Abstract

This paper discusses the effect of varying UV intensity on weathering degradation rates of materials. The effects of increasing intensities of solar UV on materials obeying strict reciprocity and materials deviating from strict reciprocity are considered. A second new high-intensity natural UV weathering device is introduced based on ASTM G90. The paper presents data from two materials degrading under different intensities of UV and compares natural weathering with data obtained at increasing levels of UV intensity with implications on SLP calculations.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Reciprocity

- UV intensity

- Weathering

- Acceleration

- Correlation

- ORWET

- Polystyrene

- Irradiance

- Temperature

- Ultra-Accelerated Weathering System

- UA EMMA

- Exposure

- Extrapolation

- ASTM G90

- Color

- Outdoor

- Static

- Dynamic

- Hypervolume

Introduction

The concept of reciprocity is a foundational concept used in the weathering industry and affects interpretation of results whenever two different exposures are timed or compared by radiant energy. The concept of reciprocity, laid down by Bunsen and Roscoe in 1876 [1], is an underlying assumption of much current weathering methodology representing a simple concept: Materials react to energy and energy is the product of intensity (see y-axis of Fig. 11.1) times duration (x-axis of Fig. 11.1). For this paper, under the assumption of strict reciprocity, an exposure at twice the intensity for half of the time is the energy equivalent to the same exposure at half the intensity for twice the time. Watts (intensity) times seconds (time) equals joules (energy), and typical weathering exposures are timed in kilo- or mega-joules per meter squared (MJ/m2) of total solar (295–2,500 nm), total ultraviolet (UV 295–385 nm), or narrow band (e.g., 340 nm). The function has a characteristic shape with the independent variable raised to the power of −1 and will be defined as strict reciprocity for the purposes of this paper.

Background

Sedona 2004 NIST Service Life Prediction Symposium

In 2004 at the Sedona meeting of the NIST Service Life Prediction (SLP) Symposium, this author presented a simple paper checking the basic assumption of strict reciprocity in accelerated outdoor weathering and service life prediction [2]. The hypothesis tested in that paper is summarized in Fig. 11.1 and is based on the idea that equal energies of weathering exposures result in equal levels of degradation within limits (e.g., the “within limits” being that the intensity must not be so high as to cause thermal burning of the material). The key assumption tested in the Sedona paper said that within limits, two equal energy exposures with different intensities should result in the same level of property change—all other things being equal.

The Sedona paper described a simple experiment exposing polystyrene standard reference materials (SRMs) to outdoor accelerated weathering conditions under concentrated solar irradiances at four different levels out to the same level of radiant energy. The exposure temperatures were held constant across different irradiance intensities via linked exposure devices. The data from the Sedona paper showed significant deviations from strict reciprocity predictions for the polystyrene SRMs in the experiment as shown in Fig. 11.2. The data indicated that the assumption of strict reciprocity was not a valid assumption for the data shown.

Additionally, the implications of these results for very high irradiance weathering testing pointed toward an interesting extrapolated prediction when the curves from Fig. 11.2 were extrapolated to irradiances achievable by weathering instrumentation under development at that time as shown in Fig. 11.3. This prediction—that if the curves for predicted and observed reciprocity were extrapolated out to very high solar irradiances, the observed degradation rate may be approximately half of what would be expected under the assumption of strict reciprocity for this material—is shown in Fig. 11.3. If correct, the implications of the prediction were clear for highly accelerated testing. For materials which did not obey strict reciprocity, for example, if weathering researchers observed failure in the real-world end use at 308 MJ/m2 UV and then tested the material to 308 MJ/m2 UV under high irradiance accelerated tests, the researcher may not observe failure. Under the extrapolation in Fig. 11.3, the researcher might not observe failure in the accelerated test for twice the duration than predicted by strict reciprocity. Clearly, the prediction observations represented important considerations in SLP, high irradiance testing and accelerated weathering. If the prediction was supported, it would mean strict reciprocity could be a very dangerous assumption for weathering researchers, and extrapolating the assumption of strict reciprocity can be perilous for SLP. Current ASTM and SAE accelerated weathering standards, although highly caveated, did not explicitly state possible deviations from strict reciprocity. Simultaneously, researchers regularly time accelerated weathering exposures to annual cumulative radiant energy levels observed in un-accelerated outdoor exposure reference environments. Additional research efforts were published, while instrumentation to test the extrapolated predictions was under development.

