on olive oil but on one of the main olive oil mill wastes (olive husk or olive pomace) was performed (Mansueti and Raggi 2002). In particular, this study reports the results of a comparative LCA between power generation from olive husk combustion and that from conventional technologies, highlighting that power generation from olive husk combustion (dark bars), for this specific case study, only deals with two kinds of impact categories: respiratory inorganic effects and acidification/eutrophication. As far as climate change is concerned, the olive husk combustion process has virtually no effect, since, as it is well known, CO2 from biomass is not considered responsible for global warming.

After this paper, other LCA applications specifically focusing on olive oil mill waste were published and/or presented, such as the following studies:

-

In Romani et al. (2004), a comparison of two different uses for olive mill wastewater (fertilisation–irrigation and optimised purified procedures able to recover higher quantities of polyphenols in view of possible future industrial application) is presented: a lower environmental load for the treatment allowing the recovery of polyphenols is highlighted;

-

In Russo et al. (2008), an analysis of the environmental advantage deriving from the use of olive pits as fuel (by combustion in furnaces commonly fed with wood pellets or de-oiled pomace), comparing the environmental impact with that generated by the recovery of de-oiled pomace and the production of wood pellets, was performed. The results show that the recovery of olive pits offers environmental advantages with respect to other alternative fuels. This depends fundamentally on the higher net calorific value of the pit fuel and also on its simple recovery method (at the beginning of the process of olive oil extraction);

-

In Olivieri et al. (2010a, b), an LCA study applied to a new integrated technology for olive oil mill wastewater (OMW) treatment and polyphenols recovery from a biphasic olive mill is presented. This method treats olive oil wastewater and, at the same time, produces novel products exploiting the antioxidant properties of polyphenols as a semi-manufactured good for ‘novel food’ (e.g. phytotherapy, cosmetics). The results of a sensitivity analysis show that the LCA of this process has less impact, with an overall percentage of 57 % with respect to the traditional process. The recovery of polyphenols from olive oil wastewater is important to add value to this waste as these substances can be an important source of new antioxidant products in ‘novel food’. Moreover, the recovery of polyphenols helps to avoid phytotoxicity in soil;

-

Intini et al. (2012) carried out an LCA in order to compare the environmental performance of using de-oiled pomace and waste wood as fuel. Only the global warming potential was calculated and compared with that of a plant for energy production that uses refuse-derived fuel (RDF) and that of one that uses coal. The LCA shows the important environmental advantages of biomass utilisation in terms of the reduction of greenhouse gas emissions;

-

In Chatzisymeon et al. (2013), the LCA methodology was utilised to evaluate three different advanced oxidation processes for olive oil mill wastewater treatment (UV heterogeneous photocatalysis–—UV/TiO2; wet air oxidation—WAO; and electrochemical oxidation—EO). Both EO and WAO can be competitive processes in terms of COD, TPh and colour removal. EO was found to be a more environmentally friendly technique as it yields lower total environmental impacts, including CO2 emissions to the atmosphere. The environmental impacts of all three treatments show that human health is primarily affected, followed by impacts on resource depletion. Overall, it was found that the environmental sustainability of these treatments is strongly related to their energy requirements and that their total environmental impacts decline according to the following order: UV/TiO2 > WAO > EO;

-

In El Hanandeh (2013), LCA was used to analyse the carbon emission reduction potential of utilising olive husk as a feedstock in a mobile pyrolysis unit. Four scenarios, based on different combinations of pyrolysis technologies (slow versus fast) and end-use of products (land application versus energy utilisation), were compared and the results show that all the scenarios result in significant greenhouse gas emission savings;

-

In Kalogerakisa et al. (2013), an LCA of the extraction of compounds, such as hydroxytyrosol and tyrosol as well as total phenols (TPh), from real olive oil mill wastewater (OMW) was performed, in order to provide the best available and most sustainable extraction technique using ethyl acetate, chloroform/isopropyl alcohol and diethyl ether. The use of ethyl acetate yields low environmental impacts and high antioxidant recovery performance and, therefore, it is assumed to be the best option, from both an environmental and a technical point of view, while the chloroform/isopropyl alcohol mixture was found to impose detrimental effects on the ecosystem, human health and fossil resources.

