Abstract

Large scale, animal cell culture in stirred tank bioreactors, is responsible for greater than &100 billion in sales of human biopharmaceuticals. This success was achieved in spite of the concern of the “shear sensitivity” of animal cells. In this contribution, a summary of the current state of this “shear sensitivity” concern will be discussed, demonstrating that it is not in general a problem with current bioprocess. Example of what is considered the current limits above which effects of hydrodynamic and interfacial concerns begin to negatively impact bioprocesses will also be presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

6.1 Introduction

The innate ability of animal cells to properly fold, post-translationally process, and secrete proteins has made them the preferable host for producing a large number of biological therapeutic and diagnostic products. These properties, combined with the high current productivities (compared to what was achievable 30 year ago), has led to a commercial, world market greater than 100 billion US dollars from more than 150 different products, which include viral vaccines, monoclonal antibodies (MAbs), hormones, enzymes, growth and blood factors. Although the industrial exploitation of animal cell cultures started over five decades ago, (an early example is the production of the Salk polio virus vaccine in primary monkey kidney cells (Griffiths (2000)), it has been during the last 30 year period that there has been a rapid increase in the number of FDA approved products produced in mammalian cell culture, starting in 1986 with the production of recombinant tissue plasminogen activator (tPA).

Despite reports showing that animal cell culture has been conducted for over a 100 years, (Harrison 1907) no rigorous methodology for scale-up of animal cell culture exists. Diverse culture methodologies, typically with staring with small scale static cultures (T-flask), to roller bottles, cultures on either microcarriers, or freely suspended cells in batch, fed batch, or perfusion systems exist. While freely suspended, fed-batch processes have emerged as the predominate approach, much of this evolution has been guided by the particularities of the process, the cell line, and most importantly, expertise of specific organizations. Despite examples of large scale (1,000–2,000 l) airlift bioreactors (Birch et al. 1985; Varley and Birch 1999; Hesse et al. 2003) virtually all of the licensed processes for recombinant proteins, antibodies and vaccines use either freely suspended or microcarriers cultures in traditional stirred tank bioreactors with reported capacities up to 20,000 L.

Despite the concern of the “shear sensitivity” of animal cells, traditional stirred tank bioreactors, STB, is the preferred method of culture for a number of reasons, not the least of which is the vast empirical knowledge accumulated for the design, scale-up and operation of STB, in the chemical and biochemical industries over the last century. Further STB are versatile and relatively simple to operate. This chapter will discuss what is current know with respect to hydrodynamic forces and animal cells of industrial importance. For a discussion of the engineering considerations of animal cell bioreactors, see Chap. 5 of this volume.

6.2 Hydrodynamic Forces Acting on Cells

The perceived “shear sensitivity” of animal cells has been, and continues to be, a source of significant concern and confusion. Given the original mechanical and nutrient support of vascularized tissue, this concern is not unfounded. The relative large size of animal cells, compared to microorganisms further contributes to this concern. Finally, as will be discussed below, hydrodynamic forces, created as a result of mixing, in some conditions can remove animal cells attached to microcarriers.

At the most fundamental level, “shear stress” is only one of two types of hydrodynamic stress, the other being normal stress. Both stresses are mathematically defined as a viscosity multiplied by a velocity gradient; when the gradient is perpendicular to the flow it creates a shear stress, (i.e. dux/dy), when the gradient is in the direction of the flow it creates a normal stress (i.e. dux/dx). To add further complexity, in non-simple laminar flow, as well as in turbulent flow, the local flow rate is changing with time.

Beyond the biotechnology community, the very large field of chemical mixing is also interested in these forces; in most cases it is desired to maximizing these forces with the least energy input. Consequently, a great deal of research, both basic as well as highly practical, has been conducted to attempt to understand and optimize mixing. Unfortunately, while ideally it is desirable to quantify and design mixing systems from first principles, it is still not currently possible/practical. This limitation has led to a number of semi-empirical equations and parameters to characterize and estimate global and local fluid conditions in STB.

Energy Dissipation Rate, EDR

One of these characterization parameters, used in the mixing community for over 60 years, is the energy dissipation rate (Kresta 1998). Further, EDR was proposed by Blustein and Mackros (1969) to characterize cell damage to blood cells. EDR can be expressed mathematically for a incompressible Newtonian fluid as:

where ε is EDR (W/m3), τ is the stress tensor (N/m2), μ is the viscosity (Pa · s), U is the velocity vector, ∇U is velocity gradient vector, and ∇U T is the transpose of ∇U. ∇U can be further defined as:

When the flow conditions, and system geometries is sufficiently understood/defined, it is possible to obtain analytical solutions to Eq. 6.1 and determine both the EDR and shear and normal stresses that a cell experiences can be known. Mollet et al. (2004, 2007) provides solutions for a number of these situations.