Gothenburg EWS

In 2005 at the European Weathering Symposium (EWS), a paper was presented which repeated the Sedona exposure for a different material (commercial polycarbonate) which indicated two important results [3]: First, that paper referenced a classical SLP approach. In the classical SLP approach, researchers utilize a three-step method. In step one, a model is created, typically in laboratory artificial weathering devices using DOE full factorial methods and/or multi-linear regressions varying the input factors (typically including irradiance, temperature, and moisture). In step 2, researchers then obtain time slices of environmental variables from the environment in question and enter the time slice data into the model and solve for degradation for that particular time slice. In step 3, researchers sum up the degradation contribution from all the time slices for a prediction of accumulated degradation in that environment. Within this classical SLP methodology, a key consideration becomes evident with regard to the extrapolated prediction from the Sedona paper; the light intensity factor may be significant and important for some materials, i.e., light intensity is a significant and important factor in the degradation model as indicated by the DOE and regressions. Second, the EWS Gothenburg paper showed data from polycarbonate which differed from the polystyrene SRM data in terms of reciprocity characteristics pointing toward a material dependency of strict reciprocity and indicating strict or even consistent reciprocity was not a valid assumption across different materials.

Key Largo NIST SLP Symposium

In 2006 at the NIST SLP Symposium in Key Largo, a third paper in the series on reciprocity was presented [4]. This paper expanded the reciprocity characterization to artificial light sources (xenon) inside the laboratory. The data confirmed the outdoor results observed in the Sedona paper closely in different weathering exposure apparatus.

Budapest EWS

In due time, the development of the apparatus needed to test the extrapolated prediction from the Sedona paper was completed and fully described in a paper entitled “Ultra-Accelerated Weathering System I: Design and Functional Considerations” [5] and represented the precursor to this paper (“Ultra-Accelerated Weathering II: Considerations for Accelerated Data-Based Weathering Service Life Predictions”). A photograph of the Ultra-Accelerated Weathering System (UAWS) and the spectral reflectance of the mirror facets are shown in Fig. 11.4. “Ultra-Accelerated Weathering System I” presented results from acceleration and correlation studies of a thin film material which appeared to obey strict reciprocity; the ORWET SRM, a European SRM produced by the Swiss Federal Laboratories for Materials Testing…EMPA. (ORWET is a thin film paint of melamine resin with a CIBA pigment on aluminum substrate that has been very highly characterized for color change as a function of UV exposure.) The quantitative acceleration data indicates to researchers how fast the weathering device performs the simulation of degradation on materials with time on the x-axis (exposure in days). Figure 11.5 shows acceleration data for ORWET under four different exposure conditions at different intensities (ultra-accelerated, Florida real time, Arizona real time, and EMMA an ASTM G90 device).

The quantitative correlation indicates to researchers how well the device simulates the natural degradation function with UV radiant energy on the x-axis as shown in Fig. 11.6 under the same exposure conditions as seen in Fig. 11.5. It was apparent from the Budapest data in “Ultra-Accelerated Weathering System I” that the UAWS device offered a very highly accelerated weathering method for materials having degradation behaviors like ORWET (which specifically obey strict reciprocity), and the data confirmed the radiometric characteristics of the UAWS device.

Experimental

Research Questions I

With the development of the UAWS initially completed and qualified using the acceleration and correlation data for ORWET, the capability to test the extrapolated predictions from the Sedona paper was in hand. The general research question for this work was to expose the polystyrene material, test the extrapolated predictions from the Sedona paper, and see if the significant quantitative deviations from strict reciprocity extrapolate out to the very high intensities (approximately 60 times real-time UV radiant exposure rates) and would actually be observed. Would the ultra-accelerated exposure require approximately twice the UV radiant exposure to produce the same level of degradation as less accelerated exposures on polystyrene as indicated by the extrapolation of deviations from strict reciprocity in the Sedona paper?

Conversely, the null hypothesis tested for this effort may be stated as there is no difference observed between degradation rates for polystyrene SRMs weathered in un-accelerated exposures and ultra-accelerated exposures when compared (normalized) for UV radiant exposure on the x-axis of the degradation curves.