Another kind of LCA study in this sector relates to the analysis of the main life cycle phases. Indeed, in 2002, a paper presenting a cradle-to-gate analysis was presented (Salomone 2002), including the cultivation of olives, olive oil production, olive husk treatment and transport between these treatment phases. This was the first study to include pomace treatment in the LCA analysis of the product ‘olive oil’. The motivation was to avoid allocation, as suggested by ISO 14044 (at the time of the research ISO 14041), expanding the system in order to include the treatment of this by-product of olive oil production as well. After this, other papers studied the olive oil production chain, including the reuse of by-products and waste, such as the above-mentioned comparative LCAs of different olive oil production scenarios (Salomone and Ioppolo 2012; Salomone et al. 2010a), but in these cases the motivation was mainly connected with a vision of integrated environmental management of the whole olive oil production chain (thus including by-product treatment and valorisation). Furthermore, in Cini et al. (2008), LCA was used to evaluate the environmental impact of olive oil production considering different possibilities for the by-product reuses, but (similarly to De Gennaro et al. 2005) the paper does not include the cultivation step, just taking into account the extraction process of olive oil following different methods: the extraction process with oil production and pomace treated as waste; the extraction process with oil production and pomace used as a fertiliser; the extraction process with oil and pomace stone production; the extraction process with oil and pomace stone production; and the use of pomace residue as a fertiliser.

In 2007, table olive production also started to be investigated, mainly because of the growing interest in this specific sector caused by the increase in their cultivation and processing activities, as well as the relevant amount of wastes generated by the connected processing industries. Different papers have analysed this particular kind of production and its various aspects in depth: green olive cultivation and olive processing using the Spanish-style method (Cappelletti et al. 2010; Nicoletti et al. 2007a); black olive cultivation and olive processing using the Californian-style method (Cappelletti et al. 2008); a comparison of three different methods used for processing ripe table olives—two different methods of the Californian-style and the Spanish-style method (Russo et al. 2010, 2012); a comparison of the different packaging systems (Nicoletti et al. 2007b); and a study (Cappelletti et al. 2011) focusing on the production processes, the characteristics of wastewater and the pollution prevention technologies (in this case, the LCA results underline that eutrophication is a very important impact for the table olive processing industries, and it derives from the pollution of the wastewater).

Some LCA applications in the olive oil sector relate to the analysis of olive oil production in specific geographic areas, such as:

-

Avraamides and Fatta (2008)—LCA was used to evaluate the consumption of raw materials and emissions of pollutants from olive oil production in Cyprus (Greece) and to identify the processes causing the most significant environmental burdens. The interpretation results were organised in an interesting classification of the individual processes in priority categories according to their potential optimisation: fertilisation and oil extraction processes should be considered as priority 1 processes, irrigation and pruning are classified in priority 2, pest control and soil management in priority 3 and tree planting, collection and transportation of olives to the processing unit (as their contribution to all the environmental flows considered was less than 0.5 %) in priority 4;

-

Fiore et al. (2009)—in this paper, the results of an LCA application to the Sicilian (Italy) olive oil production, obtained from olives cultivated by an intensive managing system, are described. The study highlights the environmental burden deriving from the agricultural phase as well as the packaging phase, which involves an environmental impact due to the glass bottle production;

-

Christodoulopoulou et al. (2011)—a comprehensive LCA was carried out on olive oil of extra virgin quality, produced from 487 olive groves by 3 groups of 68 olive growers in southern Greece. The first goal of the study was to assess the environmental performance of olive oil in order to use it for an Environmental Product Declaration (EPD) according to PCR 21537 of Environdec. The second goal was to use the LCA as a starting point for the continuous improvement procedure with regard to the environment, by identifying the areas with the most significant impacts and by taking measures for their control;

-

Busset et al. (2012)—an LCA study of the French olive oil production sector is presented: it was elaborated partly in order to reduce the carbon footprint and to optimise the waste management of the olive oil sector in the SUDOE area (Spain, Portugal and France). The first results permitted the definition of all the scenarios for olive oil production in France based on the different olive production techniques (with or without irrigation, mechanical or not, organic or not), the different extraction processes (pressing, centrifugation in two phases or centrifugation in three phases) and the different waste management schemes (incineration or spreading). The expected result was a comparison of all the scenarios in order to identify the parameters that influence the environmental consequences of olive oil production;

-

Salomone and Ioppolo (2012)—the LCA methodology was applied to investigate the olive oil sector and identify useful information for taking strategic decisions aimed at the improvement and optimisation of a local olive oil chain in the province of Messina (Italy), directly involving a sample of companies of the local association of oil producers;

-

Notarnicola et al. (2013) analysed the cultivation phase of olives for the production of olive oil performed on 63 farms in the northern area of the city of Bari in Puglia (Italy), with the aim of assessing the variability of the LCA results. This is one of the few papers to analyse with the same inventory more than 60 data sets. The results indicate great variability within the management methods of the olive orchards, with agronomical practices differing from producer to producer (even from the same area). This is reflected in the high degree of variability of the inventory and impact assessment results.