Alternatively, for complex flow, and turbulent, or near-turbulent conditions, such as in a typical STB, as stated above, first principles solutions are not possible. In these cases, well known correlations, which have substantial experimental validation, can be used. For example, the mean specific energy dissipation rate, ε mean , in a STB can be estimated from:

where P/M is the specific power, M is the mass of the fluid, Po is the power number for the specifically used impeller, D is the impeller diameter, and ρ is the density of the fluid.

A number of studies, including the extensive studies by Zhou and Kresta (1996a, b) have experimentally demonstrated that the maximum EDR in a mixing vessel (STB) can range from 10 to 200 times the mean value:

Where φ can vary from 10 to 200. As will be discussed below, significant work has been, and continues be conducted to relationship between EDR and lethal and non-lethal effects on cells

Kolmogorov Microscale of Turbulence, λ

An alternative/complementary parameter to using EDR to characterize the hydrodynamic conditions in which an animal cell is subjected, is the application of the Kolmogorov’s theory of turbulence to cell culture (Kolmogorov 1941a, b) in STBs. Out of this theory, which assumes that the turbulence is isotropic (uniform in all directions) a relationship/term is defined, referred to as the Kolmogorov microscale, λ:

where ν is kinematic viscosity of the liquid (m2/s). Independently, Cherry and Papoutsakis, (1986, 1988, 1989) and Croughan et al. (1987, 1989) suggested that when the value of λ is the same size as a single suspended cell, or a microcarrier with cells attached, significant cell death occurs. However, as with EDR discussed above, accurate, local estimates of EDR, ε, is needed.

6.3 Experimental Studies Attempting to Quantify Cell Damage

Over the last 50 years, a large number of studies have been conducted in an attempt to quantify the damage, or lack thereof, of hydrodynamic forces on animal cells. These studies can be simplistically divided into two categories: (1) studies that put suspended animal cells in a variety of devices in which hydrodynamic forces can be accurately determined on a scale compatible with a cell (i.e. rheological instruments), or (2) studies in which attempts were made to determine/quantify the hydrodynamic forces in typical bioprocess equipment (i.e. spinner flask, bioreactor, centrifuge, etc.) and subsequently relate the cell cultures performance to the conditions in the equipment.

As in any comprehensive comparison of studies from many laboratories over many decades, challenges exist in providing a basis by which this comparison can be made quantitatively. Never-the-less, Fig. 6.1 attempts to create such a comparison of some of the more relevant studies using EDR as point of comparison. While at the most fundamental level, EDR does not take into consideration all of the complexities of the flow, especially in turbulent systems, it does provide a “high-level” comparison. Figure 6.1 uses a linear line to represent the scalar value of EDR, with specific arrows representing specific EDR values grouped into (1) reported non-lethal effects on cells (arrows above the line), (2) lethal effects on cells, (arrows above the line) and (3) estimates of EDR values in a variety of situations/equipment (arrows below the line).

Comparison of some of the more relevant studies using EDR as point of comparison. Above the logarithmic line EDR (w/m3) a number of sub-lethal and lethal effects of hydrodynamic forces on cells is presented while below the line various levels of EDR, created in various types of bioprocess equipment is presented

A number of significant points should be noted in Fig. 6.1. First, the mean and maximum EDR values (101–103 W/m3) in typically operated STB are orders of magnitude lower than what has been shown by many studies (107–108) to kill suspended animal cells. Second, animal cells attached to microcarriers are damaged/removed from microcarriers at EDR values that are in the range of typically operated STB. While Fig. 6.1 indicates that typical STB operated at levels that are orders of magnitude lower than what has been shown to damage cells, that is not case for many post STB bioprocessing equipment, such as membrane filtration and centrifugation systems. Figure 6.1 also includes reported non-lethal effects of EDR on cells which will be discussed further below.

6.4 Cell Damage from Sparging

Sparing related cell damage has long been a threat to suspended cell culture and process scale-up. It has been well accepted that cell-bubble interactions, rather than agitation, play a major role in physical cell damage in bioreactors (Oh et al. 1989; Kunas and Papoutsakis 1990; Chalmers and Bavarian 1991; Trinh et al. 1994; Nienow 1996; Michaels et al. 1991; Ma et al. 2002). Potential cell damage zones in sparged bioreactors include the bubble formation, rising, and disengaging regions. The impeller region is also a possible damage zone should bubble coalesce or breakup occur as a result of agitation.