Procedure I

The previously described UAWS device was used to expose randomly selected polystyrene from the same lot previously exposed on Arizona and Florida real time 45° racks facing south as well as ASTM G90 devices [6]. The exposure procedure requires several caveats: The exposure temperatures on the UAWS were not controlled to closely simulate the un-accelerated exposure temperatures. The UAWS exposure temperatures were controlled to approximately 65 ± 10 °C, slightly higher than the normal exposure temperatures for the non-UAWS exposures. Higher exposure temperatures, however, typically result in faster degradation rates. In order to achieve these moderate exposure temperatures at the high irradiances, exposures utilized mirrors with reflectance spectra as shown in Fig. 11.4 reducing irradiance greater than 450 nm. The UAWS polystyrene exposure was identical to the UAWS ORWET exposure and utilized forced convective cooling to maintain specimens near 65 ± 10 °C (slightly warmer than the real time and G90 exposure temperatures for polystyrene). The UAWS exposure was also performed in mid-October, while the comparative real-time Arizona, Florida, and G90 exposures were performed during summer. The G90 and UAWS exposures were performed without applied moisture, while in the 45° south exposures, moisture was uncontrolled.

Observations I

For the polystyrene SRM exposure as seen in Fig. 11.7, the data appears to show very high acceleration rates. The UAWS achieved in 2 days color change requiring approximately 115 days in Arizona real time and approximately 50 days on ASTM G90 exposure. Simultaneously, the data in Fig. 11.8 appears to show significant departure from correlation between the UAWS and real time or G90 exposures when normalized for radiant exposure in MJ/m2 UV on the x-axis. These results fail to support the null hypothesis of this experiment for polystyrene. The data showed significant deviation from strict reciprocity, and specifically, the observed degradation rate of polystyrene on the ultra-accelerated exposure appeared to be approximately half of what was predicted by strict reciprocity when compared with the un-accelerated exposures. These observations appear consistent with predictions of the extrapolated prediction from the Sedona paper.

Discussion I

Clearly, significant deviations from strict reciprocity represent important aspects of any weathering SLP effort. Extrapolating the assumption of strict reciprocity can be perilous to SLP efforts. Simply interchanging radiant exposure of an accelerated weathering test for real-time SLP calculations, without quantifying possible deviations from strict reciprocity, can result in considerable error as observed in the polystyrene example above. Fortunately, these characteristics are easily quantified by using DOE, multi-linear regressions, and methodologies described in this paper and elsewhere [2, 7, 8]. It is unclear if the general weathering industry addressed the reciprocity concept sufficiently in many previous SLP efforts and significant deviations from strict reciprocity might help explain previous SLP failures.

So far, this paper investigated the concept of reciprocity at extremely high acceleration rates (high irradiance) however; a possible alternative at rates between the UAWS extreme on the one hand and the current ASTM G90 acceleration rates on the other hand may yield more reasonable correlation. Might it be possible to observe less deviation from strict reciprocity at acceleration rates closer to currently used ASTM G90 weathering test methods?

Research Questions II

The general questions addressed in the previous section ask if strict reciprocity (as defined in this paper’s introduction) can be assumed for very highly accelerated weathering devices. This paper’s focus returns to less accelerated rates and specifically asks if increasing UV intensity reasonably predicts degradation observed at lower UV intensity for materials when exposure temperatures are comparable.

The general research question involved in this effort is to determine if strict reciprocity can be assumed for exposures closer in UV radiant intensity above current ASTM G90 methods than previously tested. If UV radiant exposure rates are approximately doubled from existing ASTM G90 Fresnel concentrators (by increasing from 10 to 20 mirrors), will similar material degradation levels be observed at the same level of UV radiant exposure as indicated by strict reciprocity? In other words, will the degradation level of materials be reached in approximately one-half the exposure time as predicted under strict reciprocity when radiant intensity is approximately doubled? Of course this effort requires temperatures be similar for both intensities.

Conversely, the null hypothesis tested for this effort may be stated as there is no difference observed between degradation rates for 10 and 20 mirrors (approximately doubled irradiance) when compensated for radiant exposure and temperature with ORWET and polystyrene SRMs weathered on G90-type Fresnel concentrator devices.