Other interesting applications of the LCA methodology within the field of olive oil production include its use for supporting the definition of environmental management strategies and the integration of tools. In this category of studies, three cases could be included:

-

The first one is the case reported in different papers discussing integrated environment quality–HACCP systems aimed to realise useful guidelines for the acquisition of a territory product mark (Olivieri et al. 2007a, b, 2008). LCA was used to characterise environmental critical states in the cultivation and production of virgin oil; the most important problems identified are the use of fertilisers, the use of pesticides for olive fly capture and land use in conventional olive cultivation;

-

The second one is the case of a study specifically focused on the design of a model of a Product-Oriented Environmental Management System (POEMS) for agri-food companies (Salomone et al. 2013a), which includes the use of the LCA methodology for the product orientation of integrated management systems; one of the case studies reported is the comparison of two different packaging systems of extra virgin olive oil: glass vs PET bottle. The overall comparison highlights higher scores for the glass bottle system compared with the PET bottle system, except for the fossil depletion category, in which the higher score is linked to the PET bottle system, caused by PET production;

-

The third one is an LCA applied to the production of extra virgin olive oil in the Val di Cornia, Tuscany, Italy (Testa et al. 2012; Iraldo et al. 2013). The LCA study is intended to support the experimental implementation of a system of environmental qualification of a product, managed locally, which combines the features of type I and type III eco-labels. The agricultural phase is the most impactful of all the categories, in particular due to acidification, eutrophication and water consumption. The major impacts result from the production of pesticides. However, the use of pruning residues as a fertiliser and for domestic heating brings significant benefits for certain impact categories. In the extraction phase, olive mill waste water recovery as a fertiliser leads to a reduction in water consumption, eutrophication and global warming.

Another application of LCA presenting new insights is provided by Salomone et al. (2009), in which a comparison between a conventional extra virgin olive oil and a high-quality extra virgin olive oil with the characteristic of excellence is presented. The new element consists of an attempt to integrate the environmental impacts and the quality characteristics of the product into the LCA methodology by inserting an impact category called ‘cardiovascular risk’ defined on the basis of the contribution that the phenols, contained in olive oil, make to increasing HDL cholesterol (which helps to reduce cardiovascular risks); the aim of the study was to match the potential environmental impacts of the entire product life cycle with strategies for quality exploitation of the same and to assess the potential ways of integrating environmental aspects and quality improvements into the strategic decision making of firms.

Finally, the LCA methodology was part of different research projects in the olive oil sector, such as the ECOIL project in Greece (ECOIL n.d.), the OiLCA project in the SUDOE area (Spain, Portugal and France) (Busset et al. 2012), the EMAF project in Italy (Salomone et al. 2013b) and the Life + ECCELSA project in Val di Cornia, a rural area in the south of Tuscany, Italy (Iraldo et al. 2013).

2.3.2 Life Cycle Costing

Economic tools, also in the agro-food sector, can be combined with LCA in several ways (though not completely integrated) as a separate complementary analysis, within a toolbox or as a way of expanding it.

Generally speaking, these tools can play two main roles in life cycle management (LCM): on the one hand, they can provide ways of accounting for costs within the same boundaries and with reference to the same functional unit (FU) as in LCA (microeconomic-oriented accounting tools); on the other hand, macroeconomic-oriented accounting tools, such as input–output tables, either in monetary or in physical terms (in the latter case leading to material flows analysis—MFA), aim to study the way in which materials and substances flow through the economy.