Various theoretical and experimental studies have demonstrated that the bubble disengagement region can be a major source of cell damage (Handa et al. 1987; Bavarian et al. 1991; Chalmers and Bavarian 1991; Orton and Wang 1991; Trinh et al. 1994). When a bubble sitting at the top media-air interface ruptures, a highly energetic event occurs, resulting in a rapid upward and downward jet of fluid.

A combination of high speed video photograph and computer simulations elucidated the rupture process (Boulton-Stone and Blake (1993); Garcia-Briones et al. (1994)). After a bubble rises above the liquid surface, the upper liquid film thins until a hole forms in the dome, surface tension subsequently pulls the film away from the hole, resulting in a toroidal ring retreating rapidly toward the bulk liquid, and down into the bubble cavity within the liquid. The collision of this flow of liquid results in an upward and a downward jet of fluid (Fig. 6.2a). The most intensive energy dissipation occurs during the collision at the bottom of the bubbles (Fig. 6.2b). Simulation also indicated that smaller bubbles are more damaging as the EDR associated with the bubble rupture increases with decreasing bubble size. The maximum local EDR during bubble rupture is several orders of magnitude higher than that generated by agitation (Fig. 6.1). As an alternative to the computer simulation approach, Christi (2000) using the Kolmogoroff microscale/eddy length correlation, also argued that rupturing bubbles are sufficient to damage cells.

Experimentally, Trinh et al. (1994) quantitatively studied the detrimental effect of bubble rupture on insect cells using a specially designed bubble column which allowed a large number of 3.5 mm bubbles to be generated and ruptured, with and without the presence of the commonly used protective additive, Pluronic F-68. On average, 1,050 cells were killed by each bubble rupture; conversely, when 0.1 % Pluronic F-68 was present, no statistically significant cell death could be detected. To further confirm the damage mechanism, Trinh et al. also collected samples of the upward jet (flying liquid drops) from some of the rupturing bubbles. While virtually all of the cells in the bulk were viably, nearly all of the cells in the upward jet, which were at a concentration over twice that in the bulk, were dead.

A number of additives have been advocated to reduce cell damage in sparged and agitated animal cell cultures. The removal of serum (as a result of regulatory issues), which has some protective effect, further necessitated the use of protective additives. Additives that have been evaluated include: Pluronic F-68, polyvinyl alcohol (PVA), polyethylene glycol (PEG), dextran, and methylcellulose (Murhammer and Goochee 1990; Goldblum et al. 1990; Michaels et al 1991; Michaels et al. 1992; van der Pol et al. 1995; Hu et al. 2008). Of all of these, Pluronic F-68 was demonstrated to be the most effective, and has been widely used in virtually all large-scale, mammalian cell culture media. PF-68 is a nonionic surfactant, belonging to a family of triblock copolymers consisting of a hydrophobic center, poly(propylene oxide), and two hydrophilic tails composed of poly(ethylene oxide). The average molecular weight is 8,400. The protective effect of PF-68 is, to some extent, concentration dependent. The typical concentration ranges used is 0.3–3 g/L (Chisti 2000; Murhammer and Goochee 1990).

Three protective mechanisms for PF-68 and other protective additives had been proposed: (1) nutritive effects, (2) the physical strengthening of the cell membranes, and (3) the suppression of bubble-cell attachments. Because experimental results demonstrated that the time required to achieve measurable protective effects was short after the addition of the supplements, it has been generally assumed that the primary mechanism of protection was not nutritive (Kunas and Papoutsakis 1990; Goldblum et al. 1990; Michaels et al. 1991). Three independent laboratories have over the years demonstrated that physical properties/strength of the cell increased when PF-68 was present: Goldblum et al. (1990) in constant shear stress instrument, Ramirez and Mutharasan (1990) demonstrated decreased plasma membrane fluidity, and Zhang et al. (1992) demonstrated increased membrane bursting tension of hybridoma cells when PF-68 was present. However, Zhang et al. (1992) recognized that the strengthened membrane alone was not enough for the protection observed in bioreactors.