Procedure II

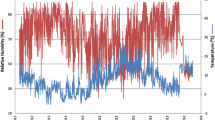

Two near identical G90 type Fresnel collector weathering devices were utilized for outdoor exposures. The first was maintained in a configuration with 10 standard mirrors and designated “standard EMMA” or simply “EMMA” for “Equatorial Mount with Mirrors for Acceleration.” The second device utilized additional mirrors, increasing the number of mirrors to 20, and this configuration was designated as “UA EMMA” for “ultra-accelerated EMMA” as shown in Fig. 11.9. Because temperature is a co-variable of irradiance, the UA EMMA mirror facets utilized technology fully described in [5], with reflectance spectra shown in Fig. 11.9. A performance comparison of black panel temperatures (backed and unbacked) achieved simultaneously on the two devices with 10 and 20 mirrors is shown in Fig. 11.10. The final 8 standard to 20 UA mirror ratio between these devices was adjusted to achieve approximately equal exposure temperatures as demonstrated by black standard temperature sensor data shown in Fig. 11.11 and measured with Xenocal® sensing and logging devices. The approximate irradiance differences simultaneously measured on the two devices are shown in Fig. 11.12 also measured with Xenocal devices.

A series of caveats are important to note regarding this procedure: There are many variables in outdoor exposure testing that were not blocked in this experiment including moisture—moisture was not applied in the G90 exposures. The mirrors on the UA EMMA device significantly reduced the irradiance above 450 nm in comparison to the standard EMMA spectral distribution. The irradiance differences were measured at 340 nm which has a high level of variability in outdoor weathering. Other unknown variables may also have affected the exposure results; however, best efforts were expended to mitigate these variables as much as possible.

Observations II

For the ORWET SRM exposures, as seen in Fig. 11.13, the data appears to show reasonable acceleration. The UA EMMA achieved in 12 days color change requiring approximately 30 days on standard EMMA. Simultaneously, the data in Fig. 11.14 appears to show reasonable correlation between UA EMMA and standard EMMA when normalized for radiant exposure with MJ/m2 UV on the x-axis. These results appear to support the null hypothesis for ORWET. Additionally, these observations appear similar to observations reported in previous efforts [5].

For the polystyrene SRM exposure, the data appear to show some acceleration. The UA EMMA achieves color change in 12 days that requires approximately 18 days on standard EMMA as shown in Fig. 11.15. Simultaneously, for the polystyrene exposure, however, the data in Fig. 11.16 fails to show reasonable correlation between the UA EMMA and standard EMMA when normalized for radiant exposure on the x-axis. For the polystyrene SRM, the UV radiant exposure in MJ/m2 UV from the less intense standard EMMA exposure had a greater effect than the UV radiant exposure from the more intense exposure on the UA EMMA at the same level of UV radiant exposure. This observation does not appear to support the null hypothesis for polystyrene. Additionally, these observations appear similar to observations in previous efforts [2, 3].

Discussion II

Clearly, the correlation graphs shown in Figs. 11.14 and 11.16 describe different behavior between the ORWET SRM (which appears to behave as predicted by strict reciprocity) and the polystyrene SRM (which does not appear to behave as predicted by strict reciprocity).

The assumption of strict reciprocity for the ORWET SRM may lead to successful service life prediction simply by accelerating the exposure’s radiant intensity. The assumption of strict reciprocity for the polystyrene SRM using the same basis, however, may lead to considerable discrepancies between predicted and observed end-use color change. Thus, there appear to be limits to the assumption of strict reciprocity when extrapolated out to higher intensities as performed in these procedures.

There are several hypotheses beyond the scope of this paper as to why the polystyrene SRM deviates from strict reciprocity. One major consideration of this effort is represented by the different spectral distribution between these exposures. The reflectance facets used in the UA EMMA do not provide longer wavelengths of solar irradiance experienced on the standard EMMA target area. The effect of UVB on polystyrene interacting with the highly variable UV spectral distribution outdoors may have introduced uncertainties in the polystyrene degradation curves. Another major consideration involves the composition of the material being exposed; do normal manufacturing variations affect reciprocity characteristics of materials?