As far as the accounting for costs at the microeconomic level is concerned, although life cycle costing (LCC) is not as standardised, as LCA is, there is a significant body of literature that addresses its conceptual framework and methodology. Thus, applications to food products, being applications of more generalised concepts, might seem not to pose major methodological problems: there is, in fact, evidence that LCC is also being used as a decision support tool within the LCA of food products. However, the literature provides few applications of LCC to food products and, more generally, to non-durable products: in this sector, applications of traditional LCC make sense only if an investment in a brand new food production plant is being evaluated. Furthermore, the approaches adopted when LCC is used within environmental management may vary significantly: cost elements, especially subsidies and external costs, are expected to affect the ranking of alternative options heavily, unless one specific option is found to be both environmentally sustainable and cost effective compared with the others.

On the contrary, examples of expansion of LCA by means of combined environmental–economic analyses include applications of input–output analysis along with MFA and LCA. In this case, as stated before, macroeconomic-oriented accounting tools, such as input–output tables, are used. Either they can be used in hybrid LCA of food products to extend the system boundaries to include all the complex transactions that characterise the entire economic system (such an approach has been used even at the institutional level to support integrated product policies) or they can be used to reveal the importance of understanding the physical structure underlying any food production system. The combination of macroeconomic analysis and LCA may prove to be particularly useful since, compared with detailed life cycle inventories, many models of entire economies employ a much smaller number of categories for representing production and consumption activities (Settanni et al. 2010).

As regards the application of LCC, or another kind of economic analysis, in the olive oil sector, the literature review highlighted seven studies (from 2003 to 2013): in particular, five of them are about the integrated application of LCA and LCC (Carvalho et al. 2012; De Gennaro et al. 2012; Notarnicola et al. 2003, 2004; Roselli et al. 2010), one is about the application of a sustainable model (economic and environmental analysis) (Palese et al. 2013) and the last one is about an energy, economic and environmental analysis (Pergola et al. 2013). Of the seven papers, just four were reviewed in depth because three of them (Notarnicola et al. 2003; Pergola et al. 2013; Rosselli et al. 2010) are parts of other papers (respectively: Notarnicola et al. 2004; Palese et al. 2013; De Gennaro et al. 2012).

As with the LCA studies (see Sect. 2.3.1), most of the LCC studies are of a comparative nature (organic vs conventional extra virgin oil; different olive-growing systems; alternative agronomical techniques vs conventional ones). Regarding the geographical boundaries of the examined papers, four focus on Italian case studies (De Gennaro et al. 2012; Notarnicola et al. 2004; Palese et al. 2013; Pergola et al. 2013) and one on a European case study (Carvalho et al. 2012). Furthermore, just two papers focus on the food product ‘olive oil’, respectively extra virgin olive oil (Notarnicola et al. 2004) and olive oil (Carvalho et al. 2012), while the others are about olive-growing models or agronomical techniques.

The paper by Carvalho (2012) was developed within the OiLCA international project with the aim of improving the competitiveness of the olive SUDOE space (Spain, Portugal and the south of France) and reducing the environmental impact of olive oil production through the application of the principles of eco-efficiency. This paper does not develop a comparative study, aiming to identify opportunities for waste management among the olive oil production using cutting edge technology that takes into account economic aspects, encouraging the modernisation of the sector and contributing to improving the quality of the final product. The management of these residues represents a big challenge because of their predominance and unavoidable production; it is thus important to take into account the available or emerging technologies, which may result in both economic and environmental benefits. The study was conducted by coupling the LCA and LCC methodologies, with 1 L of olive oil as the FU and the following phases as system boundaries: cultivation, oil production and packaging. Accordingly, it was possible to identify improvement solutions with their associated investment and production costs, providing business people with useful tools for making decisions based on economic (and environmental) criteria. These solutions have not yet been disclosed to the public.

Regarding the comparative studies, the one by Notarnicola et al. (2004) aimed to compare the production systems of organic and conventional extra virgin olive oil in order to assess their environmental and cost profiles and to verify whether the two dimensions (environmental performance and costs) move in the same direction. For the cost assessment, in particular, the LCC methodology was applied with the same FU and system boundaries as the LCA study: 1 kg of extra virgin olive oil and all the direct (agriculture practices, harvesting, transport and oil extraction) and indirect (production and transport of the pesticides, fuels, etc.) activities. The transportation of chemicals (from the factories to the agricultural fields), of materials and of the workers involved in the harvesting and pruning operations (from town to orchard) and of olives (from the orchard to the oil mill) were also included in the system boundaries. All the related internal and external costs of the two systems are reported in the study (see Table 2.3), showing (for example) that the damage caused by conventional agriculture due to the use of fertilisers and pestidicides (in terms of reclamation and decontamination) costs more than 22 times that of organic agriculture or that the organic system is characterised by higher production costs due to the lower organic yields (this higher cost is, then, reflected in a higher market price).