PF-68 is a surfactant, one of a large family of surfactants made by BASF, all of which have clear surface tension/surface active effects (Mizrahi (1983) and Jordan et al. (1994)). Chattopadhyay et al. (1995) and Micheals et al. (1995) investigating the relationship of these surface active compounds and cell protection found that the most effective (with respect to cell protection) surface active, protective compounds not only significantly reduce air-medium interfacial tension, but also achieve it rapidly. Therefore, they suggested that the lowering of dynamic surface tension was more important than lowering the equilibrium surface tension. As PF-68 lowers dynamic surface tension, it could out compete cells absorbing to the air-liquid interface, hence preventing cell-bubble attachment. As a result, when a bubble ruptures, there is no or only limited number of cells in the impact region. Chalmers and Bavarian (1991) visually demonstrated that a large number of cells are present on the bubble surface when no PF-68 was present (Fig. 6.3a); conversely, the presence of 1 g/L PF-68 prevented nearly all of the cells from being attached to the bubble film (Fig. 6.3b)tached attached. Ma et al. (2004) collected foam from a bubble column and compared cell concentration in the foam liquid to that in the main liquid. They found that the ratio of cells in the foam liquid to that in the main body (defined as enrichment factor) could be 10 times higher when no PF-68 was presented (Fig. 6.4). The enrichment factor decreased with rising PF-68 concentration, reaching 1 at 0.1 g/L PF-68 and stabilized at 0.5 after PF-68 concentration reached 0.3 g/L. An enrichment factor of 0.5 at high PF-68 concentrations indicates that although PF-68 could significantly reduce cell-bubble attachment, there are still cells trapped in the foam. This is not surprising as the bubble film is thicker than cells’ diameter, so that cells could be floating in the foam liquid without attaching to the air-liquid interface. As foam is always present on top of sparged cell culture, PF-68 could not completely removed cell from the vicinity of bursting bubbles. At a cell density of 107 cells/mL and PF-68 concentration of 1 g/L, there was about 103 cells around each bubble (Ma et al. 2004; Fig. 6.5).

The effect of PF-68 concentration on the enrichment factor, defined as the ratio of cell concentration in the film liquid and bulk liquid. The dotted line was determined by the concentration of lactate dehydrogenase and the solid line was determined by cell concentration (Ma et al. 2004)

A three-dimensional plot of the number of cells associated with each bubble as a function of cell concentration (cells/mL) and PF-68 concentration. The dots indicate experimental data (Ma et al. 2004)

With a molecular weight on the order of 8,400, the polymer PF-68 has the potential to interfere with downstream filters and purification resins. A potential alternative is a small molecule surfactants that could be more easily removed during down-stream purification process. Hu et al. (2008) screened various small-molecule ionic or non-ionic surfactants. Of a number of similarly structured molecules, n-Nonyl-b-D-Maltopyranoside showed the best properties of rapidly lowering the dynamic surface tension and low cytotoxicity. While a potential candidate to augment and or replace the protective effect of PF-68, a thorough evaluation of its impact on cell metabolism, product quality, and potentially patients is still needed.

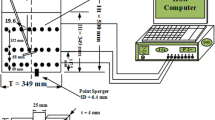

In addition to the bubble rupture zone, and or the foam layer, cell damage at bubble formation site (sparger) has been reported (Murhammer and Goochee 1990; Zhu et al. 2008). Zhu et al. (2008) found damage of NS0 cells at the sparger site at high linear air flow rates of 30 m/s, and the damage followed first-order kinetics. A similar phenomenon had been reported for microalgae culture where the critical gas-entrance velocity for cell damage was around 30–50 m/s (Barbosa et al. 2004). None of the additives was reported to be able to alleviate this damage. However, increasing the bore and size could minimize the sparger site cell damage. Extending these observations at gas spargers, Liu et al. (2014) has developed a new hydrodynamic correlation, stress induced turbulent energy production, STEP, which they suggest correlates well with experimental data indicating that increased gas flow rate at spargers increases cell damage. Unlike EDR, the authors suggest that STEP is a more complete and representative of the actual process by considering energy transfers associated with the two phase flow aspect of the bubble generation. Unlike EDR, or other purely hydrodynamic calculations which indicated that the highest EDR is away from the bubble generation area, STEP calculations are highest right at the bubble generation site, and STEP values increase as gas entrance velocities increase. It should also be noted that STEP values are vector with units the same as EDR.

6.5 Experimental Sublethal Effect of Hydrodynamic Stress

Compared to other forms of stimulation/assault, investigations on the physiological impacts of hydrodynamic forces on mammalian cells are limited. Further, the majority of studies on the effect of hydrodynamic and or physical forces on cells are on anchorage dependent cells of medical interest, not bioprocess interest/applications.