A major unanswered question, however, is represented by differences observed between variable cycles seen outdoors in end use and typical laboratory artificial test cycles. Do deviations from strict reciprocity significantly affect degradation rates for some materials at intensities observed outdoors and in artificial laboratory exposures? The self-similar nature of the strict reciprocity curve in combination with the extrapolation confirmation work above leads one to consider the effect at lower irradiance intensities. For example, the variety of irradiance intensities (approximate) for 3 days outdoors in Arizona is shown in Fig. 11.17. It is now clear from this and previous work that degradation from the maximum intensity is not equal to twice the degradation of the half maximum intensity for materials deviating from strict reciprocity in these types of variable outdoor environments. Thus, the simple intensity curves, shown in Fig. 11.17, result in complex, non-intuitive cumulative degradation functions for these types of materials. Comparing the natural outdoor intensity curves in Fig. 11.17 to a typical artificial weathering method intensity distribution as shown in Fig. 11.18 points out the highly artificial nature of these types of steady-state test methods in light of the possible deviations from strict reciprocity as defined in the introduction of this paper. The steady-state test methods simply do not simulate the degradation effects possible with the distribution of intensities in light of possible deviations from strict reciprocity and the variability of the outdoor exposure environment.

Additionally, steady-state artificial test methods may not account for interactions with other variables such as temperature, for example. A co-variable of light intensity, temperature in outdoor exposures, as shown in Fig. 11.19, dramatically affects degradation rates by interacting with the effects of light intensity and reciprocity characteristics. However, typical artificial weathering test methods maintain static temperature levels like those shown in Fig. 11.20. The dynamic temperature changes, in combination with dynamic light intensity changes and in combination with possible deviations from strict reciprocity, appear to make it highly unlikely that steady-state artificial laboratory tests alone are suitable tools for SLP, especially for materials known to deviate from strict reciprocity. Therefore, it is highly recommended that SLP efforts include quantification of reciprocity characteristics for materials under investigation through DOE, multi-linear regression, or other suitable approaches. It is also highly recommended that SLP efforts include consideration of the highly dynamic and interactive nature of the outdoor end uses in the n-dimensional hypervolume environment [9].

References

Hamilton JF (1966) The theory of the photographic process. Macmillan, New York, p 132

Hardcastle HK (2005) A new approach to characterizing reciprocity. In: Martin JW, Ryntz RA, Dickie RA (eds) Service life prediction, challenging the status quo. Federation of Societies for Coatings Technology, Blue Bell, PA

Hardcastle HK (2005) A characterization of the relationship between light intensity and degradation rate for weathering durability. In: Reichert T (ed) Natural and artificial ageing of polymers. 2nd European weathering symposium. Publication No. 6. Gesellschaft fur Umweltsimulation, Germany

Scott KP, Hardcastle HK (2009) A new approach to characterizing weathering reciprocity in xenon arc weathering devices. In: Martin JW et al (eds) Service life prediction of polymeric materials global perspectives. FSCT, Springer, New York, Chapter 6

Hardcastle HK, Jorgensen GJ, Bingham CE (2009) Ultra-accelerated weathering system I: design and functional considerations. In: Reichert T (ed) Natural and artificial ageing of polymers. 4th European weathering symposium, Publication No. 11, Gesellschaft fur Umweltsimulation, Germany. Subsequently re-published in CoatingsTech. American Coatings Association, Washington, DC (2010) vol 7(8), pp 28–37

ASTM G 90-94 (1998) Standard practice for performing accelerated outdoor weathering of nonmetallic materials using concentrated natural sunlight. 1998 Annual book of ASTM standards. American Society for Testing and Materials, Philadelphia, PA

Hardcastle HK (2005) United States patent application no.: 20050120811, Method and apparatus for characterizing weathering reciprocity of a material, June 2005

Hardcastle HK (2004) Considerations for relating artificial laboratory and natural outdoor weathering durability testing. In: Proceedings of the annual technical conference of the society of plastics engineers, Chicago, IL, May 2004

Hardcastle HK, Searle ND (2001) Weathering test methods. In: Ryntz R (ed) Plastics and coatings durability, stabilization, testing. Hanser, Munich, pp 189–240, Chapter 9

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Hardcastle, H.K. (2015). Ultra-Accelerated Weathering II: Considerations for Accelerated Data-Based Weathering Service Life Predictions. In: White, C., Martin, J., Chapin, J. (eds) Service Life Prediction of Exterior Plastics. Springer, Cham. https://doi.org/10.1007/978-3-319-06034-7_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-06034-7_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-06033-0

Online ISBN: 978-3-319-06034-7

eBook Packages: EngineeringEngineering (R0)