Regarding the obtained outcomes, in the LCA–LCC comparison between conventional and organic extra virgin oil, if the external costs are not taken into account, the organic olive oil has a higher cost profile; on the contrary, if these costs are added to the conventional (internal) company costs and to the less tangible, hidden and indirect company costs, the organic olive oil has a lower total cost in comparison with the conventional one. All that considered, it is important to account for external costs, as the European Commission is already doing in several projects, for example the ExternE project (ExternE 2013). As far as the LCA results are concerned, the study demonstrated that the organic olive system is more eco-compatible than the conventional one by a factor of five due to the great difference in the TETP and FAETP categories.

Another comparative study is the one by De Gennaro et al. (2012), about the integrated assessment (environmental and economic) of two innovative olive-growing systems, ‘high density’ (HDO, over 200 tree/ha) and ‘super high density’ (SHDO, over 1,500 trees/ha), during their life cycle. The system boundaries included the phases of planting, cultivation, growing production, full production and plant removal and disposal, with an FU of 1 t of olives. The production of fertilisers and pesticides was also included, while transformation, distribution and consumption were excluded because they are the same for the two systems. The economic assessment was performed as requested by the LCC methods using, as criteria, the net present value (NPV) and the internal rate of return (IRR). This analysis shows that the HDO could be considered more convenient than the SHDO (the most innovative system): in fact, despite the lower operating costs of the latter, due to the complete mechanisation of pruning and harvesting operations, these costs are counterbalanced by the higher initial investment costs that the company has to face (which result as three times those of the HDO system). Furthermore, the HDO model achieves better performance (in terms of NPV and IRR) than the SDHO model: this result is mainly driven by the lower plantation costs, longer production cycle, higher productivity of olives and greater efficiency in the use of inputs that characterise the HDO model. Furthermore, the full production phase represents the major impact for both systems (more than 75 % of the whole impact in all the impact categories in HDO, between 50 and 75 % in SHDO). Regarding the environmental assessment, this analysis also shows a better performance of the HDO system for all the impact categories (Global Warming Potential GWP, Ozone Depletion Potential ODP, Acidification Potential AP, Photochemical Ozone Creation Potential POCP, Human Toxicity Potential HTP, Freshwater Aquatic Ecotoxicity Potential FAETP, Marine Aquatic Ecotoxicity Potential MAETP, Terrestrial Ecotoxicity Potential TETP, Nutrification Potential NP, Abiotic Depletion Potential ADP), with a percentage ranging from 21 to 37 %. The superior performance of the HDO system is mainly linked to the lower use of energy but also to lower chemical inputs and higher olive yields. As far as the energy use is concerned, the full production phase is characterised by the highest energy consumption, with 87.4 % (HDO) and 75.1 % (SHDO). Finally, the study highlights that the results remain the same even if a sensitivity analysis (modifying the olive yields of the two systems) is carried out.

Finally, the paper written by Palese et al. (2013) focuses on the proposal for a sustainable system (SS) for the management of olive orchards (156 plant ha− 1 with a distance of about 8 m × 8 m) located in semi-arid marginal areas. This new model presents two key aspects: the reuse of urban wastewater distributed by drip irrigation and the use of soil management techniques based on the recycling of the polygenic carbon sources internal to the olive orchard. Economic (and also environmental) analysis was performed to evaluate the sustainability of the proposed method when compared with the conventional management system (CS). In particular, the economic results were expressed at constant values by the formula:

with:

- TO:

-

representing the income from sales of oil and table olives

- PC:

-

showing the sum of fixed and variable costs, gross of taxes and overheads.