Nevertheless, these limited number of studies have revealed that it requires much lower hydrodynamic forces to elicit sublethal effects (in all but a few studies) than to cause catastrophic cell death. As summarized above, EDR values of 1 × 103–1 × 105 W/m3, which correspond to shear stresses on the order of 1.0–10 N/m2, can illicit non-lethal effects on suspended CHO cells. This is significantly lower than the level required to lyse similar cell lines. Using CHO cells grown attached to surface, Ranjan et al. (1995) reported that CHO cells up-regulated transcriptional activator c-fos when subjected to 2.5 N/m2 (6.2 × 103 W/m3) shear force for 1 h. Al-Rubeai et al. (1995) reported that hybridoma cells underwent apoptosis at EDR of 1.87 × 103 W/m3. Motobu et al. (1998) observed that after 24 h exposure to 0.02 and 0.082 N/m2 shear stress (EDR of 0.4 and 6.5 W/m3), nonconfluent CHO cells were arrested at G0/G1 phase and mRNA level for the recombinant product was increased; conversely, confluent CHO cells were found not sensitive to the shear forces tested. Keane et al. (2003) found that long-term exposure of attached CHO cells to high level shear stress led to reduced productivity and altered glucose metabolism. Compared to cells exposed to low shear stress of 0.005 N/m2 (0.02 W/m3), cells exposed to high shear stress of 0.80 N/m2 (6.4 × 102 W/m3) for 32 h showed 51 % lower recombinant protein production, 42 % higher glucose uptake, and 50 % lower lactate production.

In addition to the single pass studies conducted in which levels of EDR were used which will disrupt cells (Fig. 6.1), using this same specifically designed flow contraction device, Godoy-Silva et al. (2009a) placed the system in a recycle stream with a typical bench scale bioreactor. The repetitive exposure, and significantly lower levels of EDR, was an initial attempt to simulate the fluid dynamic environment in large-scale bioreactors where cells circulate between high shear and low shear regions.

With this repetitive, recycle system, the potential, physiological impact of hydrodynamic stress on CHO and NS0 cells was considered, using variables of cell growth rate, product productivity, metabolism, and mAb product quality. At a EDR of 6.0 × 104 W/m3, which is approximately two orders of magnitude lower than the single pass EDR where physical cell damage occurs, no significant physiological effects were observed; however, it was observed that mAb glycosylation pattern was shifted. The shift led to reduced G0 population, with a corresponding increase in G1 and G2 populations of the N-linked glycan on Fc. This shift of glycosylation pattern was confirmed with a second CHO cell line expressing a different mAb product. Conversely, a low EDR of 0.9 × 102 W/m3 had no effect on the glycosylation pattern (Fig. 6.6). Sieck et al. (2013) observed a similar glycosylation pattern shift estimated to be a EDR value of 4 × 102 W/m3 for a CHO cell line in an agitated bench-scale bioreactor where hydrodynamic stress was generated by the impellers. Seick et al. (2013) also observed reduced cell specific productivity at constant or periodic exposure to EDR of 4 × 102 W/m3 although neither cell growth nor glucose/glutamine metabolism was affected. Contrary to these detectable effects, Nienow et al. (2013) using similar systems to the study of Godoy-Silva et al., found no change in glycosylation for two CHO cell lines at EDR similar to that of Godoy-Silva et al. Further, in the Godoy-Silva et al. (2009b) study, it was reported that the NS0 cell line showed no change in glycosylation under high EDR. This contradiction appears to follow one of the common “rules of thumb” that specific effects can be cell line/clone dependent. However, all of these non-lethal effects are still above typical operating conditions in commercial STB and at this point have more “academic” than “industrial” significance.

Comparison of glycosylation profiles of mAbs produced in 2 L bioreactors under different level of hydrodynamic stress. Two sets of control results are included. One is the average of the four recirculating control bioreactors and the other one is the average of three historical non-recirculating bioreactors. The error bar indicates one standard deviation. (▲) galactose, (■) N-acetylglucosamine, (●) mannose, and (⋆) fucose

Conclusion and Future Directions

We suggest that we have highlighted that traditional, animal cells used for recombinant protein production are robust in typical bioprocessing, with the only current possible areas of concerns occurring in some downstream processing equipment. That being said, the field has “selected” cell lines/types that have proven to be robust, and extending this to other cell lines is not as certain. Initial studies of several human blood cancer cell lines demonstrated surprising more sensitivity (several orders of magnitude) than typical CHO lines.

However, in one assumes that the rate of increase in the routinely achievable, final cell concentrations and product titers continues, it is highly likely that in the near future conditions in bioreactors will necessitate significantly higher levels of mixing and improved cell protective additives. At that time, the field could begin to push the limits of hydrodynamic conditions that can cause cell damage and a renewed interest in better understanding these effects, and prevent undesirable ones, will be needed.

References

Al-Rubeai M, Singh RP, Goldman MH, Emery AN (1995) Death mechanisms of animal cells in conditions of intensive agitation. Biotechnol Bioeng 45:463–472

Augenstein DC, Sinskey AJ, Wang DIC (1971) Effect of shear on the death of two strains of mammalian tissue cells. Biotechnol Bioeng 13:409–418

Barbosa MJ, Hadiyanto, Wijffels RH (2004) Overcoming shear stress of microalgae cultures in sparged photobioreactors. Biotechnol Bioeng 85:78–85

Bavarian F, Fan LS, Chalmers JJ (1991) Microscopic visualization of insect cell-bubble interactions I: rising bubbles, air-medium, and the foam layer. Biotechnol Prog 7:140–150

Birch JR, Boraston R, Wood L (1985) Bulk production of monoclonal antibodies in fermenters. Trends Biotechnol 3:162–166

Bluestein M, Mockros LF (1969) Hemolytic effects of energy dissipation in flowing blood. Med Biol Eng 7:1–6

Boulton-Stone JM, Blake JR (1993) Gas bubbles bursting at a free surface. J Fluid Mech 254:103–111

Boychyn M, Yim SSS, Ayazi Shamlou P, Bulmer M, More J, Hoare M (2001) Characterization of flow intensity in continuous centrifuges for the development of laboratory mimics. Chem Eng Sci 56:4759–4770

Chalmers JJ, Bavarian F (1991) Microscopic visualization of insect cell-bubble interactions. II: the bubble film and bubble rupture. Biotechnol Prog 7:151–158

Chattopadhyay D, Rathman J, Chalmers JJ (1995) The protective effect of specific medium additives with respect to bubble rupture. Biotechnol Bioeng 45:473–480

Cherry RS, Papoutsakis ET (1986) Hydrodynamic effects on cells in agitated tissue culture reactors. Bioproc Eng 1:81–89

Cherry RS, Papoutsakis ET (1988) Physical mechanisms of cell damage in microcarrier bioreactors. Biotechnol Bioeng 32:1001–1014

Cherry RS, Papoutsakis ET (1989) Hydrodynamic effects on cells in agitated tissue culture reactors. Bioproc Eng 1:29–41

Chisti Y (2000) Animal-cell damage in sparged bioreactors. TIBTECH 18:420–432

Croughan MS, Hamel JF, Wang DIC (1987) Hydrodynamic effects on animal cells grown in microcarrier cultures. Biotechnol Bioeng 29:130–141

Croughan MS, Sayre ES, Wang DIC (1989) Viscous reduction of turbulent damage in animal cell cultures. Biotechnol Bioeng 33:862–872

Garcia-Briones MA, Brodkey RS, Chalmers JJ (1994) Computer simulations of the rupture of a gas bubble at a gas–liquid interface and its implications in animal cell damage. Chem Eng Sci 49:2301–2320

Godoy-Silva R, Mollet M, Chalmers JJ (2009a) Evaluation of the effect of chronic hydrodynamic stresses on cultures of suspended CHO-6E6 cells. Biotechnol Bioeng 102:1119–1130

Godoy-Silva R, Chalmers JJ, Casnocha SA, Bass LA, Ma N (2009b) Physiological response of CHO cells to repetitive hydrodynamic stress. Biotechnol Bioeng 103(6):1103–1117

Goldblum S, Bae YK, Hink WF, Chalmers JJ (1990) Protective effect of methylcellulose and other polymers on insect cells subjected to laminar shear stress. Biotechnol Prog 6:383–390

Gregoriades N, Clay J, Ma N, Koelling K, Chalmers JJ (2000) Cell damage of microcarrier cultures as a function of local energy dissipation created by a rapid extensional flow. Biotechnol Bioeng 69:171–182

Griffiths JB (2000) Animal cell products, overview. In: Spier RE (ed) Encyclopedia of cell technology, vol 1. Wiley, New York, pp 71–76

Handa A, Emary AN, Spier PE (1987) On the evaluation of gas–liquid interfacial effects on hybridoma viability in bubble column bioreactors. Dev Biol Stand 66:241–253

Harrison RG (1907) Observations on the living developing nerve fibre. Anat Rec 1:116–118

Hesse F, Ebel M, Konisch N, Sterlinski R, Kessler W, Wagner R (2003) Comparison of a production process in a membrane-aerated stirred tank and up to 1000 − L airlift bioreactors using BHK-21 cells and chemically defined protein-free medium. Biotechnol Prog 19:833–843