Data were evaluated for a period of 8 years, showing that the annual TO (€ ha− 1 year− 1), calculated at constant values, was strongly affected by the extent of the crop load measured in the examined period. In particular, the TO of the SS was shown to be constantly positive and greater (about three times, mostly due to the higher quality of the olive production–table olives) than the CS value. Regarding the PC, the SS showed higher values than the CS. Both systems presented a positive value of the GP/ha, but the SS was four times more profitable than the CS. Finally, the SS produced quite a regular income over the considered period thanks to the annual yield, while the CS guaranteed a GP in alternative years. The environmental assessment was focused, above all, on the CO2 stocks in plants and soil as well as the anthropogenic and natural CO2 emissions. It demonstrates that from this point of view the SS system is the most sustainable as well. By comparing the mean annual fluxes of CO2 (net primary productivity—NPP—total emissions), the SS system shows positive data with an important gain of CO2 sequestered from the atmosphere (15.45 t/ha− 1/year− 1), while the CS has total emissions that are higher than the NPP; the SS shows an annual gain of 3.85 CO2 t/ha− 1 in the first 0–0.6 m soil layer; on the contrary, the CS shows an important mean annual loss equal to 5.10 CO2 t/ha− 1. Finally, the SS is able to fix a higher amount of CO2 than CS (more than double). All that considered, the SS appears sustainable not only from the economic but also from the environmental and social points of view.

2.3.3 Simplified Life Cycle Assessment (S-LCA)

The practical use of environmental LCA methods and software tools in industry has revealed the need for simplifications of many applications. Hence, streamlined LCA methods have been derived from experience with the complex full methods (Hauschild et al. 2005). Simplified LCA (S-LCA), also known as streamlined LCA, emerged as an efficient tool for evaluating the environmental attributes of a product’s, process’s or service’s life cycle (Hayashi et al. 2006). The aim of S-LCA is to provide, essentially, results that are the same as or similar to a detailed one, i.e. covering the whole life cycle using qualitative and/or quantitative generic data, followed by a simplified assessment, thus significantly reducing the expenses and expended time. It has to include all the relevant aspects, but good explanations can, to some extent, replace resource-demanding data collection and treatment (Schmidt and Frydendal 2003). The assessment should focus on the most important environmental aspects and/or potential environmental impacts and/or stages of the life cycle and/or phases of the LCA and undertake a thorough assessment of the reliability of the results. S-LCA studies can be conducted to make a quick assessment of a product: the challenge is to adapt the LCA methodology and simplify its use, but to a more advanced LCA stage than for a screening LCA. S-LCA has to be interpreted as an ‘adapted’ LCA, depending on the effort that the LCA practitioner wants to put in for every life cycle stage. The minimum requirements can be summarised as follows:

-

the goal and scope;

-

the life cycle stages included, as well as a clear definition of the system boundaries;

-

the input materials/items included and excluded, with justification, as well as processes for energy, water, etc.;

-

an overview of the calculation rules and comments on the degree of approximation/uncertainties;

-

the impact categories considered (with justification);

-

the limitations;

-

the life cycle impact results and interpretation;

-

a statement regarding consistency;

-

the results.

The data used in a simplified study should, as far as possible, provide the existing time and budget constraints related to the country where the products are produced or being used. However, as this is not always possible, it is also acceptable to use assumptions, for example using data that represent a country with a similar electric energy grid mix and manufacturing technology. The data should represent the technology used as closely as possible.

In the olive oil production sector, LCA studies are, generally, aimed at identifying the environmental burdens associated with the processes involved and at proposing actions for further environmental improvements. Nevertheless, such goals are often complex tasks, mainly due to the lack of reliable input data related to the whole life cycle of the assessed system, thus affecting the accuracy and the significance of the study. An S-LCA procedure can make possible studies based on information that is already available, e.g. at the early conceptual design stage or when the input data do not allow the assessment of sources of environmental burdens.

The scientific literature in the sector includes a few studies that specifically apply a simplified procedure. Among them, Abeliotis (2003) focused on the analysis of a three-phase olive oil mill. It is not a comparative analysis but it aimed to assess the greatest environmental burdens of the production system examined. In each production stage, the input and output streams of mass and energy were identified (inventory phase) and the environmental impacts associated with the process were grouped together into a number of environmental impact categories (global warming potential, acidification, eutrophication and photo-oxidant formation, etc.). The boundaries of the system start with the fertilisation of the olive trees and end with the extraction of olive oil. Region-specific and agricultural phase LCI data were not available. For some processes, such as fertiliser and pesticide application, although site-specific data were desirable, estimates of emission factors and estimation techniques from the literature were used. The data for the mass and energy balance at the extraction stage were derived from the examined production process, but no experimental data were available with regard to the organic load of the effluent olive mill wastes from the treatment step, the N2O emissions and the energy embedded in fertilisers. Thus, these data were deduced from the literature sources and adapted to the analysed process.

This study shows that the most significant impact arising from the assessed process is the GWP, attributed to the electricity required for the olive oil extraction process as well as the energy used for the fertiliser production. However, two relevant impacts are not taken into account (land use and human toxicity), due to the lack of specific data about several sources of environmental burdens, such as the use of pesticides and the presence of phenols in the effluent olive mill wastes. Furthermore, no data about the treatment of the olive mill wastes are available.

Another example of an S-LCA study is presented in Raggi et al. (2000), in which the production and use of olive husk bricks, as a fuel for residential heating, were screened and a preliminary comparison of such a technology with natural gas combustion was carried out. The system boundaries were defined to cover all the steps from olive husk handling and pressing to its combustion in households, including the production of packaging and ancillary materials. The environmental burdens related to the oil extraction from olive cake were allocated in total to the extracted oil. With regard to the data quality, primary data were collected on-site directly from the economic factors involved in the product life cycle, while the literature and international databases were used for secondary data. The study presents a partial life cycle impact assessment, since only the GWP and AP were investigated. The results highlight that the most significant contribution to the GWP arises from transport, followed by the energy requirement in the husk-processing activities. No contribution of the CO2 from the combustion of olive husk was considered, assuming it to be ‘virtually’ equal to the CO2 absorbed by the plants during their vegetative cycle. With regard to the AP, the most significant contribution derives from the combustion of the biomass, due to the sulphur content in olive husks and the NOx released from the boilers.

The olive husk as a fuel in residential heating was compared with the performance of natural gas technology, with regard to the GWP and AP, in order to assess the environmental benefits and drawbacks associated with the biomass use, but the related primary energy saving was not considered. The assessed husk-based heating system contributes much less to the GWP than the use of fossil fuels, unless husk is transported over longer distances. However, the authors do not provide any specification about such distance. This study evidences the need for higher quality data in order to avoid estimations, since many of them are missing or inaccurate, such as the emission factors of husk combustion.

In the two above-cited studies, the S-LCA procedure is applied as a preliminary tool to assess different products of the olive oil chain. The former is aimed at evaluating the environmental burdens of olive oil produced in a three-phase mill, identifying and quantifying material and energy consumption and releases into the environment at the mill stage; the latter shows a preliminary LCA study of olive husk used as biomass in residential heating, comparing it with a fossil fuel, i.e. natural gas. Both the studies highlight the critical issues of the assessed production processes, such as the contribution to the GWP impact category, even though a more accurate analysis would also require the assessment of other impacts, such as the life cycle energy requirement in terms of primary energy, which is strictly connected to the GWP.

2.3.4 Footprint Labels (Carbon Footprint, Water Footprint, Ecological Footprint)

The term ‘footprint’ has become a popular means of indicating a quantitative measure of human beings’ appropriation of natural resources (Hoekstra and Chapagain 2008). All three indicators, the carbon footprint, water footprint and ecological footprint, are aimed at evaluating environmental impacts in terms of the appropriation of natural resources needed to sustain the supply chain of a generic product. Specifically, the three indicators highlight the effect of resource consumption on different environmental compartments: air (in terms of greenhouse gas emissions), water (in terms of the volume of water consumed and/or polluted) and land (in terms of land use) (Neri et al. 2010). The joint use of more than one indicator should provide a full sustainability diagnosis (Bastianoni et al. 2013).

In particular, the carbon footprint (CF) methodology is commonly defined as the quantification of greenhouse gas emissions associated with the life cycle of a good or service. Referring to the life cycle, the carbon footprint derives from the LCA methodology, but focuses exclusively on issues related to the phenomenon of global warming (Weidema et al. 2008). The PAS 2050 (BSI) was one of the first standards introduced in this context to standardise a similar methodology in 2013. Later on, the ISO published the international standard rules related to this method in May 2013—ISO/TS 14067:2013 (ISO 2013a). The unquestioned acceptance of the carbon footprint by retailers and the media has been possible thanks to its ease of comprehension and immediacy (even for non-experts) and the explicit reference to the problem of global warming. Its diffusion has been achieved thanks to the interest arising from different sectors, including the agro-industrial one, which immediately saw the carbon footprint as a tool for product/image/marketing improvement and strategic communication when it comes to the consumer.

Within the olive oil sector, the IOC (International Olive Council) is taking steps to draft guidelines for the correct and uniform application of the new ISO 14067. The carbon footprint-related scientific literature includes a small number of studies specifically related to it. Among them, only two (Lucchetti et al. 2012; Polo et al. 2010) focus on the analysis of the carbon footprint of 1 kg of olive oil (albeit only for the bottling stage): Nardino et al. (2013) carried out an empirical and tool-related assessment of the ability to fix the atmospheric carbon from the olive grove, while in Intini et al. (2011), a comparative evaluation of the use of de-oiled pomace, fossil fuels and wood biomass (in the operation of a power plant for the production of electricity and heat) was carried out. Polo et al. (2010) applied the carbon footprint methodology to five agro-industrial products, including two types of olive oil (1 L in glass bottles and 5 L in PET ones). The analysis shows that the CFPs are of 1.1 and 5.5 kg of CO2 (respectively for bottles of 1 and 5 L). Furthermore, Özilgen and Sorgüven (2011) carried out an evaluation of three different methods (energy, exergy and carbon dioxide emissions) for three different oils (soybean, sunflower and olive) using 1000 kg of raw material product as a functional unit (soybean, sunflower and olive). In this study, the agricultural phase is responsible for most of the carbon dioxide emissions due to the excessive use of fertilisers (Ozilgen and Sorgüven 2011). The total CO2 emissions for producing oil from 1 ton of olives is 323.1 kg CO2, of which 164.9 kg is linked to the agricultural phase, 123.3 kg to the oil production phase, 31.9 kg to the packaging phase and 3.0 kg to the transportation phase.

Three of the five works analysed (Intini et al. 2011; Lucchetti et al. 2012; Nardino et al. 2013) are representative of the Italian scenario, demonstrating the attention given, at a scientific level, to the agro-industrial production in Italy. On the other hand, one (Özilgen and Sorgüven 2011) was developed in Turkey, while the last, though not precisely defined, is believed to have been carried out in Spain.

No article takes into account the olive oil product from cradle to grave. Specifically, Lucchetti et al. (2012), during their analysis of the bottling process, do not use calculation software but use emission factors directly (published by government agencies and electricity producers). Furthermore, not all the GHGs provided by the IPCC are highlighted; only CO2 and CH4 are considered in the study. Intini et al. (2011) carried out an assessment of the benefits arising from the possible use of de-oiled pomace, for energy, taking into account both the current technologies that are already widespread and the nationwide availability of this product. The analysis shows the possible avoided emissions of GHGs if all the de-oiled pomace is destined not for residential users (as happens today) but for electricity and heat production plants. The analysis undertaken by Polo et al. (2010), although very interesting for the results achieved, does not show how the data collection was conducted and which software or database was used for the calculation of the carbon footprint. The study by Nardino et al. (2013), while making explicit reference to the carbon budget within an olive grove, does not use the specific methodology of the carbon footprint to assess the total mass of CO2 stored. Indeed, some methods were proposed by Nardino et al. (2013) based on the study of gas exchange between the atmosphere and tree cultivation and compared (to assess their significance) with empirical methodologies. From this work, it is apparent that olive groves are useful for carbon storage and for biomass production destined for energy purposes (values between 10 and 15 t (C) ha− 1 year− 1). In the study by Özilgen and Sorgüven (2011), the source of the emission coefficients and whether the study included all GHGs or just carbon dioxide were not clear. In general, referring to the carbon footprint methodology, it can be said that it is not, at least in the olive oil sector, a frequently applied tool, due to both the small number of papers in the literature and the lack of comprehensive studies related to our subject of interest. The reasons for this refer to the recent standardisation of the method (ISO/TS 14067:2013 was published only in May 2013), to the scientific limitations of the tool, even though it allows strong communication, and to the fact that the olive oil sector, over the past 10 years, has invested more in improving the quality of the product (acidity, content of antioxidants, etc.) and in certification of origin (protected designation of origin PDO and protected geographical indication PGI), leaving out the communication of connected environmental aspects.

The water footprint (WF) is also to be noted, being a water use indicator that considers both the direct and the indirect content related to a process or good and referred to as the volume of fresh water used per unit of the product. It is divided into three components (Hoekstra and Chapagain 2008): the blue WF (blue water, surface or underground), the green WF (rainwater that is stored temporarily in the soil or vegetation) and the grey WF (the volume of fresh water required to assimilate the load of pollutants).