Hu W, Rathman JJ, Chalmers JJ (2008) An investigation of small-molecule surfactants to potentially replace Pluronic F-68 for reducing bubble-associated cell damage. Biotechnol Bioeng 101:119–127

Hutchinson N, Bingham N, Murrell N, Farid S, Hoare M (2006) Shear stress analysis of mammalian cell suspensions for prediction of industrial centrifugation and its verification. Biotechnol Bioeng 95(3):483–491

Jordan M, Sucker H, Einsele A, Widmer F, Eppenberger HM (1994) Interactions of serum and Pluronic F-68 on the physical properties of the bubble surface. Biotechnol Bioeng 43:446–454

Keane JT, Ryan D, Gray PP (2003) Effect of shear stress on expression of a recombinant protein by Chinese hamster ovary cells. Biotechnol Bioeng 81:211–220

Kolmogorov A (1941a) Dokl Akad Nauk SSSR 30:310–305

Kolmogorov A (1941b) Dokl Akad Nauk SSSR 30:538–540

Kresta S (1998) Turbulence in stirred tanks: anisotropic, approximate, and applied. Can J Chem Eng 76:563–576

Kunas KT, Papoutsakis ET (1990) Damage mechanisms of suspended animal cells in agitated bioreactors with and without bubble entrainment. Biotechnol Bioeng 36:476–483

Liu Y, Li F, Hu W, Wiltberger K, Ryll T (2014) Effects of bubble-liquid two-phase turbulent hydrodynamics on cell damage in sparged bioreactors. Biotechnol Prog 30:48–58

Ma N, Koelling KW, Chalmers JJ (2002) Fabrication and use of a transient contractional flow device to quantify the sensitivity of mammalian and insect cells to hydrodynamic forces. Biotechnol Bioeng 80:428–437

Ma N, Chalmers JJ, Aunins JG, Zhou W, Xie L (2004) Quantitative studies of cell-bubble interactions and cell damage at different Pluronic F-68 and cell concentrations. Biotechnol Prog 20:1183–1191

MacIntyre F (1972) Flow patterns in breaking bubbles. J Fluid Mech 77:5211–5228

McCoy R, Ward S, Hoare M (2010) Sub-population analysis of human cancer vaccine cells- ultra scale-down characterization of response to shear. Biotechnol Bioeng 106:584–595

McQueen A, Bailey JE (1989) Influence of serum level, cell line, flow type and viscosity on flow-induced lysis of suspended mammalian cells. Biotechnol Lett 11:531–536

Michaels JD, Petersen JF, McIntire LV, Papoutsakis ET (1991) Protection mechanisms of freely suspended cells (CRL 8018) from fluid-mechanical injury. Viscometer and bioreactor studies using serum, Pluronic F68 and polyethylene glycol. Biotechnol Bioeng 38:169–180

Michaels JD, Kunas KT, Papoutsakis ET (1992) Fluid-mechanical damage of freely-suspended animal cells in agitated bioreactors: effects of dextran, derivatized celluloses and polyvinyl alcohol. Chem Eng Commun 118:341–360

Michaels J, Nowak JE, Mallik AK, Koczo K, Wasan DT, Papoutsakis ET (1995) Analysis of cell-to-bubble attachment in sparged bioreactors in the presence of cell-protecting additives. Biotechnol Bioeng 47:407–419

Mizrahi A (1983) Production of human interferons- an overview. Dev Biol Stand 55:93–102

Mollet M, Ma N, Zhao Y, Brodkey R, Taticek R, Chalmers J (2004) Bioprocess equipment: characterization of energy dissipation rate and its potential to damage cells. Biotechnol Prog 20:1437–1448

Mollet M, Godoy-Silva R, Berdugo C, Chalmers JJ (2007) Acute hydrodynamic forces and apoptosis: a complex question. Biotechnol Bioeng 98(4):772–788

Mollet M, Godoy-Silva R, Berdugo C, Chalmers JJ (2008) Computer simulations of the energy dissipation rate in a fluorescence activated cell sorter: implications to cells. Biotechnol Bioeng 100(2):260–272

Motobu M, Wang P-C, Matsumura M (1998) Effect of shear stress on recombinant Chinese hamster ovary cells. J Ferment Bioeng 85:190–195

Murhammer DW, Goochee CF (1990) Structural features of nonionic polyglycol polymer molecules responsible for the protective effect in sparged animal cell bioreactors. Biotechnol Prog 6:142–148

Neal G, Christie J, Keshavarz-Moore E, Shamlou PA (2003) Ultra scale-down approach for the prediction of full-scale recovery of ovine polycolonal immunoglobulins used in the manufacture of snake venom-specific Fab fragment. Biotechnol Bioeng 81(2):149–157

Nienow AW (1996) Gas–liquid mixing studies: a comparison of Rushton turbines with some modern impellers. Trans IChemE 74A:417–423

Nienow AW, Scott WH, Hewitt CJ, Thomas CR, Lewis G, Amanullah A, Kiss R, Meier SJ (2013) Scale-down studies for assessing the impact of different stress parameters on growth and product quality during animal cell culture. J Eng Res Des 91:2265–2274

Oh SKW, Nienow AW, Al-Rubeai M, Emery AN (1989) The effects of agitation intensity with and without continuous sparging on the growth and antibody production of hybridoma cells. J Biotechnol 12:45–62

Orton DR, Wang DIC (1991) Fluorescent visualization of cell death in bubble aerated bioreactors. Cell culture engineering III, Engineering Foundation, 2–7 Feb 1991

Ramirez OT, Mutharasan R (1990) The role of the plasma membrane fluidity on the shear sensitivity of hybridoma growth under hydrodynamic stress. Biotechnol Bioeng 36:911–920

Ranjan V, Waterbury R, Xiao Z, Diamond SL (1995) Fluid shear stress induction of the transcriptional activator c-fos in human and bovine endothelial cells, Hela, and Chinese hamster ovary cells. Biotechnol Bioeng 49:383–390

Sieck JB, Cordes T, Budach WE, Rhiel MH, Suemeghy Z, Leist C, Villiger TK, Morbidelli M, Soos M (2013) Development of scale-down model of hydrodynamic stress to study the performance of an industrial CHO cell line under simulated production scale bioreactor conditions. J Biotechnol 164:41–49

Thomas CR, Al-Rubeai M, Zhang Z (1994) Prediction of mechanical damage to animal cells in turbulence. Cytotechnol 15:329–335

Trinh K, Garcia-Briones M, Hink F, Chalmers JJ (1994) Quantification of damage to suspended insect cells as a result of bubble rupture. Biotechnol Bioeng 43:37–45

Van der Pol LA, Beeksma I, Tramper J (1995) Polyethylene glycol as protectant against damage caused by sparging for hybridoma suspension cells in a bubble column. Enzym Microb Technol 17:401–407

Varley J, Birch J (1999) Reactor design for large scale suspension animal cell culture. Cytotechnology 29:177–205

Venkat R, Stock R, Chalmers JJ (1996) Study of hydrodynamics in microcarrier culture spinner vessels: a particle tracking velocimetry approach. Biotechnol Bioeng 49:456–466

Vickroy B, Lorenz K, Kelly W (2007) Modeling shear damage to suspended CHO cells during cross-flow filtration. Biotechnol Prog 23:194–199

Wernersson ES, Trägårdh C (1999) Scale-up of Rushton turbine-agitated tanks. Chem Eng Sci 54(19):4245–4256

Westoby M, Rogers JK, Haverstock R, Romero J, Pieracci J (2011) Modeling industrial centrifugation of mammalian cell culture using a capillary based scale-down system. Biotechnol Bioeng 108(5):989–998

Zhang Z, Thomas CR (1993) Modeling of animal cell damage in turbulent flows. In: Nienow AW (ed) Proceedings of the 3rd international conference on bioreactor and bioprocesses fluid dynamics. Mechanical Engineering Publications, London, pp 475–482. ISBN 0852988737

Zhang Z, Ferenczi MA, Thomas CR (1992) A micromanipulation technique with theoretical cell model for determining mechanical properties of single mammalian cells. Chem Eng Sci 47:1347–1354

Zhou G, Kresta SM (1996a) Distribution of energy dissipation between convective and turbulent flow for three frequently used impellers. Trans IChemE 74:379–389

Zhou G, Kresta SM (1996b) Impact of tank geometry on the maximum turbulence energy dissipation rate for impellers. AIChE J 42:2476–2490

Zhu Y, Cuenca JV, Zhou W, Varma A (2008) NS0 cell damage by high gas velocity sparging in protein-free and cholesterol-free cultures. Biotechnol Bioeng 101:751–760

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Chalmers, J.J., Ma, N. (2015). Hydrodynamic Damage to Animal Cells. In: Al-Rubeai, M. (eds) Animal Cell Culture. Cell Engineering, vol 9. Springer, Cham. https://doi.org/10.1007/978-3-319-10320-4_6

Download citation

DOI: https://doi.org/10.1007/978-3-319-10320-4_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-10319-8

Online ISBN: 978-3-319-10320-